-

酚醛树脂生产过程中会产生大量高浓度酚醛树脂废水,我国每年生产酚醛树脂产生的废水可达到8×106 t。酚醛废水中含有大量挥发酚、苯酚和游离甲醛,还含有部分甲醇和少量低分子树脂等有毒物质,其中,甲醛>1 000 mg·L−1,苯酚>5 000 mg·L−1,COD>10 000 mg·L−1,属于高浓度难降解有机废水。

酚醛废水处理的复杂性限制了某些单一的低成本处理工艺的发展及应用,故目前通常采用多种工艺联合的方法。其中,以化学-生物联用法较为普遍[1-3]。由于酚醛废水中含有大量的苯酚和甲醛,对微生物有很强的毒性和抑制性,且实际废水的可生化性差(BOD5/COD在0.10左右),因此,预处理的作用显得至关重要。常用的预处理技术包括萃取法、缩合法、生物处理法、Fenton氧化法、臭氧氧化法和铁炭微电解等[3-4]。其中,铁炭微电解法因其具有设计简单、效果稳定、人工容易操作且易实现工业化等特点而备受关注。铁炭微电解法利用Fe/C原电池反应对废水进行处理,且集氧化还原、絮凝吸附、催化氧化、络合、电沉积以及共沉淀等作用于一体[5]。然而,对于高浓度酚醛废水的处理,铁炭微电解也同样存在局限性。有研究[3]表明,以铁炭微电解为单一预处理工艺进行高浓度酚醛废水处理时,出水还达不到后续生化处理的要求。也有研究[5]表明,在好氧条件下,铁炭微电解与生物降解协同作用强化了煤气化废水中酚类物质的去除;在厌氧条件下,铁炭微电解也可以强化污泥的厌氧消化,包括厌氧水解酸化和产甲烷[6]。纯菌实验研究结果[7]也表明,铁炭微电解与微生物共作用能有效提高难降解有机物(十溴联苯醚)的生物降解效率。此外,铁的投加有助于微生物反应过程中的电子传递,从而加速有机物的降解[8]。

基于以上研究结果,本研究将铁炭微电解工艺和活性污泥组合在同一个系统中,构建铁炭微电解与微生物共作用的预处理系统。不同于以往将铁炭微电解作用于曝气和酸性条件下,为了实现预处理工艺的低成本,本研究探究了未曝气情况下微生物辅助铁炭微电解对中性酚醛废水的处理效果,分别对铁碳填料和污泥投加量进行了优化,并采用实际酚醛废水进行预处理进水负荷的研究,最终实现酚醛废水的有机物稳定去除,并为后续生物反应提供可生化性底物。本研究可为铁炭微电解和微生物共作用的预处理工艺的启动和运行提供参考。

全文HTML

-

预处理实验选用的铁碳填料购买于南京宝热化工公司,其密度约1 200 kg·m−3、比表面积约1.20 m2·g−1、空隙率>65%、直径为2.50 cm、物理强度≥1 000 kg·cm−2,铁碳填料纯度为87%,其中,含铁量为75%、碳含量为12%、金属催化剂(铜和锰)含量为5%,其他部分为高黏土。首次使用铁碳填料前,将其置于1%~2%稀盐酸溶液中曝气10~20 min进行激活。为了保证微生物种群多样性,预处理体系中接种了2种不同来源的厌氧活性污泥,即柠檬酸废水处理反应器中的厌氧活性污泥(中温颗粒污泥,15 g)和淀粉生产废水处理工艺中的厌氧活性污泥(中温絮状污泥,15 g),2种污泥混合后污泥VSS为22.63 g·L−1,VSS/TSS为0.65。实验中配置苯酚和甲醛储备液备用,其浓度分别为7.50 g·L−1和3 g·L−1。

实际酚醛生产废水取自福建天利高新材料公司,为工厂经过缩聚反应之后的废水,废水中主要成分为耗氧有机物(以COD计)、苯酚和甲醛,含盐量和氯离子的浓度均较低。原水的主要水质参数如下:pH为7.25~8.83、COD为56 000~75 000 mg·L−1、苯酚为8 389 mg·L−1、甲醛为1 854 mg·L−1、BOD5/COD为0.11。厌氧反应过程中采用的接种污泥来自酒精废水生产工艺中的厌氧颗粒污泥,VSS为23.67 g·L−1, VSS/TSS为0.62。厌氧基质的配置参考PAN等[9]的研究。

-

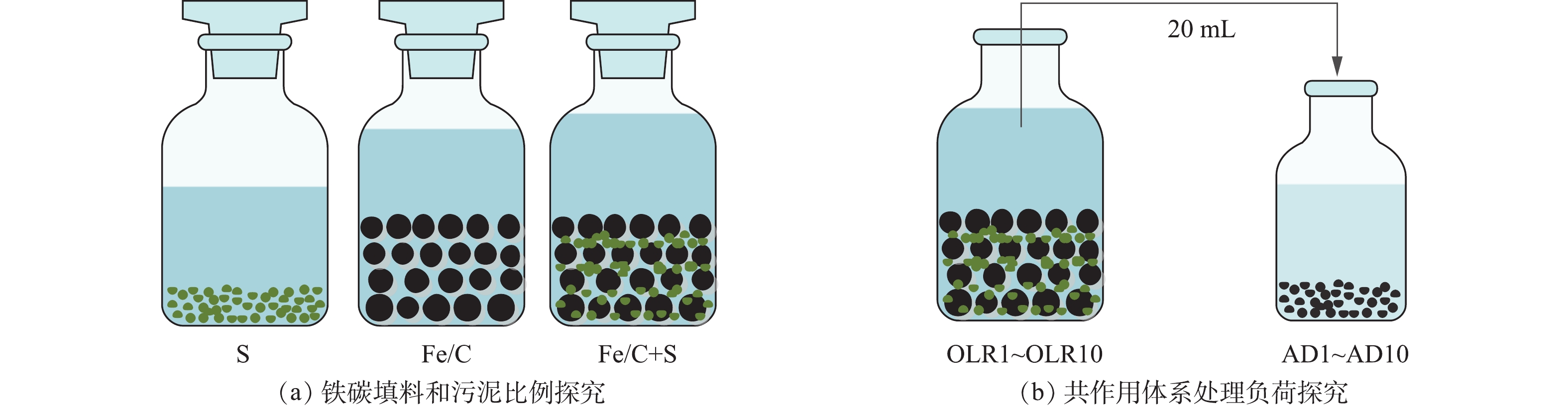

1)铁碳填料和污泥比例探究。为探究铁碳填料的投加量和污泥的投加比例对苯酚和甲醛去除效果的影响,本实验运用Design Expert 8.0.6软件中的中心复合设计(central composite design,CCD)进行两因素五水平实验,共计13组。同时针对正交实验设计中的铁碳填料添加量和污泥接种量再分别做对照实验,即只加铁碳填料(Fe/C)或只加污泥(S)。实验中污泥的投加比例参考已有的接种经验,10%~20%的接种量较为合适,正交实验设计软件设计的污泥投加比例为7.93%~22.07%。铁碳填料的投加量在实验室前期探究中为400 g·L−1,获得了较好的苯酚降解效果。也有研究[10]表明,当铁碳填料添加量为1 200 g·L−1时,难降解有机物去除效果最好,因此,参考前期的研究,软件设计的铁碳填料投加量为313.60 ~1 586.40 g·L−1。

在500 mL的反应瓶中,构建300 mL工作体积的反应体系,其中包括苯酚储备液20 mL、甲醛储备液20 mL、厌氧基质30 mL,铁碳填料和活性污泥(絮状/颗粒,1∶1)在不同实验组中的按不同的投加比例进行投加(表1),铁碳填料的量不计入300 mL的体系中,不足300 mL的部分用蒸馏水补充。反应装置见图1(a)。反应瓶置于室温下培养,定期进行取样,测定各反应体系中的pH、COD、苯酚和甲醛。最后利用Design Expert 8.0.6 软件分析结果,拟合出响应曲面。

2)铁炭微电解与微生物共作用预处理体系处理酚醛废水负荷探究。为了探究预处理体系对实际废水的处理效果以及最佳处理负荷,将酚醛生产废水原水分别进行15、10、5和2倍稀释,进行铁炭微电解与微生物共作用的预处理降解实验。在实际工程中,可通过增加回流比来实现对进水的稀释。鉴于有些有毒物质对微生物的毒害作用是一个缓慢的过程,为了明确微生物长期暴露于苯酚和甲醛环境中其活性是否会受到影响,从而探究污泥和铁碳填料共作用进行难降解有机物预处理的长期运行的可行性,本实验中投加的污泥分别选用前期暴露于苯酚和甲醛(500 mg·L−1和200 mg·L−1)环境中达2个月的污泥和未暴露的污泥。接种已驯化污泥的实验组编号为OLR1~OLR5,接种未暴露的污泥的实验组编号OLR6~OLR10,其中OLR1和OLR6为未加酚醛废水的空白对照组。

预处理体系设置为300 mL的反应瓶。在体系AD1~AD5/AD6~AD10中分别加入酚醛废水0、20、30、60和150 g,厌氧基质30 g,采用上述实验中获得的最佳铁碳填料和污泥投加比例(铁碳填料添加量为1 400 g·L−1,污泥接种量为10%),即添加420 g铁碳填料和30 g混合污泥,不足300 mL的部分由蒸馏水补充。为了更好的评估预处理的整理效果,增加了后续的厌氧批次实验,以预处理的出水为底物,厌氧批式体系为100 mL,其中包括预处理出水20 mL,厌氧颗粒污泥20 g(酒精废水处理反应器),厌氧污泥培养基质20 g,为保持100 mL工作体积,加入蒸馏水40 mL。将反应瓶置于37 ℃的振荡摇床中培养(120 r·min−1),反应48 h后,对体系中pH、COD、苯酚和甲醛浓度进行测定。反应体系编号与OLR1~OLR10相对应,分别为AD1~AD10(图1(b))。

-

pH、SS、VSS和BOD5的测定采用《水和废水监测分析方法》[11]中的标准方法;采用COD快速测定仪(连华科技,5B-3C)进行水样中COD的快速测定[12]。采用配有阴离子交换柱(Dionex IonPacTM AS11)的阴离子色谱(ICS-3000, Dionex, UAS)检测厌氧代谢过程中产生的挥发性脂肪酸(VFAs)乳酸、乙酸、丙酸和丁酸等[13],交换柱包括分析色谱柱(Dionex IonPacTM AS11-HC, 4 mm×250 mm)和保护柱(Dionex IonPacTM AG11-HC, 4 mm×50 mm)。流动相为KOH洗脱液,流速为1 mL·min−1。

苯酚和甲醛的测定采用高效液相色谱(HPLC,日立L-2000),液相色谱条件如下:C18色谱柱(250 mm×4.60 mm,5 μm),柱温为35 ℃,流动相为A(甲醇)和B(超纯水) (50∶50, 体积比),流速为1 mL·min−1,检测器为UV,检测波长分别为340 nm(甲醛)和278 nm(苯酚)。

甲醛的测定需要进行衍生,衍生剂为2,4 -二硝基苯脐溶液,配置方法如下:称取2,4 -二硝基苯肼1 g放入100 mL容量瓶中,加乙睛溶解并稀释至刻度,摇匀后置于暗处待用。采用甲醛(10 mg·mL−1)和苯酚(分析标准品≥99.50%)标准品配置标准储备液,浓度分别为200 mg·L−1和1 000 mg·L−1,溶剂为甲醇/蒸馏水(1∶1,体积比)。

甲醛标液的样品准备:取配制的甲醛溶液(200 mg·L−1) 2 mL置于10 mL容量瓶中,加入4 mL 2, 4-二硝基苯脐溶液,用蒸馏水稀释,置于40 ℃水浴锅中,避光放置12 h,经0.45 μm的微孔滤膜过滤。将滤液逐步稀释,配制成0.10~40 mg·L−1不同质量浓度的甲醛标准溶液(现配现用)。苯酚测试的样品准备:直接将1 000 mg·L−1的苯酚标准储备液用蒸馏水进行梯度稀释配制成0.10~50 mg·L−1不同质量浓度的苯酚标准溶液(现配现用)。取1 mL不同浓度的标准样品到棕色色谱瓶中,待测。样品溶液与甲醛和苯酚的标准溶液用相同的处理方法处理后进样,浓度高的样品需要进行稀释。

Fe2+离子浓度:采用邻菲罗林分光光度法,使用昂拉EU-2600分光光度计,参考标准方法HG/T 3539-2003。方法原理为:亚铁离子在pH为3~9的溶液中与邻菲罗啉生成稳定的橙红色络合物,该络合物在波长为508 nm处有最大的吸收峰。

1.1. 实验材料

1.2. 实验设计

1.3. 分析方法

-

1)各体系中pH和COD变化。反应进行24 h之后,污泥体系的pH最低,而且随反应的进行有所下降(8.20~8.40),且各实验组之间的差异并不显著(P>0.05)。铁炭微电解体系中的pH较高,为9.38~10.48,主要是由于铁炭微电解反应消耗体系中的H+而提升了系统的pH[14]。当铁炭微电解发挥作用时,体系中阳极和阴极进行的反应如式(1)和式(2)所示。

反应中产生的Fe2+和原子[H]具有较高的化学活性,能改变废水中许多有机物的结构和特性,使有机物发生断链、开环等作用。在污泥耦合铁碳填料的所有实验组中,pH为8.87~9.66,介于只加污泥体系和只加铁碳填料体系之间的值。产酸菌的生长pH为5~9,这说明在铁炭微电解和微生物共作用体系中,产酸菌降解有机物产生挥发酸,为铁炭微电解提供H+。有研究[6]还表明,铁炭微电解会通过促进乙酸激酶、磷酸转乙酰、丁酸激酶和磷酸转丁酰酶等挥发酸合成过程中关键酶实现对产酸发酵的强化。

由COD的变化来看,添加污泥体系中COD的去除率比铁炭微电解体系和共作用体系高,反应48 h后COD去除率在4.27%~8.00%。而在铁炭微电解体系和共作用体系中,随着铁炭微电解反应的进行,体系中Fe2+浓度的升高对系统COD的测定造成了干扰,使系统中测得的COD值升高。Fe2+的理论需氧量为0.11 g·g−1,体系中COD值通过测定Fe2+浓度进行校正[15]。在铁炭微电解体系(Fe/C-1~7)中,COD的去除率随着铁碳填料的增加而上升。而在污泥和铁炭微电解共作用体系中,COD的去除率为22.35%~30.41%(表2),且在Mix8体系中,污泥和铁炭微电解的共作用的贡献率最高为5.61%。

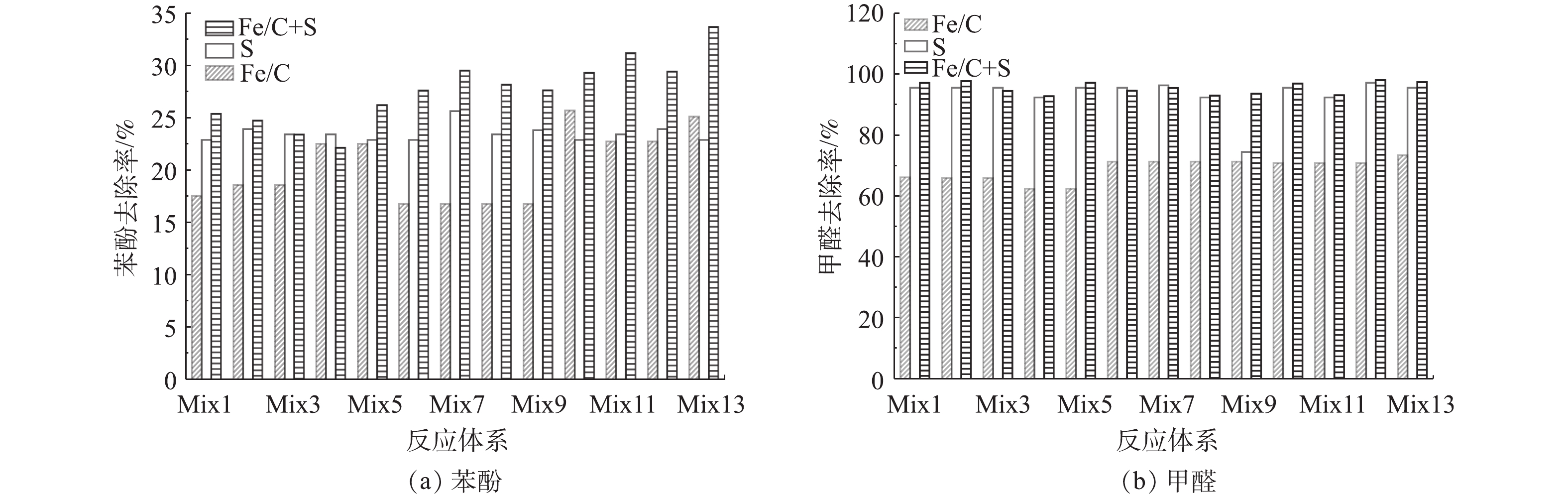

2)苯酚和甲醛的降解效果。图2对比了3种培养体系中苯酚和甲醛的去除率。由于反应进行24 h之后苯酚的降解无显著升高,因此,选择反应24 h后体系中的苯酚去除率来进行比较。从污泥和铁碳填料的单独作用来看,污泥对苯酚的去除效果更好。而且,虽然在接种量低于20%时,体系中苯酚的去除率差异不大,为22.80%~23.90%,但在接种量为22.07%的体系中苯酚去除率达到25.60%。这主要是因为微生物量的增加有助于苯酚的降解。

在所有反应体系中,共作用体系中苯酚的去除率都高于污泥或铁炭微电解单独作用的体系,说明构建铁炭微电解与微生物共作用体系可以促进苯酚的降解。而对于添加铁碳填料的体系来说,苯酚的降解效率和铁碳填料的投加量并未呈现明显正相关或者负相关的关系,其中Mix4最低(22.13%)而Mix13最高(33.68%)。虽然有研究实现了微生物和铁炭微电解共作用体系对苯酚的高效降解(92%),但是其体系中的苯酚浓度较低(330 mg·L−1)且通过曝气保持溶解氧浓度为0.50 mg·L−1[5],而本研究中的苯酚浓度为500 mg·L−1,且为了节省实际的运行成本,反应过程并未进行曝气。

与苯酚较难降解的特性不同,甲醛是小分子有机物,可以被生物很快地利用[16]。相比于苯酚在24 h降解趋于稳定,甲醛在系统反应3 h后已经被大部分降解。但为了保持统一,甲醛依然采用反应24 h之后体系中的数据进行比较。对比铁炭微电解和污泥生物降解作用单独降解甲醛的结果发现,微生物对甲醛的降解效率更高,达到了95%以上,而且污泥的接种量对实验浓度下甲醛的降解无显著影响。相比之下,铁炭微电解单独作用对甲醛去除率较低,为60%~65%。随着铁碳填料投加量升高,甲醛的去除率略有升高。由于在实验浓度下,95%左右的甲醛都已经被微生物降解了,所以在铁炭微电解和微生物共作用体系中,促进作用表现得并不明显。但依然可以看出,在所有微生物和铁炭微电解共作用体系中,甲醛的去除率均略高于单独作用体系,且去除率在95%以上。上述结果表明,甲醛在共作用体系中得到了高效去除。

综合苯酚和甲醛的降解效果发现,在不同污泥接种量和铁炭投加量情况下,微生物和铁炭微电解共作用可促进苯酚和甲醛的降解。相较于甲醛,苯酚更难被降解。此外,在同一个体系中的苯酚和甲醛的去除率均未达到最高值,苯酚的降解在Mix13体系中达到最高值,而Mix12中甲醛的降解效率最高,但是在Mix13体系中,甲醛的去除率也很高,与Mix12并未有较大差异,均大于98%。这主要是由于甲醛是小分子有机物,相较于苯酚来说,更易被降解。苯酚降解需要开环和断链,首先苯酚可转化成苯甲酸,再开环生成长链脂肪酸,最终转化成乙酸等;或苯酚双键断开形成羟基环己烷,再转化为乙酸等。由于甲醛在所有共作用体系中的去除率均大于95%,所以在实际选择铁碳填料和污泥的投加量时,应更侧重于考虑苯酚的降解。

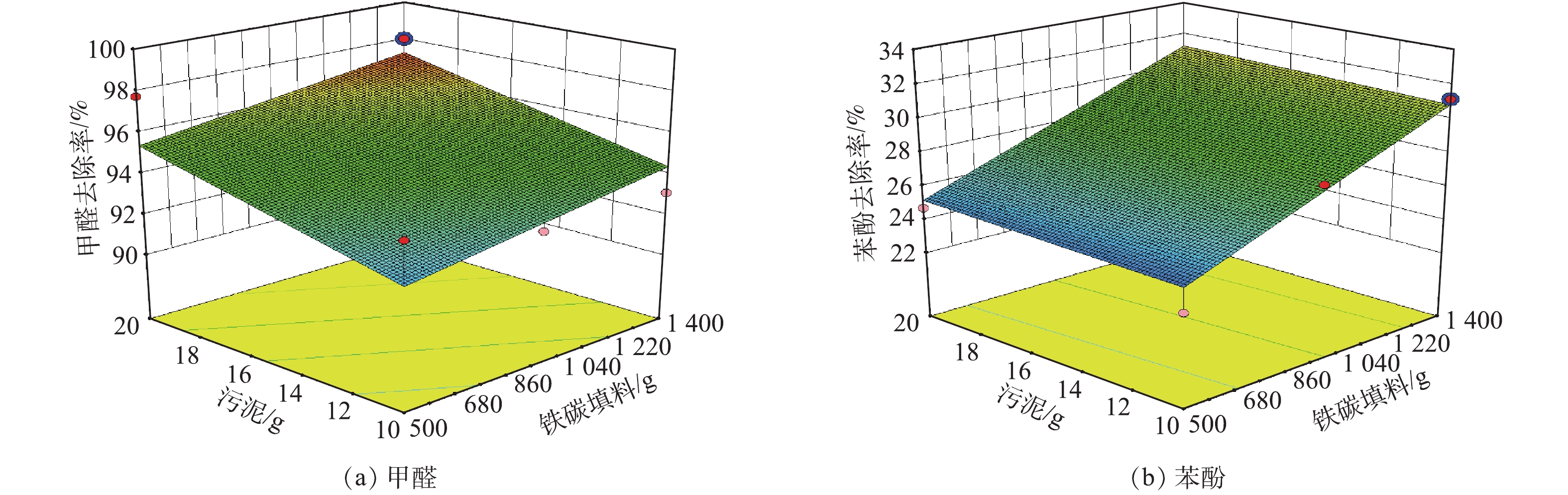

3)响应曲面分析。为了获得最适的铁碳填料和污泥的投加比例,对正交实验结果进行了响应曲面分析(图3)。结果表明,当铁碳填料添加量为1 400 g·L−1、污泥接种量为10%时,体系中苯酚的去除率最高;而当铁碳填料为1 400 g·L−1、污泥接种量为20%时,甲醛的去除率最高。由此可见,考虑到甲醛在各共作用体系均达到了90%以上的去除率,因此,以铁碳填料为1 400 g·L−1、污泥接种量为10%作为系统运行的最优参数。由图3可见,并未出现中间的凸点或凹点,最大值出现在边缘地区,这说明体系中苯酚和甲醛的去除率可能随着铁碳填料的添加或者微生物接种量的增加而增加。然而在实际工程应用中,铁碳填料的添加会造成系统运行成本的增加,因此,需要在合理的范围内进行参数的优化。

-

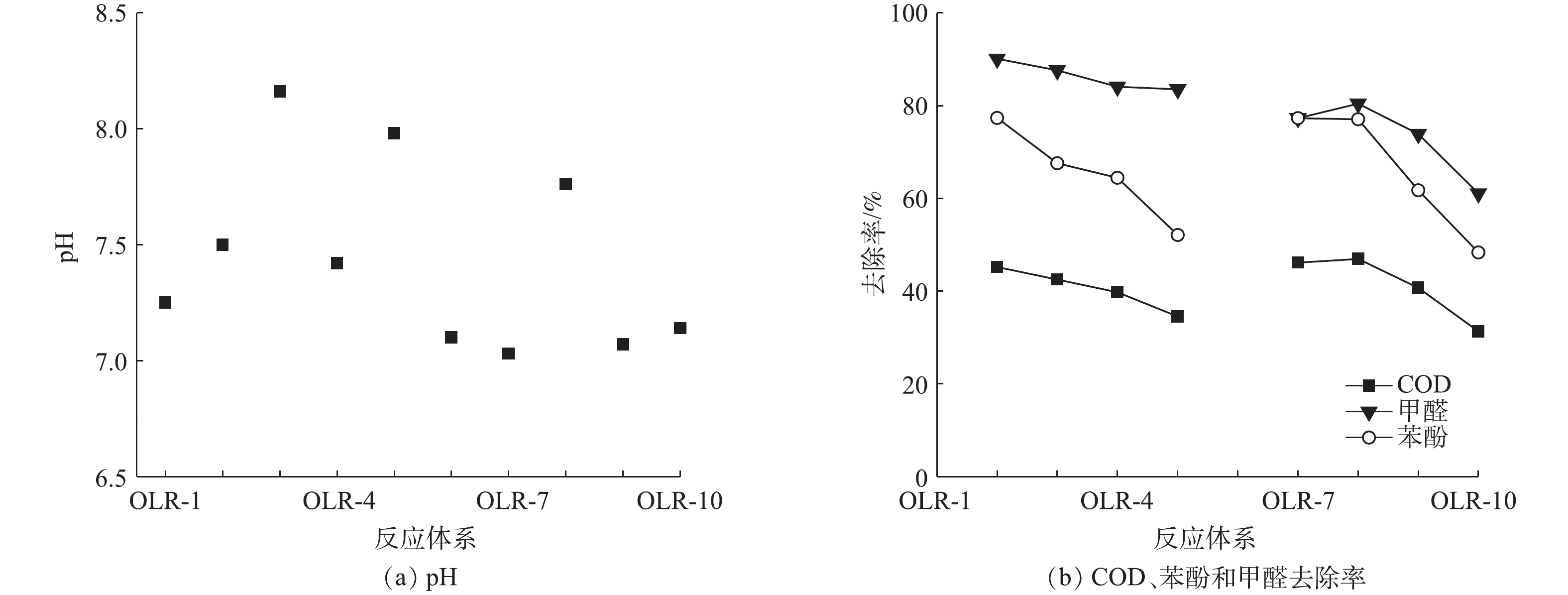

1)预处理实验结果分析。反应24 h后,对系统中的pH、COD、苯酚和甲醛含量进行了测定,结果见图4。由pH的变化来看,OLR1~OLR5反应体系中pH在7.40~8.10,而OLR6~OLR10反应体系中pH相对略低,为7~7.70,但各体系间差异相对较小。2种污泥体系在同一稀释倍数下,耗氧有机污染物的浓度(以COD计)的去除率并未呈现明显差异,然而随着稀释倍数的降低,COD的去除率也逐渐降低。当被稀释15倍和10倍时,2种污泥体系中COD的去除率均在40%以上;而稀释倍数为2倍时,前期暴露污泥体系的COD去除率降低至34%,略高于未暴露污泥添加的系统(31%)。这说明随着负荷的提高,预处理体系对COD去除率有所下降,因此,要根据系统的承受能力进行负荷的调控。

与COD的去除率变化趋势相近,苯酚的去除率也随着稀释倍数的降低而降低。且在2种污泥体系中的变化趋势相似,在同一稀释倍数下,2种反应体系中苯酚的去除率大小也无显著差异。由此可见,微生物并未因苯酚和甲醛的长期暴露而丧失活性。此外,由图4(b)可知,在同一反应体系中,甲醛的去除率明显高于苯酚。而且,在投加前期暴露于苯酚和甲醛中的污泥的体系中,虽然随着稀释倍数的降低,甲醛的去除率有所下降,但是变化不大,由90%下降至83%,然而在未暴露的污泥体系中,甲醛的去除率由80%下降至61%。这说明暴露于苯酚和甲醛中的污泥不但没有失去生物活性,反而提高了对甲醛的去除率,这很可能是长期的暴露对系统中的微生物起到了一定的驯化作用[17]。此外,相比如原始废水BOD5/COD为0.11,在预处理反应结束后,所有体系中BOD5/COD均大于0.30(表3),这表明铁炭微电解与微生物共作用预处理体系可提高酚醛废水的可生化性。虽然随着进水浓度的升高,体系对苯酚的去除量在升高,但考虑到实际运行中后续厌氧工序对苯酚浓度耐受的能力,处理负荷倾向于选择合适去除率条件下最高的进水浓度,因此,对进水进行5倍稀释(OLR-4和OLR-9)较为合适。OLR-4(OLR-9)系统中COD、苯酚和甲醛的去除率约为39.75%(40.69%),64.46%(61.75%)和84.07%(73.88%)。

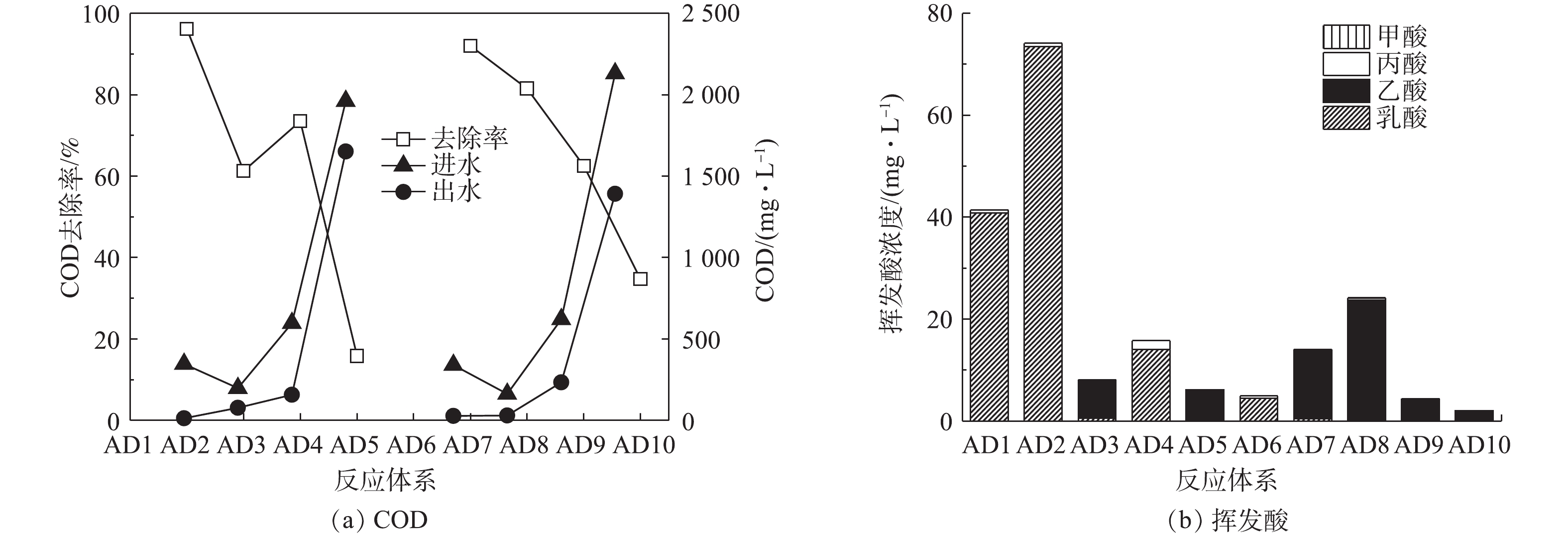

2)厌氧降解实验结果。实际工程中的厌氧反应器的水力停留时间一般为1~3 d,所以本实验选择的培养时间为3 d。如图5(a)所示,在AD2~ AD5中的COD去除率均呈现下降趋势,分别为96.14%、61.29%、73.54%和15.8%;同样,在AD7~AD10反应体系中的COD去除率也有较明显下降,分别为92.05%、81.48%、62.47%和34.67%。这种变化趋势与各个厌氧体系中初始进水耗氧有机污染物的浓度(以COD计)有关。在稀释倍数高的体系中(OLR-2/OLR-7),后续厌氧体系进水耗氧有机污染物的浓度的较低,在AD2和AD7体系中的进水COD分别为346.43 mg·L−1和340.36 mg·L−1。而当原水稀释倍数为2倍进行预处理时,进入厌氧体系的COD可达到3 000 mg·L−1以上,导致厌氧瓶中的COD去除率降低。此外,实验结果还表明,不同污泥体系对预处理出水的厌氧降解效果并无较大差别。由图5(b)可见,当停止反应时,各个体系中的VFAs的含量并不高:在AD7~AD10反应体系中,VFAs的总量在20 mg·L−1以下,且均是以乙酸为主;在AD2~AD5反应体系中,AD3和AD5中的VFAs以乙酸为主导;在AD2和AD4体系中以乳酸为主导。这说明不同污泥体系对系统中VFAs的组成成分会有影响。互营乳酸氧化菌和产甲烷菌共同作用才能完成乳酸的最终甲烷化[18],而乙酸可以被厌氧产甲烷菌直接利用,因此,未暴露的污泥的添加有利于后续的厌氧反应。

由在厌氧体系中苯酚和甲醛的去除率(表3)可知,在厌氧反应结束时,体系中甲醛的去除率为100%,而苯酚的去除率较低。除了在AD2和AD7体系中,苯酚的去除率分别为26.24%和27.05%,在其他体系中苯酚的去除率均低于10%,并且去除率随着苯酚含量的升高而降低,这说明高浓度的苯酚在厌氧体系中无法有效地被去除。因此,在传统厌氧生物处理的基础上,若想通过厌氧微生物处理降解苯酚,需要进一步探究。可考虑前期针对高浓度苯酚对微生物活性的抑制问题进行的改变温度、物理吸附、回流稀释以及投加共代谢基质等方法[19],或者通过开发新型厌氧反应器如ABR-MECs[13],以实现难降解有机物的高效稳定去除。

综合考虑预处理和厌氧反应体系中COD、苯酚和甲醛的去除率,可以采用5倍稀释的实际酚醛废水进行后续预处理反应器的启动和运行。对于预处理系统中接种污泥的选择,可以考虑将前期暴露于苯酚和甲醛的污泥和新鲜的厌氧污泥进行混合。

2.1. 铁碳填料和污泥比例探究分析

2.2. 铁炭微电解与微生物共作用系统处理酚醛废水

-

1)铁炭微电解与微生物共作用可协同促进苯酚和甲醛的降解,铁碳填料的最适投加量为1 400 g·L−1,污泥的最适接种比例为10%。

2)针对实际酚醛废水,铁炭微电解和微生物共作用预处理系统合适的启动和运行废水浓度约为COD 12 000 mg·L−1、苯酚1 676 mg·L−1、甲醛370 mg·L−1。

3)对于预处理系统的接种污泥,暴露于苯酚和甲醛体系的微生物对甲醛的降解有优势,而未暴露的活性污泥中的微生物对后续厌氧反应有促进作用,因此,可以考虑将2种污泥进行混合接种。

下载:

下载: