-

土壤重金属污染是当前人们普遍关注的环境问题之一. 有色金属冶炼活动中原料准备、熔炼和尾气吸收等环节会排放出大量含重金属的废气、废水和废渣,重金属通过迁移、滞留和沉降作用进入地块土壤并进一步污染地下水,对人体健康、周边环境生态安全带来危害和威胁[1 − 3]. 土壤作为迁移通道,对重金属的迁移转化起重要作用. 因此,有必要明确重金属的垂向迁移分布特征及其形成机制和影响因素,以促进有色金属冶炼地块土壤重金属污染的有效防治[4].

目前,一些学者开展了冶炼地块土壤重金属污染垂向分布规律研究. 如秦岭某关闭锌冶炼企业地块土壤剖面0—3 m处As、Cd、Pb和Zn等重金属呈表层聚集和纵向迁移态势[5]. 株洲某废弃大型铅锌冶炼厂不同功能区0—1 m剖面表层(0—20 cm)土壤重金属含量普遍高于深层(80—100 cm),但长期冶炼活动和淋溶会导致部分点位深层土壤重金属含量高于表层[6]. 对某铅锌冶炼地块采集3个土壤剖面(0—6 m)研究发现,土壤重金属含量随剖面深度增加下降,但部分样点4 m深处土壤As和Cd含量仍超过建设用地第一类用地筛选标准值(GB36600-2018)[7]. 株洲某废弃有色冶炼地块不同功能区剖面(0—8 m)土壤重金属垂向分布特征表明,As、Cd、Pb等重金属主要累积于地面以下3 m内土壤[8]. 重金属化学形态直接影响着其迁移能力、生物有效性和对生态环境的危害程度[9],通常冶炼活动导致土壤累积的重金属活性较高. 如白银市某冶炼污染场地表层土壤中Cd含量以弱酸提取态为主,Pb的弱酸可提取态和可还原态比例较高[10]. 株洲某铅锌冶炼地块土壤可还原态Cd含量占比随深度增加而增加[7]. 这表明冶炼活动导致的土壤重金属污染风险较高,更应引起关注. 重金属在土壤中垂向迁移化学行为影响因素复杂,其中,土壤pH值、有机质和铁铝氧化物及矿物组成等均会影响重金属的迁移、有效性和化学形态[3, 11 − 12]. 贵州某铅锌冶炼区土壤Pb、Zn含量主要以铁锰氧化物结合态为主,铁矿物对其有较强固定作用[13]. 以往研究大多集中于冶炼地块土壤浅层剖面(0—3 m)重金属总量和赋存形态的垂直分布,较少关注深层剖面(0—8 m)重金属总量和赋存形态的分布,且影响其不同形态分布的因素尚不明确. 因此,对冶炼地块土壤重金属总量和形态的垂向迁移规律和成因有待进一步研究.

地块剖面土壤层通常由填土层、素填土层、粘土层和全风化基岩层组成,填土是工程建设中常见的特殊性土,地块各层土壤性质存在明显差异. 表层杂填土主要由建筑垃圾和生活垃圾等组成,物质成分复杂. 下层素填土一般经人工扰动,由碎石土、砂土、粉土和黏土等堆填而成,不含或含少量杂质[14]. 冶炼地块土壤大多数经过回填形成不同填土层,地质条件复杂,且由于填土孔隙率较高,更易于重金属的垂向下渗迁移[15]. 因此,探明重金属在不同土壤层中的迁移行为,对于准确评估地块土壤-地下水系统中重金属的生态风险和治理修复至关重要. 但目前对冶炼地块不同土壤层重金属的积累特征研究较少. 本研究拟以某锌冶炼厂沸腾炉生产功能区及周边土壤剖面为研究对象,分析重金属含量和赋存形态垂向分布特征,评价其垂向迁移风险,探讨土壤理化性质对重金属在地块土壤中迁移的影响机制,以期为冶炼地块重金属污染土壤有效防控与治理修复提供科学依据.

-

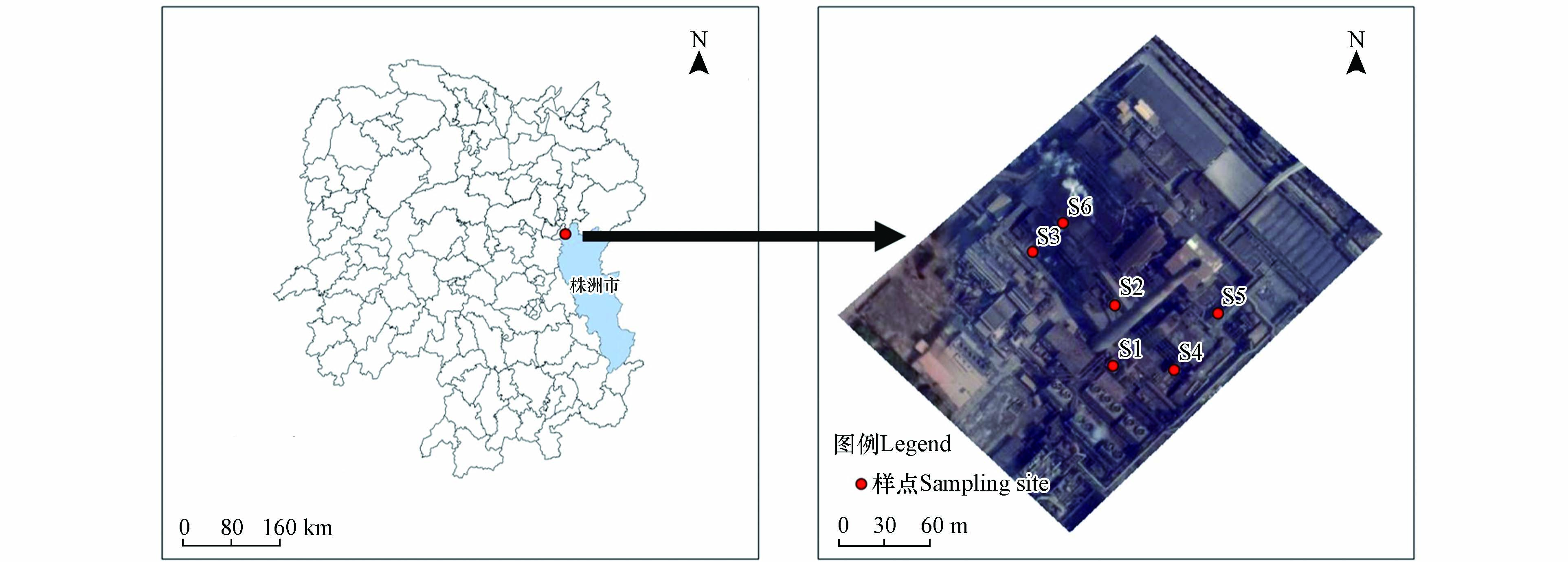

选取湖南省株洲市某废弃锌冶炼厂地块(113° 4′ 45.93″ E,27° 52′ 26.09″ N)作为研究区域,该厂年生产锌产品约50万吨,有近60年生产历史. 株洲市属亚热带季风湿润气候,年平均气温在16—18°C之间,年平均降雨量在1400—1500 mm. 本研究选择锌主要焙烧区域,按照40 m×40 m布设6个钻孔,分别为点位S1(冷却塔)、S2(多膛炉脱硫烟囱旁),S3和S6(沸腾炉区)、S4和S5(干燥窑)(图1),采用冲击式钻头取样直至到基岩为止. 根据现场记录的岩芯信息,土壤剖面自上往下大致可划分为3层,其中,杂填土层深度大约为0—3 m,素填土层约3—6 m,黏土层深度约为6—8 m. 土壤样品采集按照0—3 m每0.5 m取1个样品,3—6 m每1 m取1个土样,6—8 m每2 m取一个土样,共53个样品. 所有样品储存在密封聚乙烯袋中带回实验室. 土壤样品除杂后自然风干,分别过10目和100目筛后待测.

-

土壤理化性质分析参考鲁如坤[16]的方法:pH值采用电位法测定(土水体积比为1:2.5),有机质(SOM)采用低温外热重铬酸钾氧化-比色法测定,土壤游离Fe2O3(Fed)和Al2O3(Ald)采用连二亚硫酸钠-柠檬酸钠-重碳酸钠提取,非晶质Fe2O3(Feo)和Al2O3(Alo)采用酸性草酸铵溶液提取,比色法测定. 土壤重金属含量分析采用HNO3-HF-HClO4消解[17]. 采用改进的BCR三步连续提取法分析重金属形态,即酸可提取态(F1,相当于重金属可交换态和碳酸盐态含量之和)、可还原态(F2,相当于Fe-Mn氧化物结合态)、可氧化态(F3,有机物及硫化物结合态含量之和)和残渣态(F4)[18],土壤残渣态重金属含量参考土壤重金属总量消解方法测定. 消解液和提取液中重金属含量采用电感耦合等离子体原子发射光谱法(ICP-AES,ICAP7400Radial,赛默飞世尔科技公司,美国)测定. 土壤标准物质(GBW-08303)测定值在质控样保证值范围内,重金属回收率为90.0%—105%.

釆用X射线衍射仪(XRD,Empyrean 2,PANalytical,荷兰)分析土壤剖面样点S3(0—0.5 m、4—5 m和6—8 m)样品和样点S6(1—1.5 m)土壤物相组成,采用扫描电子显微镜(SEM,ZEISS Sigma 300,德国)和能谱仪(EDS)分析土壤形貌和元素组成.

-

采用风险评价编码法(RAC)评价土壤重金属迁移性能,即利用BCR中的弱酸提取态含量与总量的比值(

$\mathrm{RAC}=\mathrm{F1}/\mathrm{(F1+F2+F3+F4)}\times 100\mathrm{\%}$ )进行风险评价. RAC将风险水平划分为5个等级:比例<1%时,无风险;1%—10%,低风险;11%—30%,中等风险;31%—50%,高风险;比例>50%,极高风险.利用Arcgis 10.2绘制样点分布图,试验数据和图表采用Microsoft Excel 2016和Origin 2021软件分析,相关性、显著性检验和正态检验采用SPSS 26.0软件分析. 样本数据服从对数分布类型.

-

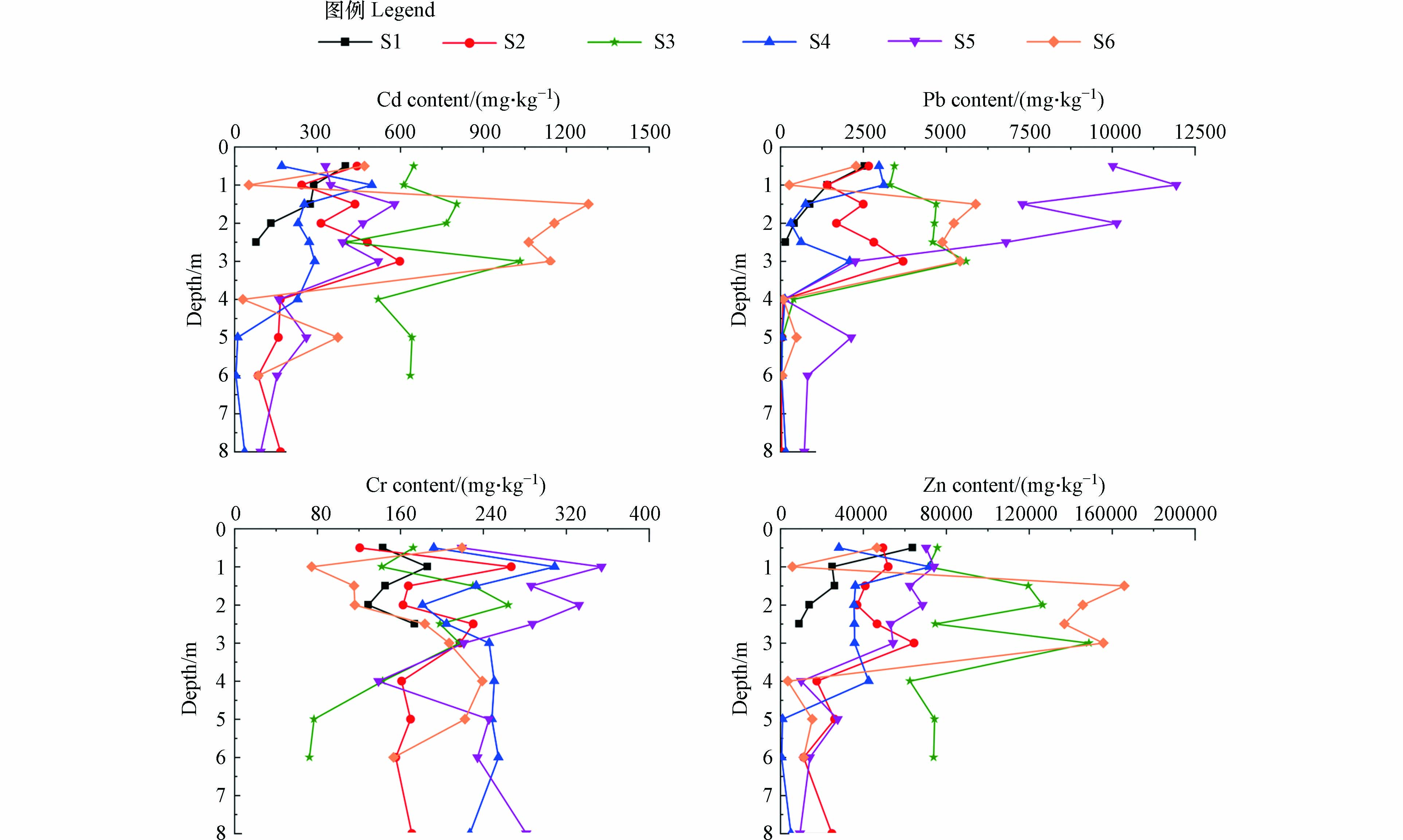

总体来看,土壤剖面Cd、Cr、Pb和Zn含量波动大,特别是地面以下0—3 m处变幅很大,3—6 m变幅相对较小,6—8 m变幅更小,4种重金属变化趋势基本一致(图2). 这与株洲某废弃铅锌冶炼地块上层(0—3 m)土壤重金属含量的变幅大于深层(3—7 m)土壤的结果相似[19]. 0—3 m处土壤Cd含量范围高达51.3—1280 mg·kg−1,表现为随剖面深度增加呈波浪式变化,其中以点位S6的变幅最大,即0—0.5 m处Cd含量较高,0.5—1 m处显著减少后急剧增加又下降再增加. 土壤Pb含量高值也主要出现在地面以下0—3 m处,范围为150—11933 mg·kg−1,其中点位S6土壤Pb含量在0.5—1 m处显著减少,1—1.5 m又急剧增加;点位S5土壤Pb含量波动幅度最大,在1 m处出现高值. 0—3 m处土壤Cr含量范围(72.2—354 mg·kg−1)相对较小,主要富集在0—1 m处. 0—3 m处土壤Zn含量变幅(5687—165863 mg·kg−1)也很大,其中以点位S3和S6土壤Zn含量波动明显. 相关研究发现,某铅锌冶炼厂生产区土壤剖面(0—1 m)重金属含量沿深度没有规律性变化[6],某工业区剖面0.8—1 m深处土壤Cu、Zn和Pb含量反高于0.4—0.6 m处相应土壤重金属含量 [11]. 这可能是由于0—3 m主要为杂填土层,组分复杂不均匀,且孔隙率较大,受强烈的人为干扰导致无明显规律[20].

随着剖面深度(3—6 m)增加,土壤重金属含量急剧下降,Cd、Pb含量在3 m处出现高值(图2),这与郭佳雯等的研究结果一致[21]. 值得关注的是,位于锌冶炼系统沸腾炉区域的S6号土壤Zn含量在3—4 m处急剧下降后又在5 m处增加. 有研究表明,某废弃金属冶炼地块大部分功能区土壤Cd、Pb和As也主要富集在地面以下3 m处,但一些区域如燃油储存区和铅冶炼区的整个土壤剖面(0—8 m)均存在Cd、Pb和As污染[8],这可能是核心区域长期冶炼散落的原料和烟尘被雨水淋溶所致.

统计分析表明,与长株潭土壤重金属背景值[22]比较,地面以下0—3 m、3—6 m和6—8 m处土壤Cd含量几何均值分别超过752、252、265倍;Pb含量分别为39.5、2.62、1.82倍,Zn含量分别超过374、104、126倍;Cr含量较低,仅分别超过2.03、1.95、1.77倍(表1). 与《土壤环境质量建设用地土壤污染风险管控标准》第二类用地管制值[23]比较,0—3 m、3—6 m和6—8 m处Cd含量超标率分别高达88.6%、40.0%和33.3%;Pb污染主要集中在地面以下3 m处,超标率高达60.0%,3—6 m处超标率仅为6.70%,6—8 m处未超标. 不同深度剖面处土壤Cd、Cr含量差异不显著(P>0.05),但0—3 m处Pb含量显著高于中深层,Zn含量呈现出0—3 m>3—6 m>6—8 m的显著差异(P<0.05).

变异系数(CV)可用于表征土壤重金属含量在空间上的变异和分散程度[24]. 除Cr外,土壤Cd、Pb和Zn含量的变异系数范围为62.7%—211%,属于高变异(CV>36%)[25],且呈现出剖面深度3—6 m>6—8 m>0—3 m趋势,这与中南某冶炼区污染地块土壤重金属含量变异系数的结果一致[4]. 这表明研究区剖面0—8 m土壤重金属含量差异很大,已明显受冶炼活动影响[26-27]. 研究显示,Zn矿伴生大量Cd、Pb元素,其在冶炼过程中随废气、废水和废渣等形式进入土壤后积累[26]. 此外,地面以下6 m深处土壤仍受到Cd、Zn严重污染,这可能是由于本场地污染年限较长,长期淋滤导致重金属不断向下输送.

-

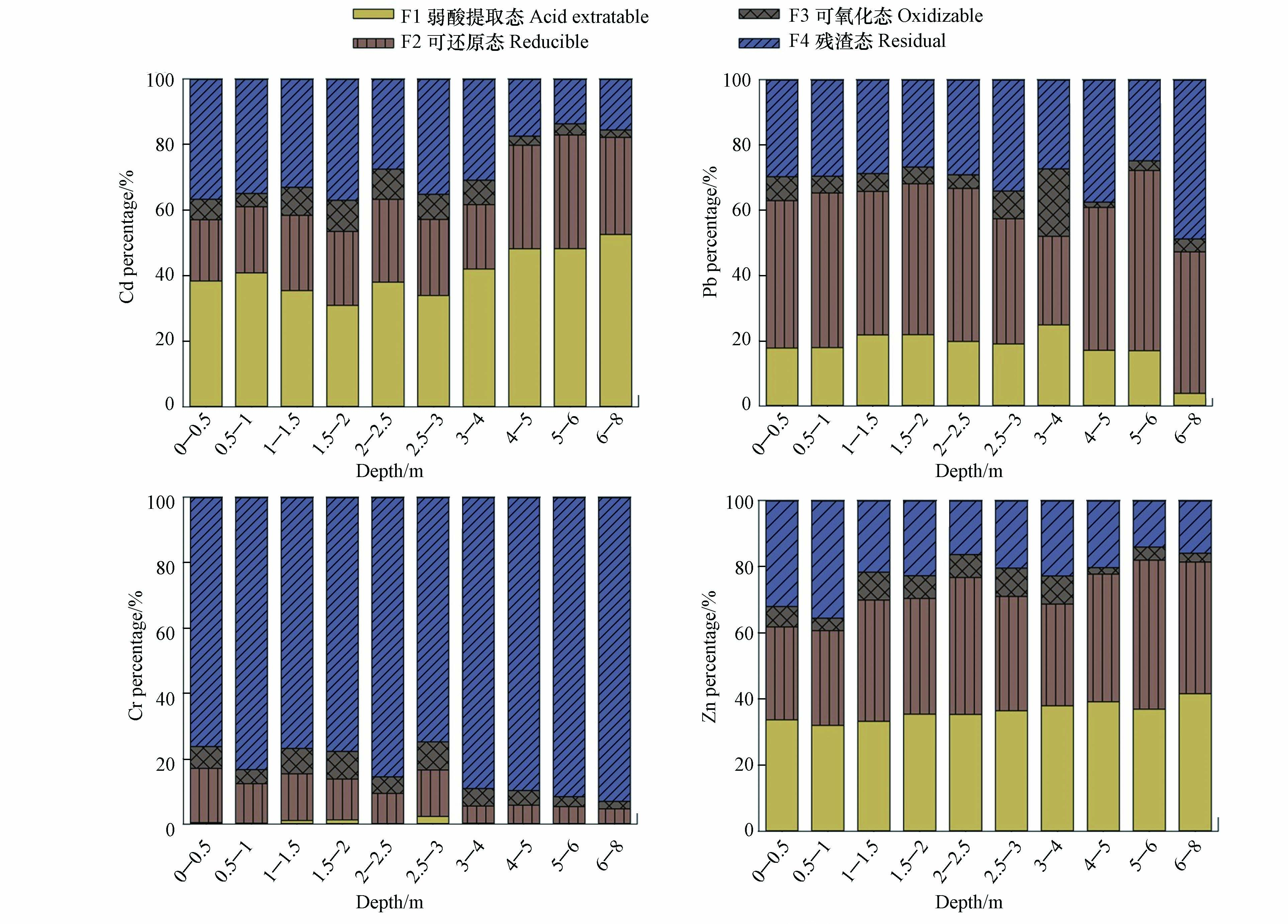

土壤剖面Cd和Zn含量主要以弱酸提取态(F1)为主,占比范围分别为35.8%—52.6%和34.4%—41.6%,其次为可还原态(F2),其占比范围分别为22.3%—29.6%和34.4%—41.6%,Cd含量的可氧化态(F3)比例相对较低. 随着剖面深度增加,土壤Cd-F1、Cd-F2和Zn-F1、Zn-F2的比例增加(图3),这与前人研究发现铅锌冶炼地块土壤剖面Cd和Zn赋存形态分布特征研究结果一致[8, 28 − 29],这表明Cd和Zn活性高,易于向土壤深处迁移,对生态环境危害较大. 土壤Cr含量以残渣态(F4)为主,占比高达79.2%—93.0%,且随剖面深度增加而增加,这说明Cr迁移性低,对周边生态环境威胁较小[30]. Pb含量以F2(占比35.0%—44.8%)形态为主,3—8 m处其占比均值随深度增加而增加,这与Pb自身性质有关,其极易固存在铁锰氧化物上[30];3—8 m处Pb-F1比例略有下降,表明Pb随着深度增加,迁移性下降.

生态风险码(RAC)为重金属的酸提取态含量与总量之比,其值越大,生态风险和迁移能力越高[31]. 从图3可知,0—3 m、3—6 m和6—8 m处Cd的平均RAC分别为37.7%、46.8%和46.0%,均为高风险(31%—51%),这说明研究区深层土壤Cd风险高于浅层. 0—3 m、3—6 m和6—8 m处土壤Zn的RAC分别为32.2%、32.4%和30.3%,均为高风险[32]. 0—3 m和3—6 m处土壤Pb的平均RAC分别为16.2%和11.8%,均为中等风险水平,6—8 m处RAC(6.40%)明显降低. 这与铜冶炼地块土壤Cd和Zn的平均RAC值分别为23.5%和14.5%,风险较大结果一致[32]. 因此,剖面土壤Cd和Zn风险高,有可能导致地下水污染,需引起重视.

-

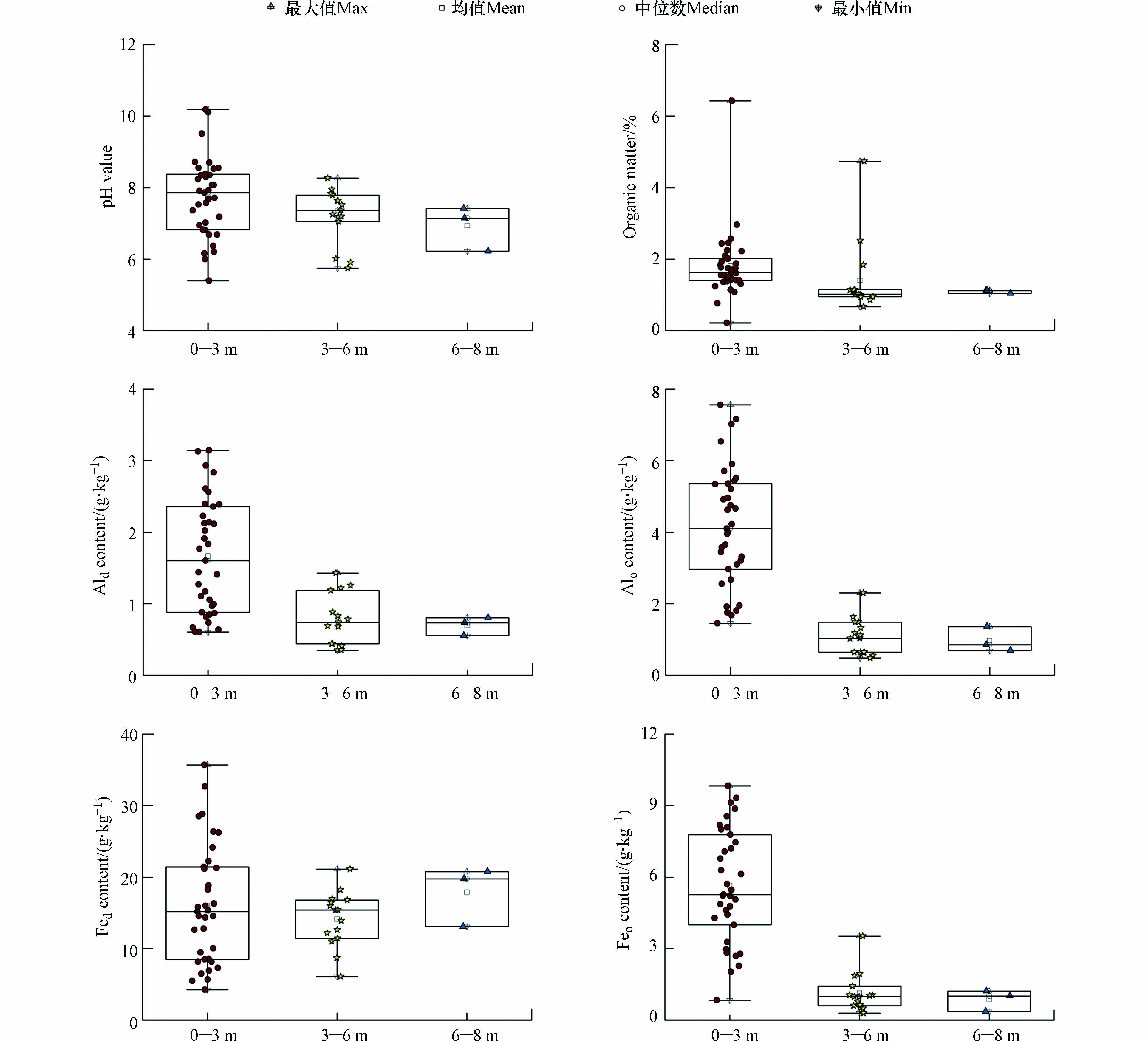

土壤pH范围变幅大(5.40—10.19),呈弱酸至强碱性(图4). pH值变幅随土壤剖面深度增加而减小,均值呈现出地面以下0—3 m>3—6 m>6—8 m的趋势,且高于某铅锌冶炼厂0—1 m剖面土壤pH值(2.04—7.69)[6],说明土壤受到了人为扰动. 土壤有机质(SOM)含量(0.21%—6.42%)波动大,变幅和均值随剖面深度增加均减小,这可能是杂填土层(0—3 m)物质组成复杂,素填土层(3—6 m)有机质含量较低有关. 土壤游离Al2O3(Ald)和非晶质Al2O3(Alo)含量范围分别为0.35—3.15 g·kg−1、0.48—7.56 g·kg−1,均随土壤深度增加其范围变小,且在6—8 m处明显降低. 土壤游离Fe2O3(Fed)含量(4.23—35.67 g·kg−1)和非晶质Fe2O3(Feo)含量(0.29—9.28 g·kg−1)变幅较大,且随深度增加而减少. 土壤0—3 m处土壤Fed、Ald、Feo和Alo含量整体上均高于6—8 m处含量.

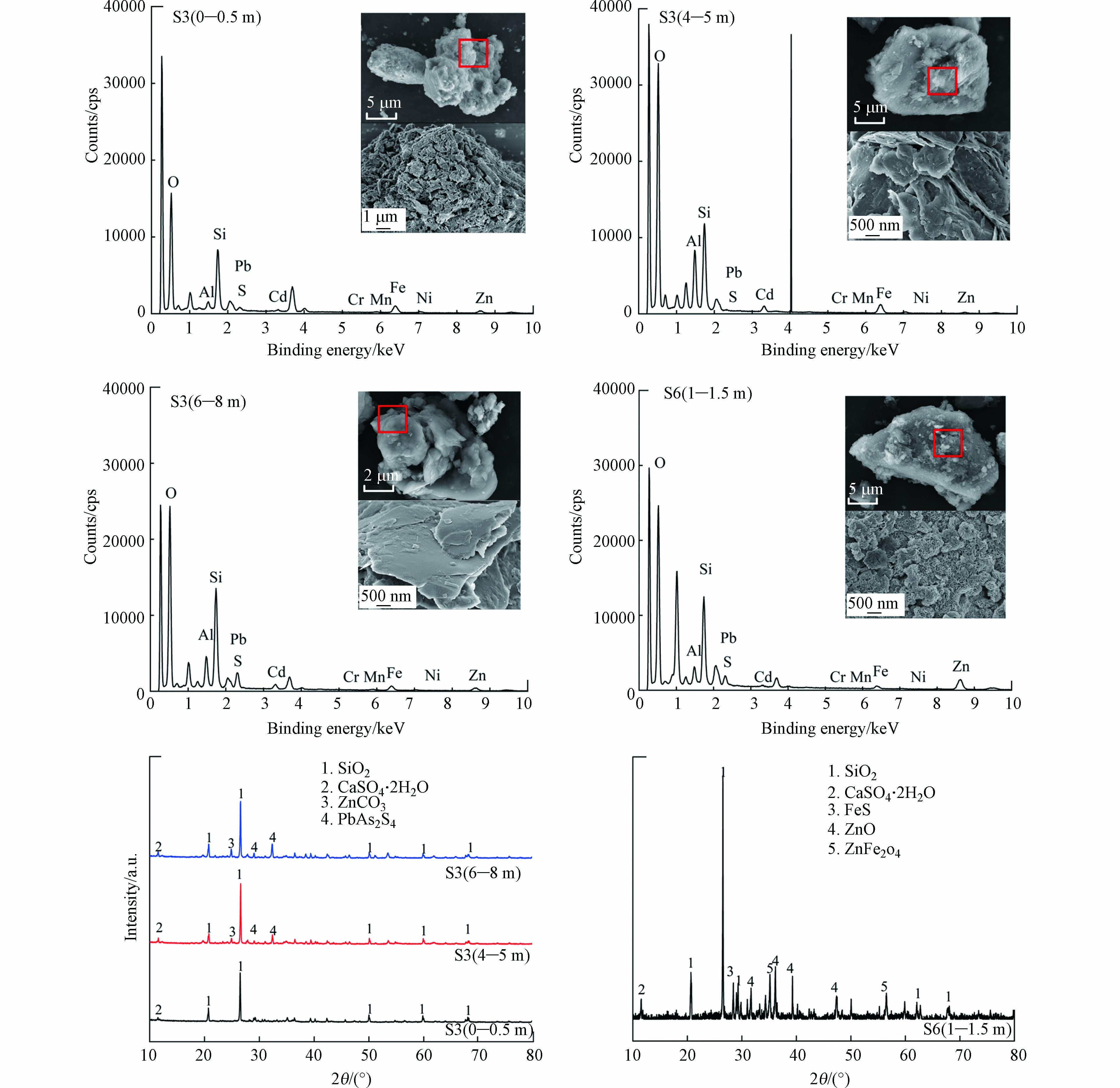

扫描电镜(SEM)结果表明,点位S3剖面土壤形貌有明显差异,0—0.5 m处土壤显示为次棱角状和棱角状,4—5 m和6—8 m处样品呈层状和片状;点位S6地面以下1—1.5 m处土壤颗粒块大,形状不规则(图5). EDS能谱结果显示,各土层样品元素组成相似,Si和Al含量较高,说明土壤含有较多硅铝酸盐,重金属离子可通过吸附和沉淀方式被固持在硅铝酸盐矿物上[33].

点位S3中4—5 m和6—8 m处土壤Cd含量较0—0.5 m处的高,这是因为前两者Si和Al的峰强较后者的高,而Cd主要赋存在硅铝酸盐上[34]. XRD结果表明,各样品中都含有CaSO4·2H2O物相,这可能是由于冶炼烟尘中含有少量石膏[35]. S3号4—5 m和6—8 m剖面土壤矿物相存在差异,出现ZnCO3和PbAsS4物相,这与之前对冶炼厂表层土壤研究发现富Zn土壤存在菱锌矿(ZnCO3)结果一致[36]. 点位S6的1—1.5 m处土壤样品检测出Pb、Zn峰强很高,存在氧化锌(ZnO)和锌铁矿(ZnFe2O4)物相,这是由于该点位属于沸腾炉炼锌区,原料锌精矿(ZnS)焙烧会生成ZnO[37],此外该区也是冶炼粉尘污染物的主要沉降区,这可以解释该样点土壤Zn含量异常高现象.

-

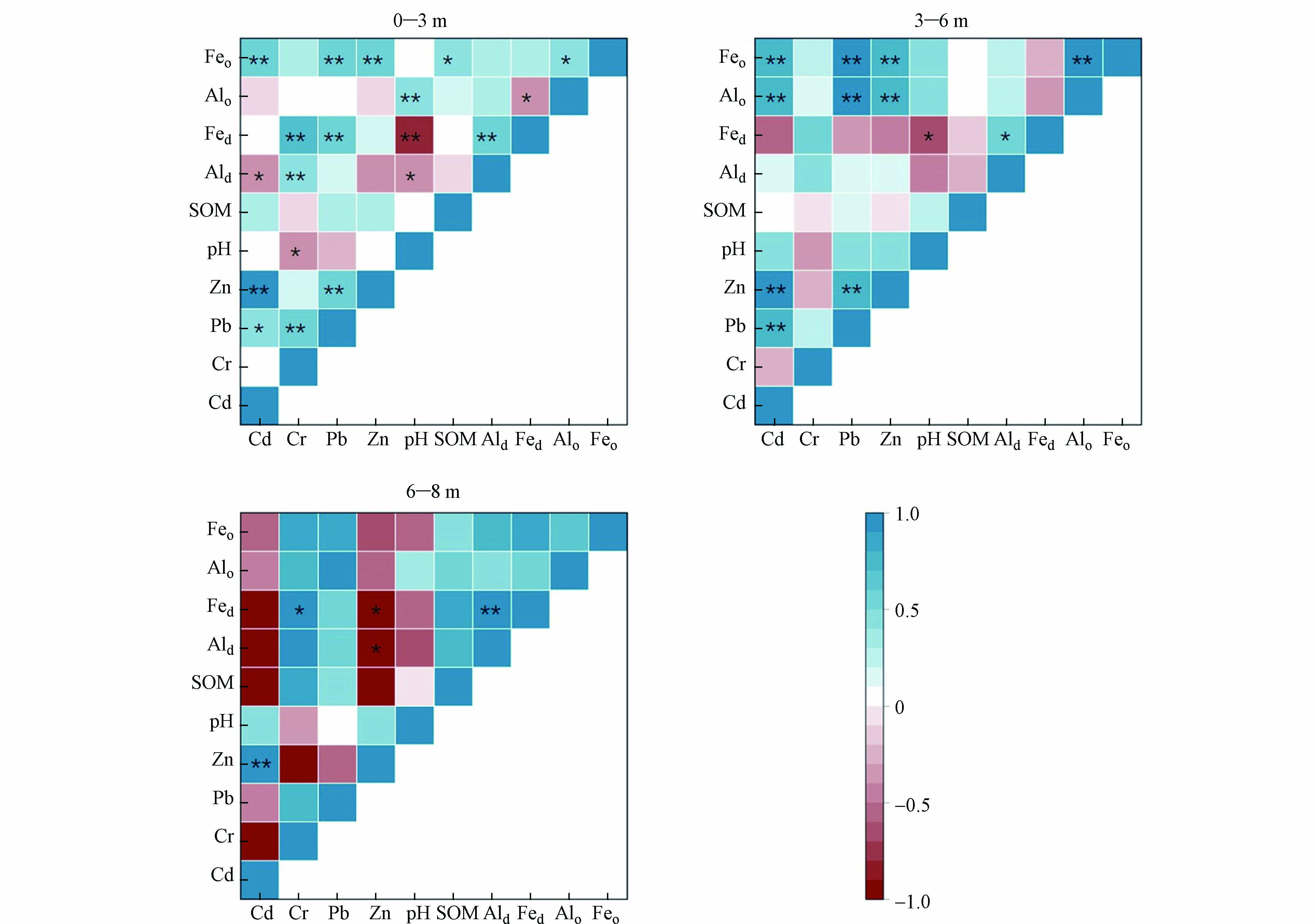

相关性分析结果表明,不同剖面深度土壤Cd含量与Zn含量均呈显著正相关(P<0.01),0—3 m和3—6 m处Zn与Pb含量呈显著正相关(P<0.01)(图6),表明Cd、Pb与Zn存在相似来源[6, 38]. 土壤Cr与Pb含量仅在0—3 m处呈显著正相关(P<0.01). 总体来看,土壤重金属含量与理化性质的相关性随着剖面深度增加有所减弱. 0—3 m处,土壤Cd含量与Ald、Feo含量有显著正相关;Cr含量与Fed、Ald含量均呈显著正相关(P<0.01),与pH值存在显著负相关(P<0.05);Pb含量与Fed、Feo含量均呈显著正相关(P<0.01),这与某铅锌冶炼厂附近污染土壤富含铁矿物颗粒中Pb含量高结果一致[39],这是因为Fed是土壤电荷主要载体,对Pb2+存在专性吸附[40];土壤Zn含量与Feo含量存在显著正相关(P<0.01). 3—6 m处,土壤Cd、Pb、Zn含量与Feo、Alo含量均呈显著正相关(P<0.01). 6—8 m处,仅Cr含量与Fed含量有显著正相关(P<0.05),Zn含量与Fed、Ald含量呈显著负相关(P<0.05). 总体来看,除Cr外,剖面土壤重金属含量与pH值、SOM含量均无显著相关性,表明该地块土壤重金属垂向分布受pH值和SOM含量影响不大. 0—6 m处,Cd、Pb和Zn含量与Feo含量间的相关性显著,说明研究区域Cd、Pb和Zn迁移主要受土壤Feo含量影响. 此外,多种重金属共存时,会发生竞争吸附作用,土壤中多种重金属会争夺相同吸附位点,降低土壤对单一重金属的吸附量[41]. Pb和Cd竞争吸附体系中,随着Pb浓度增加,Cd的吸附量呈均匀下降趋势[42]. 因此,重金属在土壤中的纵向迁移是一个复杂过程,其不仅受土壤理化性质的影响,还与元素自身性质有关.

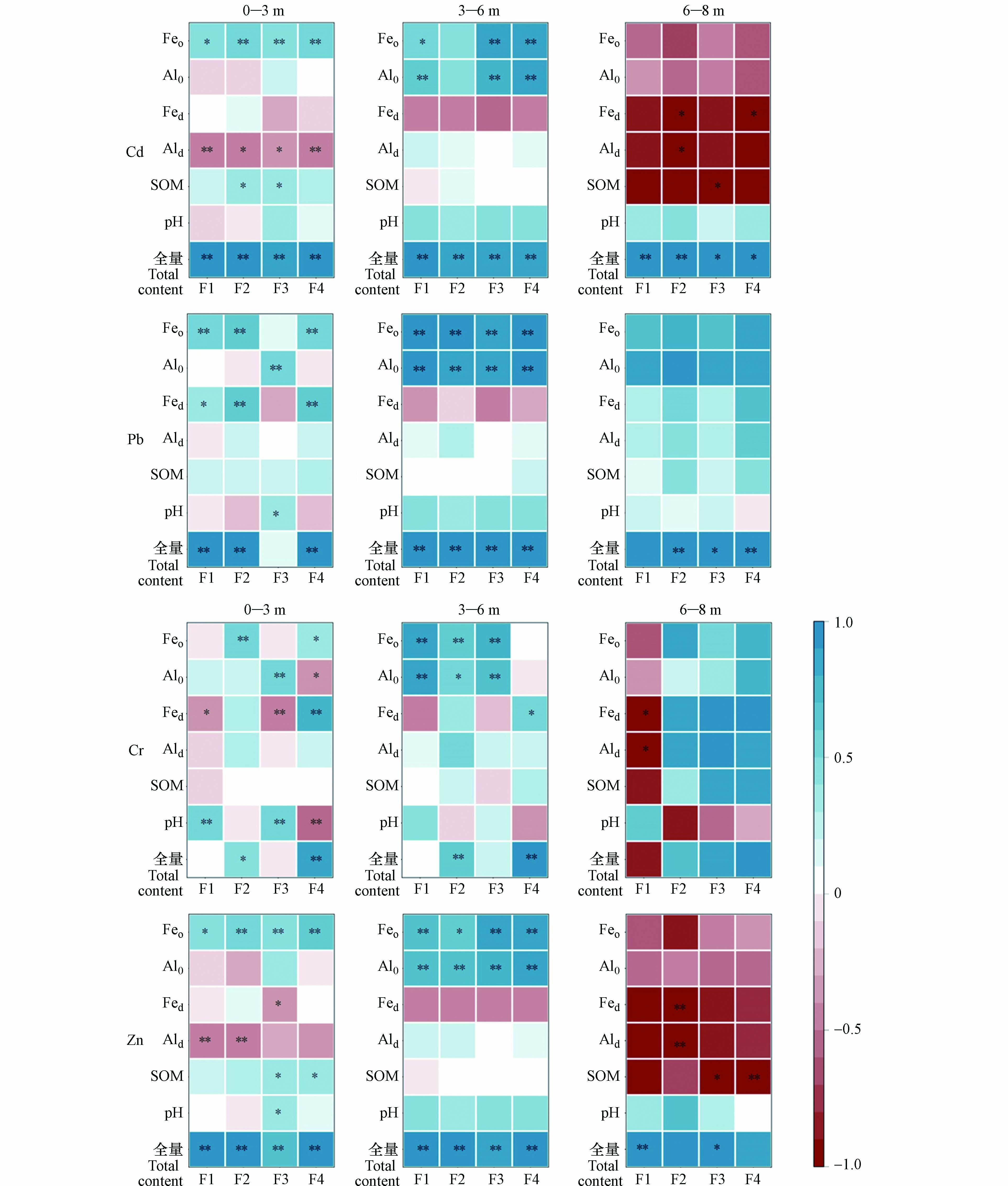

剖面土壤重金属各赋存形态含量与其全量相关性显著(图7). 地面以下0—3 m处,土壤Cd各形态含量均与Ald含量呈显著负相关,Cd、Zn各形态含量与Feo含量呈显著正相关;土壤Cr-F1和Cr-F3含量与pH呈显著正相关,但Cr-F4含量与pH呈显著负相关(P<0.01);土壤Pb的F1、F2和F4含量与Fed、Feo含量均呈显著正相关,这是由于铁氧化物对重金属有吸附作用[43]. 3—6 m处,Cd的F1、F3、F4形态含量均与Feo、Alo含量呈显著正相关;Cr的活性态(F1、F2和F3)含量均与Feo、Alo含量呈显著正相关,说明非晶质Fe、Al氧化物与活性态Cr分布相关;Pb、Zn的4种形态含量均与Feo、Alo含量呈显著正相关,研究也发现,铅锌矿中含大量铅和锌与次生风化产物铁氢氧化物、锰氧化物和铁氧羟基硫酸盐[44]. 6—8 m处,除pH外,Cd、Zn各形态含量与其余理化性质如SOM、Fed、Ald含量均呈负相关,说明随着土壤深度增加,SOM会阻碍Cd、Zn的迁移,这可能是由于土壤SOM如腐殖酸、富里酸等含有大量有机配体[45],可与重金属离子发生络合反应降低重金属活性.

综上所述,研究区域土壤理化性质对重金属含量及其赋存形态的影响主要在剖面0—6 m处. 重金属含量与其各赋存形态呈显著相关,影响Cd、Cr、Pb和Zn迁移的主要因子为Feo、Alo含量,是由于非晶质氧化物的比表面积较大[46]. 因此,可通过调控土壤中Feo、Alo含量来降低重金属的迁移风险.

-

(1)锌冶炼主要功能区土壤剖面Cd、Pb和Zn污染严重,Cr污染相对较轻,土层分布差异明显,主要富集于0—3 m处杂填土层,其含量均随深度增加呈减少趋势,Cd和Zn迁移深度较深,6—8 m处黏土层已受到污染.

(2)剖面土壤Cd、Zn含量主要以酸提取态为主,活性较高,且比例随剖面深度增加呈增加趋势,均为高风险;Pb含量以还原态为主,风险随着剖面深度增加而降低;Cr含量以残渣态为主,风险较低. 重金属可能通过吸附和沉淀等方式被固持在硅铝酸盐矿物上. 影响Cd、Cr、Pb和Zn迁移的主要因子为全量、Feo和Alo含量. 因此,可通过调控土壤中Feo、Alo含量控制重金属的迁移风险.

锌冶炼地块土壤重金属垂向分布特征及影响因素

Vertical distribution of heavy metals in soils and its influencing factors from a zinc smelting site

-

摘要: 从湖南某废弃锌冶炼厂火法炼锌区域不同功能区采集6个土壤剖面(0—8 m),分析重金属镉(Cd)、铬(Cr)、铅(Pb)和锌(Zn)含量和赋存形态的垂向分布特征,探讨其与土壤理化性质相互关系. 结果表明,土壤重金属主要累积在0—3 m杂填土层,呈现随土壤深度增加含量下降趋势. 整个剖面Cd含量高,可迁移污染至深层土壤,Cr、Pb和Zn含量表现为0—3 m>3—6 m>6—8 m的显著差异(P<0.05). 欧共体参比司(BCR)制定的三步连续提取法结果表明,剖面土壤Cr含量以残渣态(79.2%—93.0%)为主,随着剖面深度增加,Pb的残渣态比例呈增加趋势,而Cd和Zn的酸可提取态比例增加, 迁移风险高. 电镜扫描能谱仪(SEM-EDS)和X射线衍射仪(XRD)分析结果表明,土层样品含有大量硅铝酸盐和SiO2;但沸腾炉区点位S6的1—1.5 m处土壤样品存在ZnO物相,点位S3号4—5 m和6—8 m深度处出现ZnCO3矿物相,表明核心功能区冶炼活动会加剧土壤Zn富集并向下迁移. 相关性分析表明,剖面土壤重金属全量与其各赋存形态含量呈显著正相关,非晶质Fe2O3含量与Cd、Pb和Zn活性态含量也呈显著正相关(P<0.05),表现出促进迁移的效应. 污染来源、土壤理化性质共同控制重金属的垂向分布及迁移,研究结果可为冶炼地块重金属污染土壤风险管控与修复提供科学依据.Abstract: Six soil profiles were collected from an abandoned zinc smelting site in Hunan Province to study the vertical distribution characteristics of contents and chemical fractions of Cd, Cr, Pb, and Zn, and the influence factors of soil physical and chemical properties were analyzed. The results showed that high content of heavy metals was predominately accumulated in 0—3 m soil layer, and decreased with the increase in soil depth. The Cd content in profiles was high and migrated into the deep soil. The geomean contents of Cr, Pb, and Zn in soil profiles were decreased significantly followed the order of 0—3 m>3—6 m>6—8 m (P<0.05). According to BCR (European Community Bureau of Reference) sequential extraction analysis, soil profile Cr content was predominated with residual fraction, accounting for 79.2%—93.0% of total content. The percentage of acid soluble fraction Cd and Zn, residual fraction Pb was increased with the soil depth increasing, indicating that high potential migration risks of Cd and Zn in soil profiles. The SEM-EDS (scanning electron microscope-energy dispersive spectroscopy) and XRD (X-ray diffraction) analysis results showed that there were much peaks of aluminosilicate minerals and SiO2 in soil. The mineral phase of ZnO were found in 1—1.5 m depth soil from point S6, and that of ZnCO3 appeared at 4—5 m and 6—8 m soil depth from point S3. This result indicated that critical smelting activities would cause the accumulation of Zn in soil. There was significant relationship between total content and chemical fractions of heavy metals in soil. Soil chemical properties of amorphous Fe2O3 promoted the migration of Cd, Pb and Zn in soil profile. The vertical distribution of heavy metals was controlled by pollution sources and soil physical and chemical properties. The results would provide scientific basis for effective prevention, control and remediation of heavy metal contaminated soil from smelting sites.

-

Key words:

- smelting sites /

- heavy metals /

- chemical speciation /

- vertical distribution /

- influencing factors

-

-

表 1 土壤剖面重金属含量统计结果

Table 1. Contents of heavy metals in soil profiles

元素

Elements剖面

深度/m

Depth含量/(mg·kg−1)

Contens背景值倍数

Background

value

multiple变异系数/%

Coefficient

of variation超标率%

Excess

rate范围

Range算数均值

(标准差)

Arithmetic

mean (SD)几何均值

(标准差) 2

Geometric

mean(SD)中值

Median背景值

Background标准

Standard1)Cd 0—3(n=35) 51.3—1280 483(303) 391(2.01) a2) 419 0.52 172 752 62.7 88.6 3—6 (n=15) 4.79—1033 261(272) 131(4.15) a 161 252 104 40.0 6—8(n=3) 36.3—636 233(237) 138(1.24) a 130 265 102 33.3 Cr 0—3(n=35) 74.2—354 204(63.8) 193(1.4) a 201 95 — 2.03 31.3 — 3—6(n=15) 76.6—254 194(52.7) 185(1.38) a 217 1.95 27.2 6—8(n=3) 72.2—281 188(77) 168(2.82) a 199 1.77 41.0 Pb 0—3(n=35) 150—11933 3619(2898) 2383(2.89) a 2890 60.3 2500 39.5 80.1 60.0 3—6(n=15) 26.1—5596 672(1418) 158(4.73) b 86.7 2.62 211 6.70 6—8(n=3) 31.5—720 238(283) 110(1.68 )b 99.4 1.82 119 0 Zn 0—3(n=35) 5687—165863 64045(40999) 50879(2.1) a 53714 136 — 374 64.0 — 3—6(n=15) 516—148786 31055(37801) 14098(4.4) b 15256 104 122 6—8(n=3) 4988—73843 28233(27334) 17094(3.48) c 17051 126 96.8 注:1), 《土壤环境质量建设用地土壤污染风险管控标准(试行)》(GB 36600-2018)中第二类用地管控值;2), 不同小写字母表示不同剖面深度之间土壤重金属含量有显著差异(P<0.05),有相同字母表示无显著差异. -

[1] 阳安迪, 肖细元, 郭朝晖, 等. 模拟酸雨下铅锌冶炼废渣重金属的静态释放特征[J]. 中国环境科学, 2021, 41(12): 5755-5763. doi: 10.19674/j.cnki.issn1000-6923.20210508.004 YANG A D, XIAO X Y, GUO Z H, et al. Static release characteristics of heavy metals from lead-zinc smelting slag leached by simulated acid rain[J]. China Environmental Science, 2021, 41(12): 5755-5763 (in Chinese). doi: 10.19674/j.cnki.issn1000-6923.20210508.004

[2] 李强, 何连生, 王耀锋, 等. 中国冶炼行业场地土壤污染特征及分布情况[J]. 生态环境学报, 2021, 30(3): 586-595. LI Q, HE L S, WANG Y F, et al. The characteristics and distribution of soil pollution in smelting industry sites in China [J]. Ecology and Environmental Sciences, 2021, 30( 3): 586- 595 (in Chinese).

[3] XU D, FU R, LIU H, et al. Current knowledge from heavy metal pollution in Chinese smelter contaminated soils, health risk implications and associated remediation progress in recent decades: A critical review[J]. Journal of Cleaner Production, 2021, 286: 124989. doi: 10.1016/j.jclepro.2020.124989 [4] KE W, ZENG J, ZHU F, et al. Geochemical partitioning and spatial distribution of heavy metals in soils contaminated by lead smelting[J]. Environmental Pollution, 2022, 307: 119486. doi: 10.1016/j.envpol.2022.119486 [5] 他维媛, 康桢, 孟昭君, 等. 秦岭典型停产关闭锌冶炼企业场地土壤重金属污染特征研究[J]. 生态环境学报, 2021, 30(07): 1513-1521. TA W Y, KANG Z, MENG Z J, et al. Research of pollution characteristics of heavy metals in soil of typical closed zinc smelting enterprises in Qinling Mountains [J]. Ecology and Environmental Sciences, 2021, 30(7): 1513-1521 (in Chinese).

[6] LI S, ZHAO B, JIN M, et al. A comprehensive survey on the horizontal and vertical distribution of heavy metals and microorganisms in soils of a Pb/Zn smelter[J]. Journal of Hazardous Materials, 2020, 400: 123255. doi: 10.1016/j.jhazmat.2020.123255 [7] XU L, DAI H, SKUZA L, et al. Comprehensive exploration of heavy metal contamination and risk assessment at two common smelter sites[J]. Chemosphere, 2021, 285: 131350. doi: 10.1016/j.chemosphere.2021.131350 [8] YANG J, GUO Z, JIANG L, et al. Cadmium, lead and arsenic contamination in an abandoned nonferrous metal smelting site in southern China: Chemical speciation and mobility[J]. Ecotoxicology and Environmental Safety, 2022, 239: 113617. doi: 10.1016/j.ecoenv.2022.113617 [9] RODRÍGUEZ L, RUIZ E, ALONSO-AZCÁRATE J, et al. Heavy metal distribution and chemical speciation in tailings and soils around a Pb–Zn mine in Spain[J]. Journal of Environmental Management, 2009, 90(2): 1106-1116. doi: 10.1016/j.jenvman.2008.04.007 [10] 陈任连, 蔡茜茜, 周丽华, 等. 甘肃某冶炼厂区土壤重金属铅、镉污染特征及其对微生物群落结构的影响[J]. 生态环境学报, 2021, 30(3): 596-603. CHEN R L, CAI X X, ZHOU L H, et al. Characteristics of soil contamination with heavy metals (Pb and Cd) in a smelting plant of Gansu and their effects on microbial community structure [J]. Ecology and Environmental Sciences, 2021, 30(3): 596-603 (in Chinese).

[11] LI F, FAN Z, XIAO P, et al. Contamination, chemical speciation and vertical distribution of heavy metals in soils of an old and large industrial zone in Northeast China[J]. Environmental Geology, 2009, 57(8): 1815-1823. doi: 10.1007/s00254-008-1469-8 [12] ZHONG X, CHEN Z, LI Y, et al. Factors influencing heavy metal availability and risk assessment of soils at typical metal mines in Eastern China[J]. Journal of Hazardous Materials, 2020, 400: 123289. doi: 10.1016/j.jhazmat.2020.123289 [13] 杨元根, 刘丛强, 张国平, 等. 铅锌矿山开发导致的重金属在环境介质中的积累[J]. 矿物岩石地球化学通报, 2003(4): 305-309. YANG Y G, LIU C Q, ZHANG G P, et al. Heavy metal accumulations in environmental media induced by lead and zinc mine development[J]. Bulletin of Mineralogy Petrology and Geochemistry, 2003(4): 305-309 (in Chinese).

[14] 刘凌青, 肖细元, 郭朝晖, 等. 锌冶炼地块剖面土壤对镉、铅的吸附特征及机制[J]. 环境科学, 2021, 42(8): 4015-4023. Liu L Q, XIAO X Y, GUO Z H, et al. Adsorption characteristics and mechanism of Cd and Pb in tiered soil profiles from a zinc smelting site[J]. Environmental Science, 2021, 42(8): 4015-4023 (in Chinese).

[15] Di SANTE M, MAZZIERI F, PASQUALINI E. Assessment of the sanitary and environmental risks posed by a contaminated industrial site[J]. Journal of Hazardous Materials, 2009, 171(1-3): 524-534. doi: 10.1016/j.jhazmat.2009.05.145 [16] 鲁如坤. 土壤农业化学分析方法[M]. 北京: 中国农业科技出版社, 2000. LU R K. Methods for agricultural chemical analysis of soil[M]. Methods for agricultural chemical analysis of soil, 2000 (in Chinese).

[17] SHI L, GUO Z, LIU S. Effects of combined soil amendments on Cd accumulation, translocation and food safety in rice: a field study in southern China[J]. Environmental Geochemistry and Health, 2022, 44(8): 2451-2463. [18] DAVIDSON C M, DUNCAN A L, LITTLEJOHN D, et al. A critical evaluation of the three-stage BCR sequential extraction procedure to assess the potential mobility and toxicity of heavy metals in industrially-contaminated land[J]. Analytica Chimica Acta, 1998, 363(1):45-55. [19] GUO Z, ZHANG Y, XU R, et al. Contamination vertical distribution and key factors identification of metal(loid)s in site soil from an abandoned Pb/Zn smelter using machine learning[J]. Science of The Total Environment, 2023, 856: 159264. doi: 10.1016/j.scitotenv.2022.159264 [20] ZHANG X Y, LIN F F, WONG M T F, et al. Identification of soil heavy metal sources from anthropogenic activities and pollution assessment of Fuyang County, China[J]. Environmental Monitoring and Assessment, 2009, 154(1-4): 439-449. doi: 10.1007/s10661-008-0410-7 [21] 郭佳雯, 廖敏, 谢晓梅, 等. 铅锌冶炼厂冶炼渣淋溶释放的铅在红壤中垂直迁移特征[J]. 环境污染与防治, 2021, 43(8): 990-996, 1009. GUO J W, LIAO M, XIE X M, et al. Characteristics of vertical migration of Pb released from smelting slag of lead-zinc smelter in red soil area[J]. Environmental Pollution & Control, 2021, 43(8): 990-996, 1009 (in Chinese).

[22] 龙永珍, 戴塔根, 邹海洋. 长沙、株洲、湘潭地区土壤重金属污染现状及评价[J]. 地球与环境, 2008(3): 231-236. LONG Y Z, DAI T G, ZOU H Y. The status quo and evaluation of heavy metal pollution of soils in the Changsha, Zhuzhou and Xiangtan areas[J]. Earth and Environment, 2008, 36(3) : 231-236 ( in Chinese) .

[23] 李勖之, 姜瑢, 孙丽, 等. 不同国家土壤生态筛选值比较与启示[J]. 环境化学, 2022, 41(3): 1001-1010. LI X Z, JIANG R, SUN L, et al. Ecological soil screening values among different countries and implication for China[J]. Environmental Chemistry, 2022, 41 (3): 1001-1010 (in Chinese).

[24] OKONKWO S I, IDAKWO S O, AMEH E G. Heavy metal contamination and ecological risk assessment of soils around the pegmatite mining sites at Olode area, Ibadan southwestern Nigeria[J]. Environmental Nanotechnology, Monitoring & Management, 2021, 15: 100424. [25] 陈丹丹, 谭璐, 聂紫萌, 等. 湖南典型金属冶炼与采选行业企业周边土壤重金属污染评价及源解析[J]. 环境化学, 2021, 40(9): 2667-2679. doi: 10.7524/j.issn.0254-6108.2021010901 CHEN D D, TAN L, NIE Z M, et al. Evaluation and source analysis of heavy metal pollution in the soil around typical metal smelting and mining enterprises in Hunan Province[J]. Environmental Chemistry, 2021, 40 (9): 2667-2679 (in Chinese). doi: 10.7524/j.issn.0254-6108.2021010901

[26] ZENG J, LUO X, CHENG Y, et al. Spatial distribution of toxic metal(loid)s at an abandoned zinc smelting site, Southern China. [J]. Journal of Hazardous Materials, 2022, 425: 127970. doi: 10.1016/j.jhazmat.2021.127970 [27] TIBANE L V, MAMBA D. Ecological risk of trace metals in soil from gold mining region in South Africa[J]. Journal of Hazardous Materials Advances, 2022, 7: 100118. doi: 10.1016/j.hazadv.2022.100118 [28] STERCKEMAN T, DOUAY F, PROIX N, et al. Vertical distribution of Cd, Pb and Zn in soils near smelters in the north of France[J]. Environmental Pollution , 2000, 107(3): 377-389. doi: 10.1016/S0269-7491(99)00165-7 [29] LI P, LIN C, CHENG H, et al. Contamination and health risks of soil heavy metals around a lead/zinc smelter in southwestern China[J]. Ecotoxicology and Environmental Safety, 2015, 113: 391-399. doi: 10.1016/j.ecoenv.2014.12.025 [30] GUO Z, YANG J, SARKODIE E K, et al. Vertical distribution of the toxic metal(loid)s chemical fraction and microbial community in waste heap at a nonferrous metal mining site[J]. Ecotoxicology and Environmental Safety, 2021, 228: 113037. doi: 10.1016/j.ecoenv.2021.113037 [31] YU Z, LIU E, LIN Q, et al. Comprehensive assessment of heavy metal pollution and ecological risk in lake sediment by combining total concentration and chemical partitioning[J]. Environmental Pollution, 2021, 269: 116212. doi: 10.1016/j.envpol.2020.116212 [32] LIU W, HU T, MAO Y, et al. The mechanistic investigation of geochemical fractionation, bioavailability and release kinetic of heavy metals in contaminated soil of a typical copper-smelter[J]. Environmental Pollution, 2022, 306: 119391. doi: 10.1016/j.envpol.2022.119391 [33] DU H, LI Y, WAN D, et al. Tungsten distribution and vertical migration in soils near a typical abandoned tungsten smelter[J]. Journal of Hazardous Materials, 2022, 429: 128292. doi: 10.1016/j.jhazmat.2022.128292 [34] ZHONG Q, YIN M, ZHANG Q, et al. Cadmium isotopic fractionation in lead-zinc smelting process and signatures in fluvial sediments[J]. Journal of Hazardous Materials, 2021, 411: 125015. doi: 10.1016/j.jhazmat.2020.125015 [35] KANG M, YU S, JEON S W, et al. Mobility of metal(loid)s in roof dusts and agricultural soils surrounding a Zn smelter: Focused on the impacts of smelter-derived fugitive dusts[J]. Science of The Total Environment, 2021, 757: 143884. doi: 10.1016/j.scitotenv.2020.143884 [36] TUHÝ M, HRSTKA T, ETTLER V. Automated mineralogy for quantification and partitioning of metal(loid)s in particulates from mining/smelting-polluted soils[J]. Environmental Pollution, 2020, 266: 115118. doi: 10.1016/j.envpol.2020.115118 [37] XU D, FU R. A typical case study from smelter–contaminated soil: new insights into the environmental availability of heavy metals using an integrated mineralogy characterization[J]. Environmental Science and Pollution Research, 2022, 29(38): 57296-57305. doi: 10.1007/s11356-022-19823-6 [38] LIN H, TANG Y, DONG Y, et al. Characterization of heavy metal migration, the microbial community, and potential bioremediating genera in a waste-rock pile field of the largest copper mine in Asia[J]. Journal of Cleaner Production, 2022, 351: 131569. doi: 10.1016/j.jclepro.2022.131569 [39] BUATIER M D, SOBANSKA S, ELSASS F. TEM-EDX investigation on Zn- and Pb-contaminated soils[J]. Applied Geochemistry, 2001, 16(9): 1165-1177. [40] BOLAN N, KUNHIKRISHNAN A, THANGARAJAN R, et al. Remediation of heavy metal(loid)s contaminated soils – To mobilize or to immobilize?[J]. Journal of Hazardous Materials, 2014, 266: 141-166. doi: 10.1016/j.jhazmat.2013.12.018 [41] SHAHEEN S M, TSADILAS C D, RINKLEBE J. A review of the distribution coefficients of trace elements in soils: Influence of sorption system, element characteristics, and soil colloidal properties[J]. Advances in Colloid and Interface Science, 2013, 201-202: 43-56. doi: 10.1016/j.cis.2013.10.005 [42] LI Y, LIU J, WANG Y, et al. Contribution of components in natural soil to Cd and Pb competitive adsorption: Semi-quantitative to quantitative analysis[J]. Journal of Hazardous Materials, 2023, 441: 129883. doi: 10.1016/j.jhazmat.2022.129883 [43] KUBIER A, WILKIN R T, PICHLER T. Cadmium in soils and groundwater: A review[J]. Applied Geochemistry, 2019, 108: 104388. doi: 10.1016/j.apgeochem.2019.104388 [44] MILER M, GOSAR M. Characteristics and potential environmental influences of mine waste in the area of the closed Mežica Pb–Zn mine (Slovenia)[J]. Journal of Geochemical Exploration, 2012, 112: 152-160. doi: 10.1016/j.gexplo.2011.08.012 [45] WILSON S C, LOCKWOOD P V, ASHLEY P M, et al. The chemistry and behaviour of antimony in the soil environment with comparisons to arsenic: A critical review[J]. Environmental Pollution, 2010, 158(5): 1169-1181. doi: 10.1016/j.envpol.2009.10.045 [46] 王璐莹, 秦雷, 吕宪国, 等. 铁促进土壤有机碳累积作用研究进展[J]. 土壤学报, 2018, 55(5): 1041-1050. WANG L Y, QIN L, LV X G, et al. Progress in researches on effect of iron promoting accumulation of soil organic carbon[J]. Acta Pedologica Sinica, 2018, 55(5): 1041-1050 (in Chinese).

-

下载:

下载: