-

我国城市给水厂每年所产生的污泥约为1.5×108 m3[1],其中含有大量的有机物、重金属以及致病菌和病原菌等,若不加处理任意排放,将成为危险的二次污染源,通过大气、地下水、地表水和土壤等介质进入食物链,造成严重的生态风险,影响人类健康[2]。作为给水厂的伴生产物,目前城市给水厂污泥有效资源转化率不足10%,且大多数采用卫生填埋、焚烧、土地利用[3]和投海等传统方法处理污泥,既不能有效利用可再用资源,又容易造成二次污染。给水厂污泥中不仅含有大量的铁盐、铝盐混凝剂成分,还含有活性炭组分[4],将给水厂污泥制成颗粒状吸附剂用于吸附除磷,可以降低给水厂污泥处置费用,同时污水除磷成本也大大低于化学除磷。给水厂污泥吸附除磷不会增加污泥量,不容易受出水SS、原水水质、脱氮条件等影响,去除率远高于传统生物除磷法。采用给水厂污泥吸附污水中的磷,变废为宝,还可以达到资源化利用的目的。

有关给水厂污泥吸附除磷的研究工作多采用静态吸附搅拌的方法[5-8],该方法用于实验室的实验研究是行之有效的,但难以在实际生产中推广使用。本研究以北京市某给水厂废弃污泥为原材料,制备成颗粒状吸附剂,并将其用于连续处理初沉池水的动态吸附实验中,为给水厂的污泥在实际生产中的应用提供参考。

全文HTML

-

试剂为磷酸二氢钾、抗坏血酸、钼酸铵、酒石酸锑氧钾、浓硫酸、氢氧化钠,均为分析纯,购自国药集团化学试剂有限公司。废弃铁铝泥取自北京市某大型给水厂,对该自来水厂的混凝剂投加种类和投加量等数据进行收集分析,该厂每天投加铝盐和铁盐2种混凝剂。本实验所用水均为北京某城市污水处理厂初沉池出水。

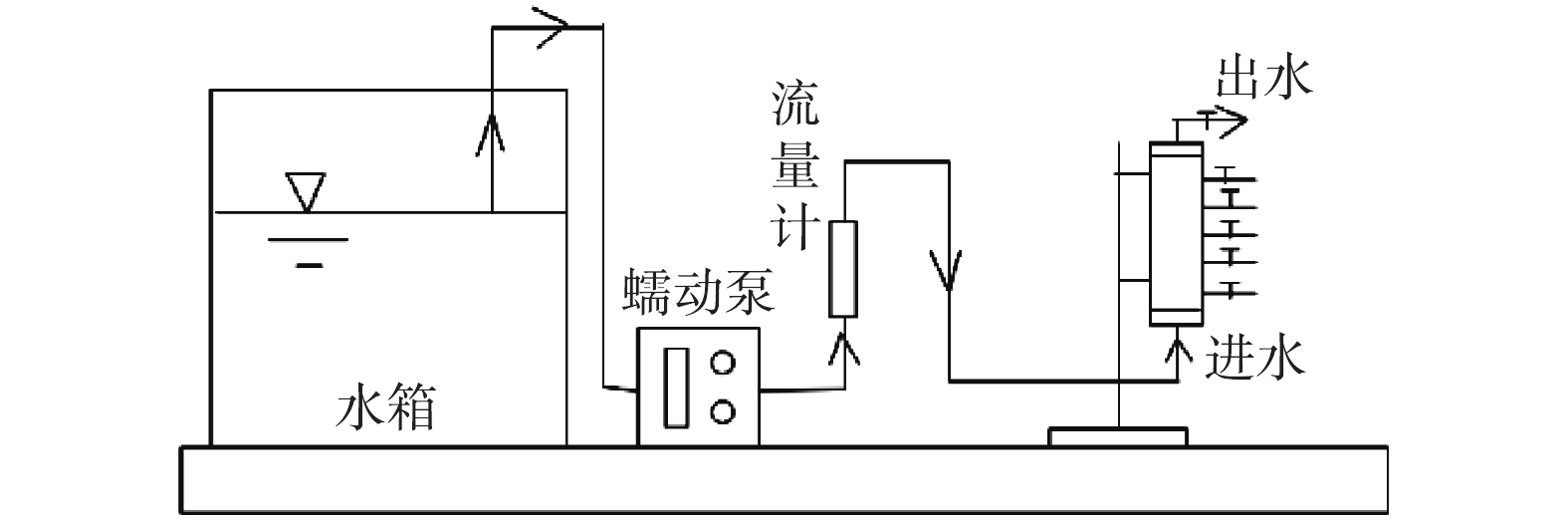

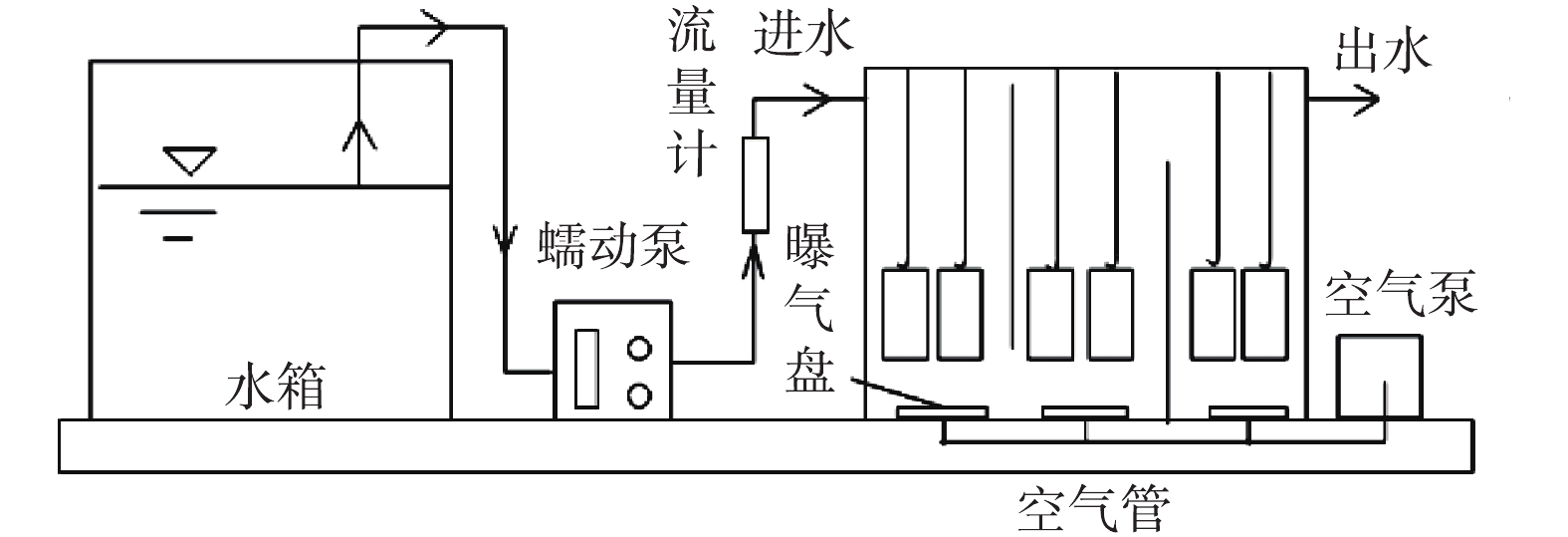

仪器包括紫外可见分光光度计、六联混凝搅拌器、恒温搅拌器、硬度测定仪等。动态吸附实验装置见图1和图2。2 mm动态吸附实验吸附装置如图1所示,长为0.94 m、宽为0.75 m、高为0.76 m,装置底部装有的曝气盘,可以向装置内部曝气,使得装置内部污水与2 mm颗粒吸附剂充分混合接触。污泥颗粒装入金属网袋中并用金属网钩均匀悬挂在装置内。小型固定床吸附柱装置如图2所示。柱身内径为4 cm,吸附剂装填高度为14.2 cm,采用上向流。

-

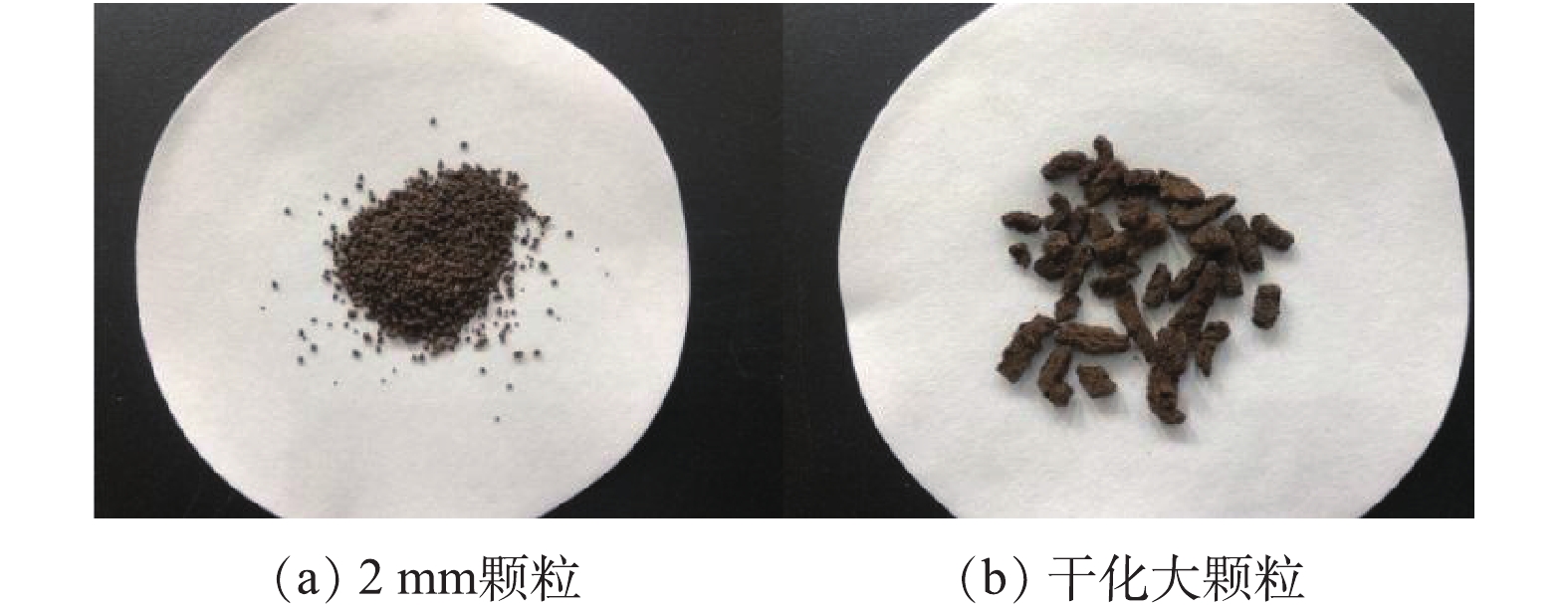

铁铝泥样品取回后,放置于室外平铺晾晒,使得污泥含水率由83%降至67%左右(污泥外表成团状)。一部分污泥用铁铲经人工碾碎,放入摇摆式造粒机中通过3 mm的孔径磨具挤出,置于室外自然风干,制成低硬度的粒径约为2 mm的小颗粒。另一部分污泥放入干化机中挤压造粒后,在干化机内部65 ℃干化1.5 h,成为含水率50%的大污泥颗粒,后再置于室外自然风干,制成长约为12 mm、直径约为7 mm的柱状高硬度干化大颗粒。

-

废弃铁铝泥中元素分析采用X射线荧光光谱分析法(XRF),检测依据是JY/T 016-1996中的波长色散型X射线荧光光谱法通则,仪器名称为X射线荧光光谱仪ZSX PrimusII。外表形貌的测定采用型号为S-3400N的扫描电子显微镜,将少量颗粒涂在导电胶上,固定在样品台上进行观察;采用ASAP2420比表面积及孔径分析仪,利用高纯氮气吸附介质测定吸附脱附等温线,采用BET法计算比表面积,采用t-plot计算微孔比表面积和微孔体积,总孔吸附平均直径根据总孔体积和比表面积计算得出;将制备的2种颗粒分别在去离子水中浸泡72 h后,先测定2种颗粒的脱落率,再用硬度测定仪分别检测浸泡前后2种颗粒的硬度。

-

向2个1 L烧杯中各加入1 L初沉池水,再分别加入10 g 2种不同粒径的颗粒,使用六联搅拌器以120 r·min−1的速度搅拌8 h,间隔2 h取一次水样,测定反应体系中各种形态的磷含量。分别考察了2 mm颗粒吸附剂和干化大颗粒吸附剂对初沉池污水中磷动态吸附的影响因素。

1)吸附剂投加量对出水磷浓度的影响。控制2 mm颗粒吸附剂投加量为10 g·L−1和20 g·L−1,将2 mm颗粒装入金属网袋中,并用金属网钩均匀悬挂在装置内,控制进水流量45 L·h−1,污水中空气曝气量7.2 m3·h−1,先开启进水泵,当装置满水并且有出水后,将装有2 mm颗粒吸附剂的金属网带悬挂放置于反应器内,同时开始计时。反应共计8 h,每间隔2 h,在出水口处取样测定出水中各种形态磷的含量。

2)吸附时间对出水磷浓度的影响。控制2 mm颗粒吸附剂投加量为20 g·L−1,将2 mm颗粒装入金属网袋中并用金属网钩均匀悬挂在装置内,控制进水流量为45 L·h−1,污水中空气曝气量为7.2 m3·h−1,先开启进水泵,当装置满水并且有出水后,将装有2 mm颗粒吸附剂的金属网带悬挂放置于反应器内,同时开始计时,反应时间为56 h,每间隔一段时间在出水口处取样,测定出水中各种形态磷的含量。

3)空床停留时间(EBCT)对出水磷浓度的影响。控制干化大颗粒滤柱的空床停留时间分别为5、10、20、30 min。分别测出不同停留时间下出水中各种形态磷的含量。

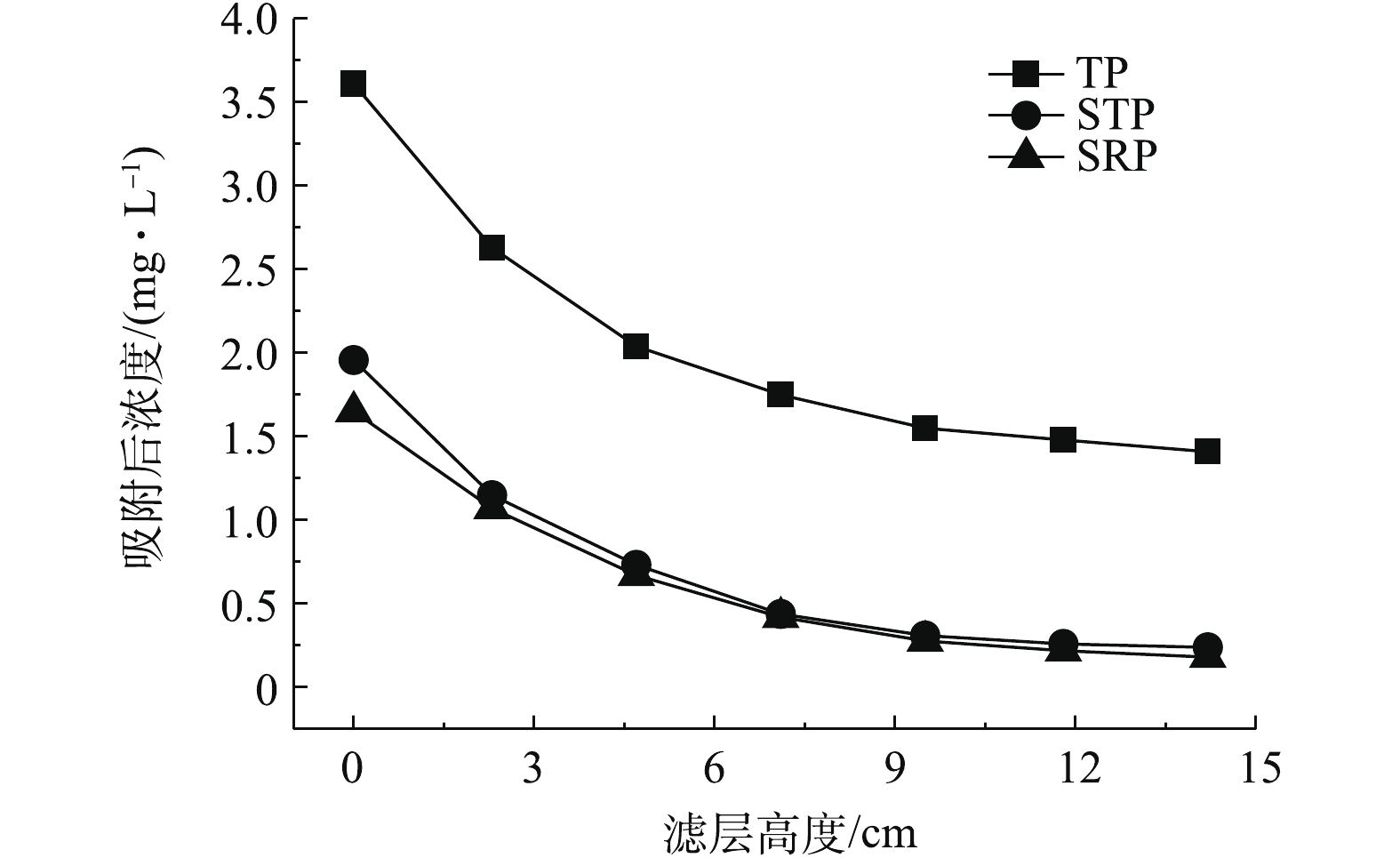

4)滤层高度对出水磷浓度的影响。控制干化大颗粒滤柱的空床停留时间为30 min,分别在不同滤层高度处(2.3、4.7、7.1、9.5、11.8、14.2 cm)检测出水中各种形态磷的含量。

5)吸附时间对出水磷浓度的影响。控制干化大颗粒滤柱的空床停留时间为30 min,滤层高度为14.2 cm。连续运行135 h,每间隔一段时间在出水口处取样,测定出水中各种形态磷的含量。

-

磷的测定采用钼锑抗分光光度法,根据不同的预处理方法将磷的形态分为总磷(total phosphorus,TP)、可溶性总磷(soluble total phosphorus,STP)、可溶性活性磷酸盐(soluble reactive phosphorus,SRP)、颗粒态磷(particulate phosphorus,PP)及其他溶解磷[9]。原水样直接消解测得TP含量;经0.45 μm滤膜过滤,消解测得STP含量;经0.45 μm滤膜过滤但不消解测得SRP含量;TP减去STP得PP;STP减去SRP得出其他溶解磷含量。

1.1. 试剂与仪器

1.2. 材料的制备

1.3. 给水厂颗粒污泥的表征

1.4. 吸附实验

1.5. 分析方法

-

废弃铁铝泥粉末XRF检测结果见表1。由表1可知,污泥粉末主要含有C、O、Al、Fe、Si、Ca等元素,质量分数分别为10.5%、51.9%、6.74%、15.9%、8.81%,主要物质应为SiO2、Al2O3、Fe2O3和CaO。检测结果与SONG等[10]的检测结果一致。由表1可知,废弃铁铝泥的性质与黏土性质相似,且该水厂Fe盐混凝剂投量高于Al盐混凝剂投量。

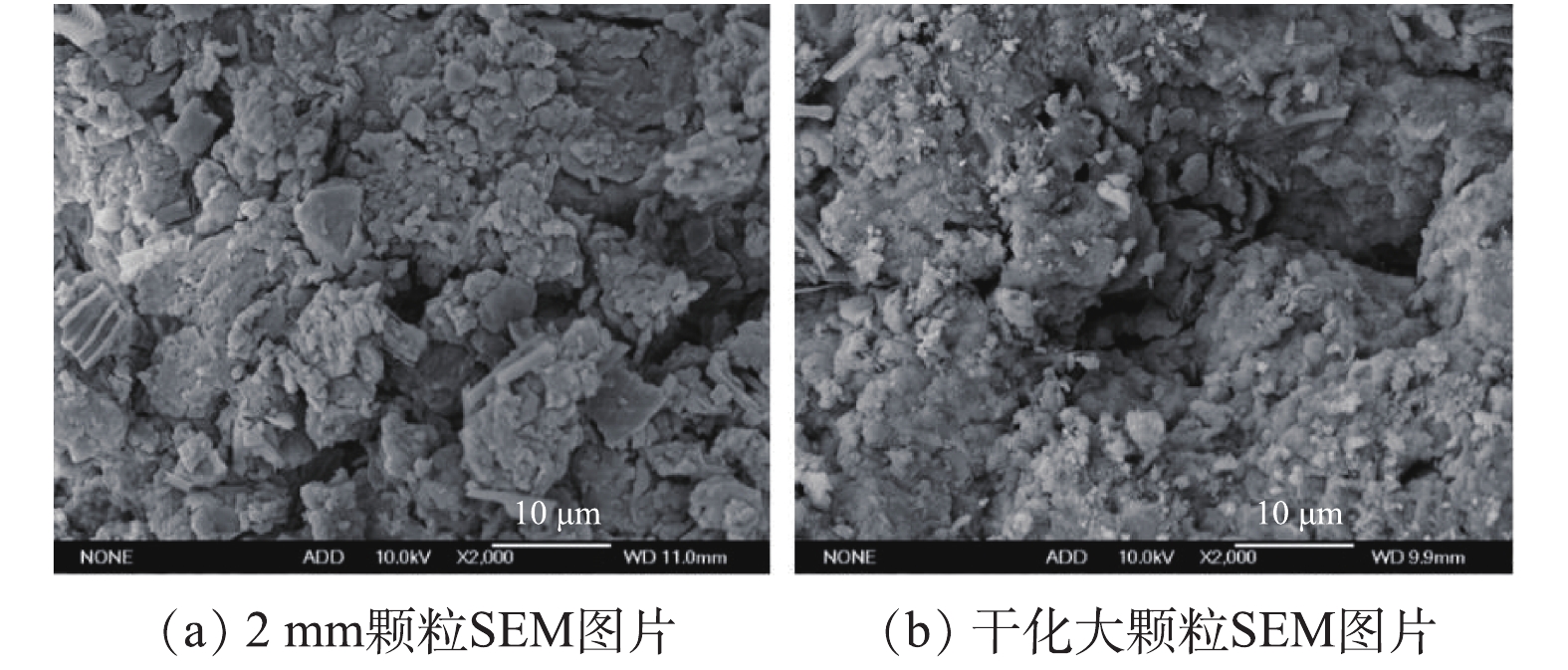

图3、图4和表2分别为2种颗粒的表面形貌、比表面积和孔隙结构表征结果。图3(a)和图3(b)分别为2 mm小颗粒和干化大颗粒的外观图。对比图4(a)和图4(b)可知,2种颗粒孔隙结构均较发达。由表1可知,干化大颗粒与2 mm小颗粒相比,比表面积和微孔体积分别减少了46.2%和33.6%,比表面积的降低是由于2种颗粒粒径相差较大,干化大颗粒比表面积远小于2 mm颗粒。微孔体积的减小推测可能是由于摇摆式造粒和干化机挤压造粒2种不同的造粒方式所致。由表1可知,干化大颗粒的优点在于具有较高的硬度,并且脱落率较低。2 mm颗粒在25 ℃、pH为7时的吸附容量为12.39 mg·g−1,高于干化大颗粒。综合考虑2种污泥颗粒的各项性能,将2 mm颗粒装入金属网袋中,且悬挂在图1所示装置内,再进行连续流动态吸附实验。金属网袋可以有效减少因水流冲刷作用造成的颗粒损失,并且当颗粒吸附达到饱和时方便及时更换。2 mm颗粒由于粒径过小且硬度同样较小,应用在滤柱装置内作为滤料可能会出现滤柱堵塞的情况发生,干化大颗粒粒径较大,硬度和脱落率较低,可有效降低滤柱堵塞的情况,因此,采用干化大颗粒作为滤柱滤料进行动态吸附除磷实验。

-

对北京市某污水处理厂的初沉池污水中磷的形态分布及其浓度水平进行了分析,采集不同时段的初沉池污水,进行不同形态磷的测定分析。结果表明,该厂初沉池出水中总磷浓度在4.0~6.8 mg·L−1,可溶性总磷浓度在3.1~5.4 mg·L−1,可溶性活性磷酸盐浓度在2.4~3.1 mg·L−1,可溶性非活性磷酸盐浓度在0.7~2.7 mg·L−1,颗粒态磷浓度在0.9~2.0 mg·L−1。各种形态磷含量的分布规律为可溶性总磷>可溶性活性磷酸盐>颗粒态磷>可溶性非活性磷酸盐。由于可溶性总磷和可溶性活性磷酸盐在初沉池出水中所占据的比重较大,因此,本研究将可溶性总磷和可溶性活性磷酸盐去除率作为衡量初沉池出水中磷去除效果优劣的标准。

-

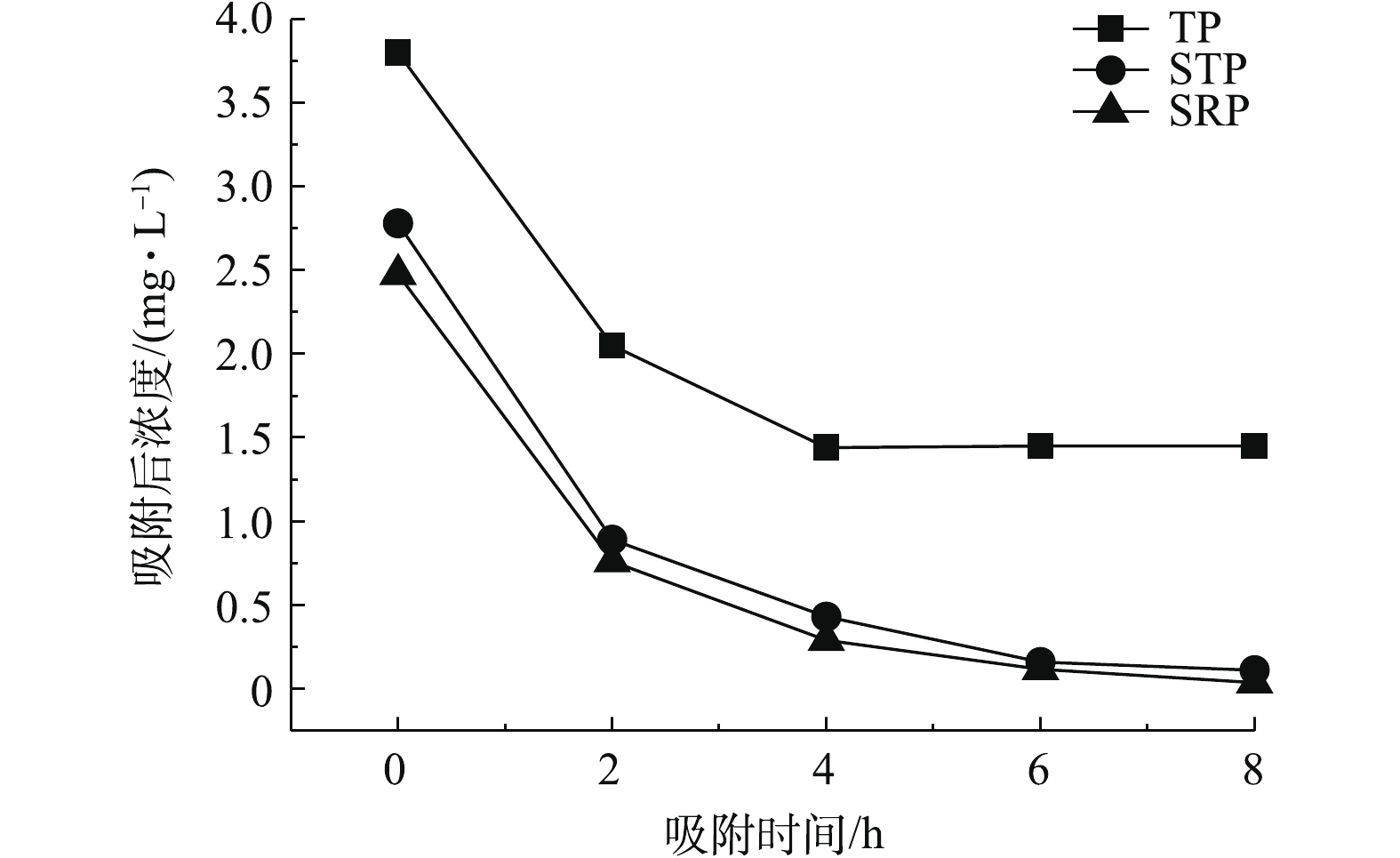

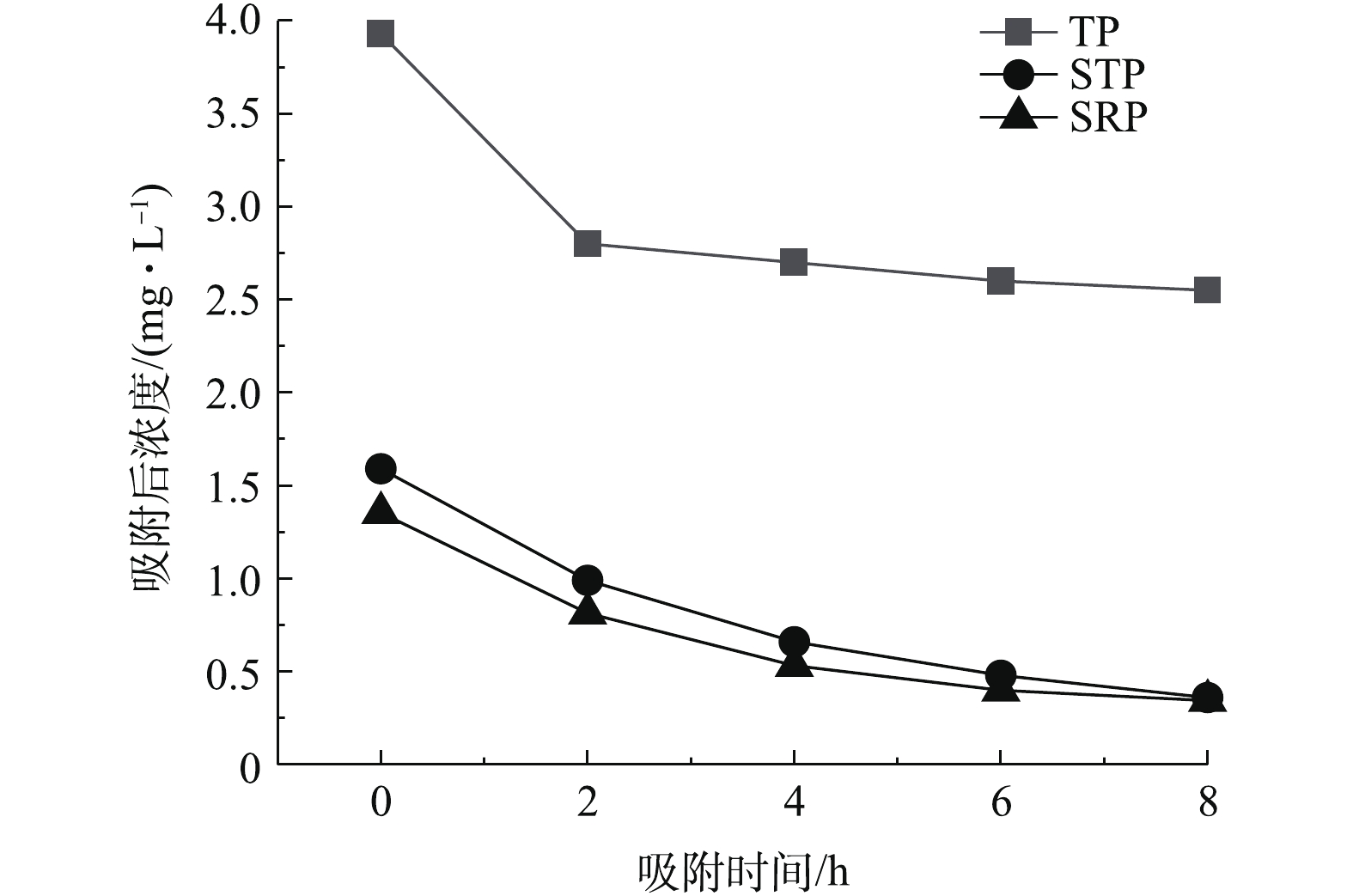

图5和图6分别为2种污泥颗粒对于初沉池中不同形态磷的去除效果。在前2 h内,污泥颗粒对水中各种形态磷的去除率均较高,8 h左右基本达到吸附平衡。通过对2种污泥颗粒对水中各种形态磷的吸附效果比较,可以看出,污泥颗粒对于水中溶解态活性磷的去除效果较好,这是由于污泥颗粒对于水中磷的吸附以化学吸附为主,其主要吸附机理是依靠污泥颗粒表面的羟基、硫酸根与磷酸盐的配位交换或者形成铝的羟基磷酸盐络合物[11]。对于水中颗粒态的磷,主要依靠污泥颗粒的孔隙截留作用去除。由于2 mm颗粒比表面积大于干化大颗粒。因此,在吸附8 h后,经2 mm颗粒处理后的出水中总磷浓度为1.45 mg·L−1,小于干化大颗粒对应的出水中总磷浓度。同时,由图5和图6可知,在反应8 h后,经2 mm颗粒处理后的出水总磷 、STP、SRP的浓度分别为1.45、0.11、0.036 mg·L−1;干化大颗粒对应的出水TP 、STP、SRP浓度分别为2.55、0.36、0.34 mg·L−1。这主要是因为2 mm颗粒比表面积和理论吸附容量均高于干化大颗粒,因此,在初沉池水中对磷的去除效果优于干化大颗粒。

-

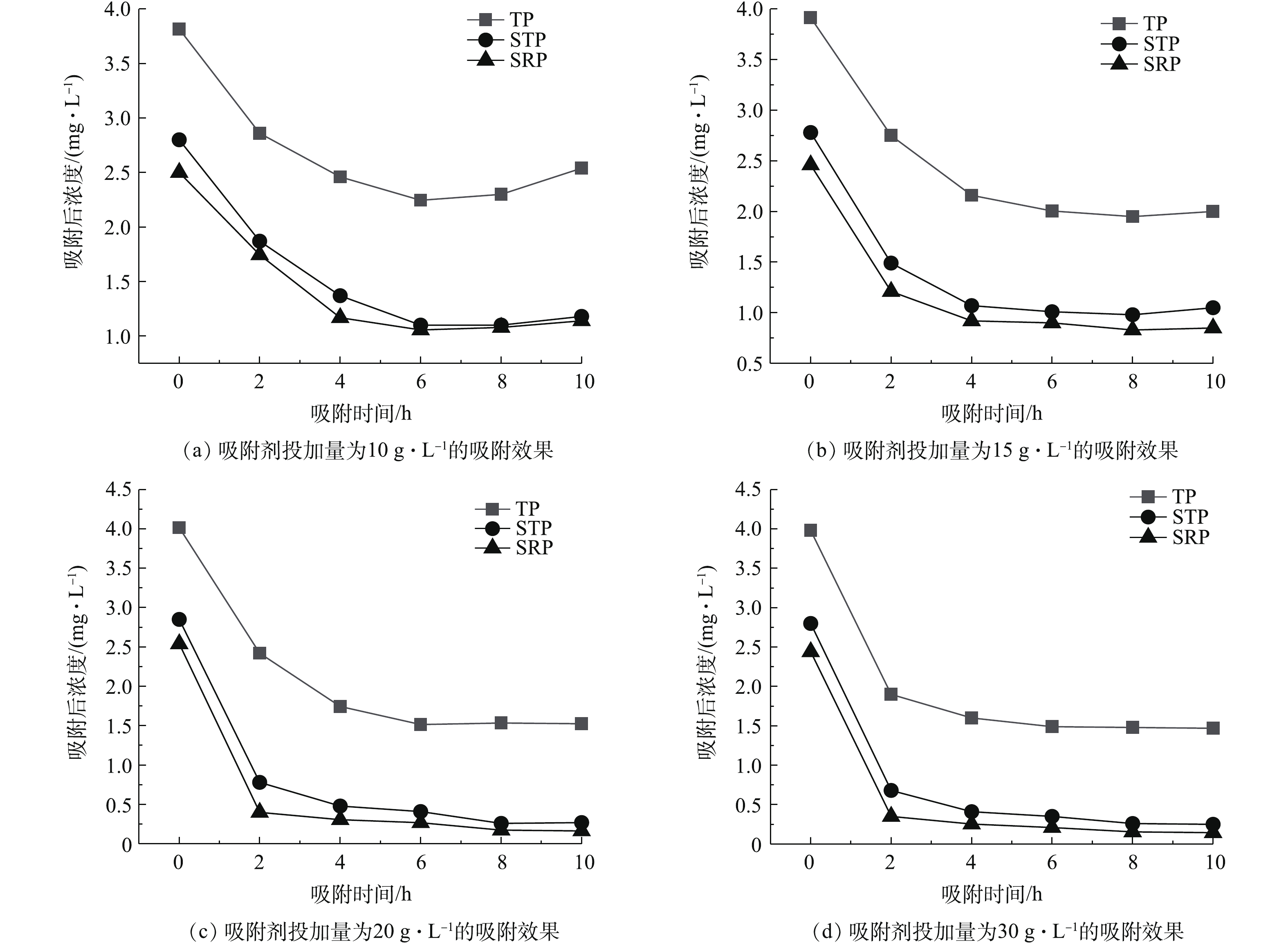

不同颗粒投加量下2 mm污泥颗粒在连续流中去除对比效果见图7。由10 g·L−1投量的静态吸附和动态吸附效果对比(图5和图7(a))可以看出,连续流吸附时,出水磷的吸附效果远低于静态吸附实验,在吸附8 h后,出水TP浓度为2.3 mg·L−1,STP和SRP浓度分别为1.1 mg·L−1和1.07 mg·L−1。增加吸附剂投加量至15 g·L−1时,吸附效果增加幅度有限。当颗粒投量为20 g·L−1时,吸附效果明显提高,出水TP浓度为1.52 mg·L−1,STP和SRP浓度分别为0.27 mg·L−1和0.16 mg·L−1。考虑到继续增加投加量至30 g·L−1,吸附效果并未显著增加,反而增加较多成本,故认为20 g·L−1为最适宜投加量。

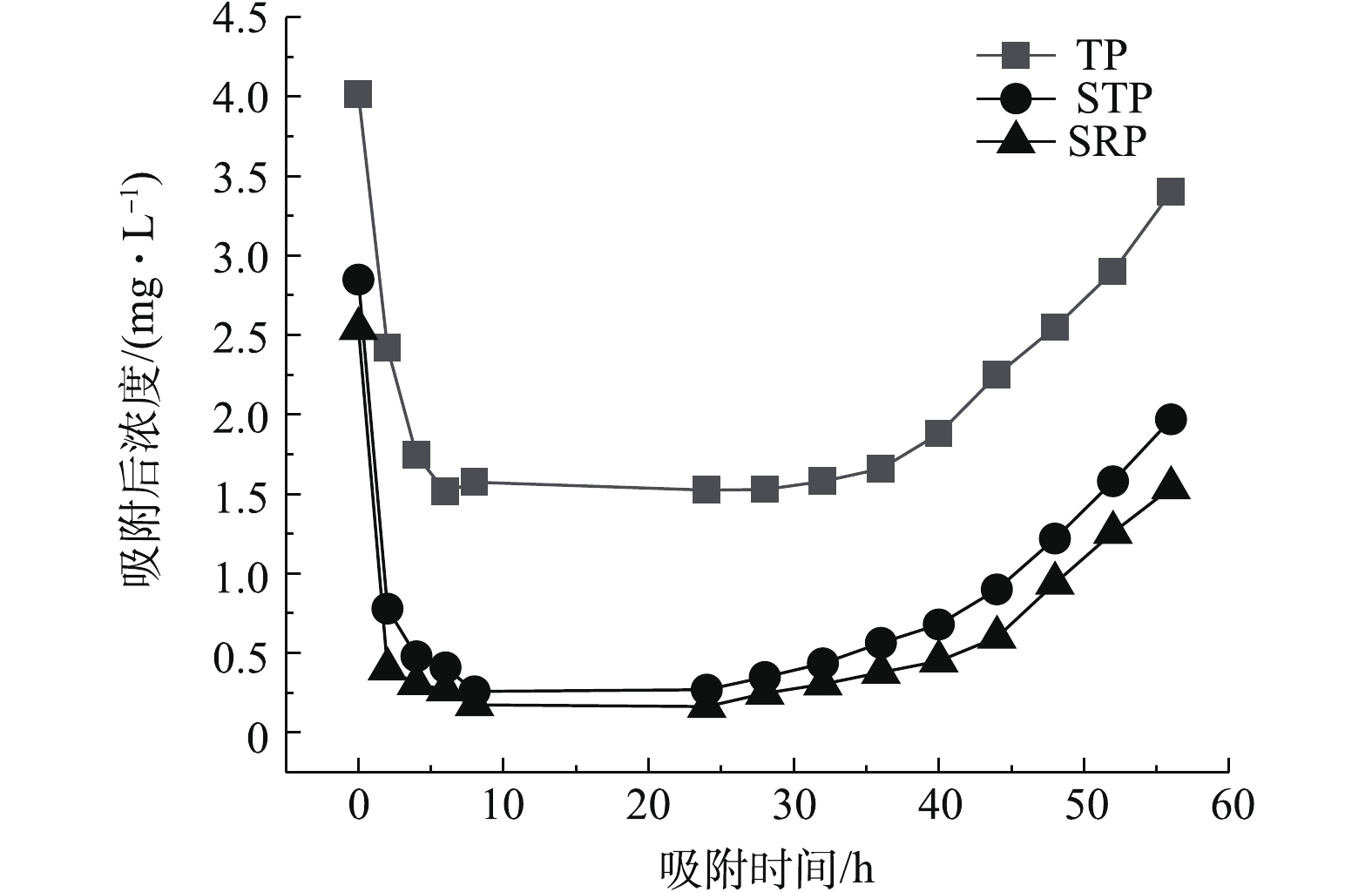

在2 mm颗粒动态吸附实验中,时间对出水磷浓度的影响结果如图8所示。在吸附初始阶段,由于颗粒表面空余活性吸附位点较多,并且污泥颗粒表面与污水界面处具有较大的磷浓度梯度,传质推动力较大,有利于污泥颗粒对于溶液中磷的吸附,因此,污水中磷浓度快速降低。在吸附2 h后,污泥颗粒表面与污水界面处磷浓度梯度逐渐减小,出水磷去除率升高缓慢;8 h后,出水磷去除率达到最大。在运行后期,反应器深度除磷持续运行效果降低。

-

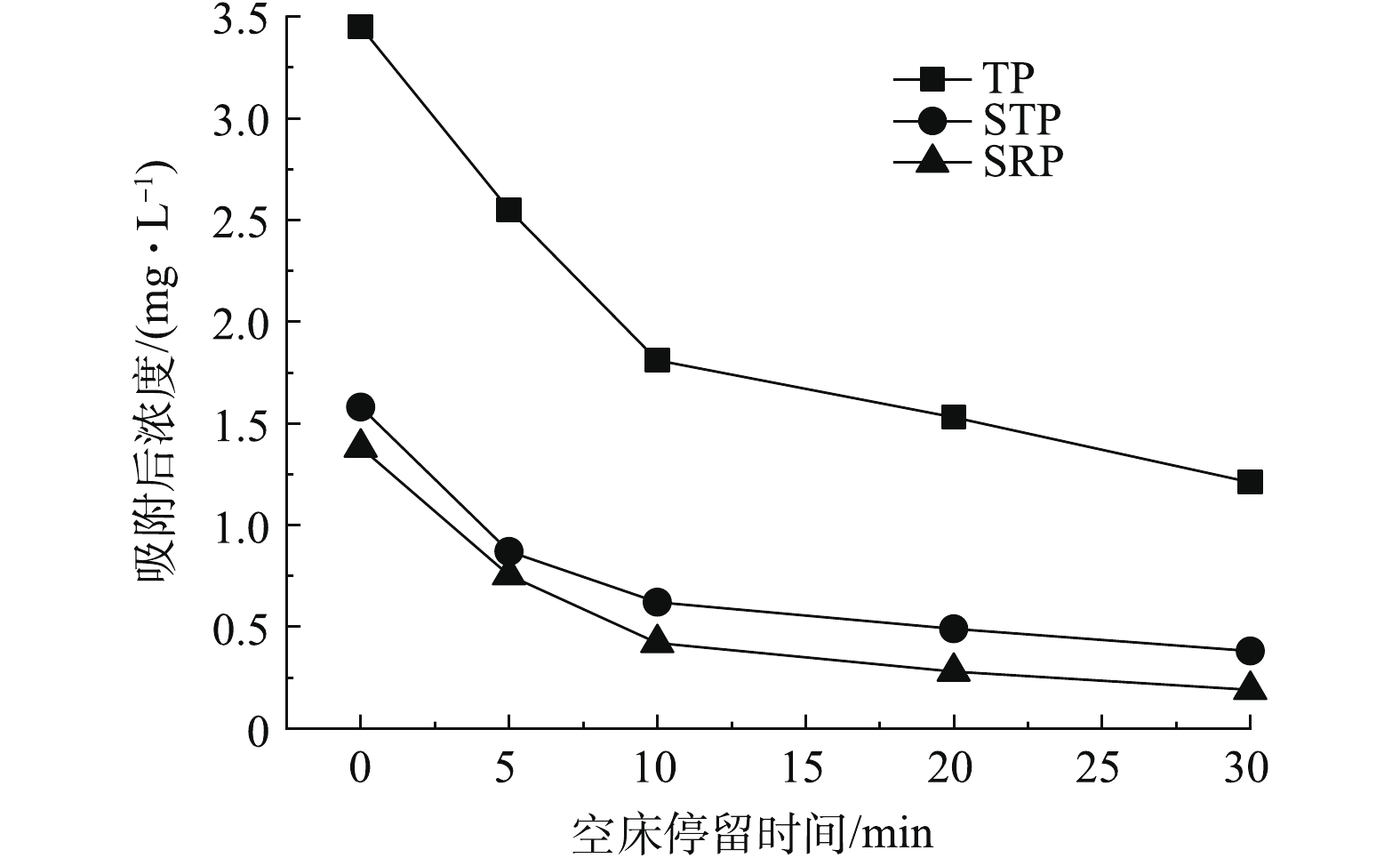

空床接触时间对各种形态磷去除率的影响结果见图9。由图9可知,总磷含量的降低大部分归功于溶解态活性磷酸盐含量的降低。颗粒态磷和其他溶解态磷含量虽然也有一定程度的降低,但幅度很小。这说明污泥颗粒主要依靠化学吸附去除水中溶解态磷,而对于颗粒态磷则依靠物理截留作用,去除效果一般。随着EBCT的增加,总磷、溶解性总磷以及可溶性活性磷酸盐的去除率均大幅度增加,这是由于EBCT较小,上柱滤速过大,一部分磷还没来得及被干化大颗粒吸附便流出滤柱。当EBCT为30 min时,各种形态的磷去除率虽有提高,但并不显著。虽然继续增大EBCT,对吸附有利,但EBCT过大,会降低处理效率,从时间上增加能耗成本,所以干化大颗粒滤柱的空床停留时间应控制在30 min左右。

不同滤层高度对出水磷浓度的影响结果见图10。由图10可知,随着滤层高度的增加,出水总磷、可溶性总磷和可溶性活性磷酸盐的浓度均大幅度降低。当滤柱的滤层高度分别为11.5 cm和14.2 cm时,出水中不同形态的磷浓度并无显著降低,故可确认11.5 cm为干化大颗粒滤柱的有效滤层高度。

为考察干化大颗粒的吸附时间对实际废水的动态处理效果影响,以运行时间t为横坐标,Ct/C0为纵坐标绘制穿透曲线,处理结果如图11所示。以出水浓度为进水浓度的10%为穿透点,反应器的穿透时间为5 h;以出水浓度为进水浓度的90%为反应终点,反应器运行至135 h后,认为达到饱和。由图11可知,反应器对于TP的吸附效果较差,这是因为初沉池水中的组分较为复杂,悬浮物质、有机质等均会引入污染吸附剂,对吸附效果造成一定影响。但从STP和SRP的处理效果来看,在固定床反应器的运行前期(0~80 h),干化大颗粒依然对实际废水有良好的处理效果。但后续水体中其他物质的影响对磷的去除影响较大,导致固定床反应器吸附除磷持续运行效果降低。

-

现依托污水处理厂为工程技术经济分析背景,以废弃铁铝泥颗粒状吸附剂生产成本为主要考虑对象,对颗粒吸附剂制备进行技术经济估算分析。利用给水厂废弃铁铝泥颗粒吸附除磷,对于STP浓度为2.85 mg·L−1的原水,按深度除磷后出水STP浓度低于0.26 mg·L−1计算,理论上处理初沉池水所需药剂费用为0.021 2元·t−1,低于化学沉淀法除磷的药剂费用。对于铁铝泥颗粒状吸附剂,虽然其无法达到深度除磷要求,但具有较低的使用成本,可以用于污水厂前端工艺中,可有效降低水厂后续工艺中絮凝剂的投加量,从而减少水厂的运行成本。此外,还可以同时降低给水厂废弃污泥的后续处置处理费用,从而达到污泥资源化利用的目的。

2.1. 2种颗粒污泥的表征

2.2. 某污水处理厂初沉池水中磷浓度及形态表征

2.3. 给水厂颗粒污泥的对初沉池污水中磷的静态吸附

2.4. 2 mm颗粒吸附剂对初沉池污水中磷的动态吸附

2.5. 干化大颗粒对初沉池污水中磷的动态吸附

2.6. 技术经济分析

-

1)给水处理厂废弃铁铝泥主要含有碳、氧、铝、铁、硅等元素,孔隙发达,具有较大的比表面积,适宜吸附水中的磷。

2)给水厂污泥制成的2种粒径颗粒作为吸附剂对初沉池水中磷进行静态吸附,由于2 mm粒径颗粒具有较大的比表面积,因此,吸附效果优于干化大颗粒。

3) 2 mm颗粒的动态吸附实验结果表明,其适宜投加量为20 g·L−1,实验初始阶段,水中磷浓度快速降低,连续运行8 h后达到最佳去除效果。

4)干化大颗粒的动态吸附实验结果表明,滤柱的空床停留时间应控制为30 min、滤层有效高度为11.5 cm。反应器穿透时间为5 h,反应器运行至135 h后,认为达到饱和。在固定床反应器运行前80 h,干化大颗粒对初沉池水有良好的处理效果。

5)经济分析表明,颗粒吸附剂理论上处理初沉池水所需药剂费用为0.021 2 元·t−1,具有较好的经济效益。

下载:

下载: