-

膜生物反应器作为一种将传统活性污泥处理技术及膜分离技术相结合的污水处理新工艺,其具有固液分离效果好、出水水质好、活性污泥浓度高、污泥产量低、抗冲击负荷强、占地面积小和管理方便等优点,在处理生活污水、工业废水等方面已被广泛地应用[1-2]。然而MBR仍然存在一些问题,使其在实际应用过程中受到限制:一方面,一体式MBR因缺少生物除磷条件而存在除磷效率低的问题,导致其难以满足严格的氮磷排放标准;另一方面,膜污染是MBR运行过程中不可避免的问题,在增加工艺过程能耗的同时,也会对膜组件造成损害。因此,寻求简单有效的方法,同时克服MBR除磷效率低以及膜污染的问题,对于MBR的广泛应用具有重要的意义。

目前,提高MBR除磷效率的研究主要集中在强化生物除磷和化学除磷2个方面。有研究[3-4]表明,采用MBR与多种工艺组合的方式可以为强化生物除磷提供条件,从而达到较好的脱氮除磷效果。但此方法的应用往往需要控制反应器好氧-厌氧条件,对MBR运行条件要求较高。而向MBR中投加铁盐、铝盐等通过化学沉淀作用辅助强化除磷的方法成本低、操作简单,故其得到了广泛的应用[5-7]。LI等[8]通过投加铁盐建立了一种同时使用化学除磷以及厌氧发酵的创新的环保MBR工艺,提高了磷去除率,同时通过污泥处理获得了较高的磷回收率。

膜污染是阻碍MBR技术应用的关键因素。目前,用于改善膜污染的方法主要有膜改性、改善污泥混合液性质新型生物方法等[9-10]。通过投加过滤助剂改善污泥混合液性质由于其操作简单、效果明显,已逐渐成为改善膜污染的重要方法[11]。污泥混合液在浸没式MBR中与膜组件直接接触,因此,污泥混合液性质如污泥浓度(MLSS)[12-13],污泥形态等均是影响膜污染的重要参数。随着人们对膜污染认识的深入,污泥混合液中胞外聚合物(EPS)和溶解性微生物产物(SMP)对膜污染的影响研究也逐渐受到国内外研究者的重视[14]。絮凝剂可以有效改善污泥混合液性质,从而改善膜污染[15],但由于污泥混合液成分复杂,絮凝剂对MBR膜污染特性的影响还需要更多研究进行更全面和深入的分析。

与其他无机絮凝剂相比,铁系絮凝剂具有价格低廉,且对环境影响较小的优点。因此,本研究通过投加无机铁系絮凝剂,铁磷摩尔比为一般传统废水处理中常用摩尔比(约为2)[16],对连续曝气的一体式MBR进出水水质进行了分析,考察了絮凝剂对MBR运行效果的影响,并对污泥混合液的性质及膜上污染物进行了分析,研究了絮凝剂对污泥混合液的影响及其缓解膜污染的机理,以期为一体式好氧MBR及膜污染控制技术的应用提供参考。

-

实验用水为每日现配模拟废水,主要以葡萄糖和无水乙酸钠作为碳源,以硫酸铵作为氮源,以磷酸二氢钾作为磷源,按生活废水C∶N∶P=100∶5∶1(元素质量比),配制成COD约为400 mg·L−1的模拟废水,氨氮浓度约为20 mg·L−1,总磷浓度约为4 mg·L−1,同时添加部分微量元素以维持反应器长期运行过程中微生物生长的需要。

-

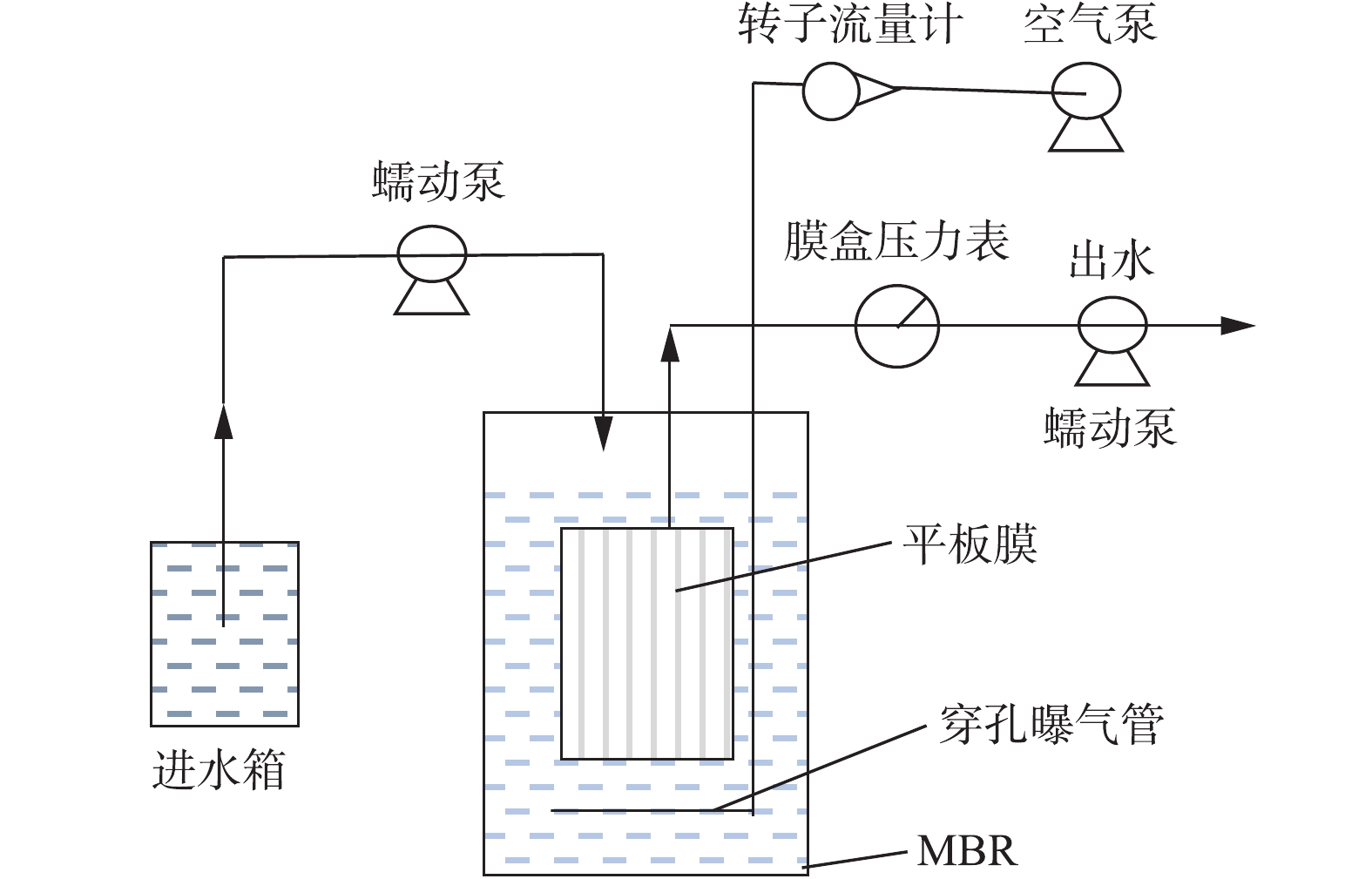

实验装置如图1所示。进水由一个进水箱及蠕动泵(BT100-2J 型,兰格恒流泵有限公司)组成,MBR由有机玻璃容器(有效体积12 L)、膜组件(PVDF平板膜2张,膜面积0.06 m2,平均孔径0.1 μm)、活性污泥(广州市沥滘污水处理厂二沉池污泥)及曝气装置组成。反应器连续运行的处理水量为36 L·d−1、水力停留时间为8 h、pH为7~8、水温为20~30 ℃。处理后废水通过膜组件以滤液形式由蠕动泵负压抽出,出水流量为30 mL·min−1,使用时间控制器控制蠕动泵间歇运行,开5 min后停止1 min,以缓解膜污染。

-

实验采用MBR装置长期运行处理模拟废水,分别以铁磷比约为2的比例,向正在运行中的MBR投加铁系单体絮凝剂(FeSO4)、铁系聚合体絮凝剂(PFS),并与不投加任何药剂的情况进行对比。工况设置及运行时间如表1所示。

-

实验中进出水水质检测指标主要包括COD、氨氮(NH3-N)和总磷(TP),活性污泥特性分析指标主要包括MLSS、MLVSS、SV30和SVI,均采用国家标准方法测定。污泥中EPS和SMP,以蛋白质及多糖浓度表征,采用考马斯亮蓝法测定蛋白质浓度,苯酚-硫酸法测定多糖浓度。分析过程中使用的药品均为分析纯。

实验中跨膜压差变化通过膜盒压力表检测,每天记录。每次工况结束后,污泥及膜表面污染物采用三维荧光(日立F-4600荧光光谱仪)分析。在阶段结束后,依次采用清水水力冲洗、500 mg·L−1的次氯酸钠(NaClO)浸泡24 h和3%盐酸(HCl)溶液浸泡2 h步骤对膜进行清洗。在每个清洗步骤后,测试跨膜压差和清水透过率,并与使用前新膜的跨膜压差进行比较,进而计算透水性能恢复率。

-

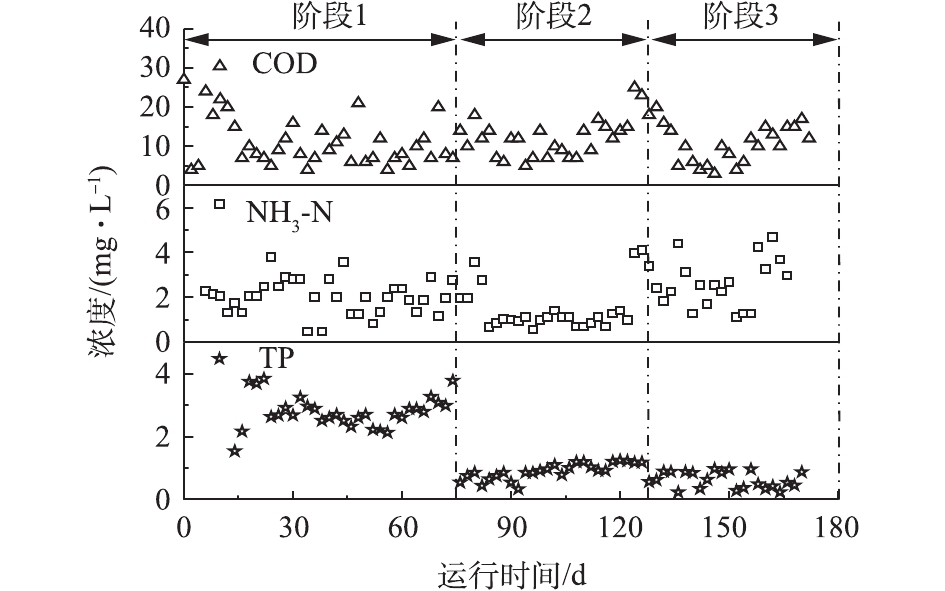

在不同絮凝剂条件下,实验考察了MBR对水中COD、氨氮和总磷去除的影响,结果如图2所示。本研究中膜出水COD基本保持在20 mg·L−1以下,氨氮浓度小于5 mg·L−1,符合国家生活污水处理排放标准一级A(GB 19818-2020)。投加的2种絮凝剂均对MBR去除污水中的氨氮产生较小的影响,这可能是由于Fe3+浓度过高,会减少相应硝化细菌和反硝化细菌的种类和数量,故导致生物活性降低,导致污染物氨氮去除效果较低[17]。

在3个阶段中,膜出水总磷浓度变化较大,在不加入絮凝剂的条件下,单纯依赖生物除磷的MBR对污水中总磷浓度去除率很低,平均出水浓度为2.76 mg·L−1。絮凝剂的加入可以提高MBR除磷效率。在加入FeSO4和PFS的条件下,膜出水平均总磷浓度分别为1.01 mg·L−1和0.62 mg·L−1。FeSO4中的铁以离子形式存在于污水中,主要通过水解以及与磷酸根离子反应去除磷。PFS则主要以聚合态,通过电中和、吸附架桥及卷扫絮凝作用去除磷酸根[18]。

-

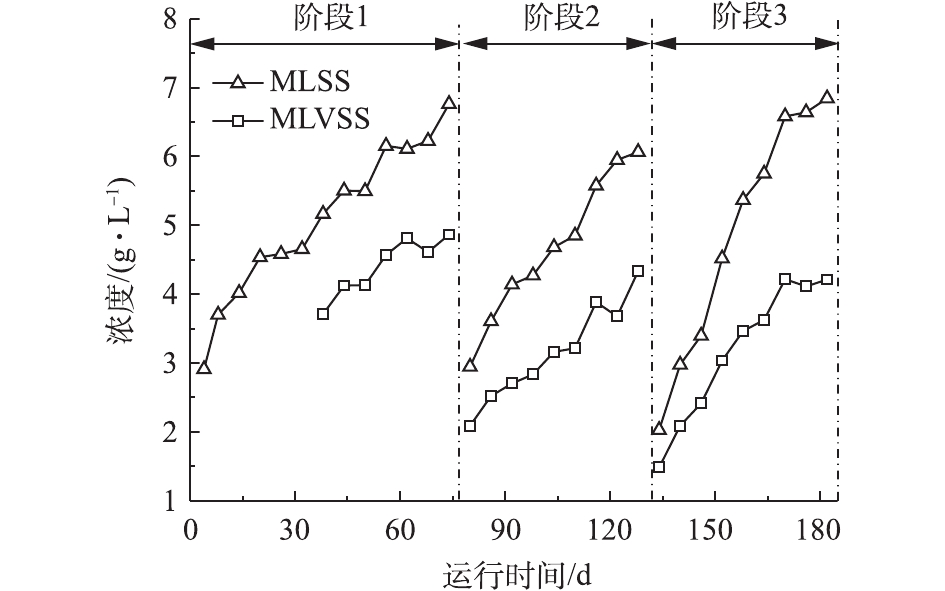

在加入絮凝剂后,污泥浓度随时间的变化如图3所示。由图3可知,在每个阶段开始,通过排泥控制初始污泥浓度保持在2~3 g·L−1,MLSS及MLVSS在每个阶段均保持随时间的延长而增长的趋势,符合微生物生长规律。阶段2的MLSS相较于阶段1和阶段3较低,这可能是由于在本实验中的该阶段处于冬天,温度较低,故对微生物活性造成了一定的影响。但在加入絮凝剂的情况下,污泥浓度增长率均有所提升,且在加入PFS的条件下,污泥增长率最大。但MLVSS与MLSS的比值逐渐降低,这是由于絮凝剂的加入使系统内无机成分累积而造成的。

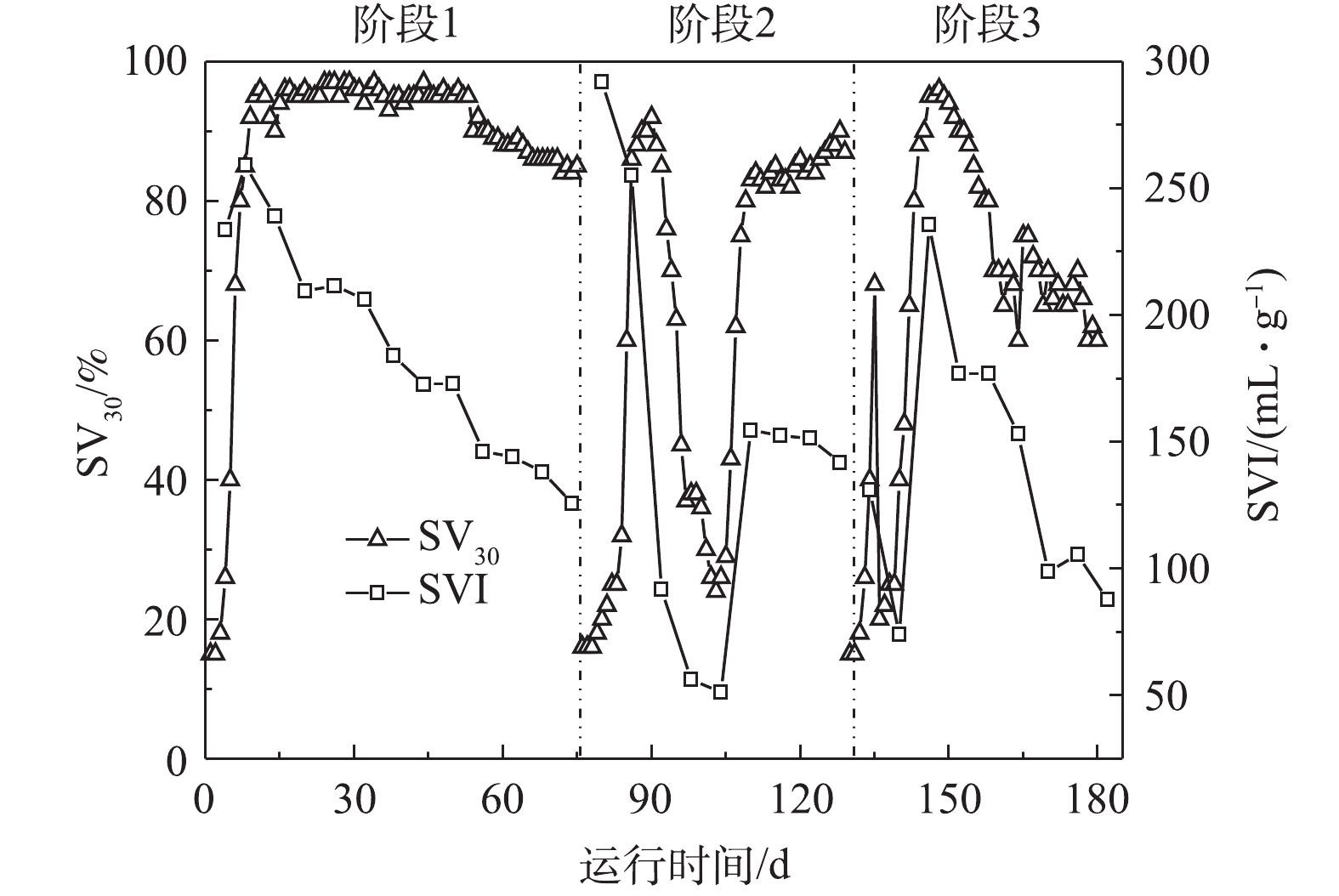

污泥沉降性能是污泥性能变化的一个重要指标。由图4可知,在不排泥的情况下,加入絮凝剂可以明显改善前期污泥沉降性能快速变差的情况,这可能是由于发生了与污泥黏度有关的非丝状菌膨胀,从而导致污泥性能恶化[19]。污泥黏度一方面代表反应器内黏性物质增加,另一方面也影响反应器内曝气模式,使污染物更容易在膜上累积,从而造成膜污染[20-21]。混合液因絮凝剂的加入降低了混合液黏度,有利于减缓膜上污染物的累积速度。

-

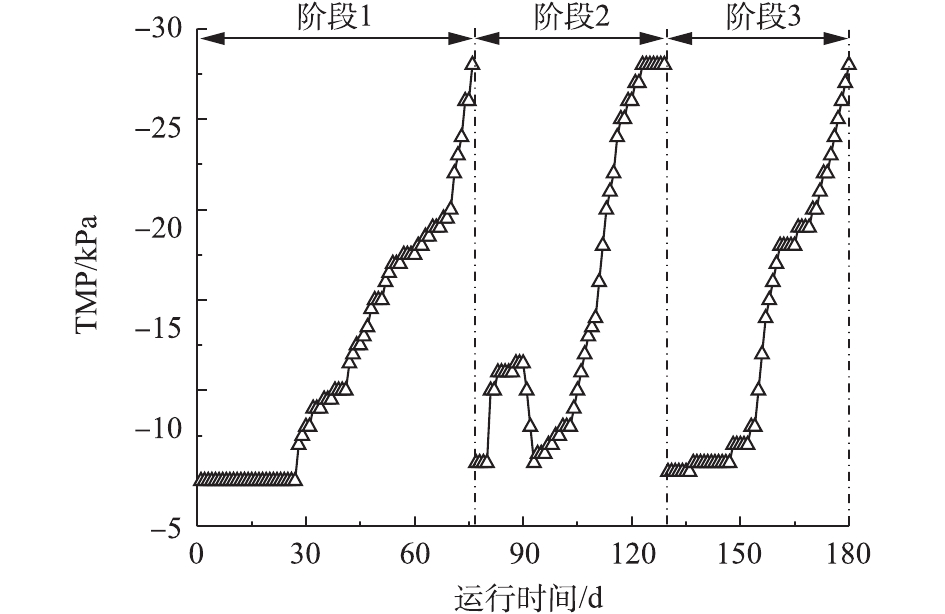

跨膜压差可以直接表征反应器内膜污染情况。图5显示了跨膜压差TMP随MBR运行的变化。可以看到,在固定通量的条件下,TMP的增长主要分为前期缓慢增长以及后期急剧上升2个部分,这可能与在2个阶段中不同形式膜污染形成有关[22]。阶段2中FeSO4加入初期并未达到有效控制TMP增长的效果,这可能是由于FeSO4加入初期对改善污泥混合液性质效果不明显,但随着絮凝剂累积,FeSO4改善膜污染作用逐渐明显,这也与污泥沉降性变化相对应。

-

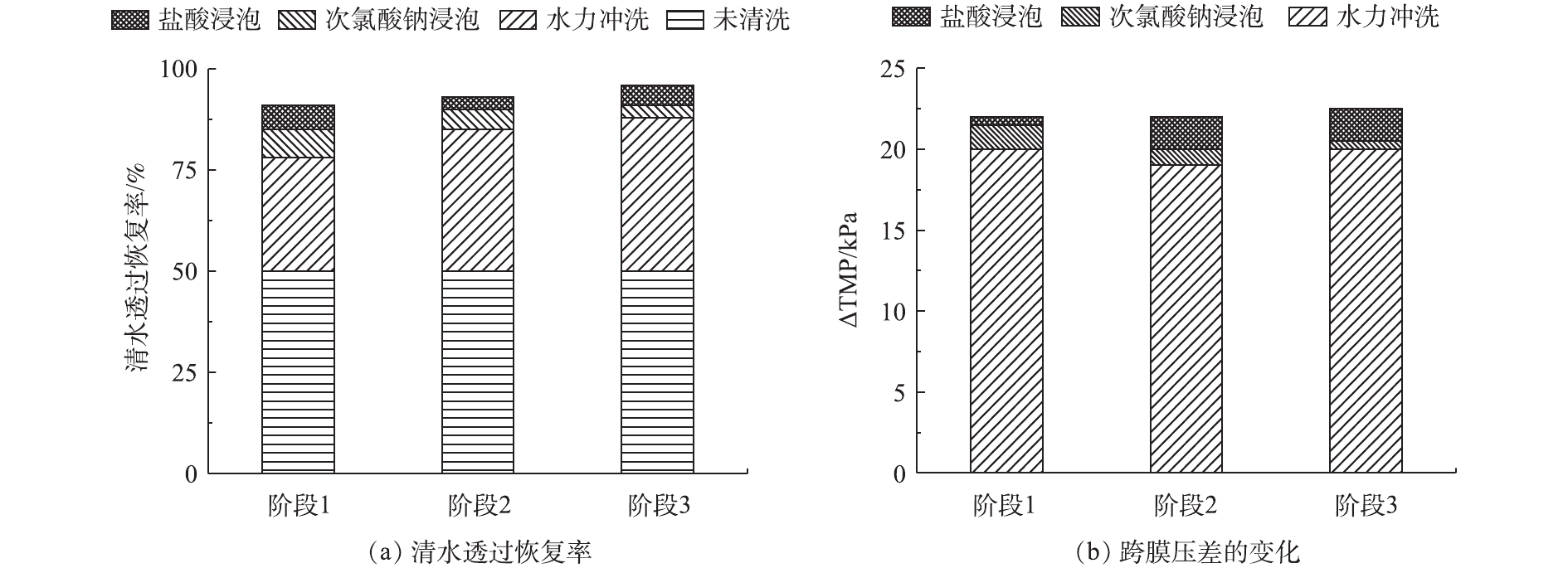

为深入了解膜污染过程,选择行之有效的膜清洗方法,定期进行膜清洗,以保障MBR可持续运行[10, 23]。本研究统计了3个阶段膜透水率下降50%所用的时间,分别为45、53和50 d(阶段1过程中新膜条件下膜透水率不下降的时间忽略不计),这说明2种絮凝剂的加入均有效缓解了膜污染的增长速度。在膜透水率下降50%时,对膜进行清洗,并分析每个清洗步骤之间清水透过恢复率和跨膜压差的变化,以考察膜受到不同类型污染的程度,结果如图6所示。在3个阶段中,经过清洗后的跨膜压差变化较小,总体均能恢复到初始-6 kPa左右,投加絮凝剂后总的通量恢复率略有增加,但不同清洗方法后的压差以及通量变化有所不同。其中水力冲洗用于去除膜表面由污泥絮体形成的泥饼层污染,占膜污染的主要部分。泥饼层的形成会直接导致TMP的快速增加[24]。实验中通过水力冲洗去除的泥饼层占比增大,说明絮凝剂的加入可能使膜上泥饼层更加疏松且易于清洗。酸洗部分占比增加是由于无机絮凝剂在反应器中累积,形成了更加严重的无机污染层,但是这部分污染容易通过盐酸清洗,因而整体上清洗后膜通量的恢复率得到提高。

-

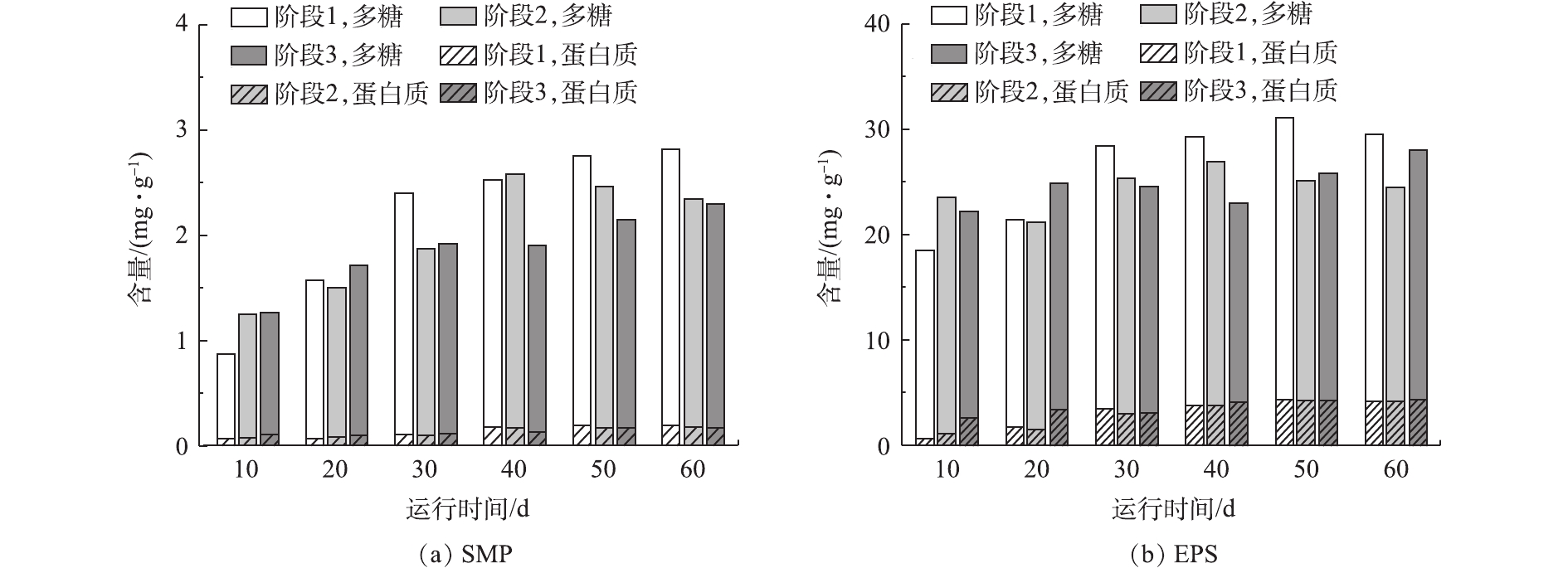

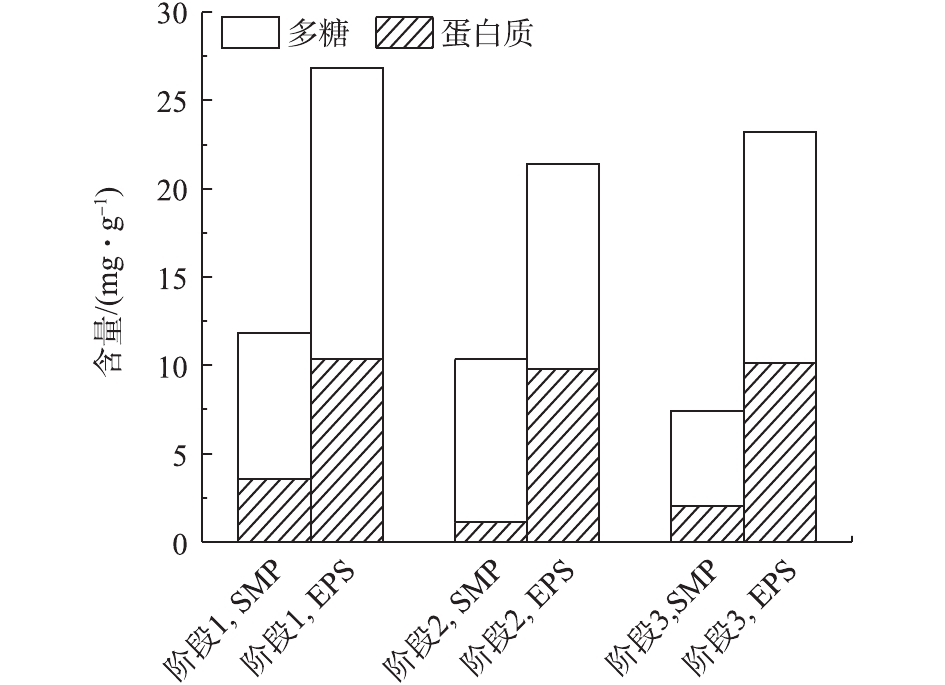

胞外聚合物是一类聚集在微生物表面的代谢产物,分为溶解性胞外聚合物(SMP)和紧密结合性胞外聚合物(EPS),其与膜污染存在紧密联系[25-27]。污泥胞外聚合物成分复杂,其中,有机物与膜之间存在物理化学作用,其可在膜表面或进入膜孔附着和累积,从而严重影响着膜过滤性能[28]。本实验提取了不同阶段中不同时间污泥及膜清洗获得的泥饼层胞外聚合物EPS和SMP,以多糖及蛋白质浓度对其进行表征(图7和图8)。结果表明,在未投加任何药剂的条件下,SMP和EPS均随时间的延长而增加,且前期迅速增长,这解释了前期出现的由于黏性物质积累而导致的污泥性能恶化的原因。在投加不同絮凝剂后,污泥SMP和EPS总量均有所下降,且显著降低了泥饼层胞外聚合物浓度。PFS对污泥及泥饼层SMP的减少作用更加明显,这可能是由于PFS具有更好的吸附性能,能有效减少污泥混合液中溶解性有机物,从而减少膜上污染物浓度[29]。从泥饼层SMP及EPS浓度可以看出,EPS占泥饼层污染的主要部分,原因是EPS是在微生物表面紧密附着的并在运行过程中随微生物黏附于膜面的物质。而SMP由于其溶解性更加容易进入膜孔,形成凝胶层或造成膜孔堵塞。

分别对比污泥SMP和EPS中蛋白质及多糖浓度的变化,蛋白质浓度变化并不明显,而多糖浓度在加入不同絮凝剂的条件下出现了明显的变化,这与已有一些研究结果类似。胞外聚合物组成和结构受环境影响较大[30],一些絮凝剂可以影响污泥中多糖和蛋白质的浓度,改善污泥脱水性[31]。絮凝剂的加入可能促进胞外聚合物聚集,进而影响了微生物自身代谢和多糖的分泌,而具体成分变化还需要更加深入的研究。

-

有研究[32]认为,一些蛋白质和腐殖质是造成膜污染的主要原因。三维荧光光谱 (3D-EEM)能够显示出丰富的物质种类及其含量的信息。YU等[33]使用3D-EEM,结合相关标准曲线,建立了一种可以定量分析膜上污染物的方法。LIU等[34]利用三维荧光光谱法对臭氧预氧化膜生物反应器中的膜上有机污染层进行了表征,发现预臭氧氧化可以明显降低膜污染层上蛋白质类的物质浓度以及影响产生的腐殖酸类的物质结构。

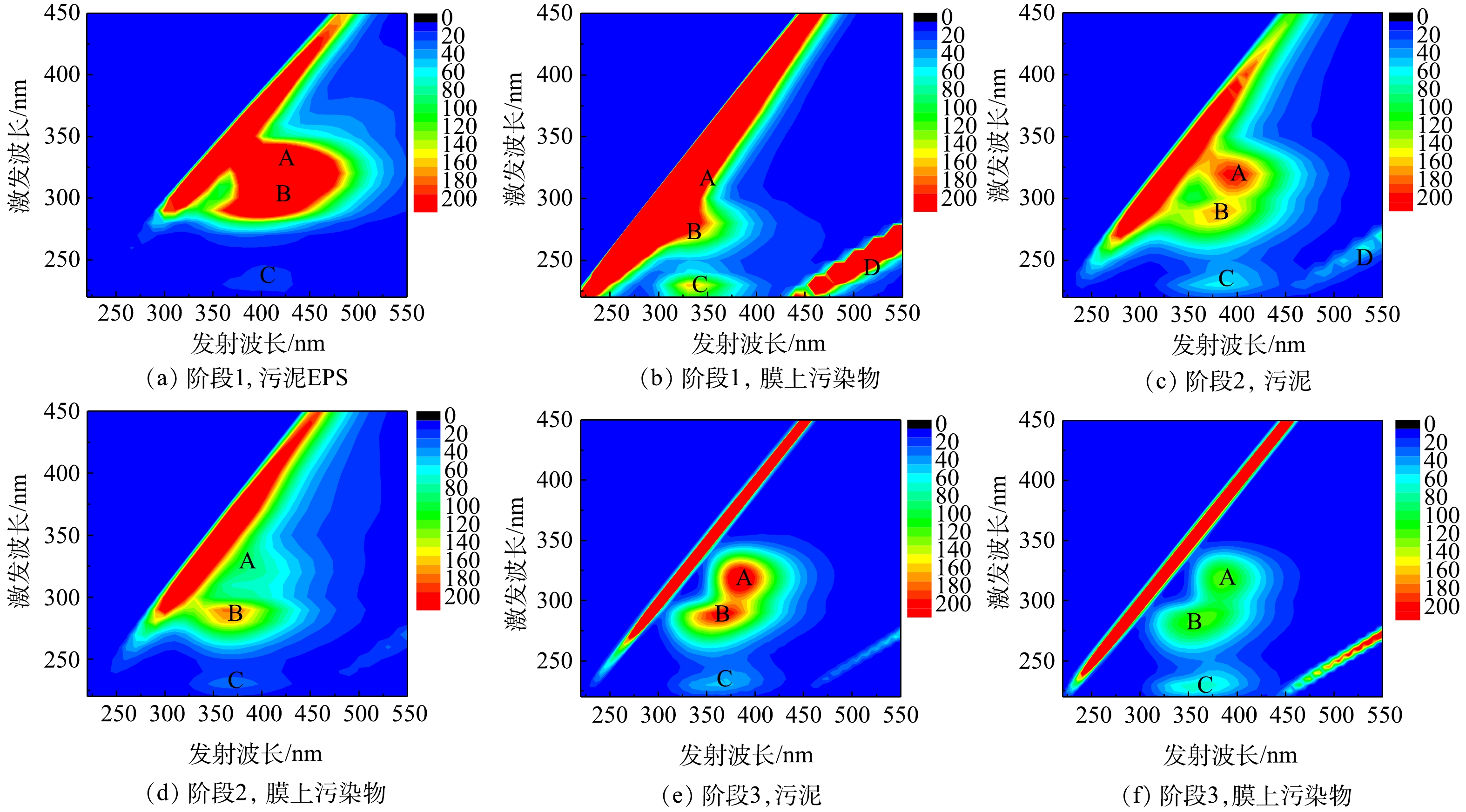

采用三维荧光技术对以上3个阶段中污泥胞外聚合物及膜清洗所得膜上污染物进行了分析,结果如图9所示。经平行因子分析法(PARAFAC)[35],去除水背景及拉曼等干扰后,对比相关组分三维荧光激发-发射矩阵图[36],可以得出,污泥EPS及膜上污染物主要有4种荧光成分:峰A(Ex/Em=(300~350) nm/(350~400) nm),为胡敏酸类物质;峰B(Ex/Em=(200~300) nm/(340~380) nm),为蛋白质类的可溶性微生物产物;峰C(Ex/Em=(200~250) nm/(330~380) nm),为芳香族蛋白质;峰D(Ex/Em=(225~250) nm /(500~550) nm),为富里酸类物质。

一般认为,腐殖类荧光峰是水样中疏水性基团的主要标志,而蛋白类荧光峰则表示水样中存在一定的亲水基团。刘铮等[37]利用3D-EEM表征了不同亲疏组分物质对膜污染的影响,发现偏疏水性物质比亲水性物质更容易造成膜污染。本研究中,加入絮凝剂后,胡敏酸类物质(峰A)荧光强度降低,而色氨酸类蛋白质(峰B)类物质成为主要膜污染物。一方面疏水性腐殖酸类物质的减少有利于缓解膜污染,另一方面大分子蛋白质类物质由于分子质量大,对膜污染影响较小,因而减缓了膜污染。

此外,由图9可知,在不同阶段中的荧光峰位置均有一定的变化。荧光峰蓝移表示极性基团如羧基、氨基、羟基等的减少,而红移是由于羰基、羟基、烷氧基、氨基和羧基的增加引起的[38]。B峰在加入絮凝剂后出现了蓝移,D峰出现一定的红移,这表明絮凝剂可能引起膜上不同种类的污染物增加或减少,另外也可能影响微生物代谢产物种类的变化。总体来看,加入絮凝剂,膜上芳香族类蛋白质(峰C)富里酸类物质(峰D)的荧光强度降低,表明这些物质造成的膜污染在一定程度上得到缓解。

-

1) FeSO4及PFS的投加对COD和氨氮的去除效果影响均较小,但均可以明显提高一体浸没式MBR的除磷效率,可保持良好的出水水质。

2)絮凝剂的加入对污泥特性改善明显,污泥增长速率有所提高,污泥胞外聚合物SMP和EPS浓度均有所降低,且使污泥胞外聚合物多糖浓度明显降低,降低混合液黏性,沉降性能变好,可使污泥SVI保持在较低水平。

3)絮凝剂的加入可以减缓膜污染,絮凝剂后的膜污染层结构更为松散,易于清洗,但造成膜上无机污染部分增加。通过三维荧光对膜上污染物进行分析可知,絮凝剂的加入可能影响污泥微生物产物种类以及结构的改变,主要可以减缓膜上胡敏酸以及蛋白质类物质造成的膜污染。

4)此工艺运行过程成本主要包括能耗、絮凝剂成本、膜清洗成本3个部分,按实验室处理规模,计算运行成本大约为1.3元·(t·d)−1,成本较为合理,出水可用于回收,这说明此工艺适宜于实际运用。

FeSO4和PFS对膜生物反应器运行及膜污染特性的影响

Effect of FeSO4 and PFS on membrane bioreactor operation and membrane fouling characteristics

-

摘要: 采用一体浸没式膜生物反应器(MBR)处理模拟生活污水,考察了在投加不同铁盐絮凝剂(FeSO4和PFS)条件下反应器的运行效率及膜污染特性。进出水水质分析结果表明:铁盐絮凝剂的投加可明显提高MBR的除磷效率,反应器总磷的平均去除率由20.23%分别提高至74.29%和81.09%,对COD和氨氮的去除率没有明显的影响;污泥沉降得到改善,SVI明显降低,使泥饼层更加疏松,易于清洗。同时通过对不同絮凝剂条件下污泥混合液胞外聚合物以及膜上污染物的三维荧光分析,发现絮凝剂的加入能明显减少胞外聚合物中的多糖浓度以及膜上污染物质的结构类型,且主要减少了胡敏酸类物质对膜的污染。这对于提高出水水质,减缓膜污染具有重要意义。以上结果可为FeSO4和PFS在MBR中的应用提供参考。Abstract: An integrated submerged membrane bioreactor (MBR)was used to treat simulated domestic sewage, and the operating efficiency and membrane fouling characteristics of the reactor under the conditions of adding different iron salt flocculants (FeSO4 and PFS) were investigated. Quality of the influent and effluent showed that the addition of the iron salt flocculant significantly improved the phosphorus removal efficiency by MBR, and the average removal rate of total phosphorus by MBR increased from 20.23% to 74.29% and 81.09%, respectively, while had no significant impact on the removal of COD and NH3-N. Activated sludge settlement was improved, the SVI was significantly reduced, which resulted in looser and easy-cleaning cake layer on membrane. Three-dimensional fluorescence analysis on the extracellular polymer of the sludge and the membrane pollutants under different flocculant conditions showed that the dosing of flocculants could significantly reduce the polysaccharide concentration in extracellular polymers and the structure type of pollutants on the membrane, and mainly reduced the pollution effects of humic acids on the membrane. It is of great significance for improving effluent quality and relieving transmembrane pollution. The result can provide reference for application of FeSO4 and PFS in MBR.

-

Key words:

- membrane bioreactor /

- flocculant /

- phosphorous removal /

- membrane fouling

-

-

表 1 MBR运行工况

Table 1. Operating condition of MBR

阶段 运行时间/d 投加药剂 投加剂量/(mg·L−1) 1 01~76 无 — 2 77~129 FeSO4 70 3 130~180 PFS 75 -

[1] 黄霞, 曹斌, 文湘华, 等. 膜-生物反应器在我国的研究与应用新进展[J]. 环境科学学报, 2008, 28(3): 416-432. doi: 10.3321/j.issn:0253-2468.2008.03.003 [2] 孟志国, 杨凤林, 张兴文. 无纺布-膜生物反应器在生活污水处理中应用[J]. 大连理工大学学报, 2007, 47(3): 344-348. doi: 10.3321/j.issn:1000-8608.2007.03.007 [3] 赵珊珊, 胡啸, 王志良, 等. 膜生物反应器应用于脱氮除磷的研究进展[J]. 污染防治技术, 2011, 24(4): 37-41. [4] 刘运胜, 刘继先, 黄羽. MBR脱氮除磷组合工艺研究进展[J]. 绿色科技, 2016, 7(8): 46-48. doi: 10.3969/j.issn.1674-9944.2016.08.021 [5] LEE G, MODARRESI S, BENJAMIN M M. Efficient phosphorus removal from MBR effluent with heated aluminum oxide particles (HAOPs)[J]. Water Research, 2019, 159: 274-282. doi: 10.1016/j.watres.2019.05.010 [6] MBAMBA C K, LINDBLOM E, FLORES-ALSINA X, et al. Plant-wide model-based analysis of iron dosage strategies for chemical phosphorus removal in wastewater treatment systems[J]. Water Research, 2019, 155: 12-25. doi: 10.1016/j.watres.2019.01.048 [7] 高颖, 袁林江, 吕景花. 铁盐化学除磷对活性污泥生物除磷系统的影响[J]. 环境工程学报, 2016, 10(10): 5366-5372. doi: 10.12030/j.cjee.201602125 [8] LI R H, WANG X M, LI X Y. A membrane bioreactor with iron dosing and acidogenic co-fermentation for enhanced phosphorus removal and recovery in wastewater treatment[J]. Water Research, 2018, 129: 402-412. doi: 10.1016/j.watres.2017.11.035 [9] 刘锐, 黄霞, 汪诚文, 等. 一体式膜-生物反应器长期运行中的膜污染控制[J]. 环境科学, 2000, 21(2): 58-61. doi: 10.3321/j.issn:0250-3301.2000.02.014 [10] BAGHERI M, MIRBAGHERI S A. Critical review of fouling mitigation strategies in membrane bioreactors treating water and wastewater[J]. Bioresource Technology, 2018, 258: 318-314. doi: 10.1016/j.biortech.2018.03.026 [11] LE-CLECH P, CHEN V, FANE T A G. Fouling in membrane bioreactors used in wastewater treatment[J]. Journal of Membrane Science, 2006, 284(1/2): 17-53. [12] CHANG I S, KIM S N. Wastewater treatment using membrane filtration: Effect of biosolids concentration on cake resistance[J]. Process Biochemistry, 2005, 40(3/4): 1307-1314. [13] 陆继来, 刘舒华, 张敏健, 等. 污泥浓度对MBR混合液特性及膜污染的影响[J]. 中国给水排水, 2014, 30(9): 92-95. [14] WANG X M, WAI TE T D. Impact of gel layer formation on colloid retention in membrane filtration processes[J]. Journal of Membrane Science, 2008, 325(1): 486-494. doi: 10.1016/j.memsci.2008.08.016 [15] ZHANG Z, WANG Y, LESLIE G L, et al. Effect of ferric and ferrous iron addition on phosphorus removal and fouling in submerged membrane bioreactors[J]. Water Research, 2015, 69: 210-222. doi: 10.1016/j.watres.2014.11.011 [16] GANIGUE R, GUITIERREZ O, ROOTSEY R, et al. Chemical dosing for sulfide control in Australia: An industry survey[J]. Water Research, 2011, 45(19): 6564-6574. doi: 10.1016/j.watres.2011.09.054 [17] 李浩, 闫玉洁, 谢慧君, 等. Fe3+对同步硝化反硝化过程氮元素迁移转化及N2O释放的影响[J]. 环境科学, 2015, 36(4): 1392-1398. [18] 谢经良, 刘娥清, 赵新, 等. 不同形态铁盐的除磷效果[J]. 环境工程学报, 2012, 6(10): 3429-3432. [19] 孙宝盛, 张海丰, 齐庚申. 膜生物反应器中的非丝状菌污泥膨胀[J]. 天津大学学报, 2006, 39(4): 469-473. [20] P B, H Q, A O, et al. Clogging vs. fouling in immersed membrane bioreactors[J]. Water Research, 2018, 144: 46-54. doi: 10.1016/j.watres.2018.07.019 [21] 钱光磊, 谢陈鑫, 滕厚开, 等. 曝气对管式MBR膜污染及临界通量影响[J]. 环境工程学报, 2017, 11(8): 4542-4548. doi: 10.12030/j.cjee.201606166 [22] 魏春海, 黄霞, 赵曙光, 等. SMBR在次临界通量下的运行特性[J]. 中国给水排水, 2004, 22(11): 10-13. doi: 10.3321/j.issn:1000-4602.2004.11.003 [23] WANG Z, MA J, TANG C Y, et al. Membrane cleaning in membrane bioreactors: A review[J]. Journal of Membrane Science, 2014, 468: 276-307. doi: 10.1016/j.memsci.2014.05.060 [24] LEE J, AHN W Y, LEE C H. Comparison of the filtration characteristics between attached and suspended growth microorganisms in submerged membrane bioreactor[J]. Water Research, 2001, 35(10): 2435-2445. doi: 10.1016/S0043-1354(00)00524-8 [25] TIAN Y, CHEN L, ZHANG S, et al. Correlating membrane fouling with sludge characteristics in membrane bioreactors: An especial interest in EPS and sludge morphology analysis[J]. Bioresource Technology, 2011, 102(19): 8820-8827. doi: 10.1016/j.biortech.2011.07.010 [26] MENG F, ZHANG H, YANG F, et al. Identification of activated sludge properties affecting membrane fouling in submerged membrane bioreactors[J]. Separation and Purification Technology, 2006, 51(1): 95-103. doi: 10.1016/j.seppur.2006.01.002 [27] 高元, 李绍峰, 陶虎春. MBR污泥混合液特性变化及膜污染关系研究[J]. 环境工程学报, 2011, 5(1): 28-32. [28] CHEN J R, ZHANG M J, LI F Q, et al. Membrane fouling in a membrane bioreactor: High filtration resistance of gel layer and its underlying mechanism[J]. Water Research, 2016, 102: 82-89. doi: 10.1016/j.watres.2016.06.028 [29] KHAN S J, VISVANATHAN C, JEGATHEESAN V. Effect of powdered activated carbon (PAC) and cationic polymer on biofouling mitigation in hybrid MBRs[J]. Bioresource Technology, 2012, 113: 165-168. doi: 10.1016/j.biortech.2011.12.107 [30] 宋悦, 魏亮亮, 赵庆良, 等. 活性污泥胞外聚合物的组成与结构特点及环境行为[J]. 环境保护科学, 2017, 43(2): 35-40. [31] 李会东, 李璟, 张哲歆, 等. 过氧化钙联合絮凝剂调理污泥改善脱水性能[J]. 环境工程学报, 2019, 13(11): 2736-2742. doi: 10.12030/j.cjee.201901088 [32] SUTZKOVER-GUTMAN I, HASSON D, SEMIAT R. Humic substances fouling in ultrafiltration processes[J]. Desalination, 2010, 261(3): 218-231. doi: 10.1016/j.desal.2010.05.008 [33] YU H R, WU Z J, ZHANG X L, et al. Characterization of fluorescence foulants on ultrafiltration membrane using front-face excitation-emission matrix (FF-EEM) spectroscopy: Fouling evolution and mechanism analysis[J]. Water Research, 2019, 148: 546-555. doi: 10.1016/j.watres.2018.10.041 [34] LIU T, CHEN Z L, YU W Z, et al. Characterization of organic membrane foulants in a submerged membrane bioreactor with pre-ozonation using three-dimensional excitation-emission matrix fluorescence spectroscopy[J]. Water Research, 2011, 45(5): 2111-2121. doi: 10.1016/j.watres.2010.12.023 [35] MATILAINEN A, GJESSING E T, LAHTINEN T, et al. An overview of the methods used in the characterisation of natural organic matter (NOM) in relation to drinking water treatment[J]. Chemosphere, 2011, 83(11): 1431-1442. doi: 10.1016/j.chemosphere.2011.01.018 [36] WEN C, PAUL W, LEENHEER A J, et al. Fluorescence excitation-emission matrix regional integration to quantify spectra for dissolved organic matter[J]. Environmental Science & Technology, 2003, 37(24): 5701-5710. [37] 刘铮, 董秉直, 陈艳, 等. 三维荧光光谱表征膜污染物[J]. 环境化学, 2010, 29(3): 496-501. [38] ZHANG T, LU J, MA J, et al. Fluorescence spectroscopic characterization of DOM fractions isolated from a filtered river water after ozonation and catalytic ozonation[J]. Chemosphere, 2007, 71(5): 911-921. -

下载:

下载: