土壤是人类赖以生存和发展的基石,是保障生态环境和食品安全的重要基础[1]。随着我国工业化和城镇化进程的加快,人类生产活动对土壤质量的影响日益凸显。近年来,化工产品的广泛生产使用,农药、化肥的大量施用,对土壤造成严重污染与破坏[2],其中,以重金属污染尤为突出。进入土壤中的重金属被植物吸收后可抑制其生长,且随食物链传递、富集,最终进入人体,危害人类健康[3]。《全国土壤污染状况调查公报》(2014年)显示,我国土壤重金属总超标率为16.1%,其中重金属污染耕地占比19.4%,主要为铅(Pb)、汞(Hg)、铬(Cr)、铜(Cu)、锌(Zn)、镍(Ni)和砷(As)等[4]。我国污水灌溉农田土壤达1.4×106 hm2,重金属污染面积占比64.8%,其中Pb、As、Cr、Cd污染耕地面积约2×107 km2,占耕地总面积的20%[5]。

生物炭作为近年土壤学和环境科学领域的研究热点,被认为是应对气候变化、农业废弃物资源化和环境污染等问题的重要材料。生物炭是以动植物残体或粪便为原料,在200~700 ℃及限氧条件下,通过热化学转化或热解获得的重金属吸附材料[6-7]。由于生物炭表面官能团丰富、孔隙率高、具有较大比表面积、较高pH和阳离子交换量,可用于吸附去除水体和土壤中重金属,在改善土壤环境、修复环境污染、降低环境风险等方面具有广阔应用前景[8-10]。在众多生物炭制备原料中[11-18],秸秆生物炭表现出突出的重金属吸附效果[19]。例如,水稻秸秆生物炭对Pb2+和Cd2+的吸附量(126 mg·g-1和60.6 mg·g-1)显著高于木屑和米糠生物炭(47.6 mg·g-1和6.67 mg·g-1、33 mg·g-1和16.2 mg·g-1),与其较高的无机矿物组分含量(38.8% vs. 17.5%、13.8%)有关[20]。此外,我国是农业大国,秸秆产量占全球秸秆产量的1/5,秸秆资源丰富易得[21],为制备生物炭提供丰富原料。通常,秸秆作焚烧处理,易造成环境污染和资源浪费。因此,以秸秆为原料制备生物炭对重金属污染土壤进行修复,既可实现废弃物资源化利用,降低其二次污染风险,亦可达到吸附稳定/固定土壤重金属的目的,同时降低污染土壤的修复成本。秸秆生物炭具有高芳香化和杂环化结构,表面分布多样微孔结构和多种官能团,对重金属具有极高的吸附/钝化效率。本文通过介绍秸秆生物炭的制备技术、特征性能及其影响因素,重点阐述生物炭对重金属污染土壤的修复机制及实际应用效率和影响因素,并对后续研究提出展望,以期为秸秆废弃物资源化利用及秸秆生物炭吸附/钝化土壤重金属提供理论依据和技术参考。

1 秸秆生物炭制备方法及影响因素(Preparation methods and influencing factors of straw biochar)

生物炭是有机材料在一定的限氧和高温条件下产生的富碳材料,不同条件制备的生物炭钝化/吸附重金属效率不同,其性能与原料类型、制备技术和改性等因素有关。

1.1 原料类型

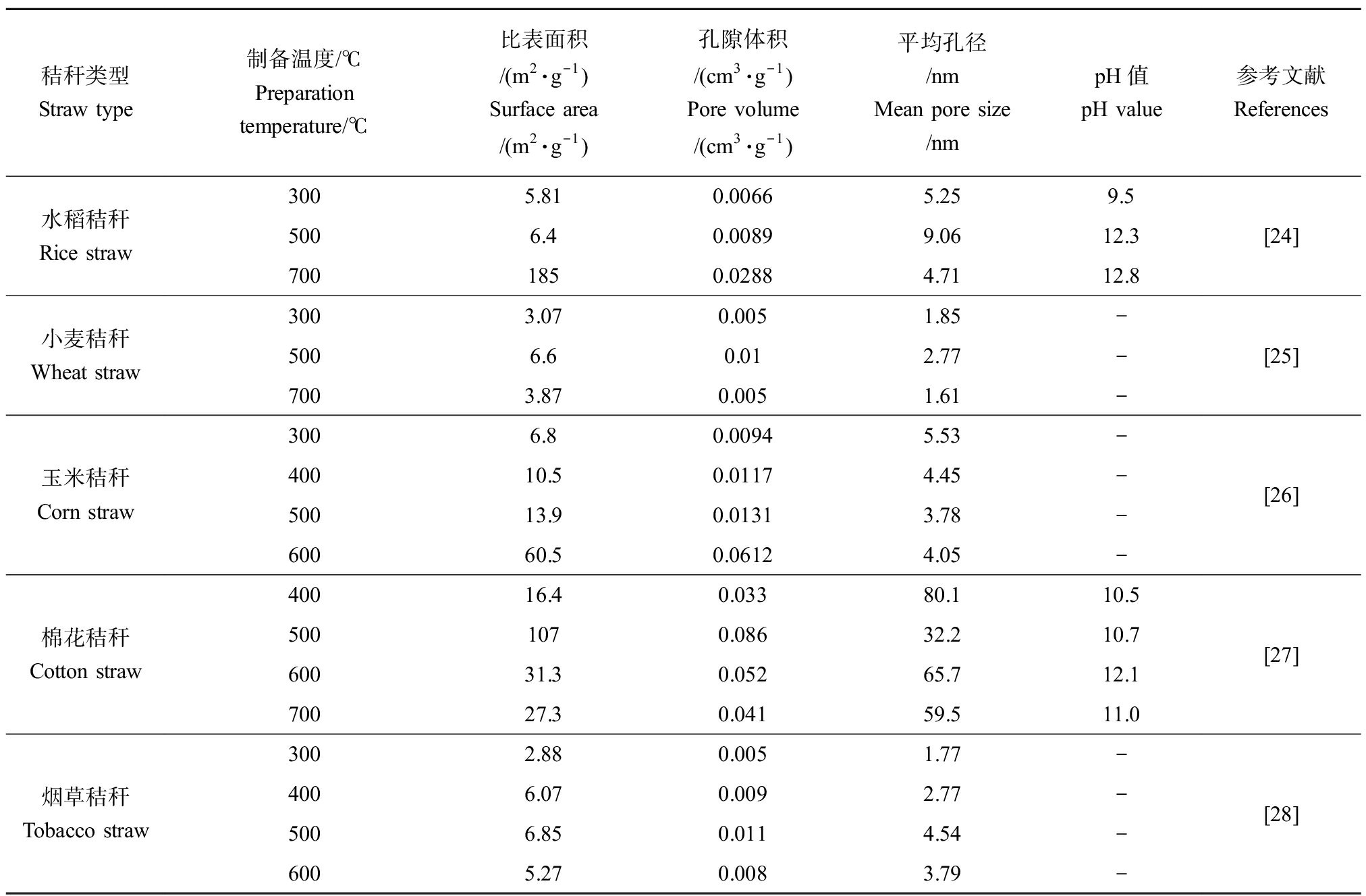

秸秆类型不同,其结构特征、元素含量和表面官能团种类等亦不同,故其制备生物炭的性质存在一定差异。邹凡等[22]对由玉米、水稻和小麦秸秆制备的生物炭吸附Pb2+研究后发现,玉米秸秆生物炭结构蓬松,—OH、—C—H和C![]() C等表面官能团较多,通过表面络合吸附Pb2+,吸附量达141 mg·g-1;水稻和小麦秸秆生物炭碳酸盐和磷酸等含量较高,通过化学沉淀吸附Pb2+,吸附量达123 mg·g-1和121 mg·g-1。此外,不同原料生物炭的孔隙结构和比表面积存在显著差异。如表1所示,不同生物炭的孔隙体积和比表面积随温度升高而增加,一定温度后降低。水稻和玉米秸秆生物炭制备温度低于500 ℃时,比表面积和孔隙体积变化不明显;当温度高于500 ℃时,生物质中纤维素、半纤维素和木质素裂解,秸秆生物炭的孔隙体积和比表面积显著增加。小麦、棉花和烟草秸秆生物炭制备温度为500 ℃时,比表面积和孔隙体积达到最高,之后随制备温度升高而降低,可能是因其维管束遭到破坏,灰分熔融,孔隙结构坍塌。此外,不同原料生物炭的pH值和表面电荷存在显著差异。Nzediegwu等[23]利用油菜秸秆和小麦秸秆在300 ℃、400 ℃和500 ℃制备生物炭发现,小麦秸秆生物炭pH值为9.4、10.0和11.7,油菜秸秆生物炭pH值为8.9、9.6和12.1。可见,制备原料对生物炭的特性(表面官能团种类、孔隙结构、比表面积和pH等)具有较大影响,进而影响其生物炭对重金属的吸附能力。

C等表面官能团较多,通过表面络合吸附Pb2+,吸附量达141 mg·g-1;水稻和小麦秸秆生物炭碳酸盐和磷酸等含量较高,通过化学沉淀吸附Pb2+,吸附量达123 mg·g-1和121 mg·g-1。此外,不同原料生物炭的孔隙结构和比表面积存在显著差异。如表1所示,不同生物炭的孔隙体积和比表面积随温度升高而增加,一定温度后降低。水稻和玉米秸秆生物炭制备温度低于500 ℃时,比表面积和孔隙体积变化不明显;当温度高于500 ℃时,生物质中纤维素、半纤维素和木质素裂解,秸秆生物炭的孔隙体积和比表面积显著增加。小麦、棉花和烟草秸秆生物炭制备温度为500 ℃时,比表面积和孔隙体积达到最高,之后随制备温度升高而降低,可能是因其维管束遭到破坏,灰分熔融,孔隙结构坍塌。此外,不同原料生物炭的pH值和表面电荷存在显著差异。Nzediegwu等[23]利用油菜秸秆和小麦秸秆在300 ℃、400 ℃和500 ℃制备生物炭发现,小麦秸秆生物炭pH值为9.4、10.0和11.7,油菜秸秆生物炭pH值为8.9、9.6和12.1。可见,制备原料对生物炭的特性(表面官能团种类、孔隙结构、比表面积和pH等)具有较大影响,进而影响其生物炭对重金属的吸附能力。

表1 不同原料和制备温度生物炭比表面积、孔隙特性和pH值

Table 1 Specific surface area, pore property and pH value of biochar prepared by different raw materials and temperatures

秸秆类型Straw type制备温度/℃Preparation temperature/℃比表面积/(m2·g-1)Surface area/(m2·g-1)孔隙体积/(cm3·g-1)Pore volume/(cm3·g-1)平均孔径/nmMean pore size/nmpH值pH value参考文献References水稻秸秆Rice straw3005.810.00665.259.55006.40.00899.0612.37001850.02884.7112.8[24]小麦秸秆Wheat straw3003.070.0051.85-5006.60.012.77-7003.870.0051.61-[25]玉米秸秆Corn straw3006.80.00945.53-40010.50.01174.45-50013.90.01313.78-60060.50.06124.05-[26]棉花秸秆Cotton straw40016.40.03380.110.55001070.08632.210.760031.30.05265.712.170027.30.04159.511.0[27]烟草秸秆Tobacco straw3002.880.0051.77-4006.070.0092.77-5006.850.0114.54-6005.270.0083.79-[28]

1.2 制备技术

制备技术(如热解方式、炭化温度等)影响生物炭的成炭率、比表面积、孔隙结构和表面基团等,秸秆生物炭相比其他生物炭更受制于温度[29]。通常,重金属吸附量随加热温度和加热速率升高而升高,成炭率随加热温度和加热速率升高而降低[30]。加热温度对成炭率的影响表现为较低温度(400 ℃)高于较高温度(500~1 000 ℃),成炭率分别为35%和10%~25%[31-32],但温度过低(350 ℃)会导致炭化不完全和炭化时间过长,导致成炭率降低[33]。加热温度对生物炭重金属吸附容量的影响表现为:随制备温度升高,原料中挥发性物质大量流失,使生物炭孔隙度和比表面积增大,但其重金属吸附量降低。例如,Ding等[34]发现,炭化温度由250 ℃升至600 ℃后,甘蔗渣生物炭比表面积由0.56 m2·g-1增至14.1 m2·g-1,但对Pb的吸附量由20.5 mg·g-1降至6 mg·g-1。类似地,Yang等[19]发现,水稻秸秆生物炭制备温度由500 °C升至900 ℃后,对Ni2+的吸附量由28.6 mg·g-1降至14.4 mg·g-1,产生这一现象的可能原因是高温炭化过程使C![]() O、—OCH3和C—H等对重金属具有吸附络合能力的表面官能团减少。

O、—OCH3和C—H等对重金属具有吸附络合能力的表面官能团减少。

生物炭制备技术有炭化技术、水热炭化、气化和微波热解等[35-39],对生物炭的结构特性有一定影响,见表2。综合考虑成炭率和重金属吸附容量,对秸秆进行炭化时,采用慢速(5~7 ℃·min-1)热裂解(400~650 ℃)较为合适[40]。

表2 生物炭制备技术及其特点

Table 2 Biochar preparation technology and characteristics

1.3 改性方法

通过直接热解生物质得到的生物炭结构稳定、质地密实、比表面积往往较低、吸附活性位点较少、表面官能团不够丰富,致使生物炭在吸附过程中对污染物的去除效率低、选择性差,阻碍了其在环境领域的实际应用。因此,有必要对生物炭进行改性处理以提高其吸附能力。生物炭改性指通过活化或功能化改变生物炭理化学性质。生物炭借此改善其孔隙结构和比表面积并增加表面官能团数量,进而提高其吸附重金属能力[41]。生物炭改性主要分物理改性、化学改性和生物改性(图1)。

图1 生物炭改性方法及特点[65,67-74]

Fig. 1 Methods and characteristics of biochar modification[65,67-74]

物理改性是通过物理方法,如球磨、紫外线照射、超声波和气体活化等方法处理生物炭,提高生物炭吸附性能。Zhang等[42]对玉米秸秆生物炭进行球磨法改性后,生物炭颗粒尺寸变小,其比表面积显著提高(147 m2·g-1 vs. 85.4 m2·g-1),土壤Cd可迁移态降低45.4%。Peng等[43]将玉米秸秆、锯末和小麦秸秆生物炭经365 nm紫外光照射24 h改性,研究后发现紫外线照射增加生物炭的比表面积,并在其表面添加大量的含氧官能团,吸附Cr6+能力增加2倍~5倍(14.4~20 mg·g-1 vs. 3.6~8.43 mg·g-1)。Hu等[44]对生物炭超声波改性后发现,改性生物炭的微孔结构和功能性官能团增加,其比表面积上升249%(1 452 m2·g-1 vs. 416 m2·g-1),吸附能力提高5.3倍(321 mg·g-1 vs. 61 mg·g-1)。Sakhiya等[45]对水稻秸秆生物炭空气活化,使其比表面积由3.61 m2·g-1增至105 m2·g-1,表面多孔结构更加分明,吸附Zn2+量达27.8 mg·g-1。物理改性操作简单,可改善生物炭特征,但物理改性程度有限,对复合污染状况有所限制。

化学改性是指利用强酸、强碱、有机溶剂或负载金属氧化物等改性生物炭,使生物炭表面官能团发生变化,提升其吸附效果。如Shen等[64]对稻壳生物炭进行KOH改性处理,使其比表面积提升12.7倍(1 818 m2·g-1 vs. 133 m2·g-1),微孔隙率达93.3%,吸附性能显著提高。Liatsou等[65]使用2-硫脲嘧啶对丝瓜生物炭纤维进行改性,发现改性生物炭纤维改性后对Cu2+吸附性提高至487 mg·g-1,且可对酸性矿山废水中的Cu2+进行选择性分离。Yang等[66]以玉米秸秆为原料,运用还原共沉淀法合成纳米级零价铁生物炭修复As/Cd污染土壤,结果表明生物炭表面负载Fe—O官能团,并与As/Cd络合,使水稻籽粒中As和Cd含量分别降低69.3%和59.8%。

生物改性是将生物炭与具备某种功能的微生物相结合,从而改善其理化性质的技术。生物炭为微生物提供繁殖生长空间和营养物质的同时,微生物通过代谢转化作用固定污染物,提高改性生物炭吸附性能。Tu等[75]以5%速率将假单胞菌负载至玉米秸秆生物炭,研究其固化土壤Cd和Cu的效果后发现,可交换态Cd降低12.8%,Fe-Mn氧化物结合Cd和残留Cd分别增加8.17%和5.49%;碳酸盐结合Cu降低26.6%,残留Cu增加11.5%。同时改善了培养结束时的土壤微生物群落,使金属稳定后的土壤功能得到恢复。生物改性将微生物的某种功能赋予生物炭,使其有效吸附污染物,但局限于微生物培养困难,难以推广,且细菌和真菌存在一定生态风险[76]。

2 秸秆生物炭修复重金属污染土壤的机制(Mechanisms of straw biochar in heavy metal contaminated soils remediation)

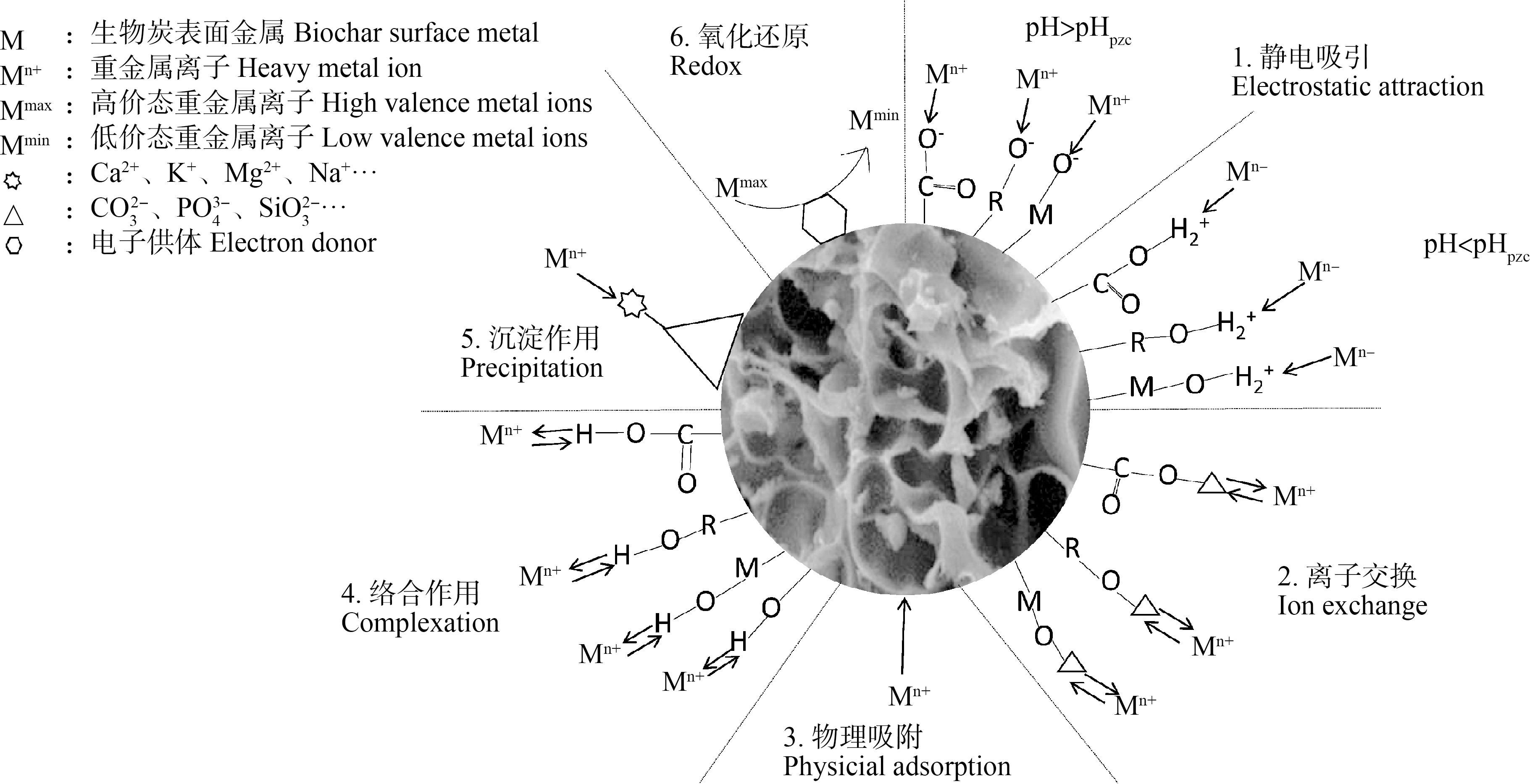

秸秆生物炭利用其表面富含的官能团和矿物质成分等吸附重金属离子涉及多种作用机理,主要包括静电吸引、离子交换、物理吸附、络合、沉淀和氧化还原(图2)。

图2 秸秆生物炭吸附土壤重金属机制示意图

Fig. 2 Mechanisms for heavy metals adsorption by straw-based biochar

2.1 静电吸引

静电吸引指生物炭利用其表面的正负电荷与重金属离子发生静电吸引从而吸附固定重金属[77]。Tong等[78]研究发现,提高pH可增加生物炭对Cu2+的吸附。当土壤pH值>零电荷点(pHPZC)时,生物炭表面呈负电性,通过静电吸引重金属阳离子,同时也可与H+结合提高土壤碱度,增强吸附作用;反之,生物炭表面携带正电荷,通过静电吸引类金属阴离子[79-81]。因此,秸秆生物炭的高电负性可促进其与正电离子的静电吸引[82],吸附强度取决于生物炭的pHPZC与土壤pH值的大小关系。

2.2 离子交换

生物炭表面存在大量K+、Ca2+和Na+等碱金属离子,能够与重金属离子发生离子交换,从而吸附重金属离子[83]。研究表明,土壤中的Cd2+可与生物炭中碱金属离子选择性置换[84],其反应式为:C—Xn+ + Cd2+ →C—Cd2+ + Xn+(Xn+表示盐基离子),这是因为Cd2+的离子半径、电荷量和键合特性等与盐基离子相似[85]。此外,生物炭中K+和Ca2+等阳离子与Cd2+[86]、Al3+[87]发生离子交换作用,进而提高生物炭对Cd2+、Al3+的吸附效率。可见,生物炭表面存在的碱金属离子可通过离子交换过程对土壤中重金属离子进行固定。

2.3 物理吸附

物理吸附由生物炭表面范德华力产生,受生物炭孔隙结构和比表面积影响[88]。研究表明,生物炭表面存在的不同大小的孔隙为Cd2+和可穿透络合物等提供吸附位点[89-90]。生物炭比表面积和孔隙体积随制备温度升高而增大,制备温度为500~700 ℃时,生物炭比表面积和孔隙体积较大。Sui等[91]研究发现用硼酸改性玉米秸秆生物炭使比表面积提高至898 m2·g-1,且随生物炭制备温度升高,其对Fe2+的吸附性能增强,800 ℃制备的改性生物炭对Fe2+的吸附量达133 mg·g-1,且吸附过程符合伪二阶动力学方程,表明生物炭对Fe2+的吸附过程为表面吸附。因此,生物炭比表面积和孔隙体积越大,对重金属的吸附能力越强。

2.4 络合作用

生物炭表面富含—COOH、—OH和—NH2等官能团,可与重金属离子发生络合,从而固定重金属[6],其中以—COOH和—OH络合作用最为突出[92]。王棋等[93]通过傅里叶红外光谱法分析生物炭吸附重金属离子前后生物炭表面官能团的变化,结果表明,生物炭的—OH伸缩振动峰(3 422 cm-1)在吸附Cu2+、Pb2+、Cd2+和Ni2+后位移均发生明显变化,表明—OH与重金属离子发生络合。相较于—OH,高硫生物炭表面的—SH对Hg2+、Cd2+等的络合能力更强[94-95],这是由于其能与Hg2+、Cd2+等形成更稳定的络合物。此外,生物炭表面官能团亦可通过间接方式与重金属离子发生络合,进而改变重金属形态。例如,生物炭表面丰富的含氧官能团可先与土壤中Fe、Mn结合形成铁锰氧化态物质,再与As发生络合作用[96]。综上,生物炭表面官能团(—OH、—SH等)通过直接或间接过程络合金属离子。

2.5 沉淀作用

生物炭灰分中的矿物成分可与重金属发生沉淀反应,从而实现重金属的固定。由于生物炭制备原料的不同导致其矿物质成分不同,生成的重金属氧化物、氯化物、碳酸盐和硫酸盐等沉淀物亦不同[6]。水稻秸秆生物炭中C2O42-和CO32-可与Pb2+分别形成PbC2O4和Pb3(CO3)2(OH)2沉淀,是固定Pb的主要机制[97]。OH-、CO32-、PO43-和SO42-等阴离子可与Pb2+生成PbCO3、Pb5(PO4)3OH等沉淀[98],与Cd2+生成Cd3(PO4)2,与Zn2+生成Zn3(PO4)2沉淀。因此,针对不同重金属种类,可通过特定的阴离子对生物炭进行改性,增强生物炭对重金属的沉淀效率,提高重金属吸附效率。

2.6 氧化还原作用

生物炭可作为电子供体或受体诱导重金属发生氧化还原反应,达到吸附和钝化重金属的目的。如生物炭表面C6H5—OH等官能团拥有转移电子的能力,可将As3+氧化为As5+或还原Cr6+为Cr3+[99]。Lyu等[100]预磁化生物炭后,将其与Ca-Mg-Al三元层状金属氧化物交联得到磁性生物炭交联金属复合材料,其对As的最大吸附容量达265 mg·g-1,其涉及的机制为改性生物炭表面的Fe2O3将As3+氧化为As5+,而后As5+与生物炭表面金属官能团配位,生成M-O-As配体。

综上,秸秆生物炭通过表面富含的碱金属离子(K+、Ca2+和Na+等)、官能团(—COOH、—OH和 —NH2等)和矿物质成分等,通过及吸附、络合、沉淀、氧化还原等过程,对重金属离子进行吸附钝化。

3 秸秆生物炭修复重金属污染土壤的效率与影响因素(Efficiency and influencing factors of straw biochar in heavy metals-contaminated soils remediation)

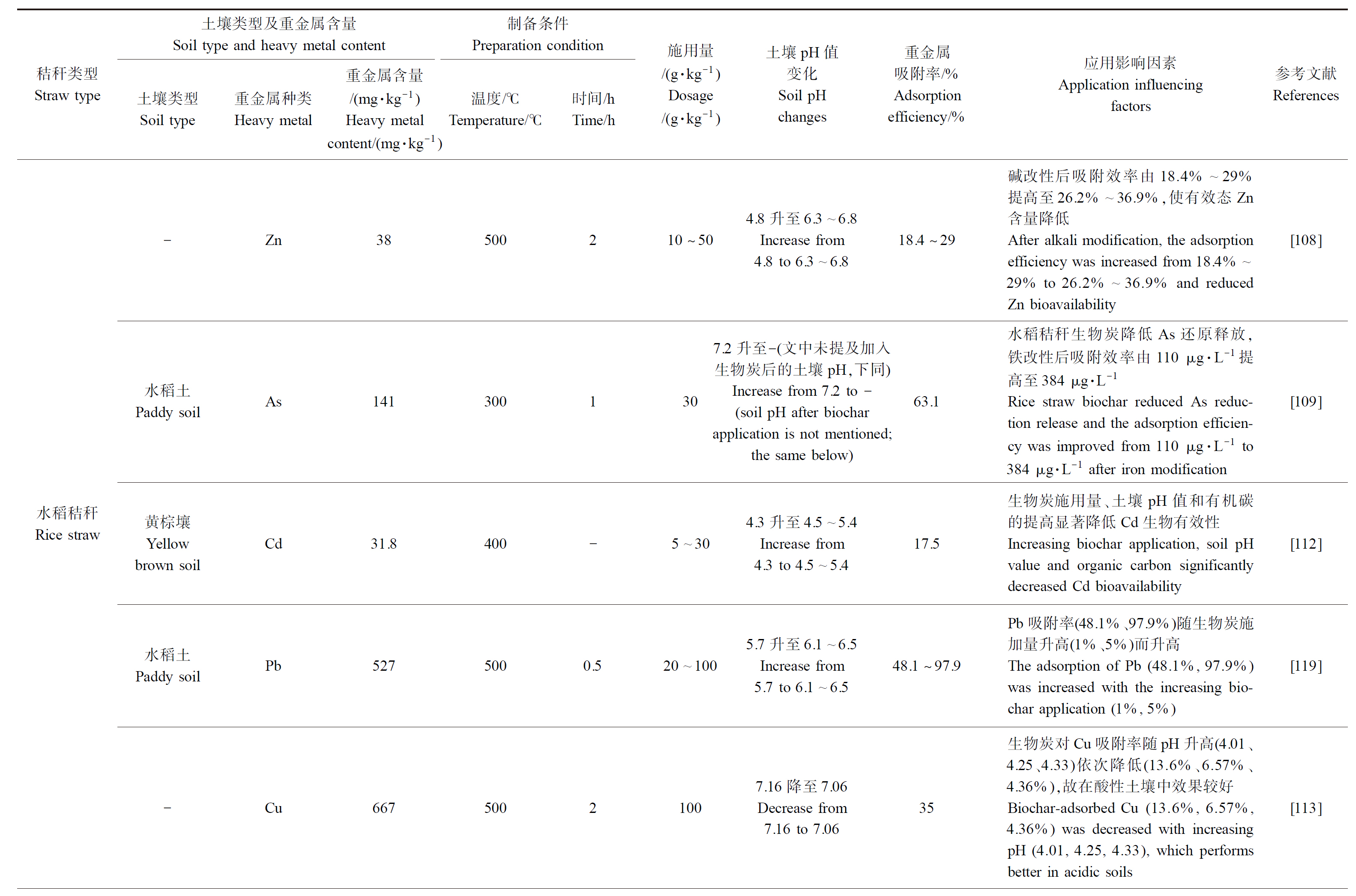

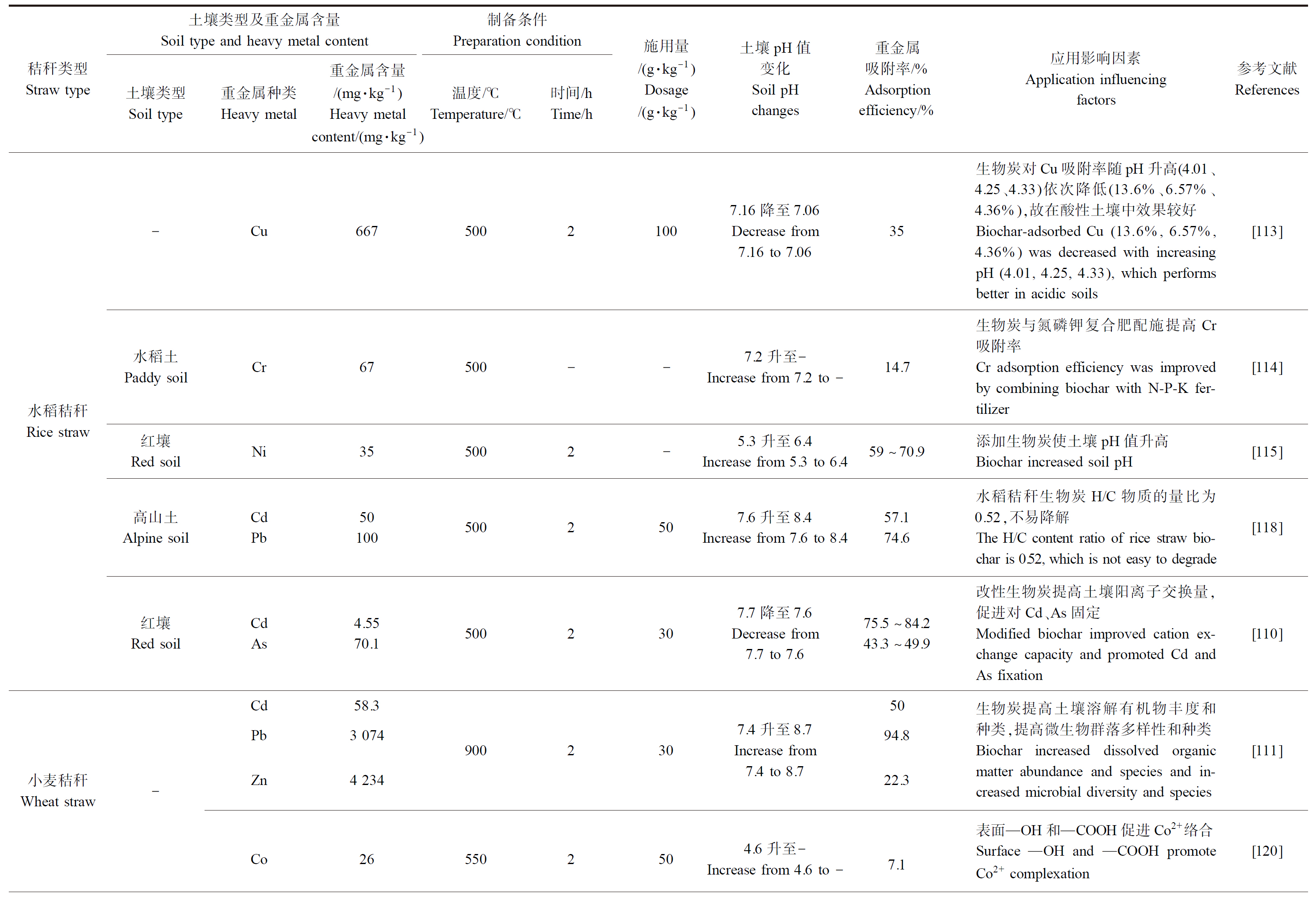

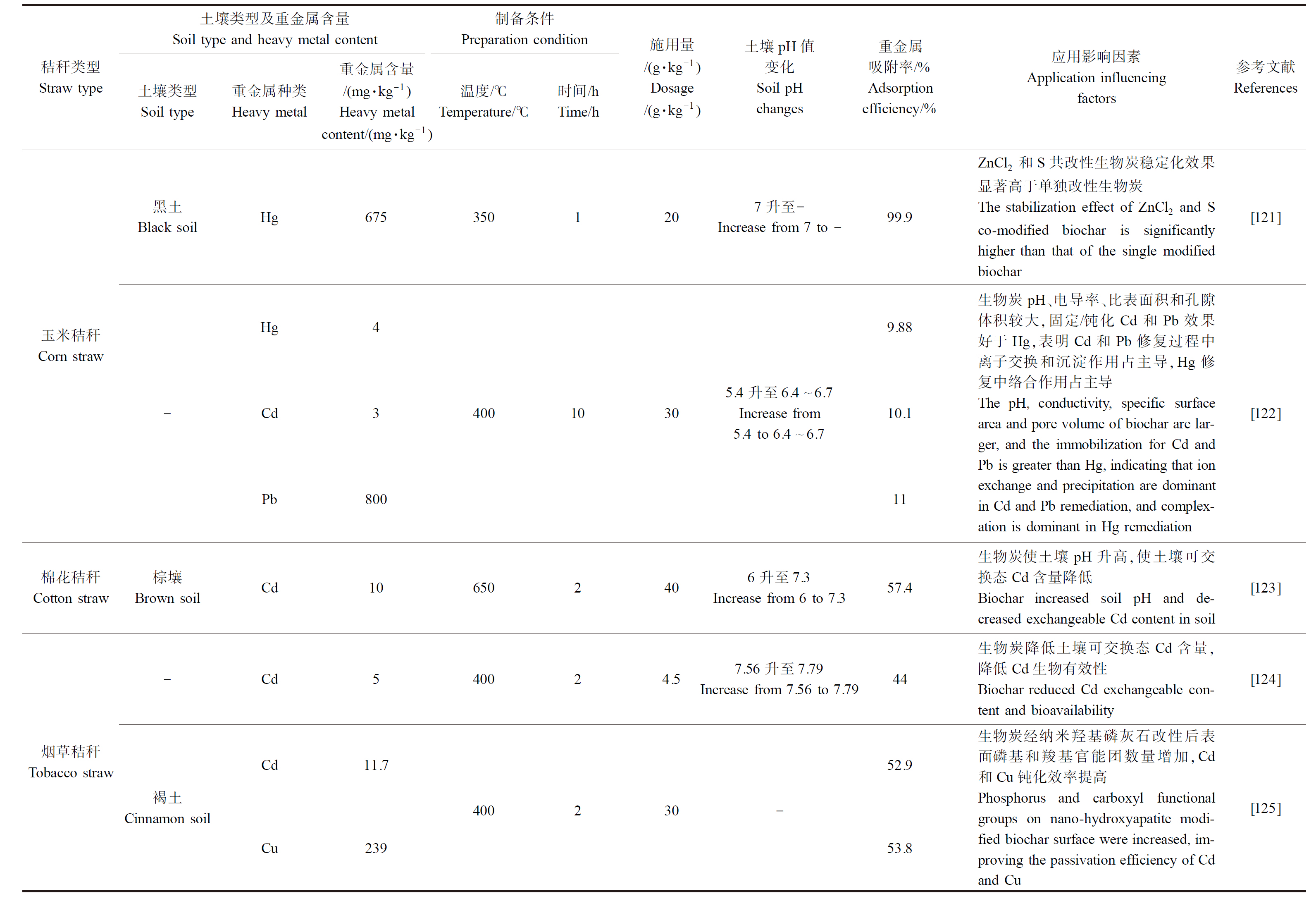

生物炭修复重金属污染土壤过程中,修复效率主要受土壤pH值、土壤类型、生物炭改性方式、重金属种类和田间管理方式等因素的影响(表3)。

表3 秸秆生物炭对重金属污染土壤的修复效率

Table 3 Remediation efficiency of straw biochar towards heavy metals-contaminated soils

续表3

续表3

3.1 土壤pH值

通常,生物炭吸附重金属的效率随土壤pH值升高而升高,但同时受生物炭制备温度和土壤阳离子强度的影响。例如,安增莉等[101]在不同温度下制备水稻秸秆生物炭,研究其在不同pH值下对Pb的吸附特性,结果表明,pH=3.5时,300 ℃和400 ℃制备生物炭对Pb的吸附量较大(6.82 mg·g-1和5.90 mg·g-1),pH=6和6.5时,500 ℃和600 ℃制备的生物炭吸附量较大(3.57 mg·g-1和1.69 mg·g-1),表明环境pH值和制备温度影响水稻秸秆生物炭对Pb的吸附效率。此外,梁程等[102]于500 ℃制备水稻秸秆生物炭,研究其对土壤Pb的吸附机制,发现适当提高pH可促进生物炭吸附Pb2+,当pH=6时吸附率可达92.6%,而较高的Na+和Ca2+离子强度使Pb2+吸附率降低,当离子强度由10 mmol·L-1增至50 mmol·L-1时,吸附率由97.6%降至92.5%,可见提高pH值可提高生物炭对Pb的吸附率,但较高的阳离子浓度可抑制重金属吸附。董丽佳等[103]研究水稻秸秆生物炭对Eu3+的吸附行为和机理时发现,土壤pH值对水稻秸秆生物炭吸附Eu3+具有重要影响,当pH=1.9~8.4时,随pH值升高吸附率由9%提高至97%,并在pH=8.4时达到最大吸附量40.7 mg·kg-1,可见生物炭吸附Eu3+效率随pH值的升高而提高。因此,合适的pH值和生物炭制备温度可提高生物炭对重金属的吸附/钝化效率。

3.2 土壤类型

我国土壤类型多样[104],不同土壤对重金属的吸附能力存在差异,如碱性土壤(灰漠土、褐土和黑土等)对Cd的吸附量(55.6~58.8 mg·L-1)高于酸性土壤(棕壤、黄棕壤和红壤等)(37.2~54.5 mg·L-1)[105]。因此,利用生物炭修复重金属污染土壤时需考虑土壤类型对吸附效率的影响。Wang等[106]以400 ℃制备玉米秸秆生物炭修复Cd污染红壤和黄棕壤时发现,添加3%生物炭后,红壤和黄棕壤pH值分别提高2.71和0.83,使红壤和黄棕壤中有效态Cd含量分别降低79.2%和49.2%,表明生物炭可通过改变不同类型土壤的理化性质进而影响重金属固定效率。张家康等[107]研究水稻秸秆生物炭对不同类型土壤中有效态Cd含量的影响,结果表明,添加5%生物炭使黄壤和水稻土pH值分别提高至5.22和7.79,土壤溶液电导率提高至590 μs·m-1和916 μs·m-1,有机质含量分别为5.67 g·kg-1和32.8 g·kg-1,使有效态Cd含量分别降低17.3%和56.3%。因此,相较于酸性黄壤,秸秆生物炭对碱性水稻土中Cd的钝化效率更高,且与土壤pH值、溶液电导率和有机质含量有关。

3.3 生物炭改性方式

为提高生物炭对重金属的吸附效率,通常采用物理、化学过程等对生物炭进行改性。例如,Liu等[108]利用水稻秸秆生物炭修复Zn污染土壤时发现,生物炭使土壤pH值提高0.7~2.0,土壤中Zn2+溶出量降低18.4%~36.9%,而KOH改性后生物炭比表面积和孔隙体积较未改性分别提高1.74倍和1.68倍,使Zn吸附效率提高12.6%,表明改性可通过提高生物炭比表面积和孔隙体积进而提高对重金属的吸附效率。何璇等[109]探究铁改性水稻秸秆生物炭对土壤中As吸附效率的影响,发现铁改性水稻秸秆生物炭使土壤中有效态As含量降低63.1%,可归因于改性后生物炭抑制As5+向As3+的还原,进而降低土壤中As的活动性。梁欣冉等[110]对水稻秸秆生物炭进行锰改性,探究其对Cd-As复合污染土壤的修复效率,结果表明,添加3%改性生物炭使土壤Cd和As的毒性淋溶(TCLP)提取态分别降低75.5%~84.2%和43.3%~49.9%,通过降低酸溶态和可还原态Cd和As含量,增加残渣态Cd和As含量使其钝化。Li等[111]以小麦秸秆为原料制备生物炭并用有机气凝胶进行改性,研究其对铅锌尾矿中多种重金属的钝化效率,发现改性后生物炭pH提高,对Cd2+、Pb2+和Zn2+的吸附率较未改性生物炭提高124%、83.3%和109%。综上,生物炭改性后可提高其pH、比表面积和孔隙体积等进而提高生物炭对重金属的吸附效率。

3.4 重金属种类

秸秆生物炭对Cd、Pb和Cu等重金属污染土壤具有较好的吸附钝化效果。张华纬等[112]采集矿区周边土壤,以400 ℃制备水稻秸秆生物炭作为修复剂,探究其对Cd污染土壤中有效态Cd(二乙基三胺五乙酸提取态Cd,DTPA-Cd)含量的影响,发现添加3%水稻秸秆生物炭10 d后土壤中DTPA-Cd含量降低17.5%并达到平衡,然而,由于土壤Cd总量(31.8 mg·kg-1)和DTPA-Cd含量(25.1 mg·kg-1)较高,虽通过生物炭可固定土壤Cd,使玉米地上部Cd含量降低60.6%,但其含量(22.5 mg·kg-1)仍高于食品安全标准限值(0.1 mg·kg-1),因此,对于重金属含量严重超标的土壤,可通过生物炭与其他技术联用以保障土壤的种植安全和农作物的食品安全。Wang等[113]研究不同生物炭对Cu的吸附效果,发现水稻秸秆生物炭对土壤中Cu的吸附效率最高,施用量为100 g·kg-1时使毛竹根系对Cu的吸收降低35%,显著高于核桃壳等农业废弃物生物炭,表明秸秆生物炭相比其他农林废弃物生物炭具有更好的重金属吸附效果。谢亚萍等[114]研究水稻生物炭与肥料配施对Cr的钝化效果发现,生物炭与氮磷钾复合肥配施后,使土壤Cr有效性降低,并使水稻根系对Cr的富集系数降低68.8%,表明生物炭联合其他技术共同修复重金属污染土壤可使修复效率进一步提高。Ali等[115]研究水稻秸秆生物炭对Ni的吸附效率,发现Ni的可交换态随生物炭施用量增加(由1%增至2%)而降低(由70.9%降至59%),促进Ni与Fe/Mn和碳酸盐结合,形成难溶性稳定复合物,降低Ni在土壤中的活动性和迁移性,可见生物炭修复重金属污染土壤效率随施用量增加而提高。

此外,重金属污染土壤一般为多金属复合污染[116],生物炭通过对多种重金属的吸附、离子交换和氧化还原等,使重金属形成沉淀以降低其迁移性[117]。周雷等[118]以水稻秸秆生物炭为土壤吸附/钝化剂研究其修复Cd-Pb复合污染土壤效果,通过元素分析和FTIR等方法分析得出,添加生物炭后,土壤中Cd和Pb有效态和酸溶态含量显著降低(47.6 mg·kg-1 vs. 20.4 mg·kg-1,32.9 mg·kg-1 vs. 15.4 mg·kg-1;89.5 mg·kg-1 vs. 22.73 mg·kg-1,36.6 mg·kg-1 vs. 9.47 mg·kg-1)。同时,Cd和Pb残渣态含量提高(2.62 mg·kg-1 vs. 18.7 mg·kg-1,10.3 mg·kg-1 vs. 49.3 mg·kg-1),使土壤中Cd和Pb固化稳定化,表明生物炭可通过络合沉淀作用修复Cd-Pb复合污染土壤。综上,生物炭对重金属污染土壤的修复包括物理吸附、络合和沉淀等多种机制共同作用,且受重金属种类和含量的影响。

3.5 田间管理方式

生物炭对重金属的钝化效率易受水分条件等的影响,淹水和干旱过程导致土壤氧化还原反应呈周期性交替变化,影响土壤pH值、有机质含量和矿物转化,进而影响重金属的形态分布[126]。水分条件和生物炭的协同效应与土壤理化性质及生物炭对重金属的吸附能力高度相关。例如,李富荣等[127]研究水作和旱作栽培方式下,水稻秸秆生物炭对土壤中有效态Cd和Pb含量的影响,发现施用6 g·kg-1生物炭后水作和旱作土壤pH值分别提高0.3和0.1,有机质含量提高68.9%和45.9%,从而使水作和旱作土壤中有效态Cd、Pb含量分别降低7.05%、6.4%和6.55%、6.2%,表明施用生物炭对水作条件下土壤中Cd和Pb的钝化效率更高。汤家庆等[128]研究淹水和干湿交替条件下水稻秸秆生物炭对Cd-Pb复合污染钝化效率的影响,发现施用1%水稻秸秆生物炭后,淹水和干湿交替条件下土壤pH值分别提高1.09和1.04,可溶性有机碳分别提高19.8%和31.5%,淹水和干湿交替条件下毒性淋溶(TCLP)提取态Cd、Pb含量分别降低25.4%、31.9%和16.1%、20.3%,表明生物炭可通过提高土壤pH值和可溶性有机碳实现Pb和Cd的有效钝化,且对淹水条件下Cd、Pb钝化效率更高。因此,生物炭对重金属污染土壤的修复效率受田间管理方式的影响,且在淹水条件下对重金属的钝化效率较高。

4 结论与展望(Conclusions and prospects)

由于经济性和原料丰富易得,秸秆被广泛用作生物炭制备原料。本文基于秸秆生物炭原料类型的选择、制备技术和改性方法,总结了生物炭修复重金属污染土壤的机制及其实际应用效率与影响因素。分析得出:利用慢速热裂解制备秸秆生物炭可安全有效吸附土壤重金属;秸秆生物炭吸附重金属效率随制备温度升高而提高,但温度过高可抑制其吸附性能;秸秆生物炭改性后可进一步提高其吸附性能;秸秆生物炭主要通过络合和沉淀作用吸附固定重金属,该过程受其表面官能团种类和含量影响。

虽然秸秆生物炭在重金属污染土壤治理方面具有良好的应用前景,但目前研究仍存在一定局限性。为提高秸秆生物炭修复重金属污染土壤效率,未来可加强以下方面研究:(1)目前研究大多停留在生物炭修复单种重金属污染土壤,对复合重金属污染土壤修复效率及是否受共存元素(其他重金属和无机盐离子)影响有待深究;(2)秸秆生物炭具有多环芳烃、Pb和As等有毒有害物质,施加后生物炭与土壤难以分离,随土壤环境变化和时间延长,其本身含有的毒害物质和吸附固定的重金属是否会释放到环境中,即是否会产生二次释放及影响二次释放的关键环境因子值得研究;(3)秸秆生物炭多用来修复酸性和中性污染土壤,修复碱性污染土壤研究较少,因此需加深秸秆生物炭修复碱性污染土壤的作用机理及效率的研究。

[1] Wang J A, Wang R. The physical and chemical properties of soil crust in straw checkerboards with different ages in the Mu Us Sandland, northern China [J]. Sustainability, 2019, 11(17): 4755-4764

[2] Cui S F, Fu Y Z, Zhou B Q, et al. Transfer characteristic of fluorine from atmospheric dry deposition, fertilizers, pesticides, and phosphogypsum into soil [J]. Chemosphere, 2021, 278: 130432

[3] Clemens S, Ma J F. Toxic heavy metal and metalloid accumulation in crop plants and foods [J]. Annual Review of Plant Biology, 2016, 67: 489-512

[4] 中华人民共和国国务院. 国务院关于印发土壤污染防治行动计划的通知[EB/OL]. (2016-05-31) [2023-04-12]. http://www.gov.cn/zhengce/content/2016-05/31/content_5078377.htm

[5] 李方方. 土壤重金属污染现状分析及防治对策[J]. 河南农业, 2017(19): 29

[6] He L Z, Zhong H, Liu G X, et al. Remediation of heavy metal contaminated soils by biochar: Mechanisms, potentialrisks and applications in China [J]. Environmental Pollution, 2019, 252: 846-855

[7] Yi Y Q, Huang Z X, Lu B Z, et al. Magnetic biochar for environmental remediation: A review [J]. Bioresource Technology, 2020, 298: 122468

[8] Mansoor S, Kour N, Manhas S, et al. Biochar as a tool for effective management of drought and heavy metal toxicity [J]. Chemosphere, 2021, 271: 129458

[9] Wang H, Tang Y H. Research progress of biochar materials for remediation of heavy metal contaminated soil [J]. Journal of Physics: Conference Series, 2020, 1676(1): 012081

[10] Islam M S, Kwak J H, Nzediegwu C, et al. Biochar heavy metal removal in aqueous solution depends on feedstock type and pyrolysis purging gas [J]. Environmental Pollution, 2021, 281: 117094

[11] Shen Z T, Hou D Y, Jin F, et al. Effect of production temperature on lead removal mechanisms by rice straw biochars [J]. The Science of the Total Environment, 2019, 655: 751-758

[12] An Q, Jiang Y Q, Nan H Y, et al. Unraveling sorption of nickel from aqueous solution by KMnO4 and KOH-modified peanut shell biochar: Implicit mechanism [J]. Chemosphere, 2019, 214: 846-854

[13] Tang S Q, Shao N N, Zheng C M, et al. Amino-functionalized sewage sludge-derived biochar as sustainable efficient adsorbent for Cu(Ⅱ) removal [J]. Waste Management, 2019, 90: 17-28

[14] Bandara T, Xu J M, Potter I D, et al. Mechanisms for the removal of Cd(Ⅱ) and Cu(Ⅱ) from aqueous solution and mine water by biochars derived from agricultural wastes [J]. Chemosphere, 2020, 254: 126745

[15] Wang Z Z, Xu J, Yellezuome D, et al. Effects of cotton straw-derived biochar under different pyrolysis conditions on Pb (Ⅱ) adsorption properties in aqueous solutions [J]. Journal of Analytical and Applied Pyrolysis, 2021, 157: 105214

[16] Fan S C, Sun Y, Yang T H, et al. Biochar derived from corn stalk and polyethylene co-pyrolysis: Characterization and Pb(Ⅱ) removal potential [J]. RSC Advances, 2020, 10(11): 6362-6376

[17] Zhang W W, Du W H, Wang F, et al. Comparative study on Pb2+ removal from aqueous solutions using biochars derived from cow manure and its vermicompost [J]. The Science of the Total Environment, 2020, 716: 137108

[18] Cao Y Y, Shen G H, Zhang Y, et al. Impacts of carbonization temperature on the Pb(Ⅱ) adsorption by wheat straw-derived biochar and related mechanism [J]. The Science of the Total Environment, 2019, 692: 479-489

[19] Yang Q, Cui P X, Liu C, et al. In situ stabilization of the adsorbed Co2+ and Ni2+ in rice straw biochar based on LDH and its reutilization in the activation of peroxymonosulfate [J]. Journal of Hazardous Materials, 2021, 416: 126215

[20] 戴静, 刘阳生. 四种原料热解产生的生物炭对Pb2+和Cd2+的吸附特性研究[J]. 北京大学学报(自然科学版), 2013, 49(6): 1075-1082

Dai J, Liu Y S. Adsorption of Pb2+ and Cd2+ onto biochars derived from pyrolysis of four kinds of biomasses [J]. Acta Scientiarum Naturalium Universitatis Pekinensis, 2013, 49(6): 1075-1082 (in Chinese)

[21] 杨传文, 邢帆, 朱建春, 等. 中国秸秆资源的时空分布、利用现状与碳减排潜力[J]. 环境科学, 2023, 44(2): 1149-1162

Yang C W, Xing F, Zhu J C, et al. Temporal and spatial distribution, utilization status, and carbon emission reduction potential of straw resources in China [J]. Environmental Science, 2023, 44(2): 1149-1162 (in Chinese)

[22] 邹凡, 何春霞, 张杨燕, 等. 五种作物秸秆生物炭对重金属Pb2+的吸附性的比较[J]. 材料科学与工程学报, 2018, 36(6): 993-997, 1009

Zou F, He C X, Zhang Y Y, et al. Adsorbability comparison of some crop straw biochar to heavy metal Pb2+ [J]. Journal of Materials Science and Engineering, 2018, 36(6): 993-997, 1009 (in Chinese)

[23] Nzediegwu C, Arshad M, Ulah A, et al. Fuel, thermal and surface properties of microwave-pyrolyzed biochars depend on feedstock type and pyrolysis temperature [J]. Bioresource Technology, 2021, 320(Pt A): 124282-124312

[24] 张向前, 侯国军, 张玉虎, 等. 不同产地水稻秸秆制备生物炭结构特征及其理化性质[J]. 环境工程, 2017, 35(9): 122-126

Zhang X Q, Hou G J, Zhang Y H, et al. Structural andphysico-chemical properties of biochars prepared from different rice straw [J]. Environmental Engineering, 2017, 35(9): 122-126 (in Chinese)

[25] 叶协锋, 于晓娜, 周涵君, 等. 不同秸秆生物炭的孔隙结构及其差异[J]. 生物质化学工程, 2019, 53(2): 41-46

Ye X F, Yu X N, Zhou H J, et al. Pore structure and fractal characteristics of biochars from different straw [J]. Biomass Chemical Engineering, 2019, 53(2): 41-46 (in Chinese)

[26] 王昱璇, 王红, 卢平. 生物炭对重金属(Zn)的吸附特性及动力学[J]. 化工进展, 2019, 38(11): 5142-5150

Wang Y X, Wang H, Lu P.Adsorption and kinetics of heavy metal (Zn) over biochars in solution [J]. Chemical Industry and Engineering Progress, 2019, 38(11): 5142-5150 (in Chinese)

[27] 邢莉彬, 成洁, 耿增超, 等. 不同原料生物炭的理化特性及其作炭基肥缓释载体的潜力评价[J]. 环境科学, 2022, 43(5): 2770-2778

Xing L B, Cheng J, Geng Z C, et al. Physicochemical properties of biochars prepared from different feedstocks and evaluation of its potential as a slow-release carriers for biochar-based fertilizers [J]. Environmental Science, 2022, 43(5): 2770-2778 (in Chinese)

[28] 徐亮, 于晓娜, 李雪利, 等. 不同热解温度制备的烟秆生物炭理化特征分析[J]. 土壤通报, 2021, 52(1): 75-81

Xu L, Yu X N, Li X L, et al. Physico-chemical characteristics of biochars prepared by pyrolysis of tobacco-stalk under different temperatures [J]. Chinese Journal of Soil Science, 2021, 52(1): 75-81 (in Chinese)

[29] 闫郑方, 张嵚, 余鑫, 等. 秸秆生物炭的特性及其在重金属污染农田中的应用[J]. 湖南师范大学自然科学学报, 2023, 46(1): 38-47

Yan Z F, Zhang Q, Yu X, et al. Characteristics of straw biochar and its application in heavy metal-contaminated farmland [J]. Journal of Natural Science of Hunan Normal University, 2023, 46(1): 38-47 (in Chinese)

[30] Qiu B B, Tao X D, Wang H, et al. Biochar as a low-cost adsorbent for aqueous heavy metal removal: A review [J]. Journal of Analytical and Applied Pyrolysis, 2021, 155: 105081

[31] Li S H, Yao Y, Zhao T, et al. Biochars preparation from waste sludge and composts under different carbonization conditions and their Pb(Ⅱ) adsorption behaviors [J]. Water Science and Technology: A Journal of the International Association on Water Pollution Research, 2019, 80(6): 1063-1075

[32] Tan X F, Liu Y G, Zeng G M, et al. Application of biochar for the removal of pollutants from aqueous solutions [J]. Chemosphere, 2015, 125: 70-85

[33] 王雅君, 李姗珊, 姚宗路, 等. 生物炭生产工艺与还田效果研究进展[J]. 现代化工, 2017, 37(5): 17-20

Wang Y J, Li S S, Yao Z L, et al. Study advances regarding production technology of biochar and effects of its returning to field [J]. Modern Chemical Industry, 2017, 37(5): 17-20 (in Chinese)

[34] Ding W C, Dong X L, Ime I M, et al. Pyrolytic temperatures impact lead sorption mechanisms by bagasse biochars [J]. Chemosphere, 2014, 105: 68-74

[35] Meng J, He T Y, Sanganyado E, et al. Development of the straw biochar returning concept in China [J]. Biochar, 2019, 1(2): 139-149

[36] Al Arni S. Comparison of slow and fast pyrolysis for converting biomass into fuel [J]. Renewable Energy, 2018, 124: 197-201

[37] Gallifuoco A. A new approach to kinetic modeling of biomass hydrothermal carbonization [J]. ACS Sustainable Chemistry &Engineering, 2019, 7(15): 13073-13080

[38] He Q, Ding L, Raheem A, et al. Kinetics comparison and insight into structure-performance correlation for leached biochar gasification [J]. Chemical Engineering Journal, 2021, 417: 129331

[39] Nartey O D, Zhao B W. Biochar preparation, characterization, and adsorptive capacity and its effect on bioavailability of contaminants: An overview [J]. Advances in Materials Science and Engineering, 2014, 2014: 1-12

[40] Wang R Z, Huang D L, Liu Y G, et al. Recent advances in biochar-based catalysts: Properties,applications and mechanisms for pollution remediation [J]. Chemical Engineering Journal, 2019, 371: 380-403

[41] Cheng N, Wang B, Wu P, et al. Adsorption of emerging contaminants from water and wastewater by modified biochar: A review [J]. Environmental Pollution, 2021, 273: 116448

[42] Zhang P, Xue B, Jiao L, et al. Preparation of ball-milled phosphorus-loaded biochar and its highly effective remediation for Cd- and Pb-contaminated alkaline soil [J]. The Science of the Total Environment, 2022, 813: 152648

[43] Peng Z Y, Liu X M, Chen H K, et al. Characterization of ultraviolet-modified biochar from different feedstocks for enhanced removal of hexavalent chromium from water [J]. Water Science and Technology: A Journal of the International Association on Water Pollution Research, 2019, 79(9): 1705-1716

[44] Hu J T, Zhou X, Shi Y X, et al. Enhancing biochar sorption properties through self-templating strategy and ultrasonic fore-modified pre-treatment: Characteristic, kinetic and mechanism studies [J]. The Science of the Total Environment, 2021, 769: 144574

[45] Sakhiya A K, Baghel P, Anand A, et al. A comparative study of physical and chemical activation of rice straw derived biochar to enhance Zn2+ adsorption [J]. Bioresource Technology Reports, 2021, 15: 100774

[46] Mohanty P, Nanda S, Pant K K, et al. Evaluation of the physiochemical development of biochars obtained from pyrolysis of wheat straw, timothy grass and pinewood: Effects of heating rate [J]. Journal of Analytical and Applied Pyrolysis, 2013, 104: 485-493

[47] Choi Y K, Kan E. Effects of pyrolysis temperature on the physicochemical properties of alfalfa-derived biochar for the adsorption of bisphenol A and sulfamethoxazole in water [J]. Chemosphere, 2019, 218: 741-748

[48] Mahdi Z, ElHanandeh A, Yu Q M. Influence of pyrolysis conditions on surface characteristics and methylene blue adsorption of biochar derived from date seed biomass [J]. Waste and Biomass Valorization, 2017, 8(6): 2061-2073

[49] Ye X, Yu X, Zhou H, et al. Pore structure and fractal characteristics of biochars from different straw [J]. Biomass Chemical Engineering, 2019, 53(2): 41-46

[50] Yang K, Jiang Y, Yang J J, et al. Correlations and adsorption mechanisms of aromatic compounds on biochars produced from various biomass at 700℃ [J]. Environmental Pollution, 2018, 233: 64-70

[51] Gale M, Nguyen T, Moreno M, et al. Physiochemical properties of biochar and activated carbon from biomass residue: Influence of process conditions to adsorbent properties [J]. ACS Omega, 2021, 6(15): 10224-10233

[52] Qian K Z, Kumar A, Zhang H L, et al. Recent advances in utilization of biochar [J]. Renewable and Sustainable Energy Reviews, 2015, 42: 1055-1064

[53] Hossain N, Nizamuddin S, Griffin G, et al. Synthesis and characterization of rice husk biochar via hydrothermal carbonization for wastewater treatment and biofuel production [J]. Scientific Reports, 2020, 10(1): 18851

[54] Masoumi S, Borugadda V B, Nanda S, et al. Hydrochar: A review on its production technologies and applications [J]. Catalysts, 2021, 11(8): 939

[55] Schulzke T. Biomass gasification: Conversion of forest residues into heat, electricity and base chemicals [J]. Chemical Papers, 2019, 73(8): 1833-1852

[56] Hansen V, Müller-Stöver D, Munkholm L J, et al. The effect of straw and wood gasification biochar on carbon sequestration, selected soil fertility indicators and functional groups in soil: An incubation study [J]. Geoderma, 2016, 269: 99-107

[57] Din Z, Zainal Z A. Biomass integrated gasification-SOFC systems: Technology overview [J]. Renewable and Sustainable Energy Reviews, 2016, 53: 1356-1376

[58] Sansaniwal S K, Pal K, Rosen M A, et al. Recent advances in the development of biomass gasification technology: A comprehensive review [J]. Renewable and Sustainable Energy Reviews, 2017, 72: 363-384

[59] Molino A, Chianese S, Musmarra D. Biomass gasification technology: The state of the art overview [J]. Journal of Energy Chemistry, 2016, 25(1): 10-25

[60] Yu Y, Yu J Q, Sun B, et al. Influence of catalyst types on the microwave-induced pyrolysis of sewage sludge [J]. Journal of Analytical and Applied Pyrolysis, 2014, 106: 86-91

[61] AlShra’ah A, Helleur R. Microwave pyrolysis of cellulose at low temperature [J]. Journal of Analytical and Applied Pyrolysis, 2014, 105: 91-99

[62] Haeldermans T, Claesen J, Maggen J, et al. Microwave assisted and conventional pyrolysis of MDF — Characterization of the produced biochars [J]. Journal of Analytical and Applied Pyrolysis, 2019, 138: 218-230

[63] Wahi R, Zuhaidi N F Q, Yusof Y, et al. Chemically treated microwave-derived biochar: An overview [J]. Biomass and Bioenergy, 2017, 107: 411-421

[64] Shen Y F, Zhou Y W, Fu Y H, et al. Activated carbons synthesized from unaltered and pelletized biomass wastes for bio-tar adsorption in different phases [J]. Renewable Energy, 2020, 146: 1700-1709

[65] Liatsou I, Pashalidis I, Dosche C. Cu(Ⅱ) adsorption on 2-thiouracil-modified Luffa cylindrica biochar fibres from artificial and real samples, and competition reactions with U(Ⅵ) [J]. Journal of Hazardous Materials, 2020, 383: 120950

[66] Yang D, Zhang J W, Yang S Y, et al. Biochar-supported nanoscale zero-valent iron can simultaneously decrease cadmium and arsenic uptake by rice grains in co-contaminated soil [J]. The Science of the Total Environment, 2022, 814: 152798

[67] Li M, Li M M, Tan W, et al. Effects of ball-milling treatment on physicochemical and foaming activities of egg ovalbumin [J]. Journal of Food Engineering, 2019, 261: 158-164

[68] Peng Z Y, Zhao H, Lyu H H, et al. UV modification of biochar for enhanced hexavalent chromium removal from aqueous solution [J]. Environmental Science and Pollution Research International, 2018, 25(11): 10808-10819

[69] Meng F B, Wang D H, Zhang M. Effect of ultrasonic vibration-assisted pelleting of biomass on biochar properties [J]. Journal of Cleaner Production, 2021, 279: 123900

[70] Wang R Z, Huang D L, Liu Y G, et al. Synergistic removal of copper and tetracycline from aqueous solution by steam-activated bamboo-derived biochar [J]. Journal of Hazardous Materials, 2020, 384: 121470

[71] Liu H K, Xu F, Xie Y L, et al. Effect of modified coconut shell biochar on availability of heavy metals and biochemical characteristics of soil in multiple heavy metals contaminated soil [J]. The Science of the Total Environment, 2018, 645: 702-709

[72] Wang Y, Liu R H. H2O2 treatment enhanced the heavy metals removal by manure biochar in aqueous solutions [J]. Science of the Total Environment, 2018, 628-629: 1139-1148

[73] Fang L, Li J S, Donatello S, et al. Use of Mg/Ca modified biochars to take up phosphorus fromacid-extract of incinerated sewage sludge ash (ISSA) for fertilizer application [J]. Journal of Cleaner Production, 2020, 244: 118853

[74] Luo H Q, Zhang Y K, Xie Y, et al. Iron-rich microorganism-enabled synthesis of magnetic biocarbon for efficient adsorption of diclofenac from aqueous solution [J]. Bioresource Technology, 2019, 282: 310-317

[75] Tu C, Wei J, Guan F, et al. Biochar and bacteria inoculated biochar enhanced Cd and Cu immobilization and enzymatic activity in a polluted soil [J]. Environment International, 2020, 137: 105576

[76] Gong H B, Zhao L, Rui X, et al. A review of pristine and modified biochar immobilizing typical heavy metals in soil: Applications and challenges [J]. Journal of Hazardous Materials, 2022, 432: 128668

[77] Li H B, Dong X L, da Silva E B, et al. Mechanisms of metal sorption by biochars: Biochar characteristics and modifications [J]. Chemosphere, 2017, 178: 466-478

[78] Tong X J, Li J Y, Yuan J H, et al. Adsorption of Cu(Ⅱ) by biochars generated from three crop straws [J]. Chemical Engineering Journal, 2011, 172(2-3): 828-834

[79] Wang M M, Zhu Y, Cheng L R, et al. Review on utilization of biochar for metal-contaminated soil and sediment remediation [J]. Journal of Environmental Sciences (China), 2018, 63: 156-173

[80] Gul S, Whalen J K, Thomas B W, et al. Physico-chemical properties and microbial responses in biochar-amended soils: Mechanisms and future directions [J]. Agriculture, Ecosystems &Environment, 2015, 206: 46-59

[81] Dong H R, Deng J M, Xie Y K, et al. Stabilization of nanoscale zero-valent iron (nZVI) with modified biochar for Cr(Ⅵ) removal from aqueous solution [J]. Journal of Hazardous Materials, 2017, 332: 79-86

[82] Ahmad M, Ok Y S, Kim B Y, et al. Impact of soybean stover- and pine needle-derived biochars on Pb and As mobility, microbial community, and carbon stability in a contaminated agricultural soil [J]. Journal of Environmental Management, 2016, 166: 131-139

[83] Li M, Lou Z J, Wang Y, et al. Alkali and alkaline earth metallic (AAEM) species leaching and Cu(Ⅱ) sorption by biochar [J]. Chemosphere, 2015, 119: 778-785

[84] Zuo W Q, Chen C, Cui H J, et al. Enhanced removal of Cd(Ⅱ) from aqueous solution using CaCO3 nanoparticle modified sewage sludge biochar [J]. RSC Advances, 2017, 7(26): 16238-16243

[85] Xu X Y, Zhao Y H, Sima J K, et al. Indispensable role of biochar-inherent mineral constituents in its environmental applications: A review [J]. Bioresource Technology, 2017, 241: 887-899

[86] Fahmi A H, Samsuri A W, Jol H, et al. Bioavailability and leaching of Cd and Pb from contaminated soil amended with different sizes of biochar [J]. Royal Society Open Science, 2018, 5(11): 181328

[87] Cui Y F, Meng J, Wang Q X, et al. Effects of straw and biochar addition on soil nitrogen, carbon, and super rice yield in cold waterlogged paddy soils of North China [J]. Journal of Integrative Agriculture, 2017, 16(5): 1064-1074

[88] Medeiros D C C D S, Nzediegwu C, Benally C, et al. Pristine and engineered biochar for the removal of contaminants co-existing in several types of industrial wastewaters: A critical review [J]. The Science of the Total Environment, 2022, 809: 151120

[89] Zhang T, Zheng L C, Yu H J, et al. Multiple adsorption systems and electron-scale insights into the high efficiency coadsorption of a novel assembled cellulose via experiments and DFT calculations [J]. Journal of Hazardous Materials, 2021, 416: 125748

[90] Shi Y, Zhao Z Z, Zhong Y, et al. Synergistic effect of floatable hydroxyapatite-modified biochar adsorption and low-level CaCl2 leaching on Cd removal from paddy soil [J]. The Science of the Total Environment, 2022, 807(Pt 2): 150872

[91] Sui L, Tang C Y, Du Q, et al. Preparation and characterization of boron-doped corn straw biochar: Fe (Ⅱ) removal equilibrium and kinetics [J]. Journal of Environmental Sciences (China), 2021, 106: 116-123

[92] 韩鲁佳, 李彦霏, 刘贤, 等. 生物炭吸附水体中重金属机理与工艺研究进展[J]. 农业机械学报, 2017, 48(11): 1-11

Han L J, Li Y F, Liu X, et al. Review of biochar as adsorbent for aqueous heavy metal removal [J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(11): 1-11 (in Chinese)

[93] 王棋, 王斌伟, 谈广才, 等. 生物炭对Cu(Ⅱ)、Pb(Ⅱ)、Ni(Ⅱ)和Cd(Ⅱ)的单一及竞争吸附研究[J]. 北京大学学报(自然科学版), 2017, 53(6): 1122-1132

Wang Q, Wang B W, Tan G C, et al. Single and competitive adsorption of Cu(Ⅱ), Pb(Ⅱ), Ni(Ⅱ) and Cd(Ⅱ) onto biochar [J]. Acta Scientiarum Naturalium Universitatis Pekinensis, 2017, 53(6): 1122-1132 (in Chinese)

[94] Liu P, Ptacek C J, Elena K M A, et al. Evaluation of mercury stabilization mechanisms by sulfurized biochars determined using X-ray absorption spectroscopy [J]. Journal of Hazardous Materials, 2018, 347: 114-122

[95] Sui F F, Kang Y X, Wu H, et al. Effects of iron-modified biochar with S-rich and Si-rich feedstocks on Cd immobilization in the soil-rice system [J]. Ecotoxicology and Environmental Safety, 2021, 225: 112764

[96] 段靖禹, 李华, 马学文, 等. 青霉菌与生物炭复合修复土壤砷污染的研究[J]. 环境科学学报, 2019, 39(6): 1999-2005

Duan J Y, Li H, Ma X W, et al. Study on the remediation of arsenic pollution in soil by the combination of penicillium and biochar [J]. Acta Scientiae Circumstantiae, 2019, 39(6): 1999-2005 (in Chinese)

[97] Shen Z T, Hou D Y, Jin F, et al. Effect of production temperature on lead removal mechanisms by rice straw biochars [J]. The Science of the Total Environment, 2019, 655: 751-758

[98] Yin D X, Wang X, Chen C, et al. Varying effect of biochar on Cd, Pb and As mobility in a multi-metal contaminated paddy soil [J]. Chemosphere, 2016, 152: 196-206

[99] Tran H N, Nguyen D T, Le G T, et al. Adsorption mechanism of hexavalent chromium onto layered double hydroxides-based adsorbents: A systematic in-depth review [J]. Journal of Hazardous Materials, 2019, 373: 258-270

[100] Lyu P, Li L F, Huang X Y, et al. Pre-magnetic bamboo biochar cross-linked CaMgAl layered double-hydroxide composite: High-efficiency removal of As(III) and Cd(Ⅱ) from aqueous solutions and insight into the mechanism of simultaneous purification [J]. The Science of the Total Environment, 2022, 823: 153743

[101] 安增莉, 侯艳伟, 蔡超, 等. 水稻秸秆生物炭对Pb(Ⅱ)的吸附特性[J]. 环境化学, 2011, 30(11): 1851-1857

An Z L, Hou Y W, Cai C, et al. Lead(Ⅱ) adsorption characteristics on different biochars derived from rice straw [J]. Environmental Chemistry, 2011, 30(11): 1851-1857 (in Chinese)

[102] 梁程, 胡逸文, 嵇梦圆, 等. 稻草生物炭对土壤中Cd2+和Pb2+的吸附特性[J]. 环境科学研究, 2020, 33(6): 1539-1548

Liang C, Hu Y W, Ji M Y, et al. Adsorptive characteristics of rice straw biochar on composite heavy metals Cd2+ and Pb2+ in soil [J]. Research of Environmental Sciences, 2020, 33(6): 1539-1548 (in Chinese)

[103] 董丽佳, 吴思颖, 李生波, 等. 稻草生物炭对铕的吸附行为及机理研究[J]. 无机材料学报, 2020, 35(3): 390-398

Dong L J, Wu S Y, Li S B, et al. Sorption behaviors and mechanisms of Eu(Ⅲ) on rice straw-derived biochar [J]. Journal of Inorganic Materials, 2020, 35(3): 390-398 (in Chinese)

[104] 王莹莹, 张昀, 张广才, 等. 北方典型水稻土有机质及其组分演变特征[J]. 植物营养与肥料学报, 2019, 25(11): 1900-1908

Wang Y Y, Zhang Y, Zhang G C, et al. Evolutionary characteristics of organic matter and its components in typical paddy soils in Northern China [J]. Journal of Plant Nutrition and Fertilizers, 2019, 25(11): 1900-1908 (in Chinese)

[105] 王金贵. 我国典型农田土壤中重金属镉的吸附-解吸特征研究[D]. 杨凌: 西北农林科技大学, 2012: 24

Wang J G. Adsorption-desorption characteristics of cadmium in typical agricultural soils in China [D]. Yangling: Northwest A &F University, 2012: 24 (in Chinese)

[106] Wang Y M, Liu Q, Li M, et al. Rhizospheric pore-water content predicts the biochar-attenuated accumulation, translocation, and toxicity of cadmium to lettuce [J]. Ecotoxicology and Environmental Safety, 2021, 208: 111675

[107] 张家康, 庄雅玲, 张力文, 等. 水稻秸秆生物炭对3种土壤水溶态Cd动态变化的影响[J]. 福建农业学报, 2021, 36(2): 228-235

Zhang J K, Zhuang Y L, Zhang L W, et al. Effects of rice straw biochar on water-soluble Cd in three flooded different types of soil [J]. Fujian Journal of Agricultural Sciences, 2021, 36(2): 228-235 (in Chinese)

[108] Liu S C, Xie Z L, Zhu Y T, et al. Adsorption characteristics of modified rice straw biochar for Zn and in situ remediation of Zn contaminated soil [J]. Environmental Technology &Innovation, 2021, 22: 101388

[109] 何璇, 钱子妍, 吴川, 等. 铁改性生物炭对水稻土中砷/铁还原的影响[J]. 农业环境科学学报, 2022, 41(4): 755-764, 919

He X, Qian Z Y, Wu C, et al. Effects of iron-modified biochar on arsenic and iron reduction in paddy soil [J]. Journal of Agro-Environment Science, 2022, 41(4): 755-764, 919 (in Chinese)

[110] 梁欣冉, 郜紫依, 付庆灵, 等. 锰改性水稻秸秆生物炭对碱性土壤中砷-镉复合污染的钝化作用[J]. 湖南师范大学自然科学学报, 2022, 45(4): 93-100

Liang X R, Gao Z Y, Fu Q L, et al. Passivation of arsenic-cadmium combined pollution in alkaline soil by manganese-modified rice straw biochar [J]. Journal of Natural Science of Hunan Normal University, 2022, 45(4): 93-100 (in Chinese)

[111] Li J H, Xia C G, Cheng R, et al. Passivation of multiple heavy metals in lead-zinc tailings facilitated by straw biochar-loaded N-doped carbon aerogel nanoparticles: Mechanisms and microbial community evolution [J]. The Science of the Total Environment, 2022, 803: 149866

[112] 张华纬, 甄华杨, 岳士忠, 等. 水稻秸秆生物炭对污染土壤中镉生物有效性的影响[J]. 生态环境学报, 2017, 26(6): 1068-1074

Zhang H W, Zhen H Y, Yue S Z, et al. Bioavailability of Cd in contaminated soil after short-term application of rice straw biochar [J]. Ecology and Environmental Sciences, 2017, 26(6): 1068-1074 (in Chinese)

[113] Wang Y, Zhong B, Shafi M, et al. Effects of biochar on growth, and heavy metals accumulation of moso bamboo (Phyllostachy pubescens), soil physical properties, and heavy metals solubility in soil [J]. Chemosphere, 2019, 219: 510-516

[114] 谢亚萍, 张琳琳, 郅惠博, 等. 稻壳生物炭与肥料配施对稻田镉铅铬砷的钝化与肥效的影响[J]. 复旦学报(自然科学版), 2017, 56(2): 228-232, 240

Xie Y P, Zhang L L, Zhi H B, et al. The passivation of Pb, As, Cr, Cd and the effects of paddy after applying biochar combined with fertilizer [J]. Journal of Fudan University (Natural Science), 2017, 56(2): 228-232, 240 (in Chinese)

[115] Ali U, Shaaban M, Bashir S, et al. Rice straw, biochar and calcite incorporation enhance nickel (Ni) immobilization in contaminated soil and Ni removal capacity [J]. Chemosphere, 2020, 244: 125418

[116] Yu D Y, Wang J R, Wang Y H, et al. Identifying the source of heavy metal pollution and apportionment in agricultural soils impacted by different smelters in China by the positive matrix factorization model and the Pb isotope ratio method [J]. Sustainability, 2021, 13(12): 6526

[117] Kong S F, Tang J, Ouyang F, et al. Research on the treatment of heavy metal pollution in urban soilbased on biochar technology [J]. Environmental Technology &Innovation, 2021, 23: 101670

[118] 周雷, 嵇梦圆, 桑文静, 等. 稻草秸秆生物炭对土壤中重金属Cd和Pb的固化稳定化机制[J]. 化工环保, 2021, 41(5): 612-617

Zhou L, Ji M Y, Sang W J, et al. Solidification and stabilization mechanism of rice straw biochar to heavy metal Cd and Pb in soil [J]. Environmental Protection of Chemical Industry, 2021, 41(5): 612-617 (in Chinese)

[119] Yang X, Liu J J, McGrouther K, et al. Effect of biochar on the extractability of heavy metals (Cd, Cu, Pb, and Zn) and enzyme activity in soil [J]. Environmental Science and Pollution Research International, 2016, 23(2): 974-984

[120] Medyńska-Juraszek A, ![]() I, Jerzykiewicz M, et al. Wheat straw biochar as a specific sorbent of cobalt in soil [J]. Materials, 2020, 13(11): 2462

I, Jerzykiewicz M, et al. Wheat straw biochar as a specific sorbent of cobalt in soil [J]. Materials, 2020, 13(11): 2462

[121] 李述贤, 郑旭东, 龚建军, 等. 利用氯化锌和硫改性玉米秸秆生物炭稳定汞污染土壤[J]. 环境工程学报, 2021, 15(4): 1403-1408

Li S X, Zheng X D, Gong J J, et al. Preparation of zinc chloride and sulfur modified cornstalk biochar and its stabilization effect on mercury contaminated soil [J]. Chinese Journal of Environmental Engineering, 2021, 15(4): 1403-1408 (in Chinese)

[122] 张瑞钢, 钱家忠, 陈钰辉, 等. 玉米和小麦秸秆生物炭对土壤重金属污染修复实验研究[J]. 合肥工业大学学报(自然科学版), 2022, 45(3): 347-355

Zhang R G, Qian J Z, Chen Y H, et al. Experimental study on remediation effect of maize and wheat biochar on heavy metal contaminated soil [J]. Journal of Hefei University of Technology (Natural Science), 2022, 45(3): 347-355 (in Chinese)

[123] 曹永强, 荆延德, 申磊, 等. 生物炭与磷肥配施对棕壤中Cd形态及其有效性的影响[J]. 生态与农村环境学报, 2018, 34(10): 939-945

Cao Y Q, Jing Y D, Shen L, et al. Effect of the combined application of biochar and phosphorus fertilizer on forms and efficacy of Cd in brown soil [J]. Journal of Ecology and Rural Environment, 2018, 34(10): 939-945 (in Chinese)

[124] 杨艳征, 张银鸽, 李畅, 等. 微碱性土壤施用烟秆生物炭与磷酸盐降低小麦籽粒镉积累[J]. 环境科学, 2022, 43(12): 5769-5777

Yang Y Z, Zhang Y G, Li C, et al. Tobacco stem biochar and phosphate application decrease wheat grain cadmium accumulation in alkalescent soils [J]. Environmental Science, 2022, 43(12): 5769-5777 (in Chinese)

[125] 李海华, 丁贺, 王志琛, 等. 羟基磷灰石改性烟草秸秆生物炭钝化修复土壤镉、铜污染[J]. 华北水利水电大学学报(自然科学版), 2023, 44(3): 94-101

Li H H, Ding H, Wang Z C, et al. Passivation and repair of cadmium and copper contaminated soil by hydroxyapatite-modified tobacco straw biochar [J]. Journal of North China University of Water Resources and Electric Power (Natural Science Edition), 2023, 44(3): 94-101 (in Chinese)

[126] Wang Y Y, Liu Y D, Zhan W H, et al. Stabilization of heavy metal-contaminated soils by biochar: Challenges and recommendations [J]. The Science of the Total Environment, 2020, 729: 139060

[127] 李富荣, 李敏, 朱娜, 等. 水作和旱作施用改良剂对蕹菜-土壤系统中铅镉生物有效性的影响差异[J]. 农业环境科学学报, 2017, 36(8): 1477-1483

Li F R, Li M, Zhu N, et al. Comparing the effects of soil amendments on Pb and Cd bioavailability in water spinach under water submersion cultivation and dry farming conditions [J]. Journal of Agro-Environment Science, 2017, 36(8): 1477-1483 (in Chinese)

[128] 汤家庆, 张绪, 黄国勇, 等. 水分条件对生物炭钝化水稻土铅镉复合污染的影响[J]. 环境科学, 2021, 42(3): 1185-1190

Tang J Q, Zhang X, Huang G Y, et al. Effect of water regimes on Pb and Cd immobilization by biochar in contaminated paddy soil [J]. Environmental Science, 2021, 42(3): 1185-1190 (in Chinese)