-

随着全球能源需求的扩大,近年来页岩气产业发展迅速[1]。与从多孔岩石中开采天然气的传统方法不同,页岩盆地具有孔隙空间小,连通性差,渗透率低等特点,这阻碍了天然气在岩石中传输[2]。为了释放、采集致密页岩储层中的天然气资源,水平钻井和水力压裂技术起到了关键作用[3],两项技术的进步推动了页岩气开采效率。但是,随之而来的环境问题也逐渐引起公众关注[4]。压裂液作为水力压裂技术的关键物料,能够压裂地层并支撑裂缝,使气体逸出[5]。压裂液主要由水、支撑剂和添加剂三部分组成,其中添加剂中含有大量的化学品[6]。在压裂结束几天后,首先返回到地面的液体通常被称为返排水,返排周期通常为1—2周[7-8]。返排水主要是压裂液和页岩地层水的混合[9]。此外,在井下高温、高压的条件下压裂液中化学物质可能会发生转化[10],故返排水中含有压裂液中化学品及其转化产物。高效处理和再利用压裂废水需要全面了解其中化学污染物的组成。但是,由于化学分析技术的瓶颈,以及返排水的化学成分复杂等原因,相关分析数据仍待补充。这项工作的首要关键是厘清返排水中具有较高的扩散潜力的水力压裂相关化学物质[7]。

PMTs (Persistent, mobile and toxic substances)是指在环境中表现出持久性和弱吸附性的毒害化学物质,故不容易被沉积物、活性炭等天然或人工水处理过程去除,并逐水迁移,在饮用水水源和地下含水层中汇聚,进而影响饮用水和地下水水质,并通过饮水这一暴露途径危害人体健康。因此,PMT成为近年来全球关注的新一类高危化学品[11]。因此探索返排水中的化学污染物对区域水资源的影响,应该重点关注PMTs。研究[4,7]表明,返排水的化学特征受压裂液成分、油气埋深等诸多因素的影响,不同地区的返排水的水化学以及污染物组成特征可能具有较大差异。国外新近研究对压裂返排水特征和成分进行了分析和初探,虽然不能反映我国的真实情况,但是对我国页岩气开发化学污染防控仍具有指导、借鉴意义[12]。综上,本文将梳理相关国内外文献,总结、归纳压裂返排水中主要化学污染物的分布特征,并从中甄别、枚举易对区域饮用水资源和地下饮用水安全构成危害的PMTs。这篇综述将从化学品风险管理的角度出发,为我国页岩气产业实现绿色开发提供相关理论依据。

-

随着常规油气资源的消耗,寻找新的替代能源是全球趋势。页岩气作为一种清洁高效、分布广泛的非常规能源[13],引起了全球的关注,主要原因是页岩气可以在一定程度上替代常规天然气,减少人们对于传统能源的依赖[14-15]。当前具有商业开采规模的页岩气产区主要位于北美(美国和加拿大)、阿根廷和中国[16]。根据《岩气发展规划 (2015—2020年) 》,目前我国页岩气技术可采资源量为21.8 万亿m3,我国政府在科技和政策等方面对页岩气产业的发展提供了有力支持,以求稳步增加页岩气对天然气供应的贡献。同时,页岩气开采对区域水资源影响也不容忽视。一方面,由于我国页岩气存储位置较深[17]以及我国压裂技术和工艺差异[13]等方面的因素,我国页岩气开采用水量要高于美国。根据秦等[17]的计算,为实现《岩气发展规划 (2015—2020年) 》在2030 年的页岩气生产目标,约需消耗3.8亿m3的水。另一方面,页岩气开采具有短时间内耗水量大的特点,短时间的大量用水会显著影响当地的生产、生活。页岩气开采过程中所使用的水平钻井和水力压裂技术会消耗大量的水资源,Shi等[13]的研究表明压裂耗水量大约占页岩气开采总用水量的98%。Yu等[18]指出四川页岩气勘探活动造成某些地区出现较高的用水压力。

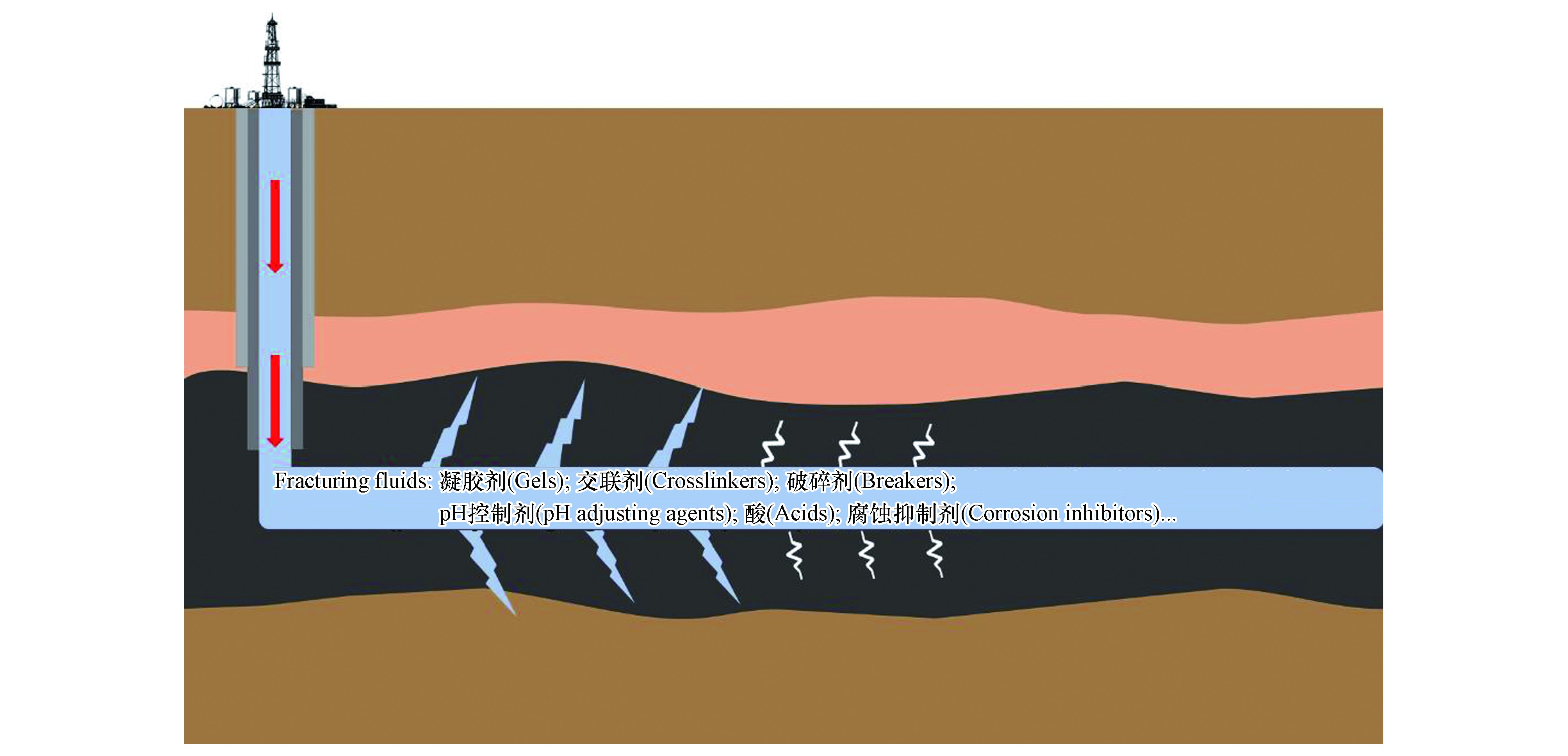

除对区域水量的影响之外,页岩气产业对水环境的污染也备受关注。如图1所示,页岩气开采过程中,水力压裂液、压裂返排水中含有大量的化学物质,其中不乏具有毒害效应的污染物,如果处理和储存不当可能引起周边土壤和水环境污染 [1,17,19]。就污染对象而言,页岩气开采可能造成的水环境污染可分为地表水污染和地下水污染[17]。根据页岩气开采的步骤,造成水污染的可能途径包括钻井过程、水力压裂过程以及采气过程。废弃钻井液、压裂返排水等处理、储存不当也可能导致地表水污染,其中返排废水数量巨大,若造成环境泄露,可能引发地表水体富营养化、影响饮用水水质以及影响农业灌溉[17]。此外,页岩气开采过程有可能通过以下几种途径影响含水层水质:(1)在钻井过程中发生的钻井液渗漏并引发地下水污染[17];(2)在开采过程中管道泄露或者遇到断层和裂缝,压裂液迁移进入浅层地下水 [1,17];(3)甲烷逸散、迁移进入含水层[20-22];(4)水力压裂过程产生的返排水回注过程可能造成地下水污染[23]。

-

目前页岩气的开采多使用水力压裂技术,水力压裂的主要原理为在高压条件下经水平钻井向地层深处注入压裂液,在井底产生高压,当地层无法承受压力时便开始碎裂,从而产生地层裂缝。随着压裂液的不断注入,裂缝逐渐延伸,压裂液中的支撑剂支撑裂缝,使得岩层渗透性增加,从而提高油气采集效率[24-25]。压裂液可分为水、支撑剂和添加剂等三个部分,水作为载体,是压裂液的主要组成,通常占比为90%;支撑剂一般是石英砂、陶粒等强度大、杂质少的物质,占比约8%;添加剂仅占比不到2%,但含有多种化学物质,因此不容忽视[5,24]。一般而言,随着页岩气储层地质特征的变化,压裂液中使用的化合物成份也会有所不同[23]。如表1所示,根据Ferrer等[24]的研究,添加剂大概可分为以下几个组分。

-

返排水是指在压裂结束后,最先返回到地面的流体,具有返排周期短、日流量大等特点[4-5,7]。另一个容易混淆的概念是产出水。产出水是指在产气阶段,伴随着抽气一起采出的流体,返排周期为整个生产阶段,但日流量较小[3-5,7]。返排水的组成通常可分为压裂液中用作添加剂的无机和有机化合物的复杂混合物、来自页岩的化合物(如盐、金属、石油和天然气化合物以及天然有机物等)、有机化合物在井下经物理化学或生物过程的转化产物[26-27]。本文关注返排水中的有机污染物的组成特征。近年来,国外已经有系列研究报道了页岩气返排水中的有机污染物分布与组成特征,但我国相关研究尚处于初步研究阶段[9,12],尤其针对单体成分的定性和定量分析的数据仍匮乏,故尚不能支持对现有返排水处理、储存工艺的选择和优化。

-

不同研究[9,28-37]报道了返排水中有机单体的组成和特征,目前检测到的有机污染物中占比最高的为烷烃。Wang等[9]对长宁页岩气矿区的压裂返排水的有机化学特征进行了分析,结果表明C6—C21直链烷烃和C7—C13环烷类有机物含量最高,达48%以上。Piotrowski等[28]分析了Marcellus页岩地区的4种返排水样品,发现其主要组成均为烷烃且占比高达42%—69%。Hoelzer等[29]对Fayetteville页岩地区的返排水样品进行了有机组分的分析,在检测到的化合物列表中,烷烃含量也最为丰富。返排水样品中,芳香族化合物也是经常被分析的一类有机化合物,Strong等[30]在Marcellus页岩的两种返排水样品中分别检测到了994种和987种有机化合物,其中26%—27%为单环芳香族化合物,2%—3%为多环芳烃 (polycyclic aromatic hydrocarbons,PAHs)。苯、甲苯、乙苯、二甲苯在返排水样品检测中最为常见,在多篇文献中[30-34]均有报道。此外,Abualfaraj和Ziemkiewicz等[31-32]也在研究中检出了其他的芳香族化合物,如苯乙烯等。PAHs可以作为岩石成因影响的标志物[35],故许多研究[9,30,35]重点检测了样品中的PAHs,如芴、菲、萘以及萘取代物等。He等[35]在返排水样品中检测出了13种母体PAHs和4种烷基PAHs,母体PAHs主要包括芴、菲,并且主要趋向于分配在水相中;而烷基PAHs主要为芴、菲的衍生物 (1-甲基芴和甲基/二甲基菲),主要倾向于分配在颗粒相中。研究[36]发现,返排水中溴化物和氯化物的含量高且压裂液添加剂中可能含有溴原子和氯原子,因此近年来返排水中的卤代物也受到了大量的关注。Luek等[37]利用超高分辨率的傅立叶变换离子回旋共振质谱结合非靶向筛查技术,对水力压裂返排水样品进行了分析,并利用同位素模拟和双质谱(MS-MS)电离特征对卤代物的分子式进行了鉴定和识别,在返排水样品中检测到大量的卤代有机物。Wang等[9]利用傅里叶变换红外光谱法、气相色谱与质谱联用技术对四川长宁地区页岩气压裂返排水的有机物组成进行分析,检测出的卤代烃主要为氯代烃和溴代烃。此外,研究[29]表明,与碳氢化合物相比,醇、羧酸、醚、环氧化合物等其他具有官能团的物质检测数量较少。更多研究[9,29]]检出了醇类物质,如2,2,4-三甲基-1,3-戊二醇、乙二醇、苯甲醇等。此外,醚、酮、酸、酯等,如丙酮、邻苯二甲酸二丁酯、辛基酚聚氧乙烯酯在一些文献[9,28-35]中也有报道。以上结果表明,页岩气开采的返排水样品中有机污染物的组成复杂,种类繁多,以烷烃为主,芳香族化合物和卤代物也在大量文献均有检出,醇、醚、羧酸等其他物质数量相对较少,但由于采样位置和检测方法的不同,检测的有机物种类也会有所差异。

-

根据返排水的产生过程,我们不难发现返排水中很可能会含有压裂液成分。同时,大量的研究也在返排水中检出了已知的或可疑的压裂液添加剂。因此,压裂液是返排水中有机污染物的重要来源之一。压裂液添加剂的有机成分包括烷烃、烯烃、芳香烃、醇类、脂类以及醚类等。就添加剂的组分而言,大量的研究表明,表面活性剂、杀菌剂、铁离子控制剂、破碎剂均在返排水样品中检测到。Zhong和He等[35,38]在页岩气开采的返排水中均检出了聚乙二醇 (polyethylene glycols,PEGs)和辛基酚类聚氧乙烯醚 (octylpenol ethoxylates,OPEs),PEGs为环氧乙烷水解产物的聚合物,OPEs在商业上被称为Triton-X,两者通常都被用作压裂液中的表面活性剂。Oetjen等[39]在返排水样品中检测到了C10到C17的杀藻铵(benzalkonium chlorides, BACs)的同系物,BACs是一种疏水阳离子表面活性剂。其他的表面活性剂,如乙氧基醇[33,40]、乙二醇[9,41]、2-丁氧基乙醇[42]、乙氧基苯酚[41]在之前的文献中也有报道。文献中报道的杀菌剂主要为烷基二甲基苄基氯化铵[24,38,40,43]、六氢-1,3,5-三甲基-1,3,5-三嗪-2-硫酮[41]和戊二醛[43]。多种邻苯二甲酸酯类化合物在多篇文献[9,12,29]均有检出,邻苯二甲酸酯可能与水力压裂过程的钻井液和破碎剂有关。Hoelzer等[29]在返排水中检测到了多种邻苯二甲酸酯,既包括公开的邻苯二甲酸酯,如双 (2-乙基己基) 邻苯二甲酸酯(用作转移剂),也包括未公开的邻苯二甲酸酯,如邻苯二甲酸二异丁基、二丁基、丁基异丁基、二辛酯和邻苯二甲酸二异辛酯。值得一提的是,样品收集过程中使用的聚合物容器是邻苯二甲酸酯的潜在来源,但并非所有使用聚合物容器的样品中均检测到邻苯二甲酸酯,检测到的邻苯二甲酸盐的具体类型仅在不同样品中有所不同,但在不同容器中保持一致而且在实验室对照研究中并没有被检出,因此Hoelzer等认为这些检测到的化合物很可能来自于水力压裂作业的返排水样品[29]。Wang等[9]在返排水样品中检测到邻苯二甲酸二丁酯,这是一类重要的具有“三元”效应的环境激素。其他添加剂组分在部分文献也有检测到,Wolford等[44]在Marcellus页岩地区的返排水样品中检测到了柠檬酸,在压裂液中通常被用作铁离子控制剂,Hoelzer等[29]检测到了1-癸醇、2-乙基-1-己醇和异丙醇(通常用作溶剂)以及偶氮二异丁腈 (一种公开的普通自由基引发剂)。

-

由于压裂液在水力压裂过程与页岩地层长时间接触,因此返排水中的有机污染物不仅来源于页岩气开采时使用的压裂液,同时也会来自页岩地层。根据研究[26],地层的有机物主要包括烷烃、烯烃、芳香烃、酚类以及酮类等。返排水中的许多有机物既可能是来自压裂液添加剂,也可能是由于地质原因产生,很难有明确的划分,如烷烃、苯及苯系物等碳氢化合物。Orem等[41]在地层水中观察到的化合物类别包括:长链脂肪酸、烷基酚、多环芳烃、烷基苯、一些杂环化合物(特别是苯并噻唑及其衍生物)和长链烷烃,这与在返排水中检测结果相似。Ziemkiewicz等[32]研究发现,在返排过程中收集的有机成分的浓度随时间不断增加而且在返排水中的浓度比注入压裂液的浓度高得多,其认为返排水中大部分成分来自Marcellus页岩地层,而不是压裂液。Hoelzer等[29]在返排水中检测到了两类几乎可以肯定是由地质原因引起的化合物:太古代地核醚脂质和五环萜类(即藿烷)。以上结果表明地层有机物也是返排水中有机物的重要来源之一。

-

在压裂过程中,大量的压裂液在高压条件下注入页岩地层,在井下高温、高压、高盐的条件以及强氧化剂的使用下,发生物理化学转化等非生物反应。此外,压裂液中的添加剂会在地下发生反应,如对压裂液中的聚合物进行化学转化和破坏,以降低表面张力[45]。尽管压裂液中含有杀菌剂,但是一些研究[46-48]仍在返排水中检测到了细菌。细菌的存在能够引起部分有机单体的微生物转化。此外,相关研究[9,27,29,37]发现,返排水中检测到的许多有机物既不属于使用的水力压裂液添加剂,也不是地质成因的有机物。因此,以上结果表明转化反应也是返排水的有机污染物的重要来源之一。Hoelzer等[29]在返排水样品中检测到了大量转化产物,并推测了其非生物转化反应的机理:(a)延迟酸(即,只有在水解裂解后才释放酸性部分,有一定的延迟时间)的水解反应,(b)卤代反应;(c)添加剂的转化反应。文献中常见的转化产物包括卤代物、有机酸、酸酐、丙酮、酯类等。有机卤代物的形成机制可分为非生物反应[29,49]和微生物转化[29,37,50]。Luek等[37]发现所鉴定的卤代物与已知的添加剂并不匹配,且通过对页岩地层水的提纯、分析,并没有发现任何天然卤化有机物。Sumner等[49]筛选了12种常用的、功能多样的水力压裂添加剂,利用一个高温、高压反应系统来揭示其转化机制,研究表明天然盐水和水力压裂添加剂之间的地下反应可能会导致卤化产物意外生成。在返排水的处理方法中,常见的一种方式为返排水回用,即将返排水进行消毒等处理后重新用作压裂液。消毒过程通常为氯化处理,而氯化处理可通过与返排废水和产出水中的有机物反应生成消毒副产物,因此在返排水中可能会检测到消毒副产物[28]。如Wang等[9]在水样中检测到硝基三氯甲烷,可能为氯基消毒剂氯化的副产物。而Piotrowski等[28]在返排水样品中未检测到卤化物和消毒副产物,作者推测可能是因为使用的压裂液几乎不含回用的返排水。此外,强氧化性杀菌剂(如含氯化合物和含溴化合物)的反应也可能会导致卤代烃和消毒副产物的生成[51]。Evans等[50]通过非目标有机卤化物化学分析和宏基因组学揭示了在水力压裂过程中促成有机卤化物转化的微生物和酶系统,发现微生物在有机卤代物的转化过程中发挥着重要的作用。此外,有机酸也是一类常见的转化产物,Hoelzer等[29]在返排水中发现一些羧酸(如戊酸、丁酸和己酸)的含量较高并假定这些物质为延迟酸的转化产物。许多研究[29,33,52]均在返排水样品中检测到了丙酮,丙酮既可能来自压裂液添加剂[44],也可能是转化产物[29]。Hoelzer等[29]在研究中鉴定丙酮为意外生成的副产物。除了卤代物、有机酸和丙酮外,文献还检测到了其他的转化产物。He等[27]在返排水样品中鉴定出了芳基磷酸酯,但这种磷酸酯化学品不在加拿大国内物质清单(Domestic Substance List,DSL)中,而其相应的三(2,4-二叔丁基苯基)亚磷酸(C42H63PO3)是DSL上常见的聚合物抗氧化剂,在氧化后会生成所检测到的磷酸酯。Kim等[52]将压裂添加剂分别与压裂循环水和淡水混合,并模拟了井下高温高压的条件,最终从以上两种样品中均检测到环氧乙烷和丙二醇功能单元,在水力压裂过程中,乙氧基化化合物用于各种功能,包括降低摩擦、防垢和破碎剂等,丙二醇也是压裂液中常见的成分之一,用作减摩剂、杀菌剂和阻垢剂,在对样品进行加热处理的过程中,丙二醇可能会转化为丙基氧化物。上文提到的OPEs[35,38]很容易被微生物降解为辛基酚,而辛基酚是一种内分泌干扰物。

-

由于缺乏标准,较少的文献对返排水中的有机污染物进行了定量分析,可以发现苯以及苯系物、一些卤代烃、丙酮等物质检测浓度较高。其中,苯是最常被检测到超出检出限的化合物。Abualfaraj等[31]在返排水样品中检测到苯的平均浓度为0.125 mg·L−1,是最大污染限值(maximum contamination level,MCL)的25倍。Ziemkiewicz等[32]检测发现返排水中苯的浓度超过MCL约40倍。Shih等[53]对61份返排水样品进行了检测,检测到苯的最高浓度为1.2 mg·L−1,远远高于MCL。此外,Abualfaraj等[31]检测到二溴一氯甲烷的平均浓度是MCL的240倍。Lester等[33]在返排水中的有机物进行了定量分析,在挥发性有机物中仅有丙酮、二甲苯(总)、丁酮在检出限以上,其中丙酮浓度高达16 mg·L−1。亚甲基蓝活性物质(methylene-blue-active substances,MBAS)在一些文献中也有检出,在Ziemkiewicz等[32]的研究中MBAS的平均浓度为0.42 mg·L−1,Shih等[53]的研究结果与其相似,平均浓度为0.45 mg·L−1。邱哲等[12]对重庆地区的页岩气返排水样品进行了检测,测得苯酚的平均浓度为8.47 μg·L−1,高于我国地表水Ⅳ类标准(5 μg·L−1);邻苯二甲酸二丁酯平均浓度为5.85 μg·L−1,高于我国集中式生活饮用水地表水源地特定项目标准限值(3 μg·L−1)。综上所述,返排水中有多种有机物污染物超出了水质标准,其中不乏一些在我国环境优先污染物名单上的物质。然而,目前的废水处理标准忽略了许多毒害有机单体,仅限制了部分有机污染物的浓度 [54]。例如,在我国的气田水回注方法[55]中,与有机物相关的标准仅有限制石油类物质的含量在30 mg·L−1以下。因此,相关水质标准的更新亟需大量相关场地观测数据的支撑.

目前,页岩气返排水水质的分析存在很多难题,在返排水样品的前处理方法上,由于水样水化学参数的复杂性和特殊性 (即总有机碳、浊度、盐度、pH值),样品的预处理和预浓缩极具挑战。针对这一问题,Regnery等[56]采用一次性十八烷基键合硅胶(C18)柱上的固相萃取(SPE)和气相色谱-质谱联用技术,建立了定量分析水力压裂废水中半挥发烃的通用方法。另外,返排水中成分复杂,可能含有重金属、放射性核素以及大量有机成分,这对分析技术提出了挑战[27]。高分辨率气相色谱-质谱对识别有机组分和表征混合烃发挥了重要作用[9],但仅限于挥发性、非极性或中、低极性的有机化合物。液相色谱-质谱是检测返排水中高极性和高水溶性化合物的高效方法,已被用于识别多种添加剂,也用于进一步鉴定转化产物 [26]。此外,傅里叶变换离子回旋共振质谱(FT-ICR-MS)是一种超高分辨率质谱分析技术,它具有极高的分辨率和稳定的质量准确度,已有少数研究应用FT-ICR-MS分析、识别了返排水中的卤代单体,为后续的研究提供了经验 [54]。

-

如上文所述,返排水中的有机污染物通常通过地下水、地表水等途径污染水环境,从而危害人体健康。相较于常见的地下水和地表水污染,返排水蒸发是一种新发现的二次污染物来源,可显著增加大气中的颗粒物浓度,造成大气污染[57]。在生活中人们不可避免地会暴露在水、空气和土壤等环境中从而直接或间接地接触到返排水中的化学物质,而返排水中一些已知的化学品是对人体健康有害的[58]。酚类和邻苯二甲酸酯是剧毒、致癌和诱变化合物,可破坏内分泌系统[59]。苯和氯乙烯可能会增加接触人群的患癌风险[31]。丙炔醇也具有很高的急性毒性和致癌性,石油碳氢化合物、柑橘萜类、醇类(甲醇、异丙醇)或烷基胺有毒且易挥发,杀菌剂即使在低浓度下也可能显示出效果[60]。此外,一些杀菌剂的降解产物比母体化合物毒性更高且更具有持久性[61]。鉴于部分有机卤代物对人体健康的危害,美国环境保护署优先控制污染物清单上超过一半的化合物为有机卤代物[62]。He等[35]将斑马鱼胚胎暴露于不同浓度的返排水和产出水(flowback and produced water,FPW)的有机提取物中,分析了有机组分对斑马鱼胚胎的毒性影响,结果显示胚胎的脊柱畸形、心包水肿和延迟孵化等现象随着有机提取物含量的上升而显著增加,而且其发现即使是短期接触多环芳烃及其甲基化衍生物,也会对鱼胚胎产生剧毒和致畸作用。Blewett等[63]将水蚤分别急性(48 h半致死浓度;LC50)和慢性(21 d)暴露于FPW中来表征FPW的毒性,在慢性暴露中观察到水蚤的生殖能力明显下降。Hull等[64]采用生物荧光抑制法(BLIA)、Ames II诱变法和酵母雌激素筛选法对FPW的毒性和微生物特征进行了分析,通过BLIA测定发现返排前220 d的水样仍有很高的毒性。以上结果说明返排水中含有毒害物质,对人体健康构成威胁。

-

研发高效、低成本的页岩气生产废水的处理技术和工艺是未来工作的重要内容之一。当前返排水的处理技术主要包括氧化技术、絮凝技术、膜分离技术、蒸馏技术以及生物技术等[65]。其中膜分离技术是一种很有前景的水处理方法,包括超滤、微滤、纳滤、正向渗透和反渗透,以及新开发的重力驱动膜过滤技术[66]。Tang等[66]将重力驱动膜过滤与颗粒活性炭吸附和太阳能曝气相结合,提出了一种简单的现场处理一体化预处理工艺,该集成系统具有能耗低、运行成本低、生产率高等优点,在页岩气废水处理方面显示了较好的潜力。Chang等[67]采用肥料前向渗透法从页岩气返排水和产出水中提取淡水用于灌溉,具有低成本和无需分离的优点。此外,由于返排水成分复杂,通常单一处理无法达到排放标准,因此返排水处理应考虑多种有效处理技术方法的联用和集成[9]。

-

由于PMT类污染物高极性和持久性的特点,一旦发生泄露,可以“穿透”各类水处理和天然屏障,在饮用水水源和地下水中汇聚,进而影响饮用水水质和地下水安全,并通过饮水这一暴露途径危害人体健康。本文对返排水中的有机化合物进行了进一步筛查、甄别,发现返排水中存在多种已知的PMT。其中代表性物质有四氯乙烯、1,1-二氯乙烯、1,3,5-三甲苯、1,4-二氧六环、甲基叔丁基醚(methyl tert-butyl ether,MTBE)、二乙二醇二甲醚 (详见表2)。四氯乙烯是一种常见的有毒卤化物,水溶性强,通常被用作溶剂,生物降解能力较弱,在环境中具有很高的持久性,进入人体后会损害人体的神经系统、消化系统等部位,从而危害人体健康,故被列入我国有毒有害水污染物名录[68-69]。1,1-二氯乙烯会对人体的中枢神经系统造成损害,燃烧产物为一氧化碳和氯化氢等,其已被列入2B类致癌物清单。MTBE在页岩气开采中通常被用作凝胶剂,其易溶于水而且易挥发,在环境中降解缓慢,因此可能会污染水环境[70-71]。综上所述,返排水中的多种有机物都具有PMT属性,如果储存、处理和排放不当会造成水污染,并威胁区域地下和饮用水资源的安全。

-

页岩气开采返排水中有机污染物的成分复杂,种类繁多,其中烷基化合物占比最高,芳香族化合物和卤代化合物也均有检出。这些有机污染物的来源分为水力压裂液、地层以及井下转化过程,已有多种压裂液添加剂组分、地质成因的化合物以及这些有机物的转化产物在返排水样品中检测到,在转化产物中,卤代化合物是近年来关注较多的一类化合物,其生成机制较复杂。在对有机污染物定量的研究中,苯是最常被检测到的有机污染物,其含量远超标准。返排水样品中检测到的多种有机污染物都会对人体健康构成危害。另外,探索页岩气返排废水中化学污染物对区域水环境和水质的影响,应该做到“有的放矢”,聚焦PMT这类具有高极性、持久性的污染物,因为PMT一旦释放到水环境,将参与水循环,最终在地下水和饮用水水源汇聚,进而影响区域水资源质量和安全。鉴于这个问题,本文甄别、例举了多个直接牵涉地下水和饮用水安全的具有PMT属性的化合物,如四氯乙烯、1,1-二氯乙烯等,我们认为优先防控这类污染物,将更好地保护区域水资源安全,保障我国页岩气产业实现绿色发展。

目前,返排水水质化学分析的难题主要可分为样品前处理和分析技术两个方面。返排水样品的成分复杂给样品前处理和化学分析带来了难题。气相色谱、液相色谱与质谱联用技术以及傅里叶变换离子回旋共振质谱在分析、识别单体物质方面各具优势。在未来的研究工作中,应该结合目标单体的物理化学性质,合理地选择样品前处理和化学分析方法。返排水处理方面,亟需研发高效、低成本水处理技术和工艺,鉴于返排水成分的复杂性,可考虑联用不同水处理技术。

目前关于返排水中有机污染物的研究仍然较为匮乏,尽管已检测、识别出了返排水中多种化学添加剂的组成,但仍有大部分单体成分未知,当前的研究多集中于表面活性剂和杀菌剂物质;压裂液和地层水中有机物的转化反应机制仍待进一步研究,上述的室内模拟实验方法为解答这一难题提供了新的研究途径;在发展化学品的分析、筛查技术的同时,应针对水力压裂全生产周期进行跟踪采样分析,探查化学污染物返排释放规律和特征;最后,应加大水力压裂化学品的管控力度,针对PMT这类高危化学品进行源头消减,将有助于降低区域水资源的化学污染风险。

页岩气开采水力压裂返排水中化学污染物的组成特征

Compositional characteristics of chemical pollutants in flowback water during shale gas hydraulic fracking

-

摘要: 伴随全球页岩气规模化开发,相关的区域环境问题引起了学界和公众的持续关注。页岩气开采与区域水资源息息相关,水力压裂不仅消耗大量水资源,而且产生返排废水,成分复杂,含数以千计的化学物质。因此,有关返排水中有机单体的相关研究越来越受关注。本文系统总结了近年来的相关文献和成果,重点论述了压裂返排水中有机污染物的来源、种类、浓度水平以及可能造成的人体健康危害。另外,针对持久、迁移性和毒性有机污染物 (PMT),这类不易吸附、降解,且可以逐水迁移易在饮用水水源和地下水中累积的化合物,通过甄别、枚举了返排水中已检测出的PMT,并阐述了PMT对区域水资源的潜在危害。最后,鉴于当前我国页岩气开发场地的化学污染相关工作尚处于初步研究阶段,对未来的重要工作进行了展望。Abstract: Accompanied with rapid growth of shale gas industry, associated environmental problems have received continuous attention from the academia and public. Shale gas production is tightly linked to regional water resources. Specifically, shale gas extraction is consuming huge amount of fresh water resources, and the produced wastewater also contain thousands of chemical components. Thus, the relevant studies focusing on organic pollutants in the flowback water are receiving increasing interests. Our study summarizes the information on types, sources, concentration levels and harmful health effects of various organic pollutants introduced during shale gas production. Specially, the known persistent, mobile and toxic compounds (PMT) detected in flowback water, which are less sorptive but persistent, which could accumulate in drinking water resources and groundwater aquifers, were exemplified. Also, the potential impact on the regional drinking water resources and groundwater quality were demonstrated. Lastly, given that chemical pollution associated with shale gas production in China is still in early stage, our study also provided outlook for future studies.

-

Key words:

- flowback water /

- shale gas /

- hydraulic fracturing /

- chemical pollutants

-

-

表 1 水力压裂作业中压裂液各组分的用途及占比

Table 1. Purposes and proportion of each component of fracturing fluid in hydraulic fracturing operation

添加剂Additives 用途 Purpose 占比 % Fraction 凝胶剂 提高压裂液的粘度,增强砂悬浮,利于支撑剂输送 0.050 交联剂 化学结合单个凝胶聚合物分子维持流体黏度,利于支撑剂输送 0.007 润滑剂 降低流体与管道表面之间的界面张力,在泵送过程中保持层流 0.070 破碎剂 通过逆转交联,降低粘度,提高产气效率,有助于压裂液回收 0.060 pH控制剂 提高交联剂的有效性 0.010 酸 清洁和溶解矿物质,利于岩石造缝 0.150 腐蚀抑制剂 防止酸和盐而对套管的腐蚀 0.002 阻垢剂 防止在管道内形成水垢(矿物)沉积 0.090 铁离子控制剂 防止铁离子沉淀 0.006 黏土稳定剂 防止页岩地层中黏土膨胀 0.120 杀菌剂 消毒抑制压裂液中的细菌 0.060 表面活性剂 控制压裂液的最佳黏度,降低压裂液和页岩之间的界面张力 0.075 表 2 已知的PMTs物质及其添加目的

Table 2. Known PMTs detected and their use type

CAS. 化学品 Chemical 添加目的 Purpose 127-18-4 四氯乙烯(tetrachloroethylene) 不明确 75-35-4 1,1-二氯乙烯(1,1-dichloroethylene) 不明确 108-67-8 1,3,5-三甲苯(1,3,5-trimethylbenzene) 表面活性剂 123-91-1 1,4-二氧六环(1,4-dioxane) 表面活性剂 1634-04-4 甲基叔丁基醚(methyl tert-butyl ether (MTBE)) 凝胶剂 111-96-6 二乙二醇二甲醚(bis(2-methoxyethyl) ether) 泡沫剂 22042-96-2 二乙烯三胺五亚甲基膦酸钠(diethylenetriaminepenta (methylenephosphonic acid) sodium salt (DMPS)) 阻垢剂 -

[1] 张文泉, 侯俊, 尚婷婷. 页岩气开采的环境问题及建议 [J]. 广东化工, 2017, 44(2): 52-53. doi: 10.3969/j.issn.1007-1865.2017.02.026 ZHANG W Q, HOU J, SHANG T T. Environmental problems and suggestions for shale gas mining [J]. Guangdong Chemical Industry, 2017, 44(2): 52-53(in Chinese). doi: 10.3969/j.issn.1007-1865.2017.02.026

[2] KARGBO D M, WILHELM R G, CAMPBELL D J. Natural gas plays in the marcellus shale: Challenges and potential opportunities [J]. Environmental Science & Technology, 2010, 44(15): 5679-5684. [3] CARRERO-PARREÑO A, ONISHI V C, SALCEDO-DÍAZ R, et al. Optimal pretreatment system of flowback water from shale gas production [J]. Industrial & Engineering Chemistry Research, 2017, 56(15): 4386-4398. [4] WANG H, LU L, CHEN X, et al. Geochemical and microbial characterizations of flowback and produced water in three shale oil and gas plays in the central and western United States [J]. Water Research, 2019, 164: 114942. doi: 10.1016/j.watres.2019.114942 [5] 孟宣宇. 页岩气开发压裂返排液水质特征及其处理技术研究[D]. 北京: 中国石油大学(北京), 2017. MENG X Y. Study on water quality characteristics and treatment technology of fracturing fluid flowback in shale gas development[D]. Beijing: China University of Petroleum, Beijing, 2017(in Chinese).

[6] 黄靓, 李慧强, 杨平. 页岩气压裂返排液的组成及处理技术[J]. 环境科学与技术, 2016, 39(增刊2): 166-171. HUANG L, LI H Q, YANG P. The components and treatment of shale gas fracturing flowback water[J]. Environmental Science & Technology, 2016, 39(Sup 2): 166-171(in Chinese).

[7] BUTKOVSKYI A, BRUNING H, KOOLS S A E, et al. Organic pollutants in shale gas flowback and produced waters: Identification, potential ecological impact, and implications for treatment strategies [J]. Environmental Science & Technology, 2017, 51(9): 4740-4754. [8] 宋磊, 张晓飞, 王毅琳, 等. 美国页岩气压裂返排液处理技术进展及前景展望 [J]. 环境工程学报, 2014, 8(11): 4721-4725. SONG L, ZHANG X F, WANG Y L, et al. Frac-back water treatment development and perspective in United States [J]. Chinese Journal of Environmental Engineering, 2014, 8(11): 4721-4725(in Chinese).

[9] WANG B, XIONG M, WANG P, et al. Chemical characterization in hydraulic fracturing flowback and produced water (HF-FPW) of shale gas in Sichuan of China [J]. Environ Sci Pollut Res Int, 2020, 27(21): 26532-26542. doi: 10.1007/s11356-020-08670-y [10] YOST E E, STANEK J, DEWOSKIN R S, et al. Overview of chronic oral toxicity values for chemicals present in hydraulic fracturing fluids, flowback, and produced waters [J]. Environmental Science & Technology, 2016, 50(9): 4788-4797. [11] SCHULZE S, ZAHN D, MONTES R, et al. Occurrence of emerging persistent and mobile organic contaminants in European water samples [J]. Water Research, 2019, 153: 80-90. doi: 10.1016/j.watres.2019.01.008 [12] 邱哲. 页岩气开采返排水污染特性与AGS-SBR处理实验研究[D]. 重庆: 重庆大学, 2018. QIU Z. Researches on pollution characteristics and AGS-SBR treatment of flowback water from shale gas extraction[D]. Chongqing: Chongqing University, 2018(in Chinese).

[13] SHI W R, WANG X Z, GUO M Y, et al. Water use for shale gas development in China's Fuling shale gas field [J]. Journal of Cleaner Production, 2020, 256: 120680. doi: 10.1016/j.jclepro.2020.120680 [14] SOVACOOL B K. Cornucopia or curse?Reviewing the costs and benefits of shale gas hydraulic fracturing (fracking) [J]. Renewable and Sustainable Energy Reviews, 2014, 37: 249-264. doi: 10.1016/j.rser.2014.04.068 [15] WANG Q, CHEN X, JHA A N, et al. Natural gas from shale formation - The evolution, evidences and challenges of shale gas revolution in United States [J]. Renewable and Sustainable Energy Reviews, 2014, 30: 1-28. doi: 10.1016/j.rser.2013.08.065 [16] BLYTHE K, JEFFRIES R, TRAVERS M. An international perspective of challenges and constraints in shale gas extraction[M]//Environmental and Health Issues in Unconventional Oil and Gas Development. Amsterdam: Elsevier, 2016: 225-248. [17] 秦浩, 陈星, 许钦. 页岩气开发过程中的水资源水环境风险分析 [J]. 水利经济, 2019, 37(3): 62-66,87. doi: 10.3880/j.issn.1003-9511.2019.03.011 QIN H, CHEN X, XU Q. Risk analysis and evaluation of water resources and water environment inexploitation process of shale gas [J]. Journal of Economics of Water Resources, 2019, 37(3): 62-66,87(in Chinese). doi: 10.3880/j.issn.1003-9511.2019.03.011

[18] YU M J, WEINTHAL E, PATIÑO-ECHEVERRI D, et al. Water availability for shale gas development in Sichuan basin, China [J]. Environmental Science & Technology, 2016, 50(6): 2837-2845. [19] SMALL M J, STERN P C, BOMBERG E, et al. Risks and risk governance in unconventional shale gas development [J]. Environmental Science & Technology, 2014, 48(15): 8289-8297. [20] BRANTLEY S L, YOXTHEIMER D, ARJMAND S, et al. Water resource impacts during unconventional shale gas development: The Pennsylvania experience [J]. International Journal of Coal Geology, 2014, 126: 140-156. doi: 10.1016/j.coal.2013.12.017 [21] DARRAH T H, VENGOSH A, JACKSON R B, et al. Noble gases identify the mechanisms of fugitive gas contamination in drinking-water wells overlying the Marcellus and Barnett Shales [J]. PNAS, 2014, 111(39): 14076-14081. doi: 10.1073/pnas.1322107111 [22] WARNER N R, CHRISTIE C A, JACKSON R B, et al. Impacts of shale gas wastewater disposal on water quality in western Pennsylvania [J]. Environmental Science & Technology, 2013, 47(20): 11849-11857. [23] 王丹, 何敏. 页岩气勘探开发对水环境的影响及建议 [J]. 环境科学导刊, 2016, 35(6): 103-107. doi: 10.3969/j.issn.1673-9655.2016.06.024 WANG D, HE M. Impacts and suggestions of shale gas exploration and development on water [J]. Environmental Science Survey, 2016, 35(6): 103-107(in Chinese). doi: 10.3969/j.issn.1673-9655.2016.06.024

[24] FERRER I, THURMAN E M. Chemical constituents and analytical approaches for hydraulic fracturing waters [J]. Trends in Environmental Analytical Chemistry, 2015, 5: 18-25. doi: 10.1016/j.teac.2015.01.003 [25] 吴青芸, 郑猛, 胡云霞. 页岩气开采的水污染问题及其综合治理技术 [J]. 科技导报, 2014, 32(13): 74-83. doi: 10.3981/j.issn.1000-7857.2014.13.013 WU Q Y, ZHENG M, HU Y X. Shale gas produced water contamination and its comprehensive treatment [J]. Science & Technology Review, 2014, 32(13): 74-83(in Chinese). doi: 10.3981/j.issn.1000-7857.2014.13.013

[26] LUEK J L, GONSIOR M. Organic compounds in hydraulic fracturing fluids and wastewaters: A review [J]. Water Research, 2017, 123: 536-548. doi: 10.1016/j.watres.2017.07.012 [27] HE Y H, FLYNN S L, FOLKERTS E J, et al. Chemical and toxicological characterizations of hydraulic fracturing flowback and produced water [J]. Water Research, 2017, 114: 78-87. doi: 10.1016/j.watres.2017.02.027 [28] PIOTROWSKI P, WEGGLER B A, YOXTHEIMER D A, et al. Elucidating environmental fingerprinting mechanisms of unconventional gas development through hydrocarbon analysis [J]. Analytical Chemistry, 2018, 90(8): 5466-5473. doi: 10.1021/acs.analchem.8b00822 [29] HOELZER K, SUMNER A J, KARATUM O, et al. Indications of transformation products from hydraulic fracturing additives in shale-gas wastewater [J]. Environmental Science & Technology, 2016, 50(15): 8036-8048. [30] STRONG L C, GOULD T, KASINKAS L, et al. Biodegradation in waters from hydraulic fracturing: Chemistry, microbiology, and engineering [J]. Journal of Environmental Engineering, 2014, 140(5): B4013001. doi: 10.1061/(asce)ee.1943-7870.0000792 [31] ABUALFARAJ N, GURIAN P L, OLSON M S. Characterization of Marcellus shale flowback water [J]. Environmental Engineering Science, 2014, 31(9): 514-524. doi: 10.1089/ees.2014.0001 [32] ZIEMKIEWICZ P F, THOMAS H Y. Evolution of water chemistry during Marcellus Shale gas development: A case study in West Virginia [J]. Chemosphere, 2015, 134: 224-231. doi: 10.1016/j.chemosphere.2015.04.040 [33] LESTER Y, FERRER I, THURMAN E M, et al. Characterization of hydraulic fracturing flowback water in Colorado: Implications for water treatment [J]. Science of the Total Environment, 2015, 512/513: 637-644. doi: 10.1016/j.scitotenv.2015.01.043 [34] OETJEN K, THOMAS L. Volatile and semi-volatile organic compound patterns in flowback waters from fracturing sites within the Marcellus Shale [J]. Environmental Earth Sciences, 2016, 75(12): 1-10. [35] HE Y H, SUN C X, ZHANG Y F, et al. Developmental toxicity of the organic fraction from hydraulic fracturing flowback and produced waters to early life stages of zebrafish (Danio rerio) [J]. Environmental Science & Technology, 2018, 52(6): 3820-3830. [36] MAGUIRE-BOYLE S J, BARRON A R. Organic compounds in produced waters from shale gas wells [J]. Environmental Science. Processes & Impacts, 2014, 16(10): 2237-2248. [37] LUEK J L, SCHMITT-KOPPLIN P, MOUSER P J, et al. Halogenated organic compounds identified in hydraulic fracturing wastewaters using ultrahigh resolution mass spectrometry [J]. Environmental Science & Technology, 2017, 51(10): 5377-5385. [38] ZHONG C, LI J Y, FLYNN S L, et al. Temporal changes in microbial community composition and geochemistry in flowback and produced water from the duvernay formation [J]. ACS Earth and Space Chemistry, 2019, 3(6): 1047-1057. doi: 10.1021/acsearthspacechem.9b00037 [39] OETJEN K, CHAN K E, GULMARK K, et al. Temporal characterization and statistical analysis of flowback and produced waters and their potential for reuse [J]. Science of the Total Environment, 2018, 619/620: 654-664. doi: 10.1016/j.scitotenv.2017.11.078 [40] THURMAN E M, FERRER I, BLOTEVOGEL J, et al. Analysis of hydraulic fracturing flowback and produced waters using accurate mass: Identification of ethoxylated surfactants [J]. Analytical Chemistry, 2014, 86(19): 9653-9661. doi: 10.1021/ac502163k [41] OREM W, TATU C L, VARONKA M, et al. Organic substances in produced and formation water from unconventional natural gas extraction in coal and shale [J]. International Journal of Coal Geology, 2014, 126: 20-31. doi: 10.1016/j.coal.2014.01.003 [42] THACKER J, CARLTON D J, HILDENBRAND Z, et al. Chemical analysis of wastewater from unconventional drilling operations [J]. Water, 2015, 7(12): 1568-1579. doi: 10.3390/w7041568 [43] FERRER I, THURMAN E M. Analysis of hydraulic fracturing additives by LC/Q-TOF-MS [J]. Analytical and Bioanalytical Chemistry, 2015, 407(21): 6417-6428. doi: 10.1007/s00216-015-8780-5 [44] WOLFORD R. Characterization of organics in marcellus shale flowback and produced waters [D]. Pennsylvania: Pennsylvania State University, 2011. [45] STRINGFELLOW W T, DOMEN J K, CAMARILLO M K, et al. Physical, chemical, and biological characteristics of compounds used in hydraulic fracturing [J]. Journal of Hazardous Materials, 2014, 275: 37-54. doi: 10.1016/j.jhazmat.2014.04.040 [46] CLUFF M A, HARTSOCK A, MACRAE J D, et al. Temporal changes in microbial ecology and geochemistry in produced water from hydraulically fractured Marcellus shale gas wells [J]. Environmental Science & Technology, 2014, 48(11): 6508-6517. [47] MOHAN A M, BIBBY K J, LIPUS D, et al. The functional potential of microbial communities in hydraulic fracturing source water and produced water from natural gas extraction characterized by metagenomic sequencing [J]. PLoS One, 2014, 9(10): e107682. doi: 10.1371/journal.pone.0107682 [48] MURALI MOHAN A, HARTSOCK A, BIBBY K J, et al. Microbial community changes in hydraulic fracturing fluids and produced water from shale gas extraction [J]. Environmental Science & Technology, 2013, 47(22): 13141-13150. [49] SUMNER A, PLATA D L. Halogenation chemistry of hydraulic fracturing additives under highly saline simulated subsurface conditions [J]. Environmental Science & Technology, 2018, 52(16): 9097-9107. [50] EVANS M, SUMNER A J, DALY R A, et al. Hydraulically fractured natural-gas well microbial communities contain genomic halogenation and dehalogenation potential [J]. Environmental Science & Technology Letters, 2019, 6(10): 585-591. [51] VENGOSH A, JACKSON R B, WARNER N, et al. A critical review of the risks to water resources from unconventional shale gas development and hydraulic fracturing in the United States [J]. Environmental Science & Technology, 2014, 48(15): 8334-8348. [52] KIM S, OMUR-OZBEK P, CARLSON K. Characterization of organic matter in water from oil and gas wells hydraulically fractured with recycled water [J]. Journal of Hazardous Materials, 2020, 397: 120551. doi: 10.1016/j.jhazmat.2019.04.034 [53] SHIH J S, SAIERS J E, ANISFELD S C, et al. Characterization and analysis of liquid waste from Marcellus shale gas development [J]. Environmental Science & Technology, 2015, 49(16): 9557-9565. [54] SUN Y, WU M H, TONG T Z, et al. Organic compounds in Weiyuan shale gas produced water: Identification, detection and rejection by ultrafiltration-reverse osmosis processes [J]. Chemical Engineering Journal, 2021,412: 128699. [55] SY/T 6596-2004, 气田水回注方法[S]. [56] Regnery J, Coday B D, Riley S M, et al. Solid-phase extraction followed by gas chromatography-mass spectrometry for the quantitative analysis of semi-volatile hydrocarbons in hydraulic fracturing wastewaters [J]. Analytical Methods, 2016, 8(9): 68. [57] BEAN J, BHANDARI S, BILOTTO A, et al. Formation of particulate matter from the oxidation of evaporated hydraulic fracturing wastewater [J]. Environmental Science & Technology, 2018, 52(8): 4960-4968. [58] SANTOS I, HILDENBRAND Z L, SCHUG K A. A review of analytical methods for characterizing the potential environmental impacts of unconventional oil and gas development [J]. Analytical Chemistry, 2019, 91(1): 689-703. doi: 10.1021/acs.analchem.8b04750 [59] AYANDA O S, OLUTONA G O, OLUMAYEDE E G, et al. Phenols, flame retardants and phthalates in water and wastewater – a global problem [J]. Water Science and Technology, 2016, 74(5): 1025-1038. doi: 10.2166/wst.2016.314 [60] ELSNER M, HOELZER K. Quantitative survey and structural classification of hydraulic fracturing chemicals reported in unconventional gas production [J]. Environmental Science & Technology, 2016, 50(7): 3290-3314. [61] KAHRILAS G A, BLOTEVOGEL J, STEWART P S, et al. Biocides in hydraulic fracturing fluids: A critical review of their usage, mobility, degradation, and toxicity [J]. Environmental Science & Technology, 2015, 49(1): 16-32. [62] U. S. Environmental Protection Agency. Toxic and priority pollutants under the clean water act[EB/OL]. [2021-5-28].https://www.epa.gov/eg/toxic-and-priority-pollutants-under-clean-water-act . [63] BLEWETT T A, DELOMPRÉ P L M, HE Y H, et al. Sublethal and reproductive effects of acute and chronic exposure to flowback and produced water from hydraulic fracturing on the water flea Daphnia magna [J]. Environmental Science & Technology, 2017, 51(5): 3032-3039. [64] HULL N M, ROSENBLUM J S, ROBERTSON C E, et al. Succession of toxicity and microbiota in hydraulic fracturing flowback and produced water in the Denver-Julesburg Basin [J]. Science of the Total Environment, 2018, 644: 183-192. doi: 10.1016/j.scitotenv.2018.06.067 [65] 黄靓, 李慧强, 杨平. 页岩气压裂返排液的组成及处理技术 [J]. 环境科学与技术, 2016, 39(S2): 166-171. HUANG L, LI H Q, YANG P. The Components and Treatment of Shale Gas Fracturing Flowback Water [J]. Environmental Science & Technology, 2016, 39(S2): 166-171(in Chinese).

[66] TANG P, LI J L, LI T, et al. Efficient integrated module of gravity driven membrane filtration, solar aeration and GAC adsorption for pretreatment of shale gas wastewater. [J]. Journal of hazardous materials, 2021: 405. [67] CHANG H Q, LIU S, TONG T Z, et al. On-Site Treatment of Shale Gas Flowback and Produced Water in Sichuan Basin by Fertilizer Drawn Forward Osmosis for Irrigation [J]. Environmental science & technology, 2020, 54(17). [68] 向夕品. 三氯乙烯和四氯乙烯处理方法研究进展 [J]. 渝州大学学报(自然科学版), 2002, 19(4): 77-82. XIANG X P. Research progress in treatment methods of trichloroethylene and perchloroethylene [J]. Journal of Yuzhou University (Natural Sciences Edition), 2002, 19(4): 77-82(in Chinese).

[69] CRAMPON M, HELLAL J, MOUVET C, et al. Degradation of tetrachloroethylene by zero valent iron nanoparticles in the presence of a natural groundwater bacterial biofilm in a sandy porous media [J]. Heliyon, 2021, 7(1): e05854. doi: 10.1016/j.heliyon.2020.e05854 [70] REN Q D, XIE X N, TANG Y, et al. Methyl tertiary-butyl ether inhibits THP-1 macrophage cholesterol efflux in vitro and accelerates atherosclerosis in ApoE-deficient mice in vivo [J]. Journal of Environmental Sciences, 2021, 101: 236-247. doi: 10.1016/j.jes.2020.08.011 [71] SQUILLACE P J, PANKOW J F, KORTE N E, et al. Review of the environmental behavior and fate of methyl tert-butyl ether [J]. Environmental Toxicology and Chemistry, 1997, 16(9): 1836-1844. doi: 10.1002/etc.5620160911 -

下载:

下载: