-

截至2019年,我国已建成5 000多座城镇污水处理厂[1],其中有数百座污水处理厂被城市发展区域包围成为“城中厂”[2]。污水处理厂在运行中会产生大量恶臭物质,由此带来的恶臭污染问题日益严重[3]。《恶臭污染物排放标准》(GB14554-1993)中规定了恶臭污染物的排放标准,要求污水处理企业应严格限制相关污染物的排放。与其他恶臭气体去除方法相比,生物除臭法具有投资少、操作简便、运行成本低、二次污染小等优点[4],因而近年来获得迅速发展。据统计,生物除臭专利近5 a的数量已占历年除臭专利总量的75%以上[5],故有必要对污水处理厂产生恶臭物质及生物除臭技术应用中的关键影响因素进行梳理。本文系统总结了污水处理厂恶臭污染的特点,并分析生物技术应用中的关键影响因素及工程应用案例,以期为污水处理厂兴建或改造现有除臭设备、解决恶臭污染问题提供参考。

-

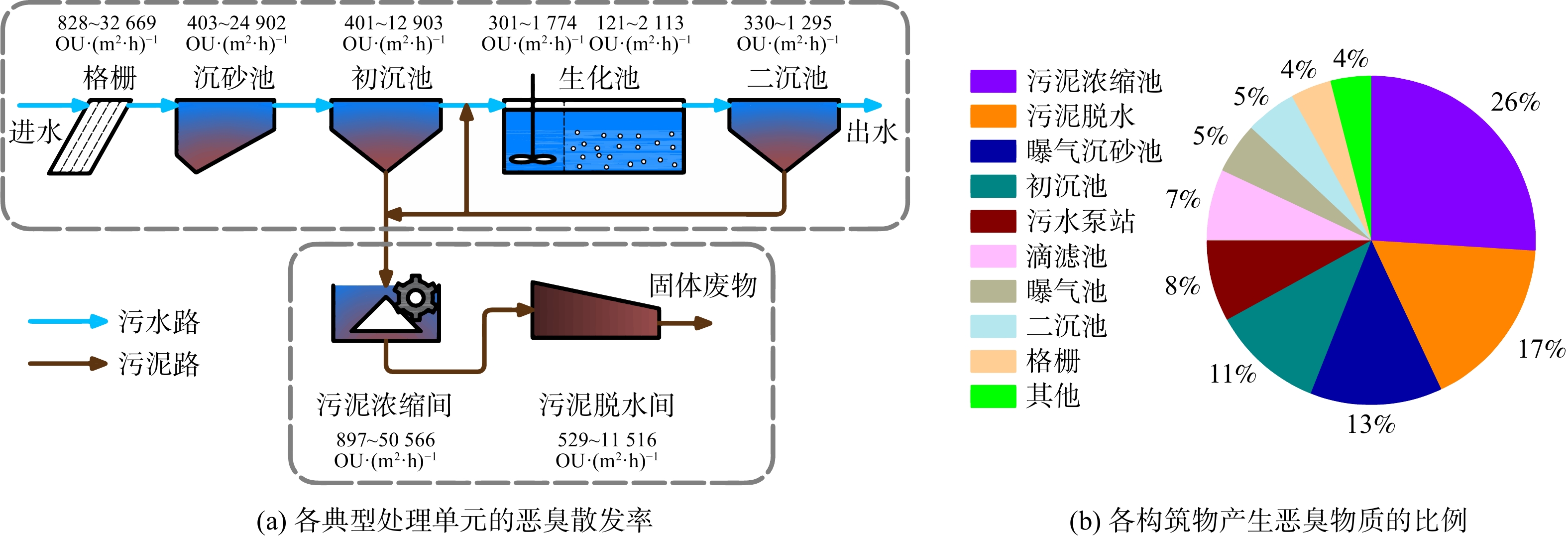

污水处理厂每个处理单元的工艺运行条件不同,使得各处理单元的污水性质存在差异,因此,各处理单元产生的恶臭物质在总量、组分和排放强度上亦不同。

恶臭浓度是基于嗅觉器官实验法对恶臭强度进行数量化表征的指标[6]。一般将无臭清洁空气对单位体积恶臭物质进行连续稀释,直至嗅辨员阈值时的稀释倍数定义为恶臭浓度,单位为OU·m−3。为评价各处理单元的恶臭排放强度,将各单元恶臭浓度乘以恶臭气体的排放量定义为恶臭散发率(图1(a))[6]。其中,排放量用气泵抽取某一密闭空间内恶臭气体的流量(m3·h−1)来表示。为评估各处理单元对污水处理厂恶臭污染的贡献,将各单元恶臭散发率乘以恶臭散发表面积(即暴露在外的水面面积,单位为m2)得到的结果定义为各处理单元产生的恶臭比例[6](图1(b))。

污水处理厂中产生恶臭物质的处理单元包括2部分:污水处理的进水区(进水泵站、格栅、沉砂池等)与污泥处理区(污泥浓缩间、污泥脱水间等)[7]。大部分恶臭物质的产生是由于污水和污泥中氧含量较低所致,通常厌氧处理工艺产生的恶臭强度比好氧处理工艺的更大[8]。长污泥龄污水处理工艺,如氧化沟,所产生的恶臭浓度高于短泥龄处理工艺,如曝气池。恶臭物质的排放受温度影响亦较为明显。如曝气沉砂池和粗格栅产生的恶臭存在明显的季节差异:夏、秋季节较高,冬、春季节较低。这是由于在不同季节污水温度差别很大,温度会影响恶臭物质生成反应的进行程度和反应速率[7]。另外,污水水质对恶臭产生的影响亦较为明显。当污水化学需氧量和硫酸盐质量浓度更高时,处理单元产生的恶臭浓度也会更高[9]。因此,对治理污水处理厂恶臭污染之前,应首先考虑污水处理工艺及各处理单元的恶臭物质排放特征,结合具体环境因素(水质、温度、氧气条件及污泥龄等),重点控制污泥处理区和污水进水区产生的恶臭物质。

-

污水处理厂各处理单元所产生的恶臭物质组成及浓度不尽相同。还原硫化合物(reduced sulfur compound, RSC)是污水、污泥处理过程中产生最重要的一类恶臭物质[10],包括H2S、甲硫醇、甲硫醚、二硫化碳、二甲基二硫醚等。RSC主要来源于厌氧条件下污水中的硫酸盐还原及含硫有机物的脱硫作用。AOKI等[11]测定了污水处理厂9个不同位置的21种恶臭物质质量浓度(表1),发现RSC是造成污水处理厂上游构筑物(进水井、格栅沉砂池、初沉池等)恶臭污染的主要污染物。JIANG等[12]基于24项不同研究的结果,总结了污水处理厂沉砂池、格栅、初沉池和生化池的环境空气中RSC特征。其中,H2S质量浓度为0.1~20 480 μg·m−3,甲硫醇质量浓度为0.4~2.4 μg·m−3,甲硫醚质量浓度为0.4~5 450 μg·m−3,二硫化碳质量浓度为3.06~9.82 μg·m−3,二甲基二硫醚质量浓度为0.62~1 600 μg·m−3。污泥处理单元的构筑物,如储泥池和污泥脱水间,所释放的恶臭物质主要是RSC及含氮化合物,其中含氮化合物主要是氨、胺、吲哚和甲基吲哚等[13]。综上所述,污水处理厂排放的恶臭物质中,约90%以上是含硫化合物,其中H2S是最主要的污染物[9-10,14-15]。

-

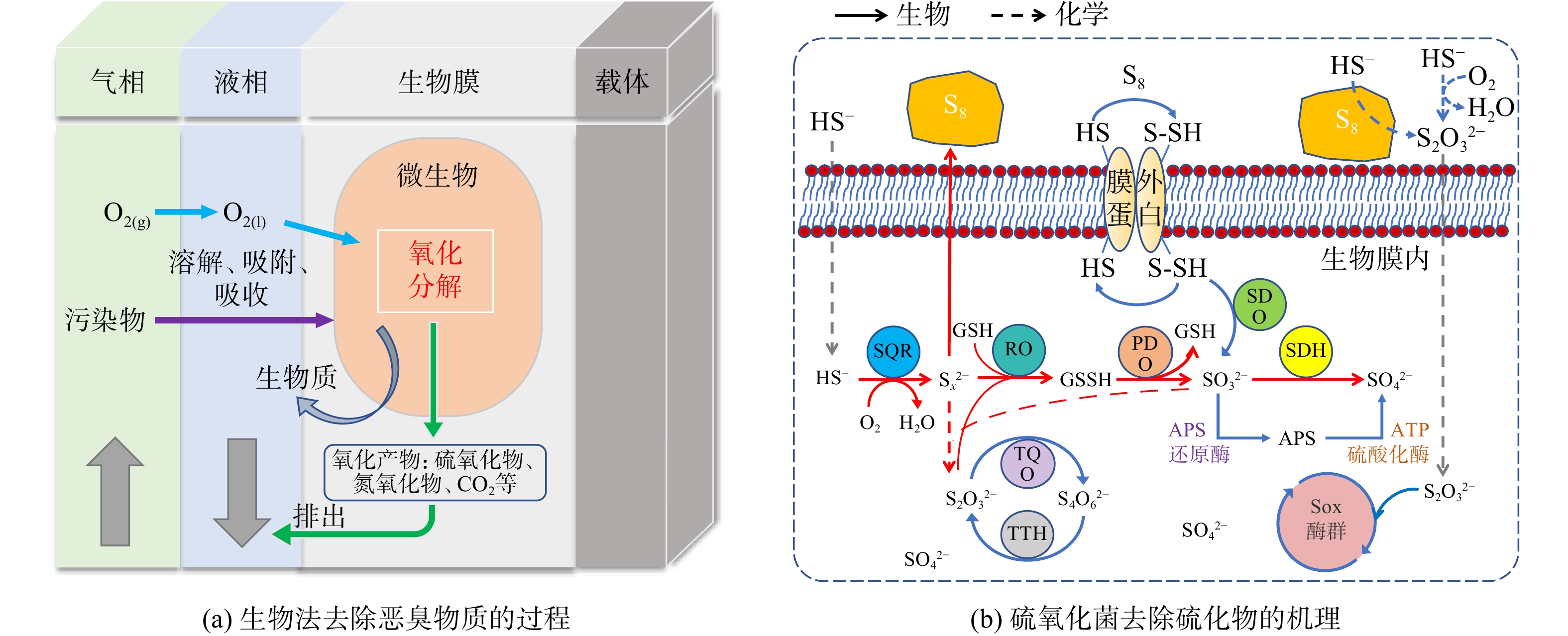

约81%~91%的城镇污水处理厂安装了恶臭物质处理系统,其中生物法占78%,化学洗涤法占11%,活性炭吸附占2%,另有9%的污水处理厂将恶臭物质引入曝气池进行处理[17]。生物处理是最常用的恶臭处理技术。该技术的本质是以恶臭物质为底物驯化适宜的微生物菌群,使恶臭污染物在微生物同化、异化的过程中被去除掉(图2)。生物除臭技术的关键影响因素如下。

1) 微生物。微生物是生物除臭过程的引擎,亦是去除污染物的执行者[18]。城镇污水处理厂的含硫恶臭物质主要靠硫氧化微生物去除(表2)。硫氧化微生物的营养类型可分为4种:专性无机营养、专性光合营养、兼性无机营养和专性有机营养[19]。专性无机营养的菌种有Thiobacillus denitrificans、Acidithiobacillus thiooxidans和 Chlorobium limicola,可在中性和酸性条件下高效去除含H2S的恶臭物质[20-21]。专性有机营养的菌种包括:Xanthomonas、Pseudomonas和Hyphomicrobium,这些菌株亦可高效去除H2S及含硫有机恶臭物质[22-23]。此类微生物通常适宜在中性条件下生存。硫氧化微生物的接种来源非常广泛,包括污水处理厂的活性污泥、被相关污染物污染过的土壤或水体、实验室中驯化可降解相关污染物的菌群以及菌群中分离获得的纯种菌[24-25]等。

2)营养液。为使微生物处于最佳代谢状态,通常需要满足的条件有:适当的水分、营养、温度、pH等。流动液相可为微生物生长提供水分和矿物质营养,并可提供控制运行条件的手段。液相通常富含基本矿物营养物质,包括氮、磷、钾和微量元素等组成的盐类,例如:KH2PO4、Na2HPO4、KNO3、(NH4)2SO4、NH4Cl、NH4HCO3、CaCl2、MgSO4、MnSO4、FeSO4、Na2MoO4和维生素[26-27]。在研究实践中,污水处理厂处理的生活污水即可作为微生物的营养液[28]。此外,营养液还可发挥冲洗微生物代谢产物并调节pH的作用。

3) pH。稳定的pH是实现高效去除恶臭污染物、避免发生抑制作用的前提条件。大部分硫氧化微生物只在特定的pH范围内具有活性,其适宜的pH一般为2.0~10.0。异养硫氧化微生物的最适宜pH接近中性,高于或低于该范围均会使其活性受到抑制。在不同pH条件下还可能演化出不同微生物群体,亦会影响微生物系统的去除性能[29]。另外,pH在减少酸性气体气液传质阻力方面具有显著作用,较高的pH有利于酸性气体溶解并提高酸性气体的去除率。在处理含硫恶臭气体时,通常会使填料床pH下降。为增强系统的缓冲能力,可通过添加缓冲材料,如碳酸钙、白云石或粉碎的贝壳来稳定系统pH,也可通过喷洒具有缓冲作用的营养液来控制pH,如Ca(OH)2、K2HPO4、NH4Cl和尿素等。

4)填料。填料床是生物反应器的核心组件,可为微生物的附着和气液接触提供场所[30],甚至提供营养及pH缓冲能力[31]。理想的填料应满足如下特点:低成本、大比表面积、高孔隙率、高化学稳定性和高结构强度、低密度,并易于微生物附着。沸石、陶粒、珍珠岩、熔岩是常用填料[32-33],具有比表面积大与孔隙率高,且利于生物膜的固定等优势。泰勒花环、聚丙烯鲍尔环、聚氨酯泡沫等塑料材料的化学性能稳定、成本低、孔隙率高,因此,这些材料在许多研究和大规模应用中被成功应用[34-36]。当污染物浓度较低时,采用大比表面积的填料可有利于克服传质阻力[37-38]。堆肥、泥炭、土壤等天然填料本身携带着丰富的微生物群体,可为微生物提供营养,然而天然填料的使用寿命有限,通常使用2~3 a后就需要更换[39]。

-

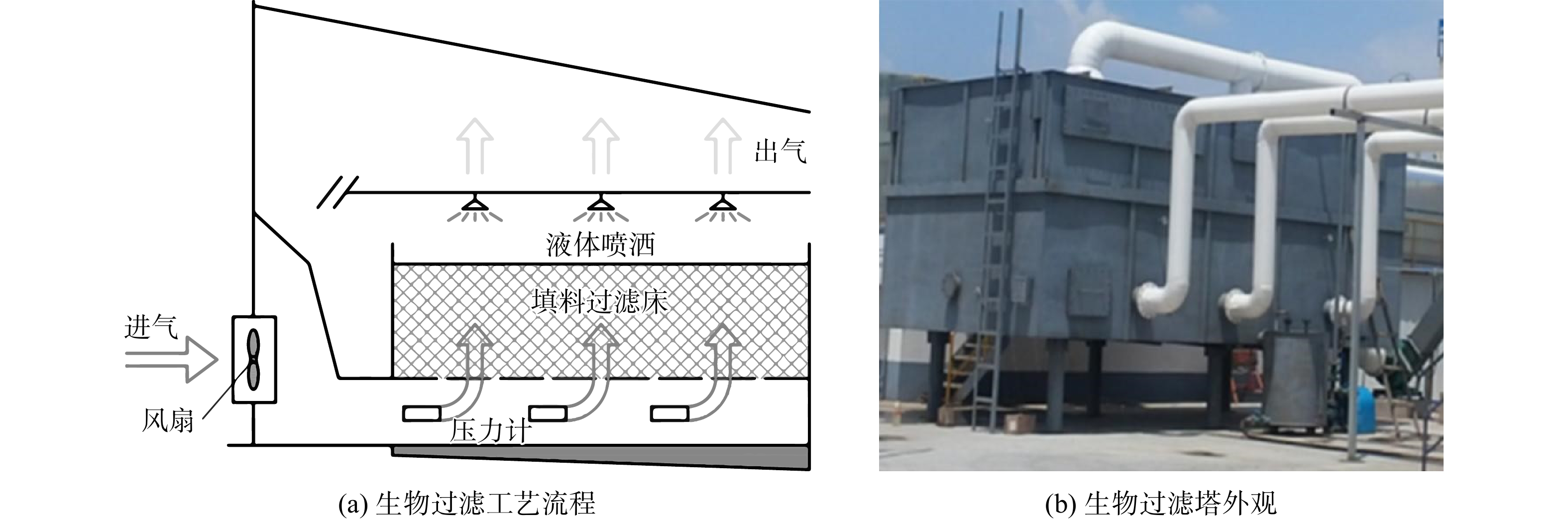

生物过滤法宜用于去除流量大但浓度低的废气,对水溶性差的污染物去除效果较好,可用于去除无量纲亨利系数等于或低于10的气态污染物[40]。付妍等的研究[41]即为利用生物过滤法处理天津某污水处理厂的恶臭气体的典型案例(图3)。该生物过滤系统包括1个生物过滤塔、1个空气增压泵和1个水泵。待处理污染物为复合型恶臭气体,来自于该厂的混合池、曝气池和污泥区,废气总量11 000 m3·h−1,平均空床停留时间(empty bed residence time, EBRT)为15 s。该案例中的恶臭物质主要有H2S及致臭挥发性有机物(volatile organic compounds, VOCs)2类,其平均进气质量浓度分别为2.5~3.5 mg·m−3和200~300 mg·m−3,平均去除率分别为100%和>90%。处理过程中反应器的平均压降为0.45 kPa·m−1。生物过滤塔采用的填料为TJ-003填料,具有大比表面积、结构稳定、耐腐蚀及易于微生物附着等特点,其填充体积和高度分别为45 m3和1.5 m。研究者根据恶臭物质类型筛选得到复合优势菌群,并将其接种于填料上。该菌群的单位填料接种生物量为4.44 kg·m−3,对此污水处理厂恶臭物质的去除效果良好,可有效降低微生物系统的启动时间。生物过滤塔所需补充水为污水处理厂进水。通过位于填料床上方的喷头对填料床进行间歇洒水以实现补水,并维持反应器内湿度;同时,污水处理厂进水含有的丰富营养元素(碳氮磷等)可为微生物提供充分的营养以维持其活性,系统的最小补水量为159 L·(m3·d)−1。然而,污水处理厂进水中丰富的营养易导致填料中微生物过度增殖,使得反应器内部堵塞频率增多。生物过滤塔的反应器结构简单、除臭效率高、建设及运行成本低;然而该反应器无连续流动液相,仅靠定期补水来维持滤床内的湿度和pH,因此,在处理高浓度含硫气体时,滤床填料易酸化腐败导致滤床堵塞,需要定期更换填料。综上所述,在生物过滤工艺运行中,应避免系统内生物过度增殖,并确保实现pH的灵活调节,以保证系统的长期稳定运行。

-

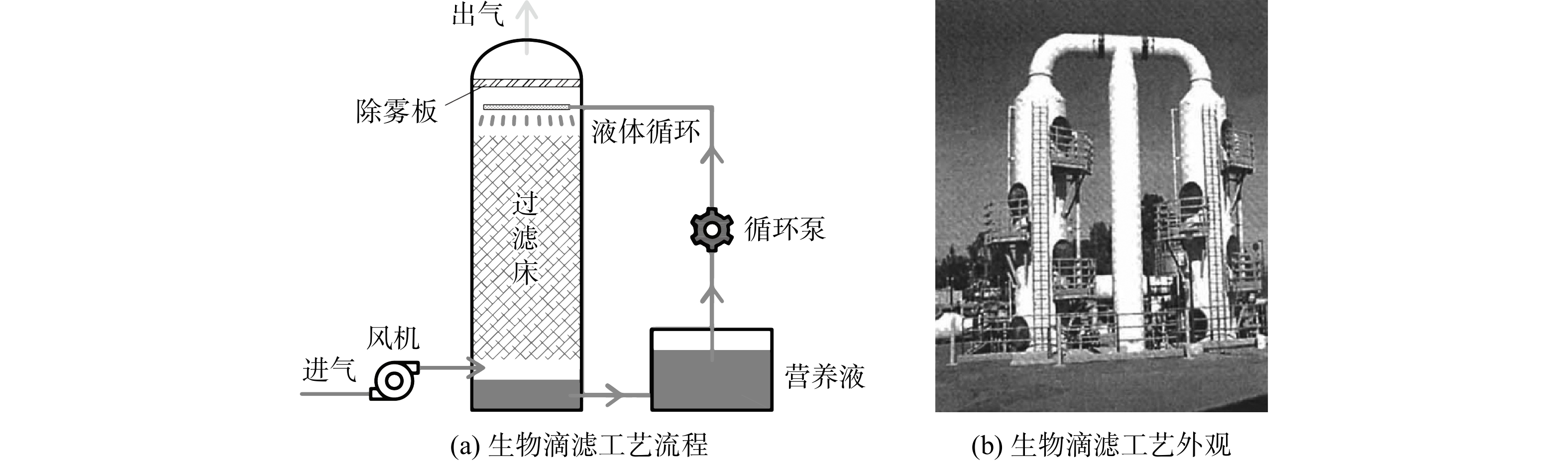

生物滴滤法适用于无量纲亨利系数等于或低于1的废气处理[40]。生物滴滤塔内保持着不断循环的液相,其工艺参数,如pH、营养物、盐含量和有毒降解产物等,易于被连续监测和控制。因此,对于易导致生物系统酸化的含硫气体,生物滴滤池的处理效果比生物过滤池更优。GABRIIL等[42]将美国加利福尼亚州某污水处理厂内处理废气的化学洗涤塔改造为生物滴滤塔(图4),用于处理含有H2S和致臭VOCs的复合恶臭气体。该污水处理厂恶臭污染物的恶臭浓度约为(1 980 ± 480)OU·m−3。改造后的生物滴滤塔内径为1.8 m、高9.7 m;塔内填料为聚氨酯泡沫(比表面积 600 m2·m−3,孔隙率97%),堆积高度为3.7 m。聚氨酯海绵拥有较大的比表面积,更利于微生物附着及气液接触。填料上的微生物来自该污水处理厂的活性污泥,降低了基础建设成本,但需要较长的启动时间来驯化除臭微生物。利用该污水处理厂的二沉池出水为生物滴滤塔的循环液,可为微生物提供水分和所需营养,且不易引起微生物过度增殖。循环液的流量为1.8 m3·(m2·h)−1。定期更新循环液将其pH维持在1.5~2.3,以避免发生微生物活性抑制的现象。恶臭气体为收集自进水下水道干管和螺杆泵外壳的臭味空气。气体流量为16 300 m3·h−1,塔内平均EBRT为2 s。实验结果表明:当H2S质量浓度为45.5 mg·m−3时,滴滤塔对H2S的去除率高达95%,去除负荷(以H2S质量计)为105 g·(m3·h)−1;当H2S的质量浓度为91.1 mg·m−3时,去除率可达90%。RSC的平均去除率为15%~40%、VOCs的去除率约为30%,恶臭浓度去除率约为65%。相比于生物过滤法,生物滴滤系统的结构更简单,建设和运行成本更低,但生物滴滤法对水溶性较差的废气去除率稍差。因此,在处理VOCs时,其质量浓度不宜高于500 mg·m−3,同时还需增加EBRT,以延长气液接触时间,从而保证系统的去除效果。

-

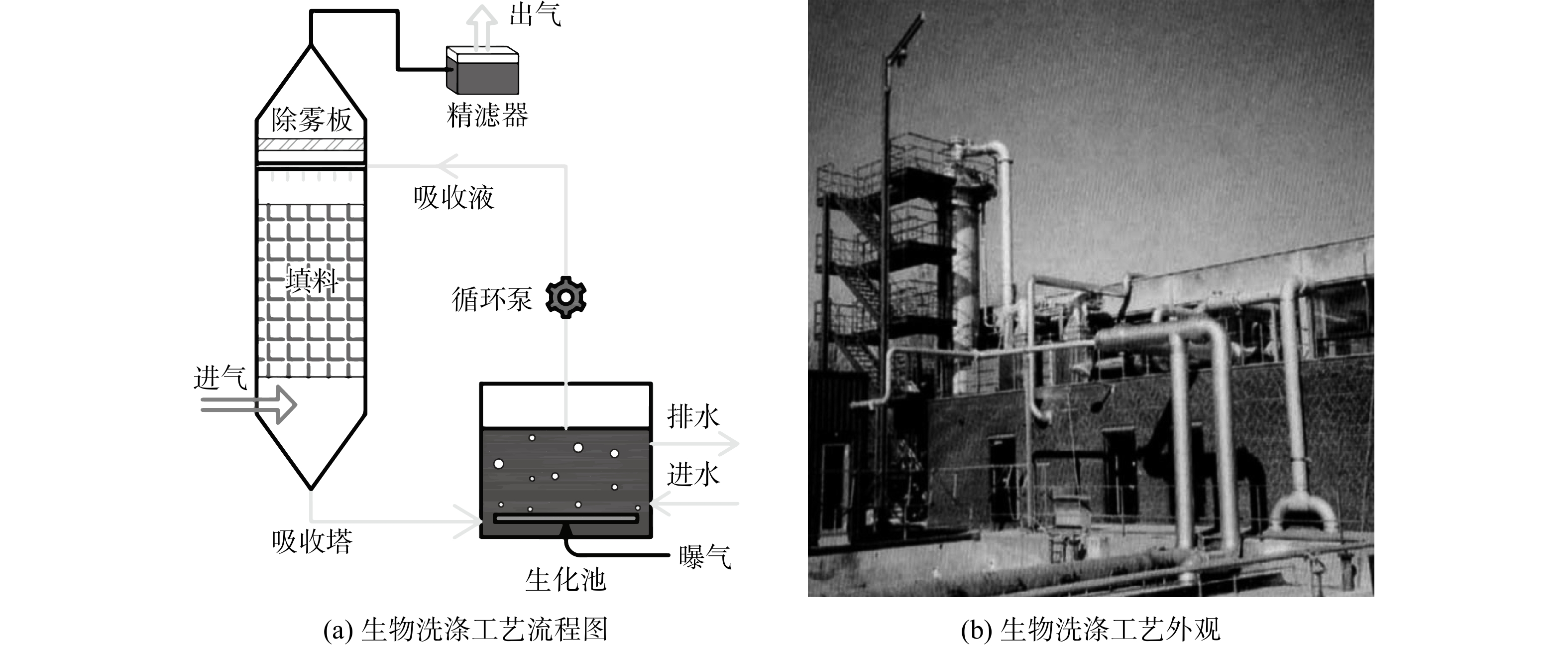

在处理污染物质量浓度高(>500 mg·m−3),且无量纲亨利系数为0.01及以下的亲水性污染物(如醇、醛、脂肪酸和二醇)时,生物洗涤法的性价比更佳[40]。HANSEN等[43]采用生物洗涤器处理丹麦哥本哈根某污水处理厂的恶臭气体,就是其中的一个典型案例。恶臭气体收集自该厂的沉砂池、油水分离池和格栅等处理单元,气体流量为6 000 m3·h−1。其中,H2S的年平均质量浓度约为10 mg·m−3,夏季和秋季平均质量浓度为25~35 mg·m−3,有机硫化合物浓度较小(<0.1 mg·m−3)。该生物洗涤器由1座填充塑料填料的吸收塔和1座基于活性污泥工艺的生物氧化池构成(图5)。吸收塔的直径为1.6 m、高12 m。采用比表面积较大且结构强度高的塑料空心环和金属混合物作为吸收塔填料,在增大气液接触面积的同时可避免因填料压缩造成的堵塞。吸收塔填料填充体积为12 m3,生物氧化池体积为11 m3。生物反应器以污水处理厂的曝气池活性污泥为菌源;同时,生物反应器中的活性污泥又被用作吸收塔的吸收液,液体流量为70 m3·h−1。生物反应器的pH通过添加化学试剂的方式(以每千克H2S气体添加的NaOH质量计,约2.4 kg·kg−1)调节,维持在8.5~9.0,以确保微生物具备良好的活性并减少酸性气体的传质阻力。研究结果表明,生物洗涤器对H2S及有机硫化合物的去除率大于99%[44]。运行过程中洗涤段的空气压降稳定,塑料填料上也未出现微生物增殖不受控制的情况。与生物过滤法和生物滴滤法相比,生物洗涤法可避免生物质生长堵塞滤床的风险。生物洗涤设备同样具备结构简单、体积小、建设成本低,运行稳定性高且运行参数的易于控制等优点。然而,为了维持系统pH的稳定,需要频繁投加碱性试剂,这使得系统运行更复杂,运行成本更高。另外,生物洗涤法很难去除水溶性较差的污染物,可考虑在液相中加入有机吸收剂、固体吸收剂、吸附剂和生物表面活性剂等,以促进对生物洗涤法对疏水化合物的去除。

-

目前,生物除臭技术应用中存在如下问题。1)生物反应器内载体表面生物膜的生长会降低滤床的孔隙率,导致压降过高,甚至滤床堵塞[45]。化学清洗,定期切换流动方向以及高速水流冲洗[37]等方法已被尝试用于防止生物质的积累,但这些方法大都停留在实验室规模的装置中,尚未有效应用于实际工程中的生物反应器。2)生物过滤法处理含高浓度H2S时,如污泥发酵产生的H2S质量浓度可达6 071 mg·m−3[46],产生的硫酸会导致反应器内环境被迅速酸化。如何避免微生物活性因pH降低而受到抑制,同时保证对H2S的高效去除是生物过滤法应用中的难点。3)生物洗涤法处理恶臭气体时需克服气液传质阻力将污染物从气相转移至液相中,这使其对水溶性较差的污染物处理效果欠佳。因此,实现对疏水性污染物的有效去除是生物洗涤法进一步优化的方向。

生物除臭技术未来发展可集中解决如下问题。1)探究功能微生物所需的最佳营养液成分,以富集高丰度的功能微生物,从而以提高生物系统的处理性能和应对冲击负荷的能力。2)研发结构强度大、比表面积高且易于微生物附着的新型填料,以改善生物反应器内的传质效果,从而提高生物系统对恶臭污染物的去除性能。3)探究维持生物反应器内pH长期稳定且更加经济可行的策略,以维持功能微生物的活性。4)探究高效去除VOCs且同时维持生物量长期平衡的策略,以避免生物反应器内部发生堵塞。5)富集耐极酸性的除臭微生物,以提高生物系统应对系统酸化的能力。6)开发有机吸收剂、固体吸收剂、吸附剂和生物表面活性剂,促进对烷烃等疏水气态化合物的吸收。7)利用基因工程手段培育特种微生物,从而提高对难降解有机物的去除效率。

城镇污水处理厂生物除臭技术的关键影响因素及案例分析

Key influencing factors and case analysis of biological deodorization technology in urban wastewater treatment plants

-

摘要: 城镇污水处理厂运行中产生恶臭气体并因此导致空气污染的问题日益严重。生物除臭技术具有操作简便、运行成本低、二次污染小等优点,适用于污水处理厂恶臭气体的处理。阐述了污水处理厂臭气的主要成分、浓度及分布特点,分析了生物除臭技术的4个关键影响因素(微生物、营养液、pH和填料),并结合影响因素剖析了3个工程应用典型案例,总结了生物除臭技术亟需解决的问题,并展望进一步研究的内容,以期为不同污水处理厂根据其自身条件解决的恶臭污染提供参考。Abstract: The operation of urban wastewater treatment plants (WWTPs) has caused more and more serious odor pollution. Biological deodorization technology has the advantages of easy operation, low operating cost and no secondary pollution, and is applicable to the treatment of malodorous gases in WWTPs. In this study, the main components, concentration and distribution characteristics of odor in WWTPs were described. Four key influencing factors (microorganism, nutrient solution, pH and packing) of biological deodorization technology were annalyzed. Three typical engineering application cases were annalyzed based on the influencing factors. The urgent problems and future development of biological deodorization technology were summarized, in order to provide reference for different sewage treatment plants to solve odor pollution.

-

Key words:

- WWTPs /

- odor pollution /

- biological deodorization technology /

- engineering application

-

-

表 1 污水处理厂各处理单元环境空气中恶臭物质的质量浓度[16]

Table 1. The mass concentration of malodorous substances in the air of each sewage treatment unit

10−2 mg·L−1 处理单元 硫化氢 甲硫醇 甲硫醚 二甲基二硫醚 氨 乙醛 丙酸 正丁酸 正戊酸 异戊酸 莰烯 提升泵房 1 244.6 85.71 16.33 31.96 0.76 10.61 0.2 0.28 0.0027 0.09 1.4 配水井 3 187.5 200 55.36 13.88 1.59 17.29 0.1 0.04 — — 3.83 浓缩池上清液回流井 212.5 65.71 110.71 28.18 3.72 29.46 0.69 0.28 0.0014 0.05 1.46 初沉池进水口 607.14 9.86 0.83 0.17 — 60.89 0.03 — — — — 生化池进水口 22.77 0.71 0.55 0.13 0.01 18.07 0.03 — — — — 缺氧段末端 3.04 1.27 3.88 0.42 — 23.57 — — — — 0.55 好氧段末端 4.71 0.2 2.77 0.34 — 29.46 — — — — 0.36 最终沉淀池出水 0.35 0.31 0.83 — — 17.68 — — — — — 出水口 0.05 — — — — 19.45 — — — — — 注:—代表结果低于检测限。 表 2 脱硫微生物的特征

Table 2. The characteristics of desulphurization microorganisms

微生物名称 营养类型 底物 最佳pH 最佳温度/℃ 硫氧化酶 Acidianus ambivalens 专性无机营养 S2-, S0 2.5 94 硫氧合酶/还原酶 Acidianus brierleyi 专性无机营养 S2-, S0, S2O32-, S4O62- 1.8 70 硫氧合酶 Oscillatoria limnetica 专性光合营养 S2- 7.5 35 硫化氢:醌还原酶 Chlorobaculum thiosulfatophilum 专性光合营养 S2-, S0, S4O62- 6.8 25~35 硫化细胞色素c;硫代硫酸盐:

细胞色素c还原酶Thiocapsa roseopersicina 兼性光合营养 S2-, S0, S2O32- 7.3 20~35 亚硫酸盐:受体氧化还原酶 Paracoccus denitrificans 兼性无机营养 S2-, S0, S2O32- 8.0 30 亚硫酸盐脱氢酶;硫代硫酸盐氧化酶系统 Paracoccus versutus 兼性无机营养 S2-, S0, S2O32- 8.0 30 亚硫酸盐脱氢酶;硫代硫酸盐氧化酶系统 Thiobacillus denitrificans 专性无机营养 S2-, S0, S2O32-, S4O62-, SO32- 7.0 30 腺苷酰硫酸还原酶;亚硫酸盐氧化酶 Acidithiobacillus ferrooxidans 专性无机营养 S2-, S0, S2O32-, S4O62-, SO32- 2.5 30 硫:铁(III)氧化还原酶;硫化物:

铁(III)氧化还原酶Acidithiobacillus thiooxidans 专性无机营养 S2-, S0, S2O32-, S4O62-, SO32- 2.5 30 亚硫酸盐:细胞色素c氧化还原酶 -

[1] 袁志强, 李超, 苑荣雪, 等. 利用富乙酸剩余污泥厌氧发酵液产中链脂肪酸[J]. 环境工程学报, 2021, 15(10): 1-13. [2] 张璐怡. 新形势下我国污水处理行业发展现状分析[J]. 环境保护, 2021, 49(2): 32-36. [3] REN B, ZHAO Y, LYCZKO N, et al. Current status and outlook of odor removal technologies in wastewater treatment plant[J]. Waste Biomass Valorization, 2019, 10(6): 1443-1458. doi: 10.1007/s12649-018-0384-9 [4] 刘树根, 苏福家, 李婷, 等. 生物滴滤法净化低浓度磷化氢及其微生物群落分析[J]. 环境工程学报, 2018, 12(12): 124-132. [5] YUAN S, LIU H, LIU M. Application status and prospects of biological deodorization in China[J]. IOP Conference Series:Earth and Environmental Science, 2021: 631. [6] FRECHEN F B. Odour emission inventory of German wastewater treatment plants-odour flow rates and odour emission capacity[J]. Water Science Technology, 2004, 50(4): 139-146. doi: 10.2166/wst.2004.0244 [7] 席劲瑛, 胡洪营, 罗彬, 等. 城市污水处理厂主要恶臭源的排放规律研究[J]. 中国给水排水, 2006, 22(21): 99-103. doi: 10.3321/j.issn:1000-4602.2006.21.027 [8] 郭静, 梁娟, 匡颖, 等. 污水处理厂恶臭污染状况分析与评价[J]. 中国给水排水, 2002, 18(2): 78-79. [9] LI R, HAN Z, SHEN H, et al. Emission characteristics of odorous volatile sulfur compound from a full-scale sequencing batch reactor wastewater treatment plant[J]. Sci Total Environ, 2021, 776: 145991. doi: 10.1016/j.scitotenv.2021.145991 [10] LEWKOWSKA P, CIESLIK B, DYMERSKI T, et al. Characteristics of odors emitted from municipal wastewater treatment plant and methods for their identification and deodorization techniques[J]. Environ Res, 2016, 151: 573-586. doi: 10.1016/j.envres.2016.08.030 [11] AOKI S, SUGIMOTO H, BAMBA D. Analysis of odor compounds in sewerage process water and deodor methods[J]. Journal of Japan Society On Water Environment, 2004, 27: 643-650. [12] JIANG G, MELDER D, KELLER J, et al. Odor emissions from domestic wastewater: A review[J]. Critical Reviews in Environmental Science and Technology, 2017, 47(17): 1581-1611. doi: 10.1080/10643389.2017.1386952 [13] 刘锴, 白登明. 污水处理系统臭气污染问题的研究[J]. 环境工程学报, 2004, 5(5): 38-42. doi: 10.3969/j.issn.1673-9108.2004.05.009 [14] BEGHI S P, SANTOS J M, REIS N C, et al. Impact assessment of odours emitted by a wastewater treatment plant[J]. Water Sci Technol, 2012, 66(10): 2223-2228. doi: 10.2166/wst.2012.409 [15] DEVAI I, DELAUNE R D. Emission of reduced malodorous sulfur gases from wastewater treatment plants[J]. Water environment research, 1999, 71(2): 203-208. doi: 10.2175/106143098X121842 [16] 王灿, 胡洪营, 席劲瑛. 城市污水处理厂恶臭污染及其评价体系[J]. 给水排水, 2005, 31(9): 15-19. doi: 10.3969/j.issn.1002-8471.2005.09.004 [17] SAHU S, LENKA R K. European Developments for Purification of Biological Waste Gas[J]. European Journal of Molecular Clinical Medicine, 2020, 7(11): 703-708. [18] 黄进刚, 徐晓军, 李淑芬, 等. 活性污泥中高效除臭菌株的驯化和筛选[J]. 环境工程学报, 2008, 2(11): 1547-1550. [19] PLANTE A F, Soil biogeochemical cycling of inorganic nutrients and metals, in: Soil microbiology, ecology and biochemistry, Elsevier, 2007, pp. 389-432. [20] НNATUSH S, MASLOVSKA O, SEHIN T, et al. Waste water treatment by exoelectrogenic bacteria isolated from technogenically transformed lands[J]. Ecological Questions, 2020, 31(1): 35-44. [21] KUSHKEVYCH I, BOSáKOVá V, VíTĚZOVá M, et al. Anoxygenic Photosynthesis in Photolithotrophic Sulfur Bacteria and Their Role in Detoxication of Hydrogen Sulfide[J]. Antioxidants, 2021, 10(6): 829. doi: 10.3390/antiox10060829 [22] VIKRANT K, KAILASA S K, TSANG D C, et al. Biofiltration of hydrogen sulfide: trends and challenges[J]. Journal of cleaner production, 2018, 187: 131-147. doi: 10.1016/j.jclepro.2018.03.188 [23] HE R, YAO X-Z, CHEN M, et al. Conversion of sulfur compounds and microbial community in anaerobic treatment of fish and pork waste[J]. Waste Management, 2018, 76: 383-393. doi: 10.1016/j.wasman.2018.04.006 [24] YANG B, NIU X, DING C, et al. Performance of biotrickling filter inoculated with activated sludge for chlorobenzene removal[J]. Procedia Environmental Sciences, 2013, 18: 391-396. doi: 10.1016/j.proenv.2013.04.052 [25] BASKARAN D, SINHAROY A, PAKSHIRAJAN K, et al. Gas-phase trichloroethylene removal by Rhodococcus opacus using an airlift bioreactor and its modeling by artificial neural network[J]. Chemosphere, 2020, 247: 125806. doi: 10.1016/j.chemosphere.2019.125806 [26] MUDLIAR S, GIRI B, PADOLEY K, et al. Bioreactors for treatment of VOCs and odours–A review[J]. Journal of environmental management, 2010, 91(5): 1039-1054. doi: 10.1016/j.jenvman.2010.01.006 [27] BADILLA D B, GOSTOMSKI P A. Nutrient addition in biofiltration for air pollution control[J]. International Journal of Environmental Engineering, 2015, 2: 161-165. [28] OMRI I, AOUIDI F, BOUALLAGUI H, et al. Performance study of biofilter developed to treat H2S from wastewater odour[J]. Saudi journal of biological sciences, 2013, 20(2): 169-176. doi: 10.1016/j.sjbs.2013.01.005 [29] JIA T, SUN S, ZHAO Q, et al. Extremely acidic condition (pH< 1.0) as a novel strategy to achieve high-efficient hydrogen sulfide removal in biotrickling filter: Biomass accumulation, sulfur oxidation pathway and microbial analysis[J]. Chemosphere, 2022, 294: 133770. doi: 10.1016/j.chemosphere.2022.133770 [30] SOREANU G, Biotechnologies for improving indoor air quality, in: Start-up creation, Elsevier, 2016, pp. 301-328. [31] DUMONT E, ANDRèS Y, LE CLOIREC P, et al. Evaluation of a new packing material for H2S removed by biofiltration[J]. Biochem. Eng. J., 2008, 42(2): 120-127. doi: 10.1016/j.bej.2008.06.012 [32] FRIEDRICH M, KOSMIDER J, TEREBECKI P, et al. Odour abatement of waste gases from sludge thickeners in wastewater treatment plant using bioscrubber[J]. Chemical Engineering Transactions, 2014, 40: 205-210. [33] 魏在山, 刘小红, 孙建良, 等. PCR-DGGE技术用于处理苯乙烯废气的生物滴滤塔中微生物优势菌种解析[J]. 环境工程学报, 2012, 6(2): 571-576. [34] SAN-VALERO P, GABALDóN C, PENYA-ROJA J, et al. Study of mass oxygen transfer in a biotrickling filter for air pollution control[J]. Procedia Engineering, 2012, 42: 1726-1730. doi: 10.1016/j.proeng.2012.07.565 [35] 陈益清, 陈雷, 伍健威, 等. 填料对生物滴滤塔去除H2S的影响[J]. 环境工程学报, 2016, 10(7): 3763-3767. doi: 10.12030/j.cjee.201512218 [36] 赵珊, 郭学彬, 杨晓芳, 等. 聚氨酯泡沫的改性及其在臭气治理中的应用[J]. 环境工程学报, 2020, 14(9): 164-170. [37] YANG C, CHEN H, ZENG G, et al. Biomass accumulation and control strategies in gas biofiltration[J]. Biotechnol. Adv., 2010, 28(4): 531-540. doi: 10.1016/j.biotechadv.2010.04.002 [38] ESTRADA J M, DUDEK A, MUñOZ R, et al. Fundamental study on gas–liquid mass transfer in a biotrickling filter packed with polyurethane foam[J]. Journal of Chemical Technology Biotechnology, 2014, 89(9): 1419-1424. doi: 10.1002/jctb.4226 [39] BINDRA N, DUBEY B, DUTTA A. Technological and life cycle assessment of organics processing odour control technologies[J]. Science of the Total Environment, 2015, 527: 401-412. [40] BARBUSINSKI K, KALEMBA K, KASPERCZYK D, et al. Biological methods for odor treatment - A review[J]. Journal of Cleaner Production, 2017, 152: 223-241. doi: 10.1016/j.jclepro.2017.03.093 [41] 付妍, 胡清源, 温暖家, 等. 石化行业恶臭废气生物净化装置的设计与运行[J]. 给水排水, 2016, 42(1): 75-78. doi: 10.3969/j.issn.1002-8471.2016.01.017 [42] GABRIIL D, DESHUSSES M A. Performance of a Biotrickhg Fillter Full-scale Treating H2S at a Gas Contact Time of 1.6 to 2.2 Seconds[J]. Environmental Progress, 2003, 22: 111-118. doi: 10.1002/ep.670220213 [43] HANSEN N G, RINDEL K. Bioscrubbing: An effective and economic solution to odour control at sewage-treatment plants[J]. Water and Environment Journal, 2001, 15: 141-146. doi: 10.1111/j.1747-6593.2001.tb00321.x [44] WANG Y C, HAN M F, JIA T P, et al. Emissions, measurement, and control of odor in livestock farms: A review[J]. Science of The Total Environment, 2021, 776: 145735. doi: 10.1016/j.scitotenv.2021.145735 [45] ARELLANO-GARCíA L, DORADO A D, MORALES-GUADARRAMA A, et al. Modeling the effects of biomass accumulation on the performance of a biotrickling filter packed with PUF support for the alkaline biotreatment of dimethyl disulfide vapors in air[J]. Applied microbiology biotechnology, 2015, 99(1): 97-107. doi: 10.1007/s00253-014-5929-7 [46] ANDRIANI D, RAJANI A, SANTOSA A, et al, A review on biogas purification through hydrogen sulphide removal [J]. IOP Conference Series: Earth and Environmental Science, 2020: 012034. -

下载:

下载: