-

随着城市污水处理规模的不断扩大,市政污水处理厂的剩余污泥产生量相应激增[1]。剩余污泥是一类含有机物、细菌菌体、无机颗粒、胶体等的复杂混合物[2],其初始含水率大于90%,初步脱水后也在80%左右,故无法满足传统处理处置方法对污泥含水率的要求[3]。因此,需要采用干化技术对污泥进行预处理。但是,在高温直接干化过程中,污泥中含硫物质会受热氧化分解,从而会导致大量以二氧化硫(SO2)为主的含硫物质的恶臭气体产生,对周围环境造成危害[4]。据报道,污泥直接干化处理过程产生的SO2质量浓度约有392~2 146 mg·m−3(即常温常压下150~820 ppm[5]),远超现行的大气污染物排放标准。

传统的烟气脱硫技术存在总体脱硫效率不高、脱硫设备系统占地面积大、投资成本高、能源消耗高、设备易腐蚀、产生废水废渣易造成二次污染等问题。因此,将其用于处理规模较小的污泥干化尾气时经济性差,且不满足环境友好的要求。生物脱硫法指部分微生物参与自然界中硫元素循环以获得能量,并利用化能自养硫细菌代谢SO2的过程,最终可将硫氧化物转化降解[6]。该方法具有操作安全、运行费用低、二次污染低、净化效率高等优点,已受到广泛关注[7]。在处理大流量、低浓度、生物降解性好的SO2时,生物法较物理化学法更具经济性和高效性。在生物滴滤法中,微生物既可固定附着在填料上,也可悬浮在喷淋循环液中,兼有生物过滤池和生物洗涤池的双重作用。因此,该方法具有操作简单、生物相和液相均循环流动、填料不易堵塞、污染物去除效率高等优点。生物滴滤塔亦为最常见的生物反应器之一[8-9]。

目前,关于生物脱硫工艺的研究主要集中在新型生物负载填料的开发和生物反应器的改良上。有研究者在60 ℃条件下,利用实验室规模的嗜热生物滤池处理SO2。该滤池以聚氨酯泡沫为填料,以嗜热脱硫细菌为主要微生物,探究了填料种类和环境条件对微生物种群数量的影响,以及对SO2去除率的影响[10-12]。另有研究者构建了一种含悬浮区和固定区的两段一体化生物反应器用于处理SO2,处理效率达85%以上[13]。然而,从生活污水污泥中筛选高效脱硫微生物的研究鲜有报道。因此,本研究以市政污泥为原料,从其中筛选高效脱硫菌嗜酸性氧化亚铁硫杆菌(Acidithiobacillus ferrooxidans,A.f),并以页岩陶粒为生物填料搭建生物滴滤塔,探究以脱除SO2为目标的小试规模生物滴滤塔的工艺参数,以期为生物脱硫技术的推广应用提供参考。

-

实验所用市政污泥来源于武汉市沙湖污水处理厂浓缩池的剩余活性污泥(waste activated sludge,WAS)与曝气池中的活性污泥(activated sludge,AS),其基本特性如表1所示。由VS/TS可知,原泥有机物含量均较低,但剩余污泥的有机物含量比活性污泥稍高一些。

选取页岩陶粒为生物滴滤塔惰性填料,购自湖北省嘉鱼县嘉众新型环保材料有限公司。页岩陶粒以黏土质页岩、板岩等为原料,经破碎筛分或粉磨成球后烧胀而成,其质轻、强度高,且有较发达的孔隙结构。填料的基本特性为:当量粒径为2~3 mm,堆积密度0.56 g·cm−3,压实密度1.31 g·cm−3,堆体孔隙率57%,比表面积1.94 m2·g−1。

-

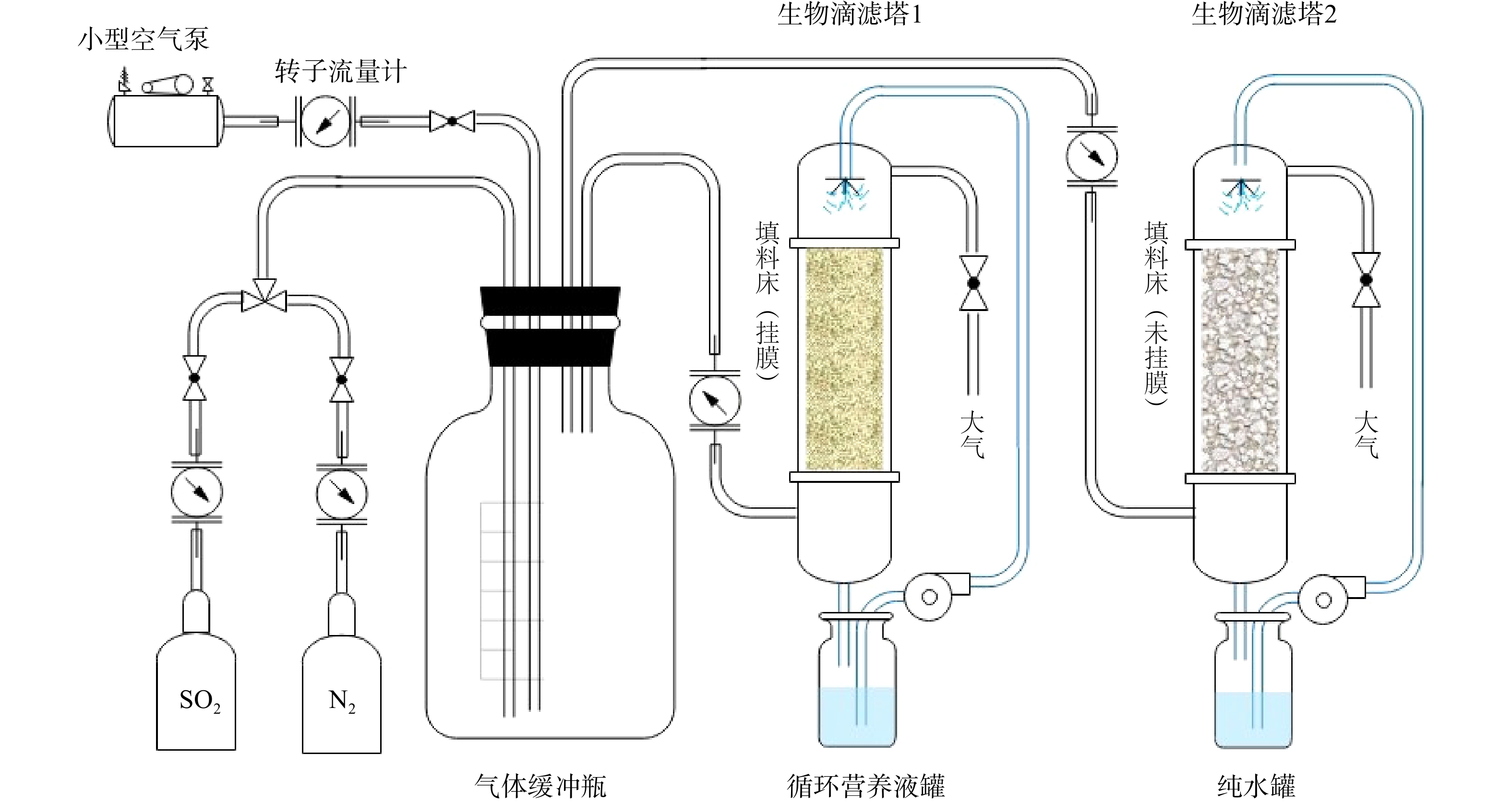

1)实验装置。生物滴滤塔为有机玻璃加工制成的耐酸式反应器,其塔体高550 mm、内径80 mm。填料床层外包裹1层硅胶加热套,用于保持填料床层的温度。床层温度控制在A.f菌的最佳生长温度((30±2)℃)。整塔共分为3层:首层为喷淋头与导液管,高度为200 mm;中段为填料层,床层高度250 mm;底部设置多孔有机玻璃滤水板与滴滤塔底部分开。滤水板上设置圆形小孔,其开孔率大于50%,可发挥支撑填料的作用,同时兼具滤水功能。

生物滴滤塔运行流程如图1所示。采用气液逆流操作,在气源部分入口端采用空气泵和高纯N2与SO2气瓶并联。其中,空气泵的流量控制为100 mL·min−1。泵入空气可为填料上的脱硫微生物生长和生物脱硫反应提供必需的氧气。通入高纯N2可改变进气流量之比,起到间接改变进口SO2体积浓度的作用。3种气体在气体缓冲室混合后通过管路连接到达滴滤塔底端。混合气体在生物滴滤塔内自下向上流动,并在流动过程中与填料表面的生物膜充分接触。然后,生物膜上的A.f菌捕获其中的SO2气体,剩余净化气从滴滤塔上端排出。另一方面,蠕动泵将储液罐中循环营养液不断运送至生物滴滤塔顶,经喷头向下均匀喷淋在填料床层上,最后经底端的排液管流进储液罐即完成液体循环。运行期间需定期更换循环营养液,保证A.f菌正常生长所需的营养,使其保持较高的生物活性。另外,设置一组规格完全相同且填料未经挂膜的滴滤塔循环纯水作为对照组。

2)性能参数。生物滴滤塔的性能参数包括脱硫效率、营养液喷淋密度、空塔停留时间等。脱硫效率表示生物滴滤塔对SO2的去除效率,根据式(1)计算;液体喷淋密度表示单位时间单位生物滴滤塔横截面积上流过的循环营养液体积,根据(2)计算;气体停留时间表示气体在空塔填料床层的停留时间,根据式(3)计算。

式中:η为脱硫效率,%;C1为生物滴滤塔进口SO2的质量浓度,mg·m−3;C2为生物滴滤塔出口SO2的质量浓度,mg·m−3;F为喷淋密度,m3·m−2·h−1;QL为循环营养液流量,m3·h−1;D为生物滴滤塔内径,m;te为气体停留时间,s;Q为入口气体体积流量,m3·s−1;V为生物滴滤塔填料床层体积,m3。

-

由于剩余活性污泥总固体含量较高,不利于微生物的接种,因此在实际操作过程中,应先将剩余活性污泥与超纯水按1:1混合稀释,再采用空气曝气(曝气量约为0.3 L·h−1)24 h后静置30 min,待污泥稳定后分别取2种污泥上清液进行微生物筛选。微生物培养采用9K培养基在空气恒温摇床中进行。温度设置为30 ℃、转速160 r·min−1、接种量为10%[14]。通过反复富集得到了较高纯度的单菌培养液,并对该菌液进行革兰氏染色和光学显微镜形态观察和鉴定,基本判断获得的菌液为A.f菌培养液。将菌液转接至新的培养基后,可在较短时间内快速变成红棕色。用重铬酸钾法测得棕红色液体中的Fe2+浓度小于 0.01 mol·L−1,即表明A.f菌已筛选富集完成,并具有较高的生长活性。

采用塔外-塔内两步法进行微生物挂膜。塔外挂膜是A.f菌在页岩陶粒上连续培养的过程。具体方法如下:选取8个250 mL 的锥形瓶,添加100 mL灭菌后的 9K培养基与100 mL已冲洗灭菌的页岩陶粒于每个锥形瓶中;第1次挂膜按培养基体积分数10%接种富集菌源,置于30 ℃、转速160 r·min−1的恒温振荡器中进行培养至培养液呈红棕色浑浊;倒出锥形瓶内全部培养液,保留页岩陶粒,更换新鲜培养基并按体积分数5%再次接种菌源;此后每次更新培养基时不再接种菌源,定时测定培养液中Fe2+浓度变化;当Fe2+被消耗掉95%以上时可认为此次挂膜完成,便开始更新培养基进行二次挂膜,以此类推;当测定的Fe2+氧化率稳定,填料表面生物量达到稳定。塔内挂膜的步骤为:将完成塔外挂膜的页岩陶粒和灭菌后未经处理的页岩陶粒层层堆叠放入填料塔中,开启液体循环系统;其中,循环液为改进的9K培养基(Fe2+浓度为0.1 mol·L−1,其他成分不变),以体积分数10%的接种量接入处于对数生长期的A.f菌液;使含有A.f的循环营养液在填料塔中循环挂膜,营养液每2 d更换1次;液相中的细菌在填料表面附着,逐渐增长、繁殖,直至形成成熟的生物膜。在挂膜成功后,通过灼烧法测得页岩陶粒上的微生物固定化率约为6.6%。

-

采用碘量法[15]测定SO2质量浓度。采用重铬酸钾滴定法测定循环营养液中的Fe2+浓度。委托美吉生物(上海)有限公司进行高通量测序分析,完成生物膜总DNA提取、PCR扩增步骤、PCR产物、Alpha多样性等。

-

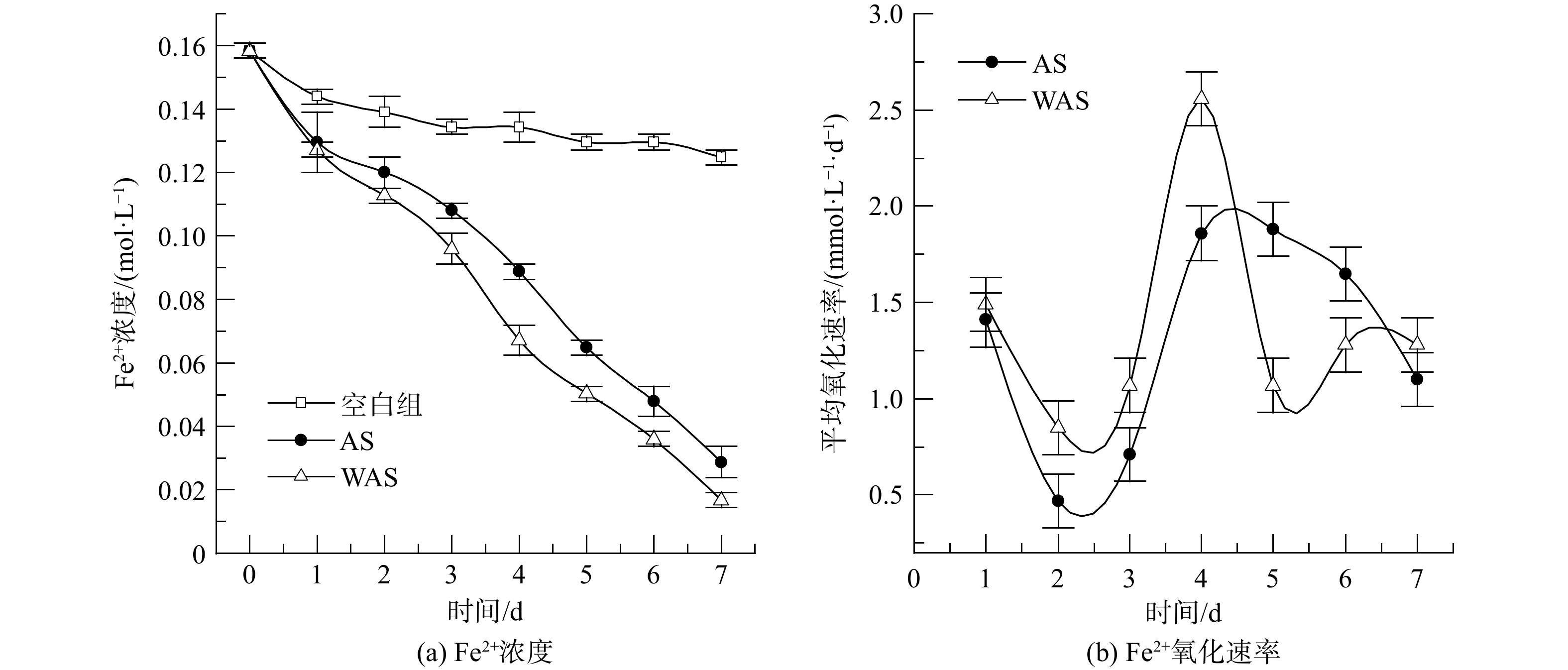

市政污泥的微生物组成复杂但群落结构稳定,生物活性较好,适宜作为菌源。A.f菌通过将9K培养基中的Fe2+氧化为Fe3+以获取生命活动所需能量。该过程主要以O2为最终电子受体。随着细菌的生长,Fe2+浓度不断降低,故可以Fe2+浓度的变化速率间接反映A.f菌的生物活性。分别测定了接种2种污泥的培养液中Fe2+浓度随培养天数的变化,结果如图2(a)所示。与接种污泥的9K选择培养基相比,在加入同等体积蒸馏水的空白对照组中Fe2+浓度也在不断下降。这表明在没有微生物催化的条件下,溶液中的Fe2+也能被空气中的O2缓慢氧化。随着Fe2+浓度的降低,空气氧化速率几乎恒定在一个较低水平。相比之下,接种活性污泥与剩余活性污泥的培养液中Fe2+的氧化速率较快,在接种第7天Fe2+浓度已降至初始值的20%。在接种了剩余活性污泥(WAS)的培养液中,Fe2+剩余量比接种了活性污泥(AS)的培养液中Fe2+剩余量低。这表明剩余活性污泥中菌种浓度较高,使得Fe2+氧化更加迅速彻底。

基于此,以污泥中的有机质含量(VS)近似表示污泥菌种浓度,可比较接种2种污泥的培养液中单位VS下Fe2+氧化速率的差异,结果如图2(b)所示。在刚接种时,2种培养基中Fe2+氧化速率均有较大幅度的下降过程。这是由于在此阶段污泥中的微生物刚进入新环境正处于适应阶段,代谢活性较弱。从接种第2天开始,Fe2+氧化速率迅速提升,并在对数生长期的第4天达到最高值0.002 5 mol·(L·d)−1。这表明培养基中微生物细胞逐步恢复活性,代谢速率加快。在第5天至第7天,2种培养基的Fe2+氧化速率迅速降低。这是由于培养环境和能源物质的限制,使得微生物的生长逐步过渡至稳定期[16]。

-

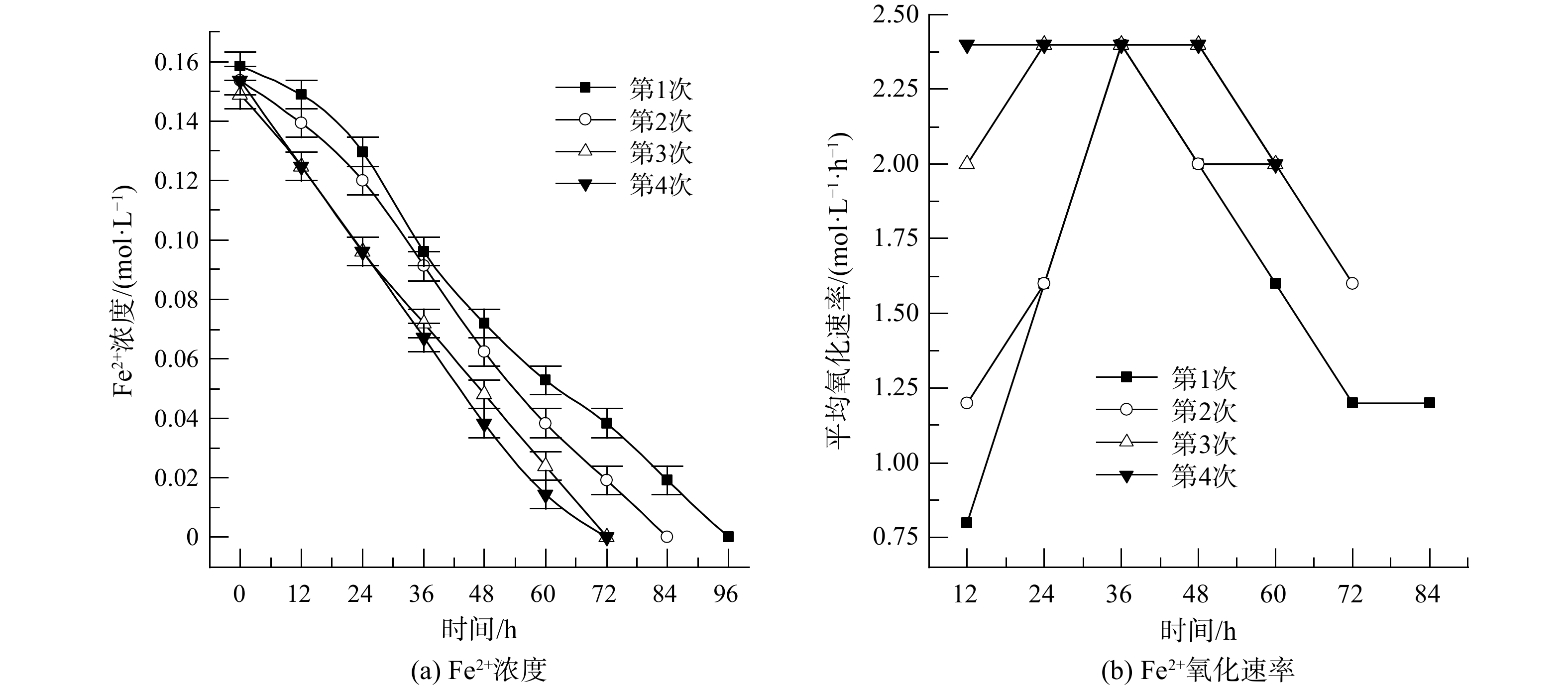

对A.f菌的富集培养实验选择筛选自剩余活性污泥的菌种作为菌源。每隔12 h对每一轮富集过程中营养液里的Fe2+浓度进行测定,计算了每12 h的Fe2+平均氧化速率变化情况,结果如图3所示。在第1次富集阶段,营养液中的Fe2+完全氧化仅需96 h,相较于菌种筛选阶段的7 d大幅度缩短。这说明菌种筛选本身就是一个目标菌种的初步富集过程。随着富集次数的增加,营养液中的Fe2+完全氧化消耗的时间已稳定至第3次富集时的72 h。由此可判断,第3次富集阶段营养液中的A.f菌生物活性已达到较高水平。图3(b)也印证了这一点。第一次富集时,A.f菌的平均Fe2+氧化速率需经过36 h才能到达最大值,接近0.002 5 mol·(L·h)−1。这一阶段是A.f菌生长的适应期和对数增长期。之后,随着营养液中Fe2+浓度的降低,并逐步过渡至稳定期,在此阶段氧化速率逐步降低。随着富集次数的增加,菌落实现对数生长期的时间不断缩短。到第3次富集时仅需24 h,到第4次富集时已不足12 h。这表明A.f菌的适应期大大缩短,生物活性逐步稳定[17]。

-

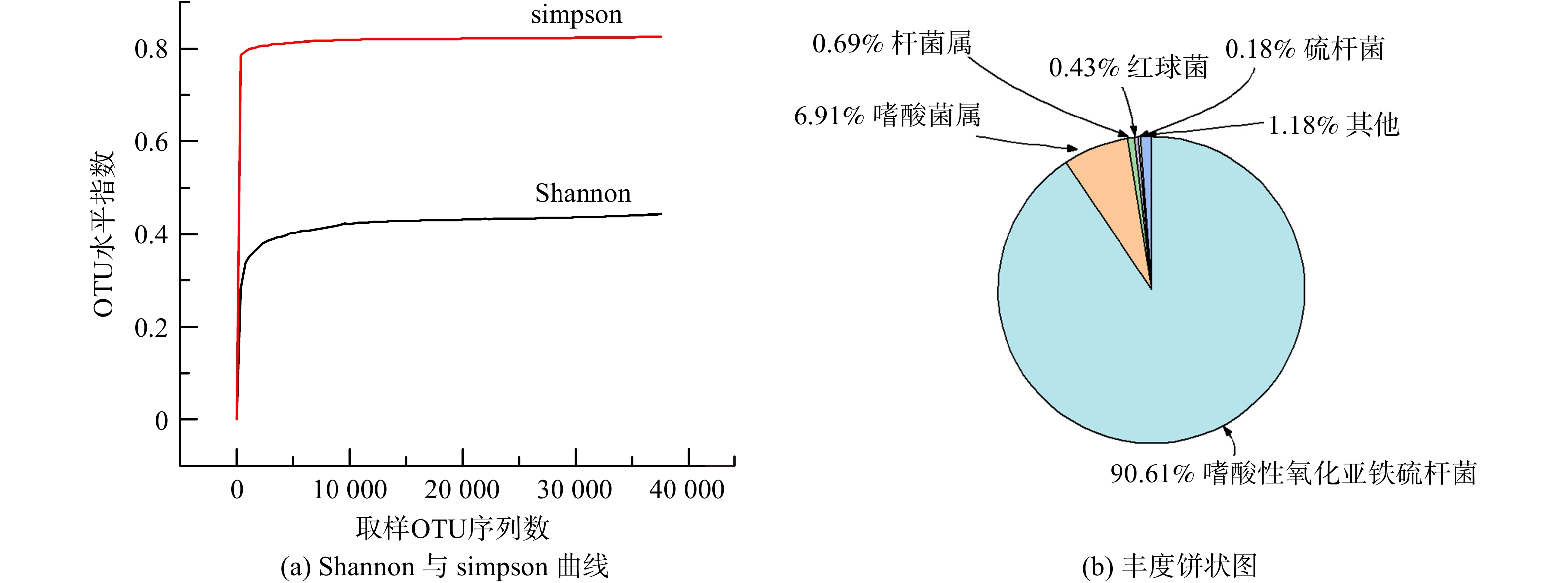

收集部分塔内挂膜完成后的页岩陶粒进行生物膜内微生物的基因组测序,并通过提取样品的总基因组DNA、利用16S rRNA的通用引物进行PCR扩增,来分析填料表面生物膜内的群落组成和结构。首先,对检测样品进行OTU分析(Operational Taxonomic Unit),即基因测序后将相似性大于98%的16S rRNA序列定义为1个OTU组,每个OTU对应于1个不同的16S rRNA序列,即对应于不同菌群。通过OTU分析,可表征检测样品中的微生物多样性和不同微生物的丰度。之后从样本中随机抽取一定数量序列,采用Alpha多样性分析中的Shannon与simpson指数进行OTU的稀有度分析,结果如图4(a)所示。当取样OTU序列数高于5 000后,Shannon与simpson指数都趋于平稳,这表明分析结果具有普遍性。

此外,在种水平上对页岩陶粒表面生物膜内的微生物群落组成进行了分析,结果如图4(b)所示。在微生物群落中,目标菌种嗜酸性氧化亚铁硫杆菌(Acidithiobacillus ferrooxidans)为优势菌种,占90.61%。因此,经过两步法挂膜后,富集纯化后微生物群落中的优势菌种A.f菌已在页岩陶粒填料表面形成稳定的生物膜,且在生物膜内仍为优势菌种。

-

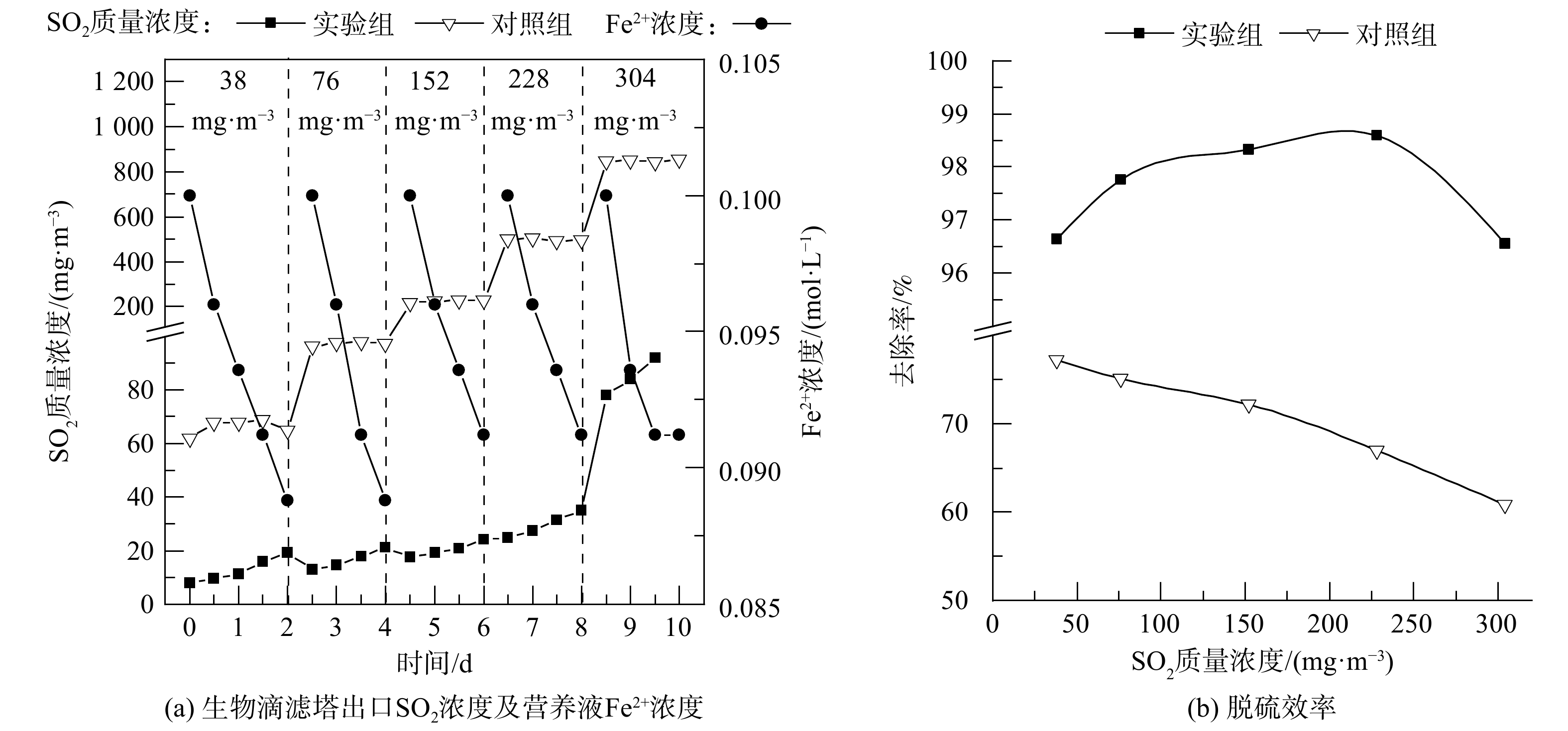

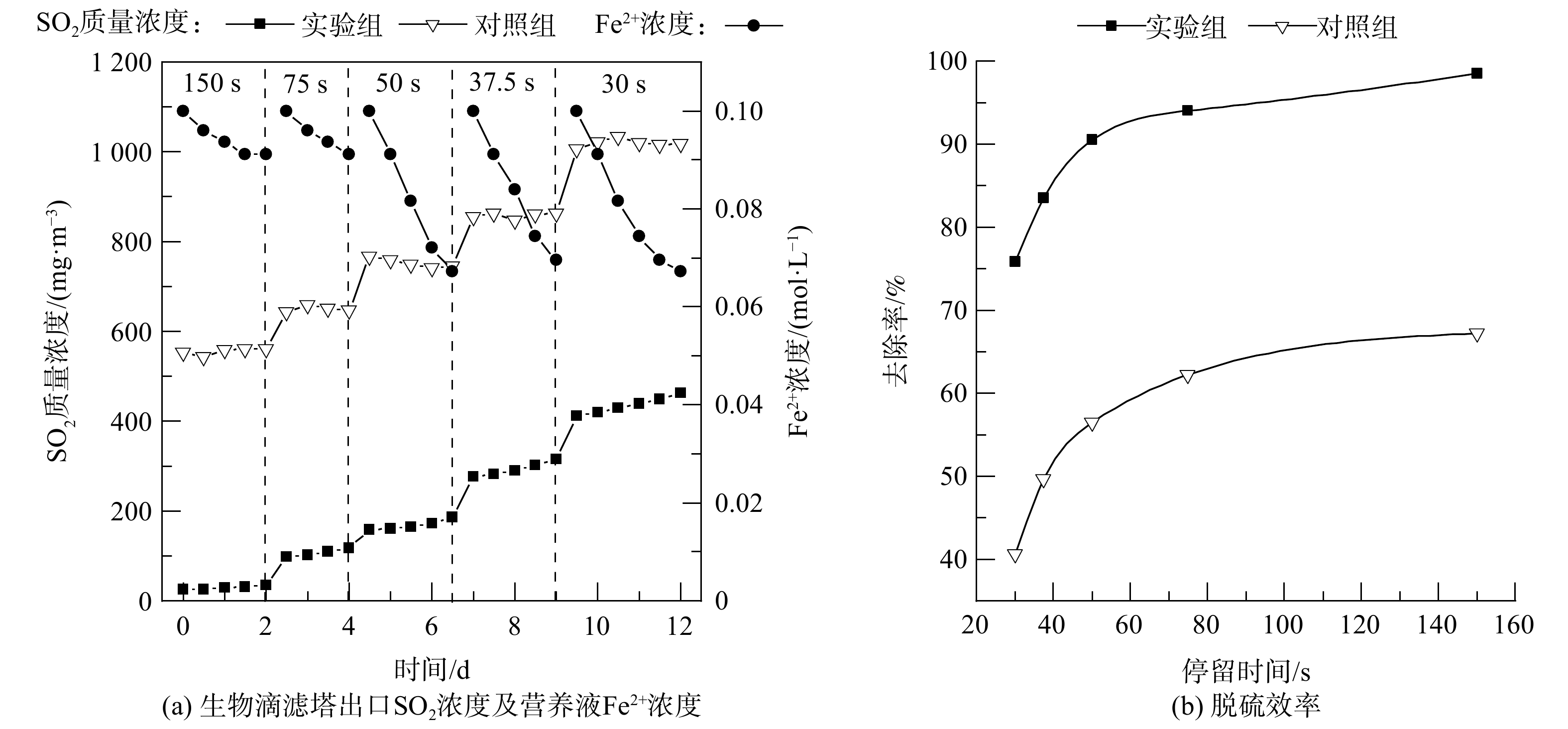

控制滴滤塔中的运行条件为:总进气流量500 mL·min−1,对应气体停留时间为150 s;循环营养液加载速率为30 mL·min−1,对应喷淋密度为0.36 m3·(m2·h)−1;初始营养液中Fe2+浓度为0.1 mol·L−1。在每次提高SO2质量浓度时更新培养液,保持填料床层的温度为30 ℃,SO2质量浓度约38~304 mg·m−3(常温常压下100~800 ppm)。进气SO2质量浓度对滴滤塔脱硫效果的影响如图5所示。

与未进行A.f菌挂膜的对照滴滤塔相比,进行过塔内塔外2次挂膜的生物滴滤塔的出口SO2质量浓度相对更低。随着进气SO2质量浓度的逐步增大,出口质量浓度也缓慢增大。当生物滴滤塔通入SO2气体后,Fe2+浓度变化速率较之前塔内挂膜阶段明显减慢,且随着SO2质量浓度的增大,Fe2+浓度变化速率的下降有逐步减缓趋势。图5(b)更直观地展示了2组滴滤塔脱硫效率的变化。挂膜后的生物滴滤塔脱硫效率超过95%,而对照滴滤塔的脱硫效率仅为60%~70%。随着进气口SO2质量浓度的提高,生物滴滤塔的脱硫效率缓慢上升。在入口质量浓度为228 mg·m−3时,脱硫效率达到最高值98.6%。随后,在入口质量浓度为304 mg·m−3时降低至96%。

在滴滤塔运行中气体停留时间不变的情况下,填料表面生物膜与SO2的接触面积在一段时间内是动态稳定的。在低进气SO2质量浓度下,绝大多数SO2分子可借由气液-液膜传质附着在生物膜上,被其捕获后可通过参与A.f菌生命活动被快速降解。随着SO2质量浓度不断增大,生物膜上附着的SO2达到动态饱和,此时整体脱硫效率达到最高[18]。随着SO2质量浓度继续增大,在一定停留时间内,生物膜上无法附着所有的SO2分子。过量的SO2则直接逸出塔外,导致除硫效率降低。此外,短时间内过量的SO2可能会对催化氧化造成抑制[19]。

-

控制滴滤塔进气SO2质量浓度为228 mg·m−3、循环营养液加载速率为30 mL·min−1、对应喷淋密度为0.36 m3·(m2·h)−1、初始营养液中Fe2+浓度为0.1 mol·L−1,并保持填料床层的温度始终为30 ℃,气体停留时间对滴滤塔脱硫效果的影响结果如图6所示。SO2总进气流量范围为500~2 500 mL·min−1,对应气体停留时间为30~150 s。

SO2停留时间在30~150 s时,生物滴滤塔出口SO2质量浓度明显低于对照组。随着SO2停留时间的快速降低,出口SO2质量浓度迅速增大。营养液中Fe2+浓度的变化趋势基本与之前研究SO2进气浓度影响的结果相一致。然而,在降低SO2停留时间的情况下,Fe2+浓度下降速率会更快。SO2停留时间对生物滴滤塔脱硫效率有很大的影响,2组滴滤塔的脱硫效率都随气体停留时间的减少而快速降低。挂膜实验组和对照组的脱硫效率分别由气体停留时间为150 s时的98%和67%,降至气体停留时间为30 s时的75%和40%。这表明,生物滴滤塔进气流量引起的SO2负载变化对脱硫效率的影响,较进气SO2质量浓度更为明显。

气体停留时间是影响净化率和处理效率的关键参数。这是由于气体中的SO2分子需要充足时间与循环营养液接触才能使更多SO2分子进入液相,才能被A.f菌吸收利用[20]。随着气体停留时间的缩短,进气流量的增加会对生物膜的产生一定的冲刷作用,从而破坏生物膜表面传质的稳定性,使得部分SO2分子回到气相主体,最终滴滤塔的脱硫效率降低[21]。

-

控制滴滤塔进气SO2质量浓度为228 mg·m−3、气体停留时间为150 s、初始营养液中Fe2+浓度为0.1 mol·L−1、料床层的温度为30 ℃,并调节液体蠕动泵的转速使循环营养液加载速率为10~90 mL·min−1,对应喷淋密度为0.12~1.08 m3·(m2·h)−1,即0.12~1.08 m·h−1,脱硫效率变化如图7所示。

在喷淋密度范围为0.12~1.08 m3·(m2·h)−1时,实验组的出口SO2质量浓度仍远低于对照组的滴滤塔。随着喷淋密度的增大,出口SO2质量浓度相应减小;但当喷淋密度高于0.36 m3·(m2·h)−1后,实验组出口SO2质量浓度几乎不再减小,而对照组出口SO2质量浓度明显减小。在此阶段,营养液中Fe2+浓度变化规律与前2组实验相似。随着喷淋密度的增大,2组滴滤塔的脱硫效率均有所提高,但实验组的脱硫效率仅在低喷淋密度范围内提高较为明显。当喷淋密度提高至0.36 m3·(m2·h)−1后,整体脱硫效率基本维持在98%左右。而对照组滴滤塔由于没有负载A.f菌,且用纯水做循环液,脱硫效率对喷淋密度的变化较为敏感,由最初的58%迅速增至82%。这是由于SO2气体在纯水溶液中的溶解度比在酸性液体中更大。在环境温度不变的情况下,喷淋密度的减小会直接影响SO2与纯水溶液的接触时间及接触面积,从而导致纯水溶液对SO2吸收量大大减少。

循环营养液不仅能保持填料表面生物膜的湿润,还可为微生物提供营养,以及在流过填料表面时将生物膜内微生物的代谢产物和多余菌胶团一起带走,从而保证微生物营养物质的新鲜和填料空隙的畅通[22]。因此,当喷淋密度过小时,不仅会造成营养液在填料床层内的分流不均,使得部分填料风干,影响微生物的生长,还会导致SO2分子在液相中传质速率的降低,最终影响脱硫效率。提高喷淋密度除了会增加运行成本外,还会造成对生物膜的过度冲刷,严重影响其结构稳定性,因此选择合适的喷淋密度尤为关键。

-

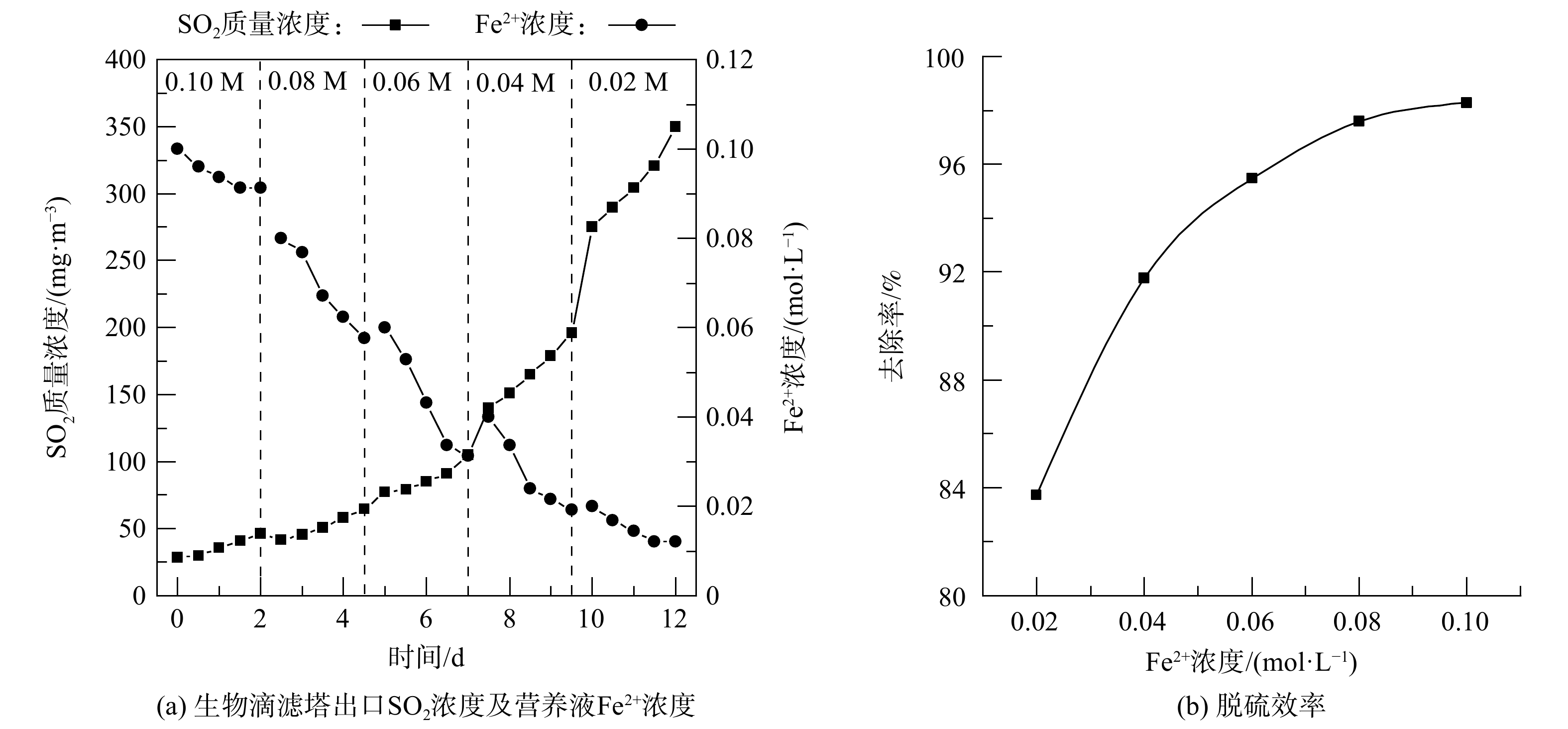

控制滴滤塔进气SO2质量浓度为228 mg·m−3、气体停留时间为150 s、营养液喷淋密度为0.36 m3·(m2·h)−1、料床层的温度为30 ℃,当初始营养液中其他组分含量不变、Fe2+浓度为0.02~0.1 mol·L−1时,脱硫效率的变化如图8所示。

随着循环营养液中Fe2+浓度由0.1 mol·L−1降至0.02 mol·L−1,出口SO2质量浓度迅速由30 mg·m−3增至270 mg·m−3。在营养液自身Fe2+浓度较低的情况下,Fe2+浓度下降速率反而较小。随着Fe2+浓度增大,脱硫效率由最初的83%快速增大,最后稳定在约98%。这是由于营养液中Fe2+浓度对生物膜中A.f菌的生物活性有较大影响,且液相中存在的Fe2+/Fe3+体系可催化氧化SO2,因此循环营养液中Fe2+浓度对生物脱硫效果影响较大。

-

在生物滴滤塔运行期间,溶解氧、SO2、Fe2+,以及脱硫微生物必需的矿物质盐均会通过扩散作用相互接触并发生反应,最终达到脱除SO2的目的。作为生物氧化脱硫工艺中最常见的化能自养硫氧化细菌,A.f菌已被广泛研究并应用在含硫废气的脱硫技术中。整个脱硫过程包括传质和反应2个阶段。其中,反应包括化学催化与酶促反应2个方面。具体包括以下步骤:SO2气体从气相主体扩散溶解至液相主体;SO2分子在液相中水解成不同S(Ⅵ)组分;S(Ⅵ)组分与液相中的Fe2+经液膜传质到达生物膜表面;S(Ⅵ)组分与Fe2+在生物膜内的传质与反应;反应产物Fe3+从生物膜到液膜的传质[23-24]。

综上所述,不同生物滴滤塔运行工艺参数对脱硫效率的影响有:SO2进气质量浓度和停留时间主要影响了SO2气液膜之间传质速率;气相中较高浓度SO2限制了其分子在液相中的扩散,较低的停留时间减小了气液间的接触面积;喷淋密度主要控制气液膜的形成面积及生物膜的厚度;营养液中Fe2+浓度直接影响了Fe3+与HSO3−的反应速率。

-

1)从市政污水污泥中分离筛选出的脱硫细菌,经驯化富集后成功接种到页岩陶粒填料表面,且活性较高。其中,嗜酸性氧化亚铁硫杆菌A.f菌是优势菌种,占90.6%。

2) SO2进气质量浓度、气体停留时间、循环营养液喷淋液密度和Fe2+浓度均对生物滴滤塔脱除SO2气体效果影响显著。在温度为30 ℃、SO2进口质量浓度为228 mg·m−3、气体停留时间为150 s、营养液喷淋密度为0.36 m3·(m2·h)−1、Fe2+浓度为0.1 mol·L−1时,生物滴滤塔对SO2的脱除率最高值为98.6%。

3)生物滴滤塔的工艺参数对脱硫效率的影响不同。其中,SO2进气质量浓度和停留时间主要影响SO2气液膜之间传质速率;气相中较高浓度SO2限制了其分子在液相中的扩散;较低的停留时间减小了气液间的接触面积;喷淋密度主要控制气液膜的形成面积及生物膜的厚度;营养液中Fe2+浓度直接影响了Fe3+与HSO3−的反应速率。

生物滴滤塔脱除污泥干化尾气中的SO2

Removal of sulfur dioxide from exhaust gas of sludge drying by biotrickling filter tower

-

摘要: 以市政污泥干化尾气中的主要含硫物质二氧化硫(SO2)为处理对象,从市政污泥中筛选出高效脱硫菌——嗜酸性氧化亚铁硫杆菌(Acidithiobacillus ferrooxidans,A.f),搭建了实验室规模的生物滴滤塔,考察了进气质量浓度、气体停留时间、营养液喷淋密度和营养液中Fe2+浓度对生物滴滤塔脱除SO2的影响。结果表明:在SO2质量浓度约合38~304 mg·m−3(即常温常压下100~800 ppm)时,脱硫效率稳定在约97%;当气体停留时间由150 s降至30 s时,脱硫效率迅速降至75%;当营养液的喷淋密度小于0.36 m3·(m2·h)−1时,脱硫效率降至92%,但喷淋密度为0.36~1.08 m3·(m2·h)−1时,脱硫效率保持在约97%;当作为生物脱硫反应关键的液相Fe2+浓度由0.1 mol·L−1降至0.02 mol·L−1时,脱硫效率迅速降至84%以下。本研究结果可为生物脱硫技术的推广应用提供参考。Abstract: Sulfur dioxide (SO2), which is the main sulfur-containing substance in the exhaust gas of sludge drying process, was chosen as the subject in this paper. A laboratory-scale biotrickling filter tower was constructed by screening the highly efficient desulfurization bacteria Acidithiobacillus ferrooxidans (A.f) from municipal sludge. The effects of inlet gas mass concentration, gas residence time, nutrient solution spray density and Fe2+ concentration in nutrient solution on the removal of SO2 in the biological trickling filter tower were investigated. Results showed that when the concentration of SO2 changed from 38 to 304 mg·m−3 (around 100 to 800 ppm under room temperature and pressure), the desulfurization efficiency basically maintained at about 97%, but the desulfurization efficiency dropped rapidly to 75% when the gas residence time decreased from 150 s to 30 s. The desulfurization efficiency rapidly decreased to 92% when nutrient solution spray density was less than 0.36 m3·(m2·h)−1, while when the spraying density was in the range of 0.36-1.08 m3·(m2·h)−1, the desulfurization efficiency remained close to 97%.. When the concentration of Fe2+ decreaced from 0.1 mol·L−1 to 0.02 mol·L−1, the desulfurization efficiency rapidly decreased to below 84%. This results of the can provide reference for the promotion and application of biodesulfurization technology.

-

Key words:

- bio-trickling filter tower /

- SO2 /

- desulfurization bacteria /

- desulfurization efficiency

-

-

表 1 原污泥特性指标

Table 1. Characteristics of raw sludge

污泥种类 含水率/% VS/(g·L−1) TS/(g·L−1) VS/TS/% CST/s SRF/

(×1013 m·kg−1)pH 密度/(g·mL−1) 剩余活性污泥 94.10 22.51 59.46 37.90 267.0 2.03 6.84 1.00 活性污泥 98.90 10.19 45.70 22.28 35.6 0.14 6.69 1.00 注:VS为挥发性固体含量(volatile solid);TS为总固体含量(total solid);CST为毛细吸水时间(capillary suction time);SRF为比阻(specific resistance to filtration)。 -

[1] 桂成民. 微波热解制备污泥生物炭研究[D]. 广州: 广东工业大学, 2015. [2] 董智伟. 污泥生物炭的理化性质及其对铜吸附特性的研究[D]. 昆明: 昆明理工大学, 2019 [3] 李笃中, 何品晶. 污泥性质、胶羽结构与处置[J]. 科技导报, 2004, 22(9): 26-30. doi: 10.3321/j.issn:1000-7857.2004.09.010 [4] 陈文和, 邓明佳, 罗辉. 污泥直接干化产生的恶臭及挥发性有机物特征研究[J]. 环境科学, 2014, 1(8): 2897-2902. [5] 丁文杰. 生物滤池去除污泥干化尾气中恶臭物质的研究[D]. 北京: 中国科学院研究生院, 2016. [6] 贾惠茗. 生物滴滤塔脱除二氧化硫的试验研究[D]. 西安: 西安建筑科技大学, 2012. [7] BURGESS J E, PARSONS S A, STUETZ R M. Developments in odour control and waste gas treatment biotechnology: a review[J]. Biotechnology Advances, 2001, 19(1): 35-63. doi: 10.1016/S0734-9750(00)00058-6 [8] 李娟娟, 段学军, 窦艳艳, 等. 改良型生物滴滤塔净化SO2废气的影响因素研究[J]. 河南科技, 2015(18): 127-129. doi: 10.3969/j.issn.1003-5168.2015.18.046 [9] 王小军, 徐校良. 生物法净化工业废气的研究进展[J]. 化工进展, 2014, 33(1): 213-218. [10] ZHANG J Y, LI L, LIU J X. Thermophilic biofilter for SO2 removal: Performance and microbial characteristics[J]. Bioresource Technology, 2015, 180: 106-111. doi: 10.1016/j.biortech.2014.12.074 [11] ZHANG J Y, LI L, LIU J X. Temporal variation of microbial population in a thermophilic biofilter for SO2 removal[J]. Journal of Environmental Sciences, 2016, 39(1): 4-12. [12] ZHANG J Y, LI L, LIU J X, et al. Temporal variation of microbial population in acclimation and start-up period of a thermophilic desulfurization biofilter[J]. International Biodeterioration & Biodegradation, 2016, 109: 157-164. [13] LIN J, DING W J, LI L, et al. Continuous desulfurization and bacterial community structure of an integrated bioreactor developed to treat SO2 from a gas stream[J]. Journal of Environmental Sciences, 2015, 37: 130-138. doi: 10.1016/j.jes.2015.05.029 [14] 李蔓. 嗜酸氧化亚铁硫杆菌驯化条件的研究[J]. 武汉科技大学学报, 2009, 22(2): 12-16. [15] 中华人民共和国卫生部, 国家标准化管理委员会. GB/T 16157-1996 固定污染源排气中颗粒物和气态污染物采样方法[S]. 北京: 中国标准出版社, 1997. [16] KUCERA J, PAKOSTOVA E, JANICZEK O, MANDL M. Changes in Acidithiobacillus ferrooxidans ability to reduce ferric iron by elemental sulfur[J]. Advanced Materials Research, 2015, 1130: 97-100. doi: 10.4028/www.scientific.net/AMR.1130.97 [17] KOEHLER M. Isolation and characterization of Thiobacillus ferrooxidans from coal acid mine drainage[J]. International Journal of Applied Environmental Sciences, 2018, 13(12): 1097-1109. [18] NESTOR D, VALDIVIA U, CHAVES A P. Mechanisms of bioleaching of a refractory mineral of gold with Thiobacillus ferrooxidans[J]. International Journal of Mineral Processing, 2001, 62(1): 187-198. [19] CHO E H. Removal of SO2 with oxygen in the presence of Fe(III)[J]. Metallurgical Transactions B, 1986, 17(4): 745-753. doi: 10.1007/BF02657136 [20] KHOSHNEVISAN B, TSAPEKOS P, NA BORJABAD, et al. A review on prospects and challenges of biological H2S removal from biogas with focus on biotrickling filtration and microaerobic desulfurization[J]. Biofuel Research Journal, 2017, 4: 741-750. doi: 10.18331/BRJ2017.4.4.6 [21] 袁博文. 生物滴滤塔脱除SO2降解菌的筛选及降解工艺的研究[D]. 西安: 西安建筑科技大学, 2010. [22] SUN Y, XUE S, LI L, et al. Sulfur dioxide and o-xylene co-treatment in biofilter: Performance, bacterial populations and bioaerosols emissions[J]. Journal of Environmental Sciences, 2018, 69: 41-51. doi: 10.1016/j.jes.2017.03.039 [23] 方力. 氧化亚铁硫杆菌的诱变及其对烟气SO2去除效果的研究[D]. 西安: 西安工程大学, 2015. [24] LÓPEZ L R, DORADO A D, MORA M, et al. Modeling an aerobic biotrickling filter for biogas desulfurization through a multi-step oxidation mechanism[J]. Chemical Engineering Journal, 2016, 294: 447-457. doi: 10.1016/j.cej.2016.03.013 -

下载:

下载: