-

城市化的发展导致生活垃圾产量急速增加,2020年,我国城市垃圾清运量达2.35×108 t[1]。为充分利用废弃物资源并改善由此带来的环境问题,近年来,我国各城市相继启动了垃圾分类收集和处理工作[2]:即采用“四分法”将生活垃圾分为可回收物、有害垃圾、厨余垃圾及其他垃圾。相较于处理技术明确的可回收物、有害垃圾和其他垃圾,我国厨余垃圾产量巨大(占生活垃圾总量的54.92%,远高于其他国家或地区[3]),存在成分复杂、杂质多、容易腐烂并产生恶臭和病菌等问题,处置利用更为困难。与此同时,厨余垃圾有机质含量高达80%~95%[4],其资源化利用价值不容忽视。

目前,典型的厨余垃圾处置利用技术包括焚烧发电、厌氧发酵、好氧堆肥和填埋等。焚烧发电通过对垃圾进行焚烧获取电力,但厨余垃圾的高含水率会影响焚烧热值且产生二恶英等有害气体[5];厌氧发酵通过厌氧微生物将厨余垃圾降解,并生成甲烷为主的沼气进行利用,发酵后的沼渣亦富含有机质[6],可采用焚烧、堆肥或填埋进行二次利用[7],但整体处理的工艺链较长;好氧堆肥利用微生物将厨余垃圾中的有机质转化为肥料,包括阳光房堆肥和机器成肥[8]等方式,但堆肥的占地面积大且时间周期长;填埋则是直接将厨余垃圾进行填埋,其工艺简单、处理量大,在固废处理上应用广泛,但存在浪费有机资源、污染环境生态的问题[9]。以上处理技术均有一定应用局限性,在推进垃圾分类的背景下,通过合适的方法评估现有厨余垃圾处置利用技术优劣尤为重要。

全生命周期评价方法(Life Cycle Assessment, LCA)能定量评价产品或系统从原材料开采、加工到最终处理全过程的能源、环境表现[10-12],因此被认为是评估固废处置管理的有效方法[13-14],已广泛应用于固废处置技术的评估[15-17]。然而,LCA中的能量转化主要依据热力学第一定律,即只考量了能量数量的变化,而忽视了不同能量的质量差异。因此,SZARGUT等[18]在生命周期的基础上结合热力学第二定律的㶲分析,提出了㶲生命周期分析(Exergy Life Cycle Analysis, ELCA),并以积累㶲消耗(Cumulative Exergy Consumption, CExC)为评价指标,评估了不可逆过程导致的可用能损失[19]。ELCA能用同一物理量量化不同物质、能量的能源消耗,在评价上具有公度性[20]。目前,ELCA在评估热交换器、燃气轮机系统、生物柴油制备等高能耗的能源化工领域实现了一系列应用,能够直观有效比较不同过程的热力学完善程度及优化潜力[21-23],然而,ELCA在厨余垃圾处置利用领域的研究依旧有所欠缺[24-25]。

本研究基于全生命周期思想,采用LCA和ELCA的方法对我国垃圾分类后典型的厨余垃圾处置利用技术进行评价。其中LCA用于量化环境影响,避免仅考虑末端环境排放的局限性;ELCA用于量化能量转化,同时考虑转化过程中附加价值的能量品质差异。所有数据来源现场采样和实地数据分析,减少仅由文献估算数据产生的误差。本研究可为城市管理部门推进固废资源化利用和“无废城市”建设提供参考。

-

根据国际标准化组织(International Organization for Standardization, ISO) 14040系列标准[12],LCA的基本框架包括目标和范围定义、清单分析、影响评价和结果解释4个步骤。ELCA方法在LCA的基础上,采用㶲分析代替能量消耗指标,其评价框架与LCA一致。

-

本研究选取4类典型的厨余垃圾处置利用技术:厨余垃圾焚烧发电S1、厌氧发酵S2、好氧堆肥S3和填埋S4。其中,焚烧发电是较为成熟的固废处理技术;厌氧发酵是备受关注的资源化处理方式;好氧堆肥则能够有效利用有机质,在乡镇应用广泛;填埋作为传统的处置方式,是本研究的对照组。

1)焚烧发电(S1)。焚烧发电是指垃圾在850~1 100 ℃下产生高温烟气,在锅炉中进行热交换产生的过热蒸汽并推动汽轮发电机组产生电能[26]。由于厨余垃圾无法单独焚烧,本研究S1选取的宁波市某生活垃圾机械炉排炉焚烧厂(处理量3×750 t·d−1)中,厨余垃圾与其他垃圾混合焚烧。鉴于焚烧烟气量与燃料收到基低位发热量呈正相关性[27],为简化处理,本研究按照厨余垃圾与其他垃圾的收到基低位发热量[28-29]计算烟气量和发电量,过程中所需氨水、消石灰、活性炭及污染物排放量等亦按比例简化。

2)厌氧发酵(S2)。厌氧发酵是在缺氧条件下,利用厌氧微生物代谢过程将厨余垃圾中的有机物降解为无机物,最终生成以甲烷为主的沼气[30]。经现场调研,厌氧发酵过程产生的沼气经脱硫净化后送至内燃发电机组发电;沼液进入离心脱水机固液分离,脱水后的上清液送至污水处理,沼渣则进行后续的处置。本研究为比较沼渣处置方式的优劣,对3个不同的处置系统:沼渣焚烧S2-a、沼渣堆肥S2-b和沼渣填埋S2-c进行了具体分析。

S2-a、S2-b选取的是宁波市某400 t·d−1的厨余垃圾中温干式厌氧发酵技术在不同时期的不同工艺。S2-a中,沼渣被运至相邻垃圾焚烧厂焚烧处置,采样检测得该沼渣热值为1 976.89 KJ·kg−1,同样按热值比例计算烟气量、发电量及污染物排放等数据。该厂在后期建设堆肥车间将沼渣与粉碎的秸秆、返料等混合发酵堆肥,即为S2-b系统。

S2-c选取的是杭州市某200 t·d−1厨余垃圾中温干式厌氧发酵技术,其沼渣与生活垃圾掺杂填埋。由于缺乏填埋气数据,本研究采用政府间气候变化专门委员会(Intergovernmental Panel on Climate Change, IPCC)提出的模型进行计算(下文简称IPCC模型),该模型考虑了可生物降解率,适用于厨余垃圾产气量的预测[31]。通过对发酵后沼渣进行采样和检测(含水率57.17%,可降解有机碳含量9.72%),可计算得沼渣的发电量。

3)好氧堆肥(S3)。好氧堆肥是在有氧条件下,利用好氧微生物将厨余垃圾中的有机质分解为可溶性有机质,渗入微生物细胞中参与新陈代谢,最终形成腐殖质肥料[30]。由于堆肥处理量较小,主要应用于乡镇地区。本研究比较了阳光房堆肥S3-a和机器成肥S3-b 2种好氧堆肥技术。

S3-a选取的是金华金东某多村共建阳光房(日处理量1.5 t·d−1),约30 d成肥,成肥量达进厂垃圾的20%。阳光房顶部透光的玻璃能充分利用太阳能,加速成肥。S3-b选取的是金华浦江快速成肥中心(日处理量34 t·d−1),处理工艺包括“预处理-机器好氧发酵-自然堆肥”3个阶段,厨余垃圾通过成肥机微生物高温好氧发酵24 h快速分解为有机肥原料,再进行7~10 h的自然堆肥腐熟处理,出肥率为25.6%。

4)填埋(S4)。S4选取的是杭州市某生活垃圾填埋场,厨余垃圾与其他垃圾混合填埋。主要的工艺流程为“垃圾收运→堆填压实→高密度聚乙烯(High Density Polyethylene, HDPE)膜覆盖→填埋气收集发电”。本研究采用IPCC模型计算厨余垃圾填埋过程的填埋气和发电量,而所需的柴油、电力、HPDE膜等数据源于生活垃圾填埋运行数据。

-

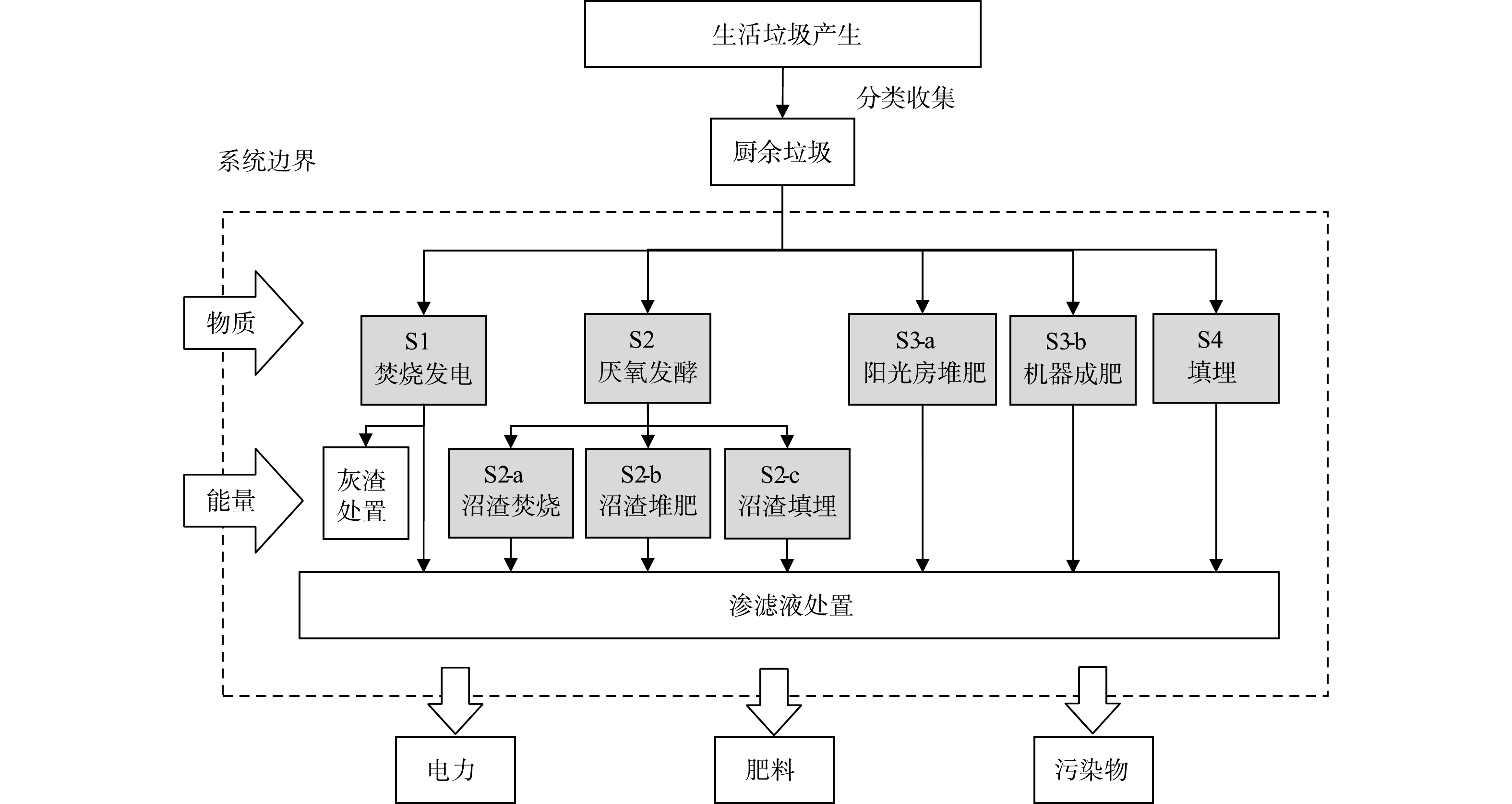

图1是本研究的系统边界,包含4类处理技术的7个系统,即焚烧发电S1、厌氧发酵-沼渣焚烧S2-a、厌氧发酵-沼渣堆肥S2-b、厌氧发酵-沼渣填埋S2-c、阳光房堆肥S3-a、机器成肥S3-b和填埋S4,下文为表示方便均用S1~S4的符号简称。评估的起点为厨余垃圾收集到处理厂,上游收垃圾收运过程可忽略,因该过程与处置利用过程相比影响较小,且不同系统间的差异较小。评价方法从生命周期的角度综合考虑了系统边界内所有物质和能量的输入及输出,包括上游制造过程产生的间接排放。针对生成的有用产物,如电力、肥料,采用替代法分配减去生产相同量的产品避免的环境排放与能源消耗。

S1~S4均为现运行处理厂的工艺,数据来自现场测量、工厂运行报告等。本研究中所有数据都折算为处理1 t厨余垃圾(功能单元)的标准计算。

-

1)环境生命周期评价LCA。本研究采用LCA的Recipe Midpoint方法,将环境影响量化为16类,每类环境影响均可按照当量法换算到同一特征污染物,并按照标准化因子标准化后加权,消除不同影响类型的量纲差异,最终得到标准人均当量(Person Equivalent, PE)的环境影响潜值大小以直观评价和分析[32]。表1为Recipe Midpoint方法的16类环境影响类型、特征单位及标准化因子。相关参数均来自GaBi 8.0生命周期评价软件。

2)㶲生命周期评价ELCA。本研究以积累㶲消耗(CExC)作为ELCA评价指标。CExC是指系统或产品从自然资源到利用的整个过程消耗的所有自然资源㶲的累计值,具有全生命周期的思想[18]。CExC考虑了获取产品需要额外消耗的能量,能够反映不同能量的品质。由于针对不同资源仅有1种物理量表现形式,无需特征化和标准化计算,避免了权重计算的影响。

积累㶲消耗效率(ηCExC)定义为系统输出的目标产物与输入的反应物的CExC总量的比值,能评估系统的能量消耗与转化效率,值越大,表示能量转化程度越高,如式(1)所示。如考虑消除系统排放的污染物到环境可接受水平,则可结合环境影响评价和能源转化评估,得到基于系统近零排放的ELCA方法[33]。环境影响消除㶲(AbatEx)则被定义为将气体污染物消除到环境可接受水平的㶲消耗。在ηCExC的输出流中减去AbatEx,即为环境影响消除㶲效率(ηAbatCExC),如式(2)所示,值越大表示减排效率越高。

式中:I和O为输入和输出流;Ouseful为输出的有用产物;Ienergy与Imaterials为输入的能量和物质;CExC为不同物质的累积㶲消耗,MJ;AbatEx为环境影响消除㶲,MJ。

-

根据前文的假设及分析,编制得到表2所示的全生命周期数据清单,并按功能单位表示。

表3为各系统主要物质的积累㶲消耗(CExC)及主要污染物气体的环境消除影响㶲(AbatEx),某些使用量较少的物质可忽略不计。厨余垃圾作为生命周期的起点,无积累㶲消耗值,仅考虑其化学㶲。

-

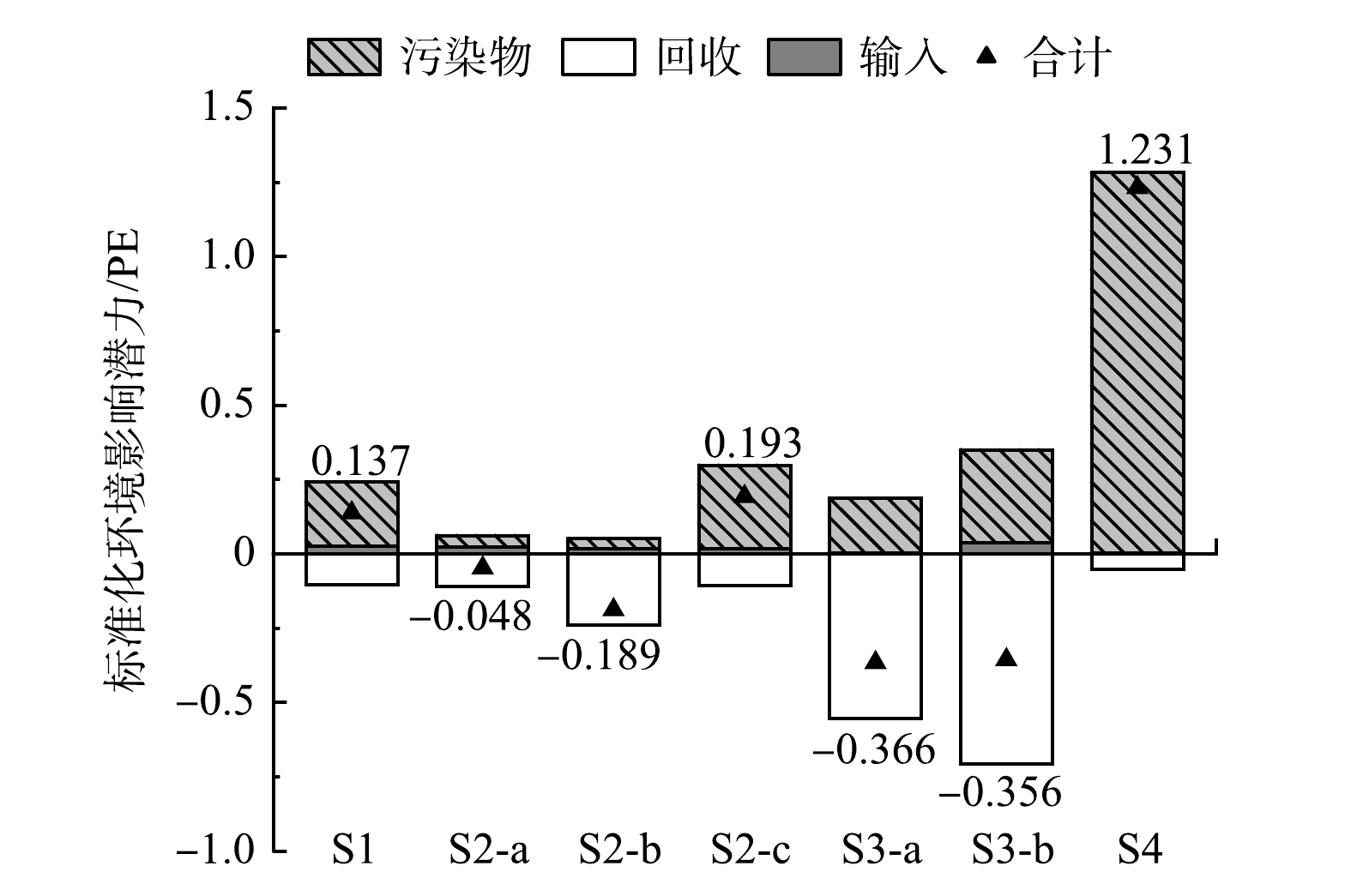

图2所示为以人均当量(PE)基准标准化后不同处置利用技术的全生命周期环境影响潜力,分为3个生命周期环节:物质及能量消耗输入的影响、污染物排放的影响及回收可利用物质避免的影响。计算的净影响为负值表示对环境产生正面影响。

S3、S2-b及S2-a的净环境影响值为负,表明这3种处理技术能获得环境收益,即系统回收的肥料和电力能抵消产生的环境 排放。其中,S3堆肥处置的环境影响表现最佳,主要原因是厨余垃圾堆肥产生肥料的转化步骤简单,肥料转化率高达20%~30%,可有效回收厨余垃圾中的有机质,从而抵消更多环境负荷。S3-a的标准化环境负荷比S3-b低2.8%,即阳光房堆肥环境表现稍优于机器成肥,究其原因,一是机器成肥需要消耗更多电力维持成肥机24 h运转;二是阳光房堆肥过程持续30 d,腐殖质会在长时间内不断络合吸附重金属,其重金属排放浓度相较于机器成肥更低[37]。

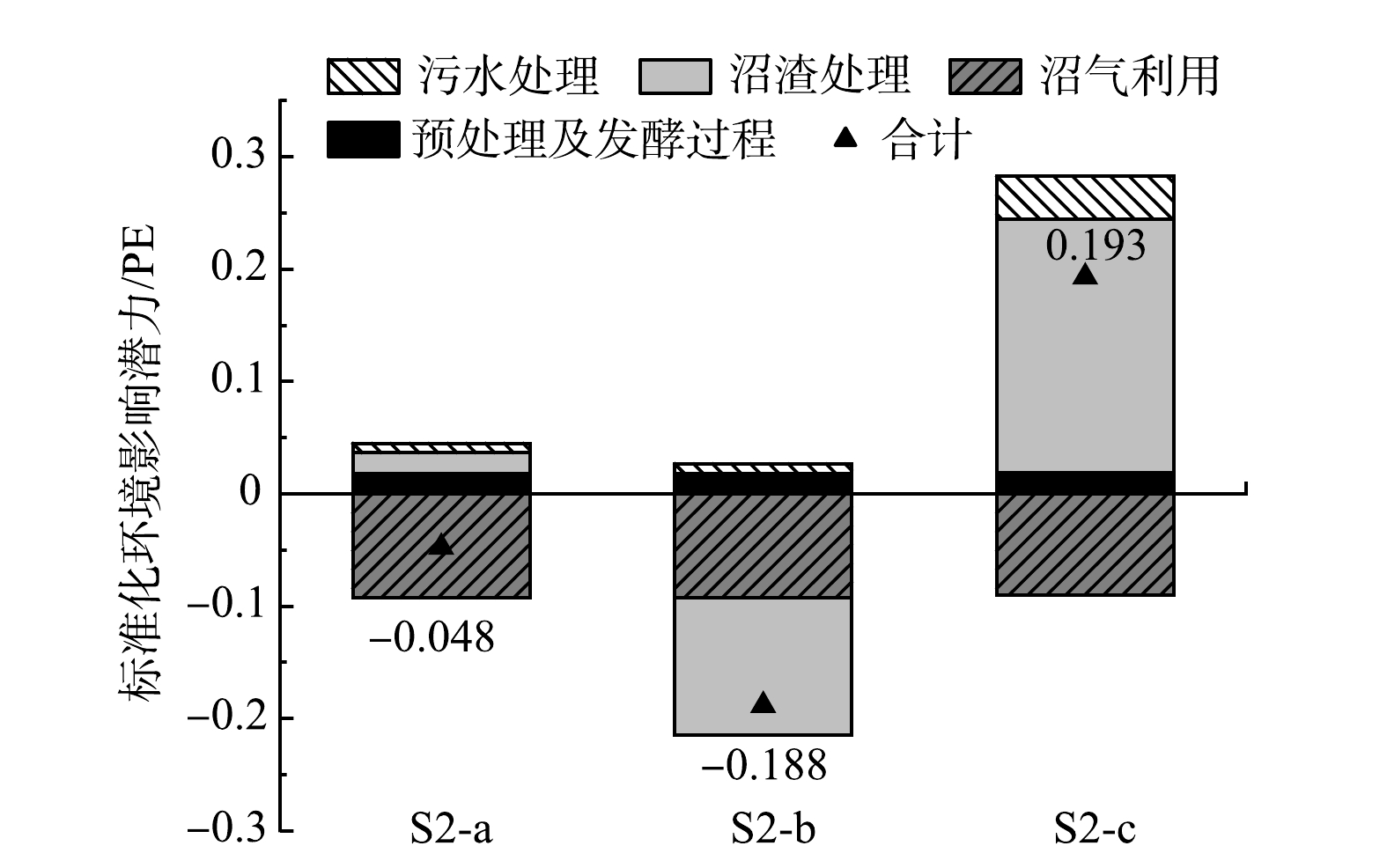

对比厌氧发酵过程不同环节的环境负荷,如图3所示,环境影响差异在于沼渣和污水处理环节。环境负荷最低的是S2-b,为-0.188,因堆肥有效回收了沼渣中的有机质,对环境的正向收益最明显;表现其次的是S2-a,可归因于厌氧发酵对沼渣的再次脱水而提高沼渣焚烧的热值,进而回收电力抵消环境排放;表现末位的S2-c虽能回收一定的电力,但难以抵消处理过程中填埋废气、废渣及大量渗滤液造成的环境污染。

S1的标准化环境负荷为0.137,对环境造成负面的影响,一是焚烧过程有机质的不完全燃烧形成了较高含量的NOx,SOx及二恶英类气体污染物排放[38];二是厨余垃圾含水率较高,湿基低位热值仅2 100 KJ·kg−1,焚烧过程蒸发湿基水分需损耗焚烧热能。

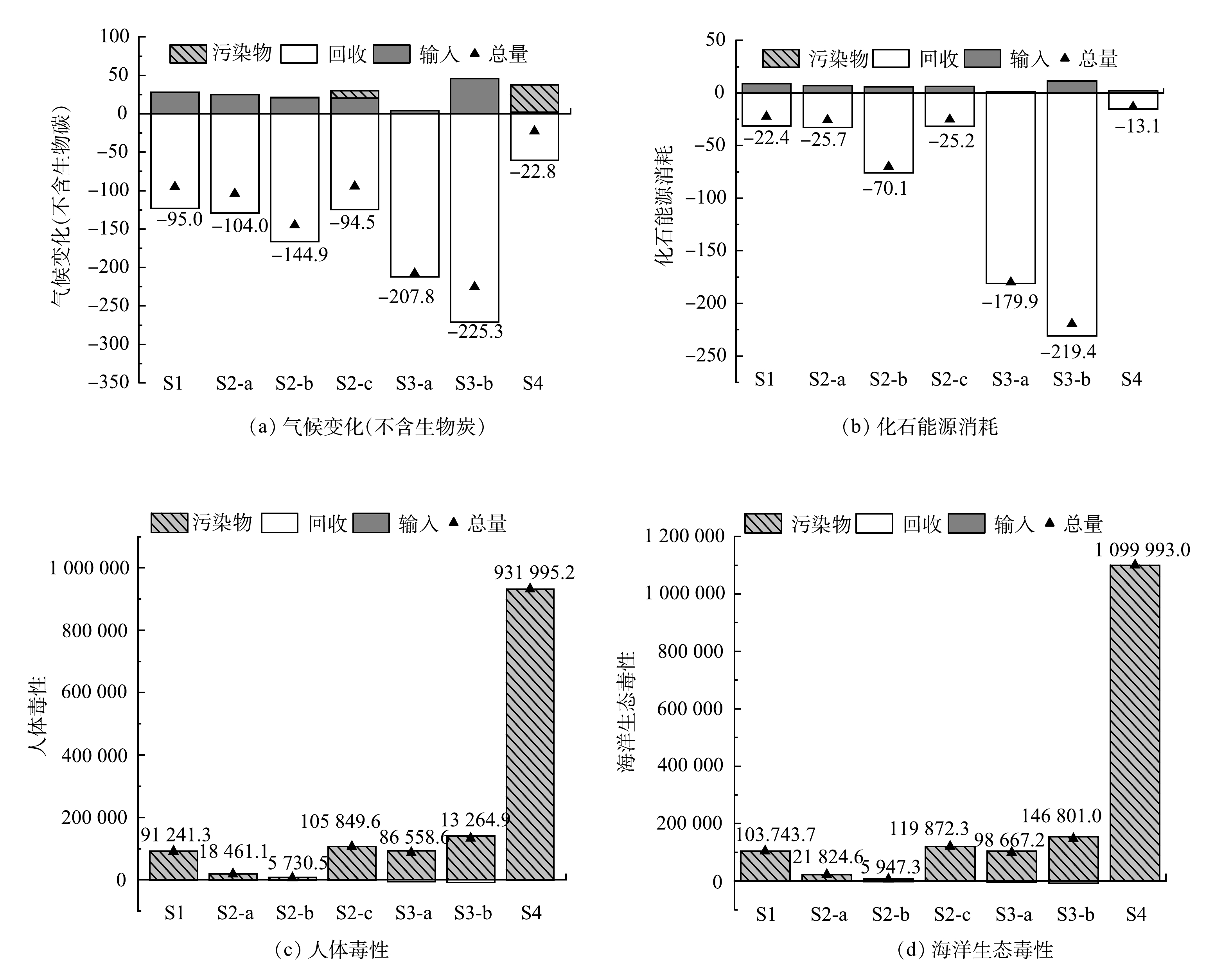

为进一步分析不同处置利用技术的环境影响,图4对比了对最终结果影响较大的4类环境类型,包括气候变化、化石能源消耗、人体毒性和海洋生态毒性。

气候变化(见图4(a))和化石能源消耗(见图4(b))的影响结果趋势相同,因气候变化主要归因于化石能源消耗产生的温室气体。S1~S4系统的净环境影响均为负值,因各系统均通过利用厨余垃圾回收能源以抵消环境负荷,表明通过对厨余垃圾的处置利用可避免气候变化和化石能源消耗造成的环境影响。具体比较,系统S3的贡献最显著,可避免225.3 kg CO2当量的气候变化影响,因有机物的高转化率堆肥回收避免了化石能源的消耗;而S2、S1和S4,均通过沼气收集、焚烧热量收集或填埋气收集利用电力补偿化石燃料利用及产生的气候升温,3者环境效益随电力利用效率逐次降低。

人体毒性(见图4(c))和海洋生态毒性(见图4(d))主要归因于污染物排放,其中重金属起决定性作用,因此所有系统的净环境影响均为正值。毒性表现最低的为S2-c,其通过厌氧发酵的微生物代谢,降低后续堆肥废渣和废气的重金属含量,从而降低整个过程污染物排放。S3则因堆肥点建设在乡镇地区,与大型厌氧发酵工程相比污染物处理环节建设不够完善,废气及废渣的净化过程较为简单,因此在毒性表现上次于S2。而S4因填埋过程产生较多填埋废气及渗滤液的排放,在人体毒性和海洋生态毒性上排在最末。

-

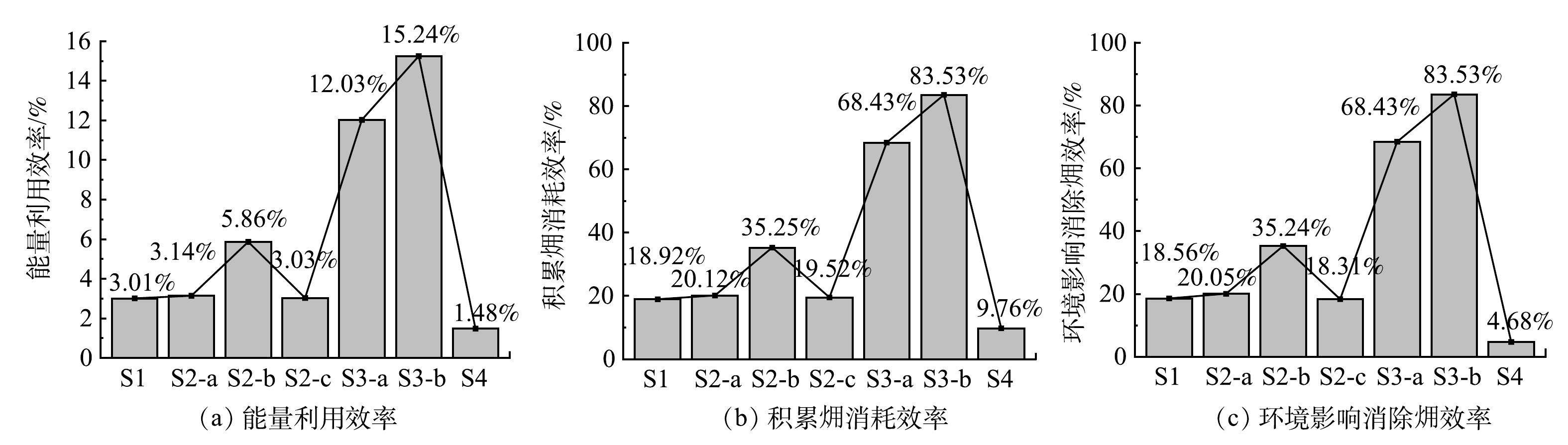

图5所示为各系统的能量利用效率、积累㶲消耗效率(ηCExC)及环境影响消除㶲效率(ηAbatCExC)。对比基于能量守恒定律的能量利用效率(见图5(a))和基于㶲分析的积累㶲消耗效率(见图5(b)),可知2者在趋势上相同,但积累㶲消耗效率的绝对值均高于前者,主要原因是积累㶲消耗综合考虑了能量品质以及能量转化过程中的附加价值。从输入流角度,厨余垃圾属于废弃物,是无积累㶲消耗的低品质能量;从输出流角度,积累㶲消耗考虑了不同价值产物累计消耗的能量高低。如对比S3-b及S4,2者在能量利用效率上仅相差13.76%,但在积累㶲消耗效率上数值差达73.77%,表明ELCA通过考虑能量品质,能够进一步表征不同技术的利用效率差异,进行更有效评价。

图5(b)积累㶲消耗效率的结果排序为S3 > S2 > S1 > S4。其中表现最佳的是S3,主要因为肥料是比电力更高附加值的产物(积累㶲消耗值32.7 MJ·kg−1),且堆肥过程相较于其他系统能量转化步骤更少、能量损失更小。亦证明了厨余垃圾作为肥料直接回收可实现更高效的能量转化。值得一提的是,虽然S3-a的环境效益稍优于S3-b,但在能量转化上,S3-b的积累㶲消耗效率比前者高15.1%,主要原因是阳光房堆肥时间较长,微生物生命活动消耗的有机质更多,即能量损失更高;而机器成肥通过密闭机器内的高温和强制通风搅拌,能在短期内快速形成肥料,肥料产量更高。针对S2的沼渣处理方式,S2-b的能源转化效率最佳,其积累㶲消耗效率为35.24%,其次为S2-a,最次是S2-c。此外,S2-a与S1相比,积累㶲消耗效率仅高出1.2%,表明厨余垃圾先厌氧发酵后焚烧与直接焚烧相比,能量转化效率提高有限,究其原因主要是厌氧发酵对发酵底物的质量有较高要求,而当前厨余垃圾的杂质含量较高会降低厌氧发酵的转化率。

环境影响消除㶲效率(见图5(c))与积累㶲消耗效率(见图5(b))的变化趋势相似,但相较后者略有下降,说明环境的可持续度下降。其中,S4的环境影响消除㶲效率下降最显著,比积累㶲消耗效率低5.08%,但总体而言差异不显著,主要是由于数据受限,表3给出的环境影响消除㶲仅包含少量气体污染物,还需进一步探索更多环境影响消除㶲,从而进一步完善该方法。

-

1)采用LCA的方法,综合考虑16类环境影响,定量评价厨余垃圾全生命周期过程的环境影响。以人均当量的标准化结果衡量环境负荷,值越低表示对环境影响越小,4类处置利用技术从低到高排序为:好氧堆肥、厌氧发酵、焚烧发电及填埋。2种好氧堆肥方式中,阳光房堆肥的环境负荷更低,为-0.366;3种厌氧发酵后沼渣的处理方式中,沼渣堆肥的环境影响最低,为-0.189;填埋在所有技术中环境负荷最高,达1.231。

2)采用ELCA的方法评价厨余垃圾的能量转化,以积累㶲消耗为评价指标,不仅考虑不同的能量品质的差异,同时避免权重计算的主观影响,在评价上更具公度性。4类处置利用技术的积累㶲消耗效率从高到低分别为好氧堆肥、厌氧发酵、焚烧发电及填埋。其中机器成肥的积累㶲消耗效率最高,为83.53%,高出阳光房堆肥15.10%;厌氧发酵的沼渣处理方式中,能量转化效率最高的是沼渣堆肥,为35.25%;填埋的积累㶲消耗效率最低,仅9.76%。

典型厨余垃圾处置利用技术的环境与㶲生命周期评价

Environmental and exergetic life cycle assessment of typical kitchen waste treatment and utilization technologies

-

摘要: 垃圾分类收集后产生的大量厨余垃圾需资源化处理。采用合适的方法进行评估,以选择更环保节能的厨余垃圾处置利用技术尤为重要。典型的厨余垃圾处置利用技术包含以下4类:焚烧发电、厌氧发酵(发酵产生的沼渣可分为焚烧、堆肥或填埋3种处置方式)、好氧堆肥(包括阳光房堆肥及机器成肥)及填埋。通过现场调研采样和实地数据分析,采用环境生命周期评价(LCA)和㶲生命周期评价(ELCA)的方法对4类技术的环境负荷及能量转化进行定量评估。其中,LCA以标准化环境负荷为指标,环境影响程度与其值呈正相关,4类技术的结果从低到高分别为好氧堆肥、厌氧发酵、焚烧发电及填埋。ELCA以积累㶲消耗效率为评价指标,能量转化效率与其值呈正相关,4类技术的结果从高到低分别为好氧堆肥、厌氧发酵、焚烧发电及填埋。2种好氧堆肥方式中,阳光房堆肥的环境负荷更低(−0.366),而机器成肥的积累㶲消耗效率更高(83.53%);3种厌氧发酵沼渣的处置方式中,沼渣堆肥的环境影响(−0.189)和积累㶲消耗效率(35.25%)均表现最佳。填埋在所有技术中环境负荷最高(1.231)且积累㶲消耗效率最低(9.76%)。本研究结果可为厨余垃圾资源化利用方法的选择提供参考。Abstract: With the implementation of the source-separated municipal solid waste collection in China, an increasing amount of kitchen waste is collected and transported separately. Therefore, the treatment and utilization of kitchen waste have become one of the greatest challenges we face. Under such circumstances, thorough investigations to assess an environmentally friendly and energy-efficient treatment and utilization technology of kitchen waste are of great significance. Environmental life cycle assessment (LCA) and exergetic life cycle assessment (ELCA) methods were used to quantitatively assess environmental burden and energy conversion efficiency of four typical kitchen waste treatment and utilization technologies, namely, incineration, anaerobic fermentation (the digestate treatment methods after anaerobic fermentation including incineration, composting or landfill), aerobic composting (including aerobic composting under sunlight and mechanical aerobic composting) and landfill. Data in this research used for the comparison was mainly based on field investigation and sampling. The standardized environmental burden was an indicator of LCA, which was positively correlated with the degree of environmental impact. The results of the four technologies were aerobic composting, anaerobic fermentation, incineration and landfill, from low to high. ELCA was assessed by cumulative exergy consumption efficiency and the energy conversion efficiency is positively correlated with its value. The results of the four technologies from high to low were aerobic composting, anaerobic fermentation, incineration and landfill. Regarding aerobic composting, the sunlight case had a lower environmental impact (−0.366), whereas the cumulative exergy consumption efficiency of mechanical aerobic composting was higher (83.53%). In terms of the digestate treatment methods after anaerobic fermentation, the composting of digestates was the most recommended option, with the best environmental impact (−0.189) and cumulative exergy consumption efficiency (35.25%). The landfill had the highest environmental burden (1.231) and the lowest cumulative exergy consumption efficiency (9.76%) among all technologies. The results obtained from this research could serve as a theoretical basis for the development and application of clean and efficient technology for kitchen waste treatment and utilization.

-

城市化的发展导致生活垃圾产量急速增加,2020年,我国城市垃圾清运量达2.35×108 t[1]。为充分利用废弃物资源并改善由此带来的环境问题,近年来,我国各城市相继启动了垃圾分类收集和处理工作[2]:即采用“四分法”将生活垃圾分为可回收物、有害垃圾、厨余垃圾及其他垃圾。相较于处理技术明确的可回收物、有害垃圾和其他垃圾,我国厨余垃圾产量巨大(占生活垃圾总量的54.92%,远高于其他国家或地区[3]),存在成分复杂、杂质多、容易腐烂并产生恶臭和病菌等问题,处置利用更为困难。与此同时,厨余垃圾有机质含量高达80%~95%[4],其资源化利用价值不容忽视。

目前,典型的厨余垃圾处置利用技术包括焚烧发电、厌氧发酵、好氧堆肥和填埋等。焚烧发电通过对垃圾进行焚烧获取电力,但厨余垃圾的高含水率会影响焚烧热值且产生二恶英等有害气体[5];厌氧发酵通过厌氧微生物将厨余垃圾降解,并生成甲烷为主的沼气进行利用,发酵后的沼渣亦富含有机质[6],可采用焚烧、堆肥或填埋进行二次利用[7],但整体处理的工艺链较长;好氧堆肥利用微生物将厨余垃圾中的有机质转化为肥料,包括阳光房堆肥和机器成肥[8]等方式,但堆肥的占地面积大且时间周期长;填埋则是直接将厨余垃圾进行填埋,其工艺简单、处理量大,在固废处理上应用广泛,但存在浪费有机资源、污染环境生态的问题[9]。以上处理技术均有一定应用局限性,在推进垃圾分类的背景下,通过合适的方法评估现有厨余垃圾处置利用技术优劣尤为重要。

全生命周期评价方法(Life Cycle Assessment, LCA)能定量评价产品或系统从原材料开采、加工到最终处理全过程的能源、环境表现[10-12],因此被认为是评估固废处置管理的有效方法[13-14],已广泛应用于固废处置技术的评估[15-17]。然而,LCA中的能量转化主要依据热力学第一定律,即只考量了能量数量的变化,而忽视了不同能量的质量差异。因此,SZARGUT等[18]在生命周期的基础上结合热力学第二定律的㶲分析,提出了㶲生命周期分析(Exergy Life Cycle Analysis, ELCA),并以积累㶲消耗(Cumulative Exergy Consumption, CExC)为评价指标,评估了不可逆过程导致的可用能损失[19]。ELCA能用同一物理量量化不同物质、能量的能源消耗,在评价上具有公度性[20]。目前,ELCA在评估热交换器、燃气轮机系统、生物柴油制备等高能耗的能源化工领域实现了一系列应用,能够直观有效比较不同过程的热力学完善程度及优化潜力[21-23],然而,ELCA在厨余垃圾处置利用领域的研究依旧有所欠缺[24-25]。

本研究基于全生命周期思想,采用LCA和ELCA的方法对我国垃圾分类后典型的厨余垃圾处置利用技术进行评价。其中LCA用于量化环境影响,避免仅考虑末端环境排放的局限性;ELCA用于量化能量转化,同时考虑转化过程中附加价值的能量品质差异。所有数据来源现场采样和实地数据分析,减少仅由文献估算数据产生的误差。本研究可为城市管理部门推进固废资源化利用和“无废城市”建设提供参考。

1. 方法

根据国际标准化组织(International Organization for Standardization, ISO) 14040系列标准[12],LCA的基本框架包括目标和范围定义、清单分析、影响评价和结果解释4个步骤。ELCA方法在LCA的基础上,采用㶲分析代替能量消耗指标,其评价框架与LCA一致。

1.1 评价对象选取

本研究选取4类典型的厨余垃圾处置利用技术:厨余垃圾焚烧发电S1、厌氧发酵S2、好氧堆肥S3和填埋S4。其中,焚烧发电是较为成熟的固废处理技术;厌氧发酵是备受关注的资源化处理方式;好氧堆肥则能够有效利用有机质,在乡镇应用广泛;填埋作为传统的处置方式,是本研究的对照组。

1)焚烧发电(S1)。焚烧发电是指垃圾在850~1 100 ℃下产生高温烟气,在锅炉中进行热交换产生的过热蒸汽并推动汽轮发电机组产生电能[26]。由于厨余垃圾无法单独焚烧,本研究S1选取的宁波市某生活垃圾机械炉排炉焚烧厂(处理量3×750 t·d−1)中,厨余垃圾与其他垃圾混合焚烧。鉴于焚烧烟气量与燃料收到基低位发热量呈正相关性[27],为简化处理,本研究按照厨余垃圾与其他垃圾的收到基低位发热量[28-29]计算烟气量和发电量,过程中所需氨水、消石灰、活性炭及污染物排放量等亦按比例简化。

2)厌氧发酵(S2)。厌氧发酵是在缺氧条件下,利用厌氧微生物代谢过程将厨余垃圾中的有机物降解为无机物,最终生成以甲烷为主的沼气[30]。经现场调研,厌氧发酵过程产生的沼气经脱硫净化后送至内燃发电机组发电;沼液进入离心脱水机固液分离,脱水后的上清液送至污水处理,沼渣则进行后续的处置。本研究为比较沼渣处置方式的优劣,对3个不同的处置系统:沼渣焚烧S2-a、沼渣堆肥S2-b和沼渣填埋S2-c进行了具体分析。

S2-a、S2-b选取的是宁波市某400 t·d−1的厨余垃圾中温干式厌氧发酵技术在不同时期的不同工艺。S2-a中,沼渣被运至相邻垃圾焚烧厂焚烧处置,采样检测得该沼渣热值为1 976.89 KJ·kg−1,同样按热值比例计算烟气量、发电量及污染物排放等数据。该厂在后期建设堆肥车间将沼渣与粉碎的秸秆、返料等混合发酵堆肥,即为S2-b系统。

S2-c选取的是杭州市某200 t·d−1厨余垃圾中温干式厌氧发酵技术,其沼渣与生活垃圾掺杂填埋。由于缺乏填埋气数据,本研究采用政府间气候变化专门委员会(Intergovernmental Panel on Climate Change, IPCC)提出的模型进行计算(下文简称IPCC模型),该模型考虑了可生物降解率,适用于厨余垃圾产气量的预测[31]。通过对发酵后沼渣进行采样和检测(含水率57.17%,可降解有机碳含量9.72%),可计算得沼渣的发电量。

3)好氧堆肥(S3)。好氧堆肥是在有氧条件下,利用好氧微生物将厨余垃圾中的有机质分解为可溶性有机质,渗入微生物细胞中参与新陈代谢,最终形成腐殖质肥料[30]。由于堆肥处理量较小,主要应用于乡镇地区。本研究比较了阳光房堆肥S3-a和机器成肥S3-b 2种好氧堆肥技术。

S3-a选取的是金华金东某多村共建阳光房(日处理量1.5 t·d−1),约30 d成肥,成肥量达进厂垃圾的20%。阳光房顶部透光的玻璃能充分利用太阳能,加速成肥。S3-b选取的是金华浦江快速成肥中心(日处理量34 t·d−1),处理工艺包括“预处理-机器好氧发酵-自然堆肥”3个阶段,厨余垃圾通过成肥机微生物高温好氧发酵24 h快速分解为有机肥原料,再进行7~10 h的自然堆肥腐熟处理,出肥率为25.6%。

4)填埋(S4)。S4选取的是杭州市某生活垃圾填埋场,厨余垃圾与其他垃圾混合填埋。主要的工艺流程为“垃圾收运→堆填压实→高密度聚乙烯(High Density Polyethylene, HDPE)膜覆盖→填埋气收集发电”。本研究采用IPCC模型计算厨余垃圾填埋过程的填埋气和发电量,而所需的柴油、电力、HPDE膜等数据源于生活垃圾填埋运行数据。

1.2 目标与范围定义

图1是本研究的系统边界,包含4类处理技术的7个系统,即焚烧发电S1、厌氧发酵-沼渣焚烧S2-a、厌氧发酵-沼渣堆肥S2-b、厌氧发酵-沼渣填埋S2-c、阳光房堆肥S3-a、机器成肥S3-b和填埋S4,下文为表示方便均用S1~S4的符号简称。评估的起点为厨余垃圾收集到处理厂,上游收垃圾收运过程可忽略,因该过程与处置利用过程相比影响较小,且不同系统间的差异较小。评价方法从生命周期的角度综合考虑了系统边界内所有物质和能量的输入及输出,包括上游制造过程产生的间接排放。针对生成的有用产物,如电力、肥料,采用替代法分配减去生产相同量的产品避免的环境排放与能源消耗。

S1~S4均为现运行处理厂的工艺,数据来自现场测量、工厂运行报告等。本研究中所有数据都折算为处理1 t厨余垃圾(功能单元)的标准计算。

1.3 生命周期评价方法

1)环境生命周期评价LCA。本研究采用LCA的Recipe Midpoint方法,将环境影响量化为16类,每类环境影响均可按照当量法换算到同一特征污染物,并按照标准化因子标准化后加权,消除不同影响类型的量纲差异,最终得到标准人均当量(Person Equivalent, PE)的环境影响潜值大小以直观评价和分析[32]。表1为Recipe Midpoint方法的16类环境影响类型、特征单位及标准化因子。相关参数均来自GaBi 8.0生命周期评价软件。

表 1 基于Recipe Midpoint的环境影响类型及特征单位Table 1. Environment impact categories and characterization unit based on Recipe Midpoint环境影响类型 特征单位 标准化因子 气候变化(不含生物碳) kg CO2 eq. 1.72×10-4 化石能源消耗 kg oil eq. 1.02×10-3 人体毒性-癌症 kg 1,4-DB eq. 3.39×10-3 人体毒性-非癌症 kg 1,4-DB eq. 4.50×10-7 海洋生态毒性 kg 1,4-DB eq. 4.06×10-7 颗粒物形成 kg PM2.5 eq. 3.91×10-2 水消耗 m3 3.75×10-3 淡水生态毒性 kg 1,4 DB eq. 3.44×10-3 淡水富营养化 kg P eq. 1.54 电离辐射 kBq Co-60 eq. to air 1.43×10-3 土地占用 Annual crop eq.·y 1.62×10-4 海洋富营养化 kg N eq. 2.17×10-1 金属消耗 kg Cu eq. 8.33×10-6 光化学臭氧形成-生态系统 kg NOx eq. 5.63×10-2 光化学臭氧形成-人类健康 kg NOx eq. 4.86×10-2 臭氧消耗 kg CFC-11 eq. 14.2 陆地酸化 kg SO2 eq. 2.44×10-2 陆地生态毒性 kg 1,4-DB eq. 6.11×10-5 注:1)特征单位中的eq.表示标准当量(equivalent),即平均每年每人造成的对应类型环境的影响。 2)㶲生命周期评价ELCA。本研究以积累㶲消耗(CExC)作为ELCA评价指标。CExC是指系统或产品从自然资源到利用的整个过程消耗的所有自然资源㶲的累计值,具有全生命周期的思想[18]。CExC考虑了获取产品需要额外消耗的能量,能够反映不同能量的品质。由于针对不同资源仅有1种物理量表现形式,无需特征化和标准化计算,避免了权重计算的影响。

积累㶲消耗效率(ηCExC)定义为系统输出的目标产物与输入的反应物的CExC总量的比值,能评估系统的能量消耗与转化效率,值越大,表示能量转化程度越高,如式(1)所示。如考虑消除系统排放的污染物到环境可接受水平,则可结合环境影响评价和能源转化评估,得到基于系统近零排放的ELCA方法[33]。环境影响消除㶲(AbatEx)则被定义为将气体污染物消除到环境可接受水平的㶲消耗。在ηCExC的输出流中减去AbatEx,即为环境影响消除㶲效率(ηAbatCExC),如式(2)所示,值越大表示减排效率越高。

stringUtils.convertMath(!{formula.content}) (1) stringUtils.convertMath(!{formula.content}) (2) 式中:I和O为输入和输出流;Ouseful为输出的有用产物;Ienergy与Imaterials为输入的能量和物质;CExC为不同物质的累积㶲消耗,MJ;AbatEx为环境影响消除㶲,MJ。

1.4 清单分析

根据前文的假设及分析,编制得到表2所示的全生命周期数据清单,并按功能单位表示。

表 2 各系统全生命周期的数据清单(基于处理1 t厨余垃圾)Table 2. Life cycle data inventory of each system (based on 1t kitchen waste treated)环节 类型 单位 S1焚烧发电 S2厌氧发酵 S3-a阳光房堆肥 S3-b机器成肥 S4填埋 a沼渣焚烧 b沼渣堆肥 c沼渣填埋 输入 电力 kWh 23.89 30.27 27.49 26.18 19.98 60.00 1.76 柴油 L 0.86 0.67 0.54 1.05 − — 1.26 絮凝剂 kg — 0.15 0.15 0.34 — — — 氧化铁 kg — 0.22 0.22 0.14 — — — 消石灰 kg 4.51 0.69 — — — — — 活性炭 kg 0.20 0.03 — — — — — 氨水 kg 1.84 0.28 — — — — — HDPE kg — — — 0.09 — — 0.45 输出 电力 kWh 161.99 168.92 144.00 162.80 — — 79.39 肥料 kg — — 53.16 — 200.00 256.00 — 气体污染物 NH3 kg — 9.21×10−4 2.31×10−3 1.95×10−2 — — 1.15×10−2 H2S kg — 3.00×10−4 3.83×10−4 2.98×10−3 4.27×10−4 5.62×10−5 1.15×10−2 CH4 kg — — — 1.71 — — 7.24 N2O kg — 2.91×10−3 2.91E-03 1.34×10−2 — — — NOx kg 3.64×10−1 5.61×10−2 — — — — — SOx kg 4.57×10−1 7.06×10−2 3.81×10−4 1.23×10−3 2.28×10−5 1.91×10−3 — HCl kg 8.34×10−2 1.28×10−2 — — — — — CO kg 1.76×10−1 2.70×10−2 — — — — — 二恶英类 kg TEQ 2.76×10−10 4.25×10−11 — — — — — 污水污染物 NH3−N kg 1.44×10−4 1.52×10−2 1.52×10−2 3.30×10−1 2.34×10−2 2.62×10−4 3.30×10−1 COD kg 1.32×10−3 2.17×10−1 2.17×10−1 6.85×10−1 4.30×10−3 7.25×10−2 6.85×10−1 BOD kg 3.95×10−4 2.54×10−2 2.54×10−2 3.95×10−2 1.80×10−3 2.83×10−2 3.95×10−2 T-N kg 1.54×10−2 3.51×10−2 3.51×10−2 2.75×10−1 3.41×10−2 4.46×10−3 2.75×10−1 T-P kg 7.11×10−6 2.38×10−3 2.38×10−3 2.38×10−3 2.34×10−5 5.12×10−5 2.38×10−3 Cd kg 1.32×10−6 2.90×10−5 2.90×10−5 5.00×10−6 4.37×10−6 2.97×10−5 5.00×10−6 Cu kg 7.64×10−6 3.25×10−5 3.25×10−5 4.90×10−5 1.49×10−5 1.49×10−4 4.90×10−5 Cr kg 1.29×10−6 9.28×10−5 9.28×10−5 1.55×10−6 8.10×10−7 4.46×10−4 1.55×10−6 Pb kg 3.69×10−6 1.16×10−4 1.16×10−4 2.35×10−5 4.37×10−6 2.97×10−4 2.35×10−5 Zn kg 2.82×10−6 4.79×10−4 4.79×10−4 4.50×10−5 9.81×10−5 5.94×10−4 4.50×10−5 Ni kg 1.05×10−5 1.00×10−4 1.00×10−4 1.15×10−4 3.27×10−5 2.97×10−4 1.15×10−4 固渣污染物 Zn to soil kg 3.65×10−2 7.27×10−3 2.15×10−3 4.14×10−2 3.64×10−2 5.34×10−2 3.85×10−1 Cu to soil kg 3.63×10−3 8.37×10−4 1.00×10−3 4.90×10−2 1.07×10−2 1.66×10−2 6.94×10−2 Pb to soil kg 1.72×10−2 1.78×10−3 9.75×10−4 1.03×10−3 1.68×10−2 8.58×10−3 3.00×10−2 Cd to soil kg 1.16×10−3 9.70×10−5 1.70×10−5 8.74×10−5 2.92×10−4 3.58×10−4 4.12×10−4 Cr to soil kg 1.31×10−4 4.63×10−5 6.65×10−4 2.44×10−4 2.13×10−3 1.67×10−2 2.50×10−2 As to soil kg 8.68×10−4 1.49×10−6 2.95×10−4 1.58×10−3 1.19×10−3 2.56×10−3 1.33×10−3 Hg to soil kg 2.72×10−5 1.94×10−5 2.81×10−5 5.28×10−5 — — 5.35×10−4 注:“—”表示该系统无对应物质或能量的输入输出,或未收集到相关数据。 表3为各系统主要物质的积累㶲消耗(CExC)及主要污染物气体的环境消除影响㶲(AbatEx),某些使用量较少的物质可忽略不计。厨余垃圾作为生命周期的起点,无积累㶲消耗值,仅考虑其化学㶲。

表 3 各物质积累㶲消耗(CExC)及环境消除影响㶲(AbatEx)值Table 3. Cumulative exergy consumption (CExC) and abatement exergy (AbatEx) value of materials MJ2. 结果与讨论

2.1 生命周期评价

图2所示为以人均当量(PE)基准标准化后不同处置利用技术的全生命周期环境影响潜力,分为3个生命周期环节:物质及能量消耗输入的影响、污染物排放的影响及回收可利用物质避免的影响。计算的净影响为负值表示对环境产生正面影响。

S3、S2-b及S2-a的净环境影响值为负,表明这3种处理技术能获得环境收益,即系统回收的肥料和电力能抵消产生的环境 排放。其中,S3堆肥处置的环境影响表现最佳,主要原因是厨余垃圾堆肥产生肥料的转化步骤简单,肥料转化率高达20%~30%,可有效回收厨余垃圾中的有机质,从而抵消更多环境负荷。S3-a的标准化环境负荷比S3-b低2.8%,即阳光房堆肥环境表现稍优于机器成肥,究其原因,一是机器成肥需要消耗更多电力维持成肥机24 h运转;二是阳光房堆肥过程持续30 d,腐殖质会在长时间内不断络合吸附重金属,其重金属排放浓度相较于机器成肥更低[37]。

对比厌氧发酵过程不同环节的环境负荷,如图3所示,环境影响差异在于沼渣和污水处理环节。环境负荷最低的是S2-b,为-0.188,因堆肥有效回收了沼渣中的有机质,对环境的正向收益最明显;表现其次的是S2-a,可归因于厌氧发酵对沼渣的再次脱水而提高沼渣焚烧的热值,进而回收电力抵消环境排放;表现末位的S2-c虽能回收一定的电力,但难以抵消处理过程中填埋废气、废渣及大量渗滤液造成的环境污染。

S1的标准化环境负荷为0.137,对环境造成负面的影响,一是焚烧过程有机质的不完全燃烧形成了较高含量的NOx,SOx及二恶英类气体污染物排放[38];二是厨余垃圾含水率较高,湿基低位热值仅2 100 KJ·kg−1,焚烧过程蒸发湿基水分需损耗焚烧热能。

为进一步分析不同处置利用技术的环境影响,图4对比了对最终结果影响较大的4类环境类型,包括气候变化、化石能源消耗、人体毒性和海洋生态毒性。

气候变化(见图4(a))和化石能源消耗(见图4(b))的影响结果趋势相同,因气候变化主要归因于化石能源消耗产生的温室气体。S1~S4系统的净环境影响均为负值,因各系统均通过利用厨余垃圾回收能源以抵消环境负荷,表明通过对厨余垃圾的处置利用可避免气候变化和化石能源消耗造成的环境影响。具体比较,系统S3的贡献最显著,可避免225.3 kg CO2当量的气候变化影响,因有机物的高转化率堆肥回收避免了化石能源的消耗;而S2、S1和S4,均通过沼气收集、焚烧热量收集或填埋气收集利用电力补偿化石燃料利用及产生的气候升温,3者环境效益随电力利用效率逐次降低。

人体毒性(见图4(c))和海洋生态毒性(见图4(d))主要归因于污染物排放,其中重金属起决定性作用,因此所有系统的净环境影响均为正值。毒性表现最低的为S2-c,其通过厌氧发酵的微生物代谢,降低后续堆肥废渣和废气的重金属含量,从而降低整个过程污染物排放。S3则因堆肥点建设在乡镇地区,与大型厌氧发酵工程相比污染物处理环节建设不够完善,废气及废渣的净化过程较为简单,因此在毒性表现上次于S2。而S4因填埋过程产生较多填埋废气及渗滤液的排放,在人体毒性和海洋生态毒性上排在最末。

2.2 㶲生命周期评价

图5所示为各系统的能量利用效率、积累㶲消耗效率(ηCExC)及环境影响消除㶲效率(ηAbatCExC)。对比基于能量守恒定律的能量利用效率(见图5(a))和基于㶲分析的积累㶲消耗效率(见图5(b)),可知2者在趋势上相同,但积累㶲消耗效率的绝对值均高于前者,主要原因是积累㶲消耗综合考虑了能量品质以及能量转化过程中的附加价值。从输入流角度,厨余垃圾属于废弃物,是无积累㶲消耗的低品质能量;从输出流角度,积累㶲消耗考虑了不同价值产物累计消耗的能量高低。如对比S3-b及S4,2者在能量利用效率上仅相差13.76%,但在积累㶲消耗效率上数值差达73.77%,表明ELCA通过考虑能量品质,能够进一步表征不同技术的利用效率差异,进行更有效评价。

图5(b)积累㶲消耗效率的结果排序为S3 > S2 > S1 > S4。其中表现最佳的是S3,主要因为肥料是比电力更高附加值的产物(积累㶲消耗值32.7 MJ·kg−1),且堆肥过程相较于其他系统能量转化步骤更少、能量损失更小。亦证明了厨余垃圾作为肥料直接回收可实现更高效的能量转化。值得一提的是,虽然S3-a的环境效益稍优于S3-b,但在能量转化上,S3-b的积累㶲消耗效率比前者高15.1%,主要原因是阳光房堆肥时间较长,微生物生命活动消耗的有机质更多,即能量损失更高;而机器成肥通过密闭机器内的高温和强制通风搅拌,能在短期内快速形成肥料,肥料产量更高。针对S2的沼渣处理方式,S2-b的能源转化效率最佳,其积累㶲消耗效率为35.24%,其次为S2-a,最次是S2-c。此外,S2-a与S1相比,积累㶲消耗效率仅高出1.2%,表明厨余垃圾先厌氧发酵后焚烧与直接焚烧相比,能量转化效率提高有限,究其原因主要是厌氧发酵对发酵底物的质量有较高要求,而当前厨余垃圾的杂质含量较高会降低厌氧发酵的转化率。

环境影响消除㶲效率(见图5(c))与积累㶲消耗效率(见图5(b))的变化趋势相似,但相较后者略有下降,说明环境的可持续度下降。其中,S4的环境影响消除㶲效率下降最显著,比积累㶲消耗效率低5.08%,但总体而言差异不显著,主要是由于数据受限,表3给出的环境影响消除㶲仅包含少量气体污染物,还需进一步探索更多环境影响消除㶲,从而进一步完善该方法。

3. 结论

1)采用LCA的方法,综合考虑16类环境影响,定量评价厨余垃圾全生命周期过程的环境影响。以人均当量的标准化结果衡量环境负荷,值越低表示对环境影响越小,4类处置利用技术从低到高排序为:好氧堆肥、厌氧发酵、焚烧发电及填埋。2种好氧堆肥方式中,阳光房堆肥的环境负荷更低,为-0.366;3种厌氧发酵后沼渣的处理方式中,沼渣堆肥的环境影响最低,为-0.189;填埋在所有技术中环境负荷最高,达1.231。

2)采用ELCA的方法评价厨余垃圾的能量转化,以积累㶲消耗为评价指标,不仅考虑不同的能量品质的差异,同时避免权重计算的主观影响,在评价上更具公度性。4类处置利用技术的积累㶲消耗效率从高到低分别为好氧堆肥、厌氧发酵、焚烧发电及填埋。其中机器成肥的积累㶲消耗效率最高,为83.53%,高出阳光房堆肥15.10%;厌氧发酵的沼渣处理方式中,能量转化效率最高的是沼渣堆肥,为35.25%;填埋的积累㶲消耗效率最低,仅9.76%。

-

表 1 基于Recipe Midpoint的环境影响类型及特征单位

Table 1. Environment impact categories and characterization unit based on Recipe Midpoint

环境影响类型 特征单位 标准化因子 气候变化(不含生物碳) kg CO2 eq. 1.72×10-4 化石能源消耗 kg oil eq. 1.02×10-3 人体毒性-癌症 kg 1,4-DB eq. 3.39×10-3 人体毒性-非癌症 kg 1,4-DB eq. 4.50×10-7 海洋生态毒性 kg 1,4-DB eq. 4.06×10-7 颗粒物形成 kg PM2.5 eq. 3.91×10-2 水消耗 m3 3.75×10-3 淡水生态毒性 kg 1,4 DB eq. 3.44×10-3 淡水富营养化 kg P eq. 1.54 电离辐射 kBq Co-60 eq. to air 1.43×10-3 土地占用 Annual crop eq.·y 1.62×10-4 海洋富营养化 kg N eq. 2.17×10-1 金属消耗 kg Cu eq. 8.33×10-6 光化学臭氧形成-生态系统 kg NOx eq. 5.63×10-2 光化学臭氧形成-人类健康 kg NOx eq. 4.86×10-2 臭氧消耗 kg CFC-11 eq. 14.2 陆地酸化 kg SO2 eq. 2.44×10-2 陆地生态毒性 kg 1,4-DB eq. 6.11×10-5 注:1)特征单位中的eq.表示标准当量(equivalent),即平均每年每人造成的对应类型环境的影响。 表 2 各系统全生命周期的数据清单(基于处理1 t厨余垃圾)

Table 2. Life cycle data inventory of each system (based on 1t kitchen waste treated)

环节 类型 单位 S1焚烧发电 S2厌氧发酵 S3-a阳光房堆肥 S3-b机器成肥 S4填埋 a沼渣焚烧 b沼渣堆肥 c沼渣填埋 输入 电力 kWh 23.89 30.27 27.49 26.18 19.98 60.00 1.76 柴油 L 0.86 0.67 0.54 1.05 − — 1.26 絮凝剂 kg — 0.15 0.15 0.34 — — — 氧化铁 kg — 0.22 0.22 0.14 — — — 消石灰 kg 4.51 0.69 — — — — — 活性炭 kg 0.20 0.03 — — — — — 氨水 kg 1.84 0.28 — — — — — HDPE kg — — — 0.09 — — 0.45 输出 电力 kWh 161.99 168.92 144.00 162.80 — — 79.39 肥料 kg — — 53.16 — 200.00 256.00 — 气体污染物 NH3 kg — 9.21×10−4 2.31×10−3 1.95×10−2 — — 1.15×10−2 H2S kg — 3.00×10−4 3.83×10−4 2.98×10−3 4.27×10−4 5.62×10−5 1.15×10−2 CH4 kg — — — 1.71 — — 7.24 N2O kg — 2.91×10−3 2.91E-03 1.34×10−2 — — — NOx kg 3.64×10−1 5.61×10−2 — — — — — SOx kg 4.57×10−1 7.06×10−2 3.81×10−4 1.23×10−3 2.28×10−5 1.91×10−3 — HCl kg 8.34×10−2 1.28×10−2 — — — — — CO kg 1.76×10−1 2.70×10−2 — — — — — 二恶英类 kg TEQ 2.76×10−10 4.25×10−11 — — — — — 污水污染物 NH3−N kg 1.44×10−4 1.52×10−2 1.52×10−2 3.30×10−1 2.34×10−2 2.62×10−4 3.30×10−1 COD kg 1.32×10−3 2.17×10−1 2.17×10−1 6.85×10−1 4.30×10−3 7.25×10−2 6.85×10−1 BOD kg 3.95×10−4 2.54×10−2 2.54×10−2 3.95×10−2 1.80×10−3 2.83×10−2 3.95×10−2 T-N kg 1.54×10−2 3.51×10−2 3.51×10−2 2.75×10−1 3.41×10−2 4.46×10−3 2.75×10−1 T-P kg 7.11×10−6 2.38×10−3 2.38×10−3 2.38×10−3 2.34×10−5 5.12×10−5 2.38×10−3 Cd kg 1.32×10−6 2.90×10−5 2.90×10−5 5.00×10−6 4.37×10−6 2.97×10−5 5.00×10−6 Cu kg 7.64×10−6 3.25×10−5 3.25×10−5 4.90×10−5 1.49×10−5 1.49×10−4 4.90×10−5 Cr kg 1.29×10−6 9.28×10−5 9.28×10−5 1.55×10−6 8.10×10−7 4.46×10−4 1.55×10−6 Pb kg 3.69×10−6 1.16×10−4 1.16×10−4 2.35×10−5 4.37×10−6 2.97×10−4 2.35×10−5 Zn kg 2.82×10−6 4.79×10−4 4.79×10−4 4.50×10−5 9.81×10−5 5.94×10−4 4.50×10−5 Ni kg 1.05×10−5 1.00×10−4 1.00×10−4 1.15×10−4 3.27×10−5 2.97×10−4 1.15×10−4 固渣污染物 Zn to soil kg 3.65×10−2 7.27×10−3 2.15×10−3 4.14×10−2 3.64×10−2 5.34×10−2 3.85×10−1 Cu to soil kg 3.63×10−3 8.37×10−4 1.00×10−3 4.90×10−2 1.07×10−2 1.66×10−2 6.94×10−2 Pb to soil kg 1.72×10−2 1.78×10−3 9.75×10−4 1.03×10−3 1.68×10−2 8.58×10−3 3.00×10−2 Cd to soil kg 1.16×10−3 9.70×10−5 1.70×10−5 8.74×10−5 2.92×10−4 3.58×10−4 4.12×10−4 Cr to soil kg 1.31×10−4 4.63×10−5 6.65×10−4 2.44×10−4 2.13×10−3 1.67×10−2 2.50×10−2 As to soil kg 8.68×10−4 1.49×10−6 2.95×10−4 1.58×10−3 1.19×10−3 2.56×10−3 1.33×10−3 Hg to soil kg 2.72×10−5 1.94×10−5 2.81×10−5 5.28×10−5 — — 5.35×10−4 注:“—”表示该系统无对应物质或能量的输入输出,或未收集到相关数据。 表 3 各物质积累㶲消耗(CExC)及环境消除影响㶲(AbatEx)值

Table 3. Cumulative exergy consumption (CExC) and abatement exergy (AbatEx) value of materials MJ

-

[1] 中华人民共和国住房和城乡建设部. 2020年城乡建设统计年鉴[EB/OL]. [2021-12-01]. http://www.mohurd.gov.cn/file/2021/20211012/dae27f9eb22debfd6d1e7965040b76ff.zip, 2021 [2] TONG Y, LIU J, LIU S. China is implementing “Garbage Classification” action[J]. Environmental Pollution, 2020, 259: 113707. doi: 10.1016/j.envpol.2019.113707 [3] ZHANG J, ZHANG Z, ZHANG J, et al. A Quantitative Study on the Benefit of Various Waste Classifications[J]. Advances in Civil Engineering, 2021: 2021. [4] LI Y, JIN Y, LI J, et al. Current situation and development of kitchen waste treatment in China[J]. Procedia Environmental Sciences, 2016, 31: 40-9. doi: 10.1016/j.proenv.2016.02.006 [5] PHAM T P T, KAUSHIK R, PARSHETTI G K, et al. Food waste-to-energy conversion technologies: Current status and future directions[J]. Waste Management, 2015, 38: 399-408. doi: 10.1016/j.wasman.2014.12.004 [6] FENG H, QU G-F, NING P, et al. The resource utilization of anaerobic fermentation residue[J]. Procedia Environmental Sciences, 2011, 11: 1092-9. doi: 10.1016/j.proenv.2011.12.165 [7] WEILAND P. Biogas production: current state and perspectives[J]. Applied Microbiology and Biotechnology, 2010, 85(4): 849-60. doi: 10.1007/s00253-009-2246-7 [8] 毕峰, 李相儒, 韩泽东, 等. 我国农村易腐垃圾机器成肥产品质量评价——以杭州市为例[J]. 农业环境科学学报, 2018, 37(5): 7. [9] Commission E. Success stories on composting and separate collection[M]. Office for Official Publications of the European Communities, 2000. [10] CHRISTIANSEN K, HOFFMAN L, VIRTANEN Y, et al. Nordic guidelines on life-cycle assessment[M]. Nordic Council of Ministers, 1995. [11] FINNVEDEN R. The Application of Life Cycle Assessment to Integrated Solid Waste Management: Part 1—Methodology[J]. Process Safety and Environmental Protection, 2000. [12] ISO. Environmental management—life cycle assessment—principles and framework[J]. En Iso, 1997. [13] WHITE P R, FRANKE M, HINDLE P. Integrated Solid Waste Management: A Lifecycle Inventory: A Lifecycle Inventory[M]. Springer Science & Business Media, 1995. [14] WINKLER J, BILITEWSKI B. Comparative evaluation of life cycle assessment models for solid waste management[J]. Waste Management, 2007, 27(8): 1021-31. doi: 10.1016/j.wasman.2007.02.023 [15] CHERUBINI F, BARGIGLI S, ULGIATI S. Life cycle assessment (LCA) of waste management strategies: Landfilling, sorting plant and incineration[J]. Energy, 2009, 34(12): 2116-23. doi: 10.1016/j.energy.2008.08.023 [16] DENISON R A. Environmental life-cycle comparisons of recycling, landfilling, and incineration: A review of recent studies[J]. Annual Review of Energy and the Environment, 1996, 21(1): 191-237. doi: 10.1146/annurev.energy.21.1.191 [17] PAES M X, DE MEDEIROS G A, MANCINI S D, et al. Municipal solid waste management: Integrated analysis of environmental and economic indicators based on life cycle assessment[J]. Journal of Cleaner Production, 2020, 254: 119848. doi: 10.1016/j.jclepro.2019.119848 [18] SZARGUT J, MORRIS D R. Cumulative exergy consumption and cumulative degree of perfection of chemical processes[J]. International Journal of Energy Research, 1987, 11(2): 245-61. doi: 10.1002/er.4440110207 [19] SZARGUT J, MORRIS D R, STEWARD F R. Exergy analysis of thermal, chemical, and metallurgical processes[J]. 1987. [20] 李巧. 基于㶲理论的生物质分级气化制氢系统的综合性能评价[D]. 南京: 东南大学, 2019. [21] CORNELISSEN R. Thermodynamics and Sustainable Development[D]. Enschede, the Netherlands: University of Twente, 1997. [22] LOMBARDI L. Life cycle assessment (LCA) and exergetic life cycle assessment (ELCA) of a semi-closed gas turbine cycle with CO2 chemical absorption[J]. Energy Conversion and Management, 2001, 42(1): 101-14. doi: 10.1016/S0196-8904(00)00033-9 [23] TALENS PEIRÓ L, LOMBARDI L, VILLALBA MÉNDEZ G, et al. Life cycle assessment (LCA) and exergetic life cycle assessment (ELCA) of the production of biodiesel from used cooking oil (UCO)[J]. Energy, 2010, 35(2): 889-93. doi: 10.1016/j.energy.2009.07.013 [24] SEDPHO S, SAMPATTAGUL S, CHAIYAT N, et al. Conventional and exergetic life cycle assessment of organic rankine cycle implementation to municipal waste management: the case study of Mae Hong Son (Thailand)[J]. The International Journal of Life Cycle Assessment, 2016, 22(11): 1773-84. [25] TANG Y, DONG J, LI G, et al. Environmental and exergetic life cycle assessment of incineration- and gasification-based waste to energy systems in China[J]. Energy, 2020, 205: 118002. doi: 10.1016/j.energy.2020.118002 [26] AUTRET E, BERTHIER F, LUSZEZANEC A, et al. Incineration of municipal and assimilated wastes in France: Assessment of latest energy and material recovery performances[J]. Journal of Hazardous Materials, 2007, 139(3): 569-74. doi: 10.1016/j.jhazmat.2006.02.065 [27] 汪永祥, 王德彬. 采用煤低位发热量计算烟气量方法的探讨[J]. 吉林电力, 2008(5): 5. [28] 邵蕾, 周传斌, 曹爱新, 等. 家庭厨余垃圾处理技术研究进展[C]// 2011中国可持续发展论坛. 2011: 420-424. [29] 夏顺丽. 厨余垃圾综合处理工艺设计及其能量和物料平衡研究[D]. 山东: 山东大学, 2017. [30] Wang H, Xu J, Sheng L. Study on the comprehensive utilization of city kitchen waste as a resource in China[J]. Energy, 2019, 173: 263-277. doi: 10.1016/j.energy.2019.02.081 [31] 石建屏, 徐黎黎, 孙会宁, 等. 城市生活垃圾填埋气测算及资源化利用研究[J]. 再生资源与循环经济, 2016, 9(12): 32-35. doi: 10.3969/j.issn.1674-0912.2016.12.009 [32] ABYAR H, YOUNESI H, NOWROUZI M. Life cycle assessment of A2O bioreactor for meat processing wastewater treatment: An endeavor toward the achievement of environmental sustainable development[J]. Journal of Cleaner Production, 2020, 257: 120575. doi: 10.1016/j.jclepro.2020.120575 [33] CORNELISSEN R L, HIRS G G. The value of the exergetic life cycle assessment besides the LCA[J]. Energy Conversion and Management, 2002, 43(9-12): 1417-24. doi: 10.1016/S0196-8904(02)00025-0 [34] SUN B, NIE Z, GAO F. Cumulative exergy consumption (CExC) analysis of energy carriers in China[J]. International Journal of Exergy, 2014, 15(2): 196-213. doi: 10.1504/IJEX.2014.065646 [35] DEWULF J, VAN LANGENHOVE H, DIRCKX J. Exergy analysis in the assessment of the sustainability of waste gas treatment systems[J]. Science of the Total Environment, 2001, 273(1/2/3): 41-52. [36] 李海燕. 基于㶲理论的生物质热解制取高品位液体燃料综合性能评价[D]. 南京: 东南大学, 2015. [37] 侯博特, 李婉玲. 重金属离子与腐殖质的相互作用机理研究[J]. 农业与技术, 2014, 34(6): 5+48. [38] 刘义清, 胡飞. 生活垃圾焚烧废气的治理研究[J]. 广东化工, 2010, 037(12): 105-6. doi: 10.3969/j.issn.1007-1865.2010.12.051 -

下载:

下载: