-

我国是生猪生产和猪肉消费大国[1],生猪养殖业在国计民生中具有重要地位。随着生猪养殖规模化发展,在一些地区产生了大量含高浓度有机物和氮、磷等物质[2]的猪场废水,对周边环境产生污染。猪场废水处理模式大致有2种:还田利用和达标处理。废水经过无害化处理后用作肥料还田 (还田利用)是最理想的处理利用方式,但需要大量供还田的土地,对于周边土地有限的大型和特大型猪场,达标处理仍然是一种现实选择。

猪场废水达标处理通常采用厌氧-好氧组合工艺。在组合工艺中,厌氧段主要去除高浓度有机物并回收可再生能源—沼气,未被去除的氮素会导致厌氧消化液(沼液)呈现低碳氮比(C/N)废水的特征[3]。厌氧出水的生化后处理单元主要采用传统序批式活性污泥法(sequencing batch reactor activated sludge process,SBR) 和缺氧/好氧活性污泥法(anoxic/oxic activated sludge process,A/O),但这些工艺处理沼液的脱氮效果均比较差[4-6],主要是因为沼液缺乏易降解有机物,不能满足传统反硝化脱氮的需求。

近年来,一些研究者采用微好氧脱氮技术处理沼液,取得了较好的脱氮效果[7-9]。微氧脱氮技术是将反应体系的溶解氧质量浓度(DO)控制在0.3~1.0 mg·L−1,在同一反应器中同时实现有机物降解和氨氮、总氮的去除。已有研究[10]表明,在低溶解氧条件下处理沼液,处理系统中能建立短程硝化-厌氧氨氧化-反硝化(shortcut nitrification-anammox-denitrification,SNAD)混合脱氮体系,存在短程硝化-厌氧氨氧化和短程硝化-反硝化2种脱氮过程,可以使自养菌、异养菌在微氧环境中共存。与传统脱氮工艺相比,微氧脱氮技术具有较好脱氮效果[11],并且可长期在低溶解氧状态下运行,N2O的排放量能减少54%[12]。

目前,微氧脱氮技术主要采用升流式微氧活性污泥反应器(up-flow micro-aerobic sludge reactor, UMSR)和内曝气升流式反应器(internal aeration up-flow reactor, IAUR)进行处理。UMSR采用在出水池中曝气和部分回流的方式来控制反应器内溶解氧浓度,导致其混合液回流比高,能耗大;IAUR设计结构复杂,工程上难以大规模应用。本研究基于IAUR反应器和升流式厌氧污泥床(up-flow anaerobic sludge bed,UASB)的原理设计了曝气沉淀一体化微氧反应器(aeration and sedimentation integrated micro-aerobic reactor, ASIMR),以污泥滞留能力和污染物去除性能为指标初步优选出2种反应器后,进行沼液处理实验,通过污染物去除性能、污泥滞留能力和活性污泥性状等指标来优选出更适合工程应用的微氧反应器。

-

实验进水(沼液)取自四川省成都市双流区某规模化猪场。活性污泥取自四川简阳某规模猪场废水处理工程好氧脱水污泥。

-

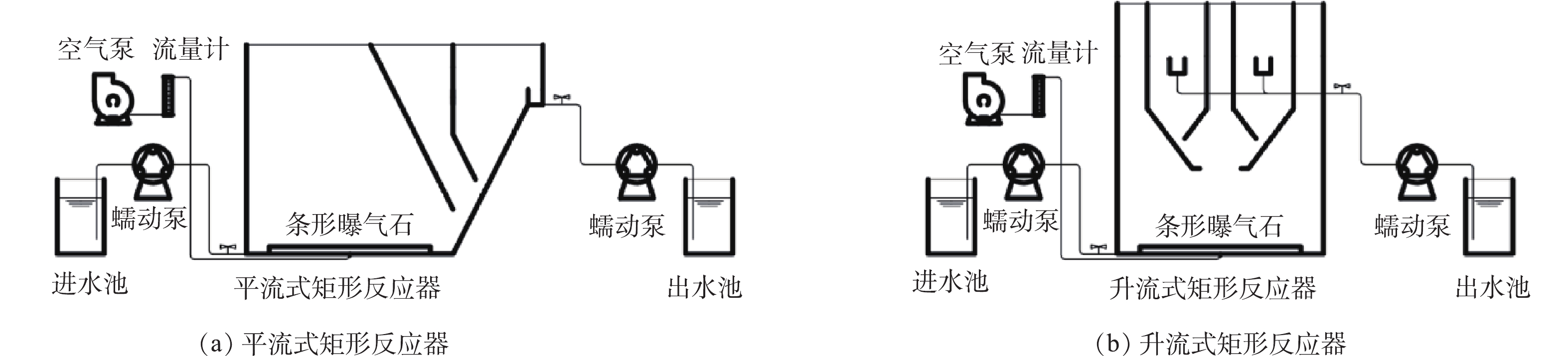

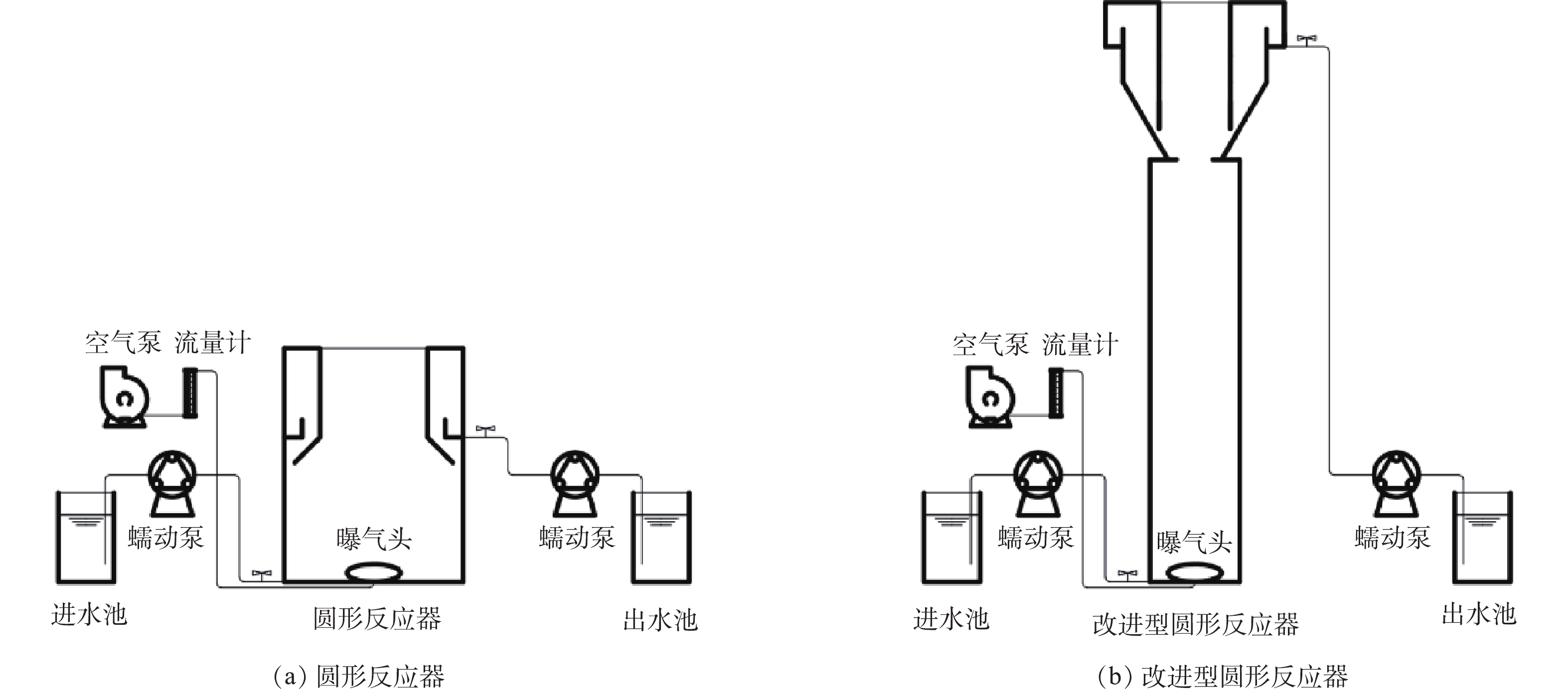

参考IAUR反应器设计了圆形曝气沉淀一体化反应器(圆形反应器,简称ASIMRC),参考平流式沉淀池设计了矩形平流式曝气沉淀一体化反应器(平流式矩形反应器,简称ASIMRFR)。为了提高反应器滞留污泥的能力,又在圆形反应器的基础上做了改进,设计了改进型圆形曝气沉淀一体化反应器(改进型圆形反应器,简称ASIMRIC)。参考UASB三相分离器的设计原理[13],改进了平流式矩形反应器的沉淀区,设计了升流式矩形曝气沉淀一体化反应器(升流式矩形反应器,简称ASIMRUR)。

反应器水力停留时间(hydraulic retention time,HRT)设计为24 h,此时,沉淀区表面负荷<4.5 m3·(m2·h)−1、溢流堰水力负荷<1.7 L·(m·s)−1、沉淀区HRT为1.5~2 h。

1)圆形反应器设计。圆形反应器直径200 mm,高262 mm,有效水深172 mm,有效容积5.4 L;改进型圆形反应器在圆形反应器的基础上增加高径比,由圆形反应器的0.86增至改进型的6.10;优化了挡板的结构,在曝气区与沉淀区交界处增长10 mm的挡板,使在不影响污泥回流到反应器的情况下减弱气流对沉淀区的影响。改进型圆形反应器直径100 mm,高728 mm,有效水深688 mm,有效容积5.4 L。2种圆形反应器的示意图见图1。

2)矩形反应器设计。平流式矩形反应器长×宽×高为275 mm×80 mm×280 mm,有效水深210 mm,有效容积5.4 L;升流式矩形反应器长×宽×高为275 mm×80 mm×335 mm,有效水深250 mm,有效容积5.4 L。二者的区别在于沉淀区,平流式矩形反应器的沉淀区参照平流式沉淀池设计,同向双层挡板,二次挡泥;升流式矩形反应器的沉淀参照UASB三相分离器设计,相向双层挡板,二次挡泥。2种矩形反应器的示意图如图2所示。

-

1)反应器优选。4个反应器有效容积同为5.4 L,装入相同的活性污泥,反应器内混合液悬浮固体质量浓度(mixed liquor suspended solids,MLSS)为(8.24±0.15) g·L−1,混合液挥发性悬浮固体质量浓度(mixed liquor volatile suspended solids,MLVSS)为(5.17±0.08) g·L−1。利用蠕动泵(Longer Pump DG15)连续进料,采用重力流出料。采用电磁式空气泵(ACO-002)曝气,用玻璃转子流量计(双环)控制曝气量以维持反应器处于微氧(DO为0.3~1.0 mg·L−1)状态。实验过程中,保持进水水质、HRT、DO范围一致。

为了分别比较改进型圆形反应器相对于圆形反应器、升流式矩形反应器相对于平流式矩形反应器的性能,将2个圆形反应器设为1组、2个矩形反应器1组分别进行对比实验,通过对污泥滞留效果、污染物(COD、NH4+-N)的去除效率等指标进行比较,优选出效果较好的反应器再进行后续沼液处理实验。圆形反应器进水COD、NH4+-N浓度、COD/TIN分别为(507±13.4) mg·L−1、(546±32.0) mg·L−1、(0.93±0.07);矩形反应器进水COD值、NH4+-N浓度、COD/TIN分别为(632±13.7) mg·L−1、(583±13.7) mg·L−1、1.09±0.04。

2)微氧反应器处理沼液实验。第1阶段(1~15 d)直接处理沼液;为了富集厌氧氨氧化菌,提升进水NO2−-N浓度,第2阶段(16~57 d)采用回流出水的方式调节进水水质。接种污泥的MLSS为(7.70±0.06) g·L−1,MLVSS为(4.96±0.02) g·L−1。

实验过程中,DO控制在0.3~1.0 mg·L−1,外加保温层维持体系温度为30 ℃,同时保温层具有遮光效果。利用蠕动泵(Longer Pump DG15)连续进料,重力流出料,采用电磁式空气泵(ACO-002)进行曝气,用玻璃转子流量计(双环)控制曝气量。二者进水水质如表1所示。

3)污泥活性实验。微氧反应器处理沼液实验中,每隔14 d,分别取出适量污泥测定氨氧化菌(ammonia oxidizing bacteria,AOB)活性、亚硝酸盐氧化菌(nitrite oxidizing bacteria,NOB)活性、反硝化菌(denitrifying bacteria,DB)活性和厌氧氨氧化菌(anaerobic ammonium oxidation bacteria,AnAOB)活性,每组活性实验做2个平行。取出的污泥混合液用2 g·L−1的KHCO3溶液清洗,清洗至不再检出NH4+-N、NO2−-N、NO3−-N。

将清净的污泥分配至150 mL锥形瓶(AOB、NOB)和100 mL血清瓶(DB、AnAOB)中,加入100 mL培养基溶液(2 g·L−1 KHCO3和微量元素)。AOB活性和NOB活性实验在恒温摇床(30 ℃)中曝气稳定30 min,DB活性和AnAOB活性实验通15 min氮气除去血清瓶中的氧气后,加盖置于恒温摇床(30 ℃)中稳定30 min。再依次在上述活性实验瓶中分别加入10 000 mg·L−1的NH4+-N贮备液1 mL、10 000 mg·L−1的NO2−-N贮备液1 mL、10 000 mg·L−1的NO3−-N贮备液和50 000 mg·L−1的C6H12O6溶液各1 mL、10 000 mg·L−1的NH4+-N贮备液0.50 mL和10 000 mg·L−1的NO2−-N 贮备液0.66 mL。加入后立即取样作为初始值,然后AOB、NOB和DB活性实验间隔1 h取样1 mL,AnAOB活性实验每隔7 d取样1 mL。水样用0.45 μm滤膜过滤后测定NH4+-N、NO2−-N、NO3−-N质量浓度。绘制反应底物随时间变化的线性回归直线,以确定底物的消耗速率。

4)胞外聚合物(EPS)的提取与测定。微氧反应器处理沼液实验中,每隔14 d,分别取出适量污泥,用PBS缓冲液清洗至上清液无明显颜色后,按步骤提取EPS(分为S-EPS、LB-EPS和TB-EPS)[14]。每份污泥样品取30 mL在台式冷冻离心机,在4 ℃、2 000 r·min−1条件下离心15 min,收集上清液过0.45 µm 滤膜即为S-EPS;剩余污泥用PBS缓冲溶液稀释重悬至原体积,在4 ℃、5 000 r·min−1条件下离心15 min,收集上清液过0.45 µm滤膜即为LB-EPS;剩余污泥继续用PBS缓冲溶液稀释重悬至原体积,80 ℃水浴30 min,待冷却至室温后再在4 ℃、5 000 r·min−1条件下离心15 min,收集上清液过0.45 µm 滤膜即为TB-EPS。提取的样品放在-20 ℃冰箱保存,分析前取出,EPS中的蛋白采用福林酚法测定[15],多糖采用蒽酮-硫酸法[16],蛋白、多糖含量之和即为EPS含量(mg·g−1)。

5)不同运行条件下出水SS的测定。先用 2 g·L−1 KHCO3清洗活性污泥,直至其中几乎不含有机物、NH4+-N、NO2−-N、NO3−-N,以避免实验中反硝化、厌氧氨氧化等生化反应对出水SS的影响。再用控制变量法,在其他条件相同的情况下,分别改变曝气量(HRT稳定在1.75 d)、HRT(曝气量稳定在576 L·d−1),用重量法测定出水SS。

6)分析方法反应器优选实验每天测DO,每天取样测定反应器进出水的 COD、NH4+-N、NO2−-N、NO3−-N、pH,TIN以NH4+-N、NO2−-N、NO3−-N之和计。

微氧反应器处理沼液实验每天测DO,每3 d取样测定反应器进出水的 COD、NH4+-N、NO2−-N、NO3−-N、pH,TIN以NH4+-N、NO2−-N、NO3−-N之和计。每两周测污泥含量(污泥沉降比(SV30)、MLSS、MLVSS、污泥容积指数(SVI))、污泥物理形态(粒径分布、体视镜、电镜)、污泥活性(AOB活性、NOB活性、DB活性和AnAOB活性)。

COD测定采用COD快速测定仪(LH-3C,中国连华科技有限公司),测定结果采用减去1.14倍NO2−-N的方式进行校正[17-18]; NH4+-N测定采用《水质 氨氮的测定 纳氏试剂分光光度法(HJ 535-2009)》;NO2−-N测定采用《水质 亚硝酸盐氮的测定 分光光度法(GB 7493-87)》;NO3−-N测定采用《水质 硝酸盐氮的测定 紫外分光光度法(试行)(HJ·T 346─ 2007)》;pH采用玻璃电极法(雷磁,上海) 测定;出水SS采用重量法;DO采用便携式溶解氧分析仪(哈西,美国)测定;离心机采用台式高速大容量冷冻离心机(H2100R,中国湘仪离心机仪器有限公司),粒径测定采用QICIP动态颗粒图像分析仪(SYMPATEC,德国);体视镜采用徕卡显微系统(Leica-M125,德国),SVI为SV30和MLSS的比值,单位为L·g−1,其中SV30为活性污泥混合液在量筒静止,沉降30 min后污泥所占的体积百分比。

-

1)圆形反应器优选。污泥滞留能力用出水SS表征,出水SS值越小,则污泥滞留能力越好。2个反应器在HRT为24、12、6 h的条件下分别运行3 d,肉眼可见改进型圆形反应器的出水澄清,无明显浮泥,而圆形反应器的出水带泥。如图3(a)所示,改进型圆形反应器的平均出水SS为(0.26±0.17) g·L−1, 圆形反应器出水SS一直显著高于改进型圆形反应器,在HRT=6 h时,由于进水氮负荷的增加,为维持溶解氧质量浓度在0.3~1.0 mg·L−1增大了曝气量,搅拌效果加强,对污泥的抬升作用更加强烈,圆形反应器出水SS高达(4.76±0.03) g·L−1,后期出水SS不高是因为反应器污泥已经所剩不多。由于活性污泥沉降性能在短期内变化不大,影响反应器SV30的主要因素是反应器内污泥质量。2个反应器接种污泥后的SV30为92%,连续运行9 d后,改进型圆形反应器的SV30降到75%,圆形反应器的SV30则降为43%。综上,改进型圆形反应器的污泥滞留能力比圆形反应器强。

圆形反应器在HRT为24、12、6 h下分别运行3 d,出水水质如图3(c、e)所示。在HRT为24、12、6 h 3个运行工况下,改进型圆形反应器的平均COD去除率分别比圆形反应器高3.83%、3.38%、17.7%,其NH4+-N平均去除率分别比圆形反应器高1.31%、2.44%、16.5%。前2个运行工况下2个反应器的污染物去除效果差别不大,这是因为2个反应器内污泥滞留量差距不明显;在HRT为6 h时圆形反应器内的活性污泥含量急剧下降,从而导致改进型圆形反应器污染物去除性能显著优于圆形反应器(P<0.05)。

2) 矩形反应器优选。2个反应器在HRT为24、12、6的条件下分别运行3 d,出水SS和SV30变化如图3(b)所示。升流式矩形反应器平均出水SS为(0.25±0.17) g·L−1。平流式矩形反应器的出水SS一直高于升流式矩形反应器,在HRT=12 h时出水SS高达(0.99±0.36) g·L−1,后期出水SS少,是因为在HRT=12 h时大部分污泥已随出水流出,反应器内污泥含量很低。在接种污泥后SV30都为90%的情况下连续运行9 d,升流式矩形反应器的SV30为80%,而平流式反应器SV30低于1%,上述结果说明,升流式矩形反应器的污泥滞留能力比平流式矩形反应器强。

在HRT为24、12、6 h 3种运行工况下,升流式矩形反应器的平均COD去除率分别比平流式矩形反应器高20.2%、21.3%、18.1%,其NH4+-N平均去除率分别比平流式矩形反应器高2.43%、16.30%、16.91%。由于平流式矩形反应器从HRT为24 h时就开始大量流失活性污泥,其体系内污泥含量一直低于升流式矩形反应器,从而导致升流式矩形反应器的污染物去除效果显著优于平流式矩形反应器(P<0.05)。

从污泥滞留能力和污染物去除能力2个方面比较,4个反应器中升流式矩形反应器和改进型圆形反应器对污泥滞留和污染物的去除能力较好。这2个反应器均能连续进出水并在内置沉淀区进行泥水分离,在保证处理效果的前提下还具有滞留污泥能力强、节省基建等优点。因此,选择升流式矩形反应器和改进型圆形反应器作为后续沼液处理的微氧反应器。

-

整个实验进程中升流式矩形反应器和改进型圆形反应器DO分别为(0.68±0.31) mg·L−1和(0.73±0.43) mg·L−1,温度控制在30 ℃左右。

1)进出水pH变化与污染物去除性能。第1阶段,进水平均pH为8.00±0.12,升流式矩形反应器和改进型圆形反应器的出水平均pH分别为8.09±0.34和7.71±0.64;第2阶段,进水平均pH为8.23±0.14,出水平均pH分别为7.01±0.42、7.25±0.50。第2阶段整体pH下降幅度比第1阶段大,特别是升流式矩形反应器,平均pH下降了1.0左右。2个阶段都没有发生沼液好氧处理过程中常见的酸化现象[5]。混合液pH由进水碱度、硝化消耗的碱度和反硝化产生的碱度所决定,结合脱氮效果可知,因为曝气量较小,NH4+-N去除率较低,硝化程度有所减弱,消耗的碱度较少,所以导致出水酸化现象不如其他研究明显。

如图4(a)所示,第1阶段升流式矩形反应器和改进型圆形反应器的COD去除率分别为(43.4±9.67)%和(40.6±15.0)%(P>0.05);第2阶段COD去除率分别为(29.6±5.74)%和(28.9±5.84)%(P>0.05)。第1阶段COD去除率远高于添加出水的第2阶段,这可能是由于pH下降导致异养微生物活性降低[19]以及污泥沉降性能变差。如图4(b)所示,第1阶段升流式矩形反应器和改进型圆形反应器的NH4+-N去除率分别为(50.2±7.76)%和(57.3±5.72)%;第2阶段NH4+-N去除率分别为(56.3±2.85)%和(54.6±4.58)%。2反应器NH4+-N去除性能无显著差异(P>0.05)。这个结果与使用SBR、A/O工艺处理沼液的氨氮去除效果接近[5]。对比2个阶段,升流式矩形反应器NH4+-N去除效果略高。有研究表明,当体系内NO2−-N质量浓度达25 mg·L−1时,会抑制硝化细菌,从而使其活性速率降低至原活性速率的1/3[20],进而导致NH4+-N去除率降低;氨氧化细菌活性受pH影响较大[21],其最适pH为7.0~8.5[22],当出水pH降到7以下时,也会抑制其活性,同时微氧条件限制了DO,故NH4+-N去除率不高。

如图4(c)所示,第1阶段,升流式矩形反应器和改进型圆形反应器的NO2−-N积累率分别为(75.6±6.68)%和(75.2±4.77)%,出水NO2−-N质量浓度分别为(185±71.2) mg·L−1和(262±58.3) mg·L−1;第2阶段NO2−-N积累率分别为(71.4±20.1)%和(71.6±20.2)%。2个反应器NO2−-N积累率无显著性差异(P>0.05),出水NO2−-N质量浓度分别高达(336±84.5) mg·L−1和(319±84.6) mg·L−1,2个阶段NO2−-N积累率均有所下降。

如图4(d)所示,第1阶段,升流式矩形反应器和改进型圆形反应器的TIN去除率分别为(19.5±7.01)%和(15.0±4.73)%;第2阶段TIN去除率分别为(10.2±9.69)%和(11.3±8.84)%,2反应器TIN去除性能无显著性差异(P>0.05)。由于未成功建立自养脱氮体系,而现存的异养脱氮体系又缺乏可生化有机碳源,进而导致反硝化缺乏底物,大部分NOx−-N未能被还原成N2而去除;反应器出水硝态氮质量浓度过高、pH降低会抑制反硝化细菌活性[20,23],导致TIN去除率下降。

微氧反应器的脱氮效果见表2。对比其他研究中的微氧反应器脱氮效果,本研究因为进水NH4+-N和TIN质量浓度较高且HRT较短,导致NH4+-N和TIN的去除率较低,但NH4+-N去除负荷高达0.479 kg·d−1,TIN去除负荷高达0.174 kg·d−1。与进水NH4+-N和TIN浓度相近的其他研究比较,本研究的去除负荷明显更高,氨氮去除负荷是吴杭航[8]的3倍,WANG[24]的6倍;总氮去除负荷优于进水C/N>5的研究,是C/N相近的研究的2~3倍。范鑫帝[7]、张布云[25]、王成等[9]研究中的去除负荷高于本研究,但其进水NH4+-N和TIN质量浓度仅为本文的31.1%~49.1%。

2)污泥性状。反应器污泥质量浓度与沉降性能变化如图5(a)所示。第56天升流式矩形反应器和改进型圆形反应器MLSS质量浓度分别为(7.53±0.13) g·L−1和(7.59±0.25) g·L−1,差异不显著,但与接种污泥( (7.70±0.06) g·L−1)相比略有下降,说明微氧环境下活性污泥生长速度缓慢,产生的污泥小于出水带走的污泥。

在接种相同污泥的情况下,升流式矩形反应器内污泥VSS/SS从64.4%增至78.0%,生物量占比提高,改进型圆形反应器降至62.1%,灰分占比上升,在二者MLSS质量浓度相近的情况下,升流式矩形反应器的生物量高于改进型圆形反应器。从污泥沉降比来看,升流式矩形反应器内污泥SV30由29%增至40%,而改进型圆形反应器涨至52%。污泥指数(SVI)是反映污泥沉降性能的重要指标。升流式矩形反应器内污泥SVI由37.7 mL·g−1增至53.1 mL·g−1,改进型圆形反应器升至68.5 mL·g−1,升流式矩形反应器污泥沉降性能优于改进型圆形反应器。二者污泥沉降性能均有所下降。这主要是由于沼液C/N过低,沼液易降解有机物不足,不易形成颗粒较大的絮体,下面的污泥粒径也说明了这个问题。

污泥粒径变化情况如图5(c)所示。由于粒径分布呈正态分布,故采用中值粒径D50为表征对污泥粒径进行分析。与接种污泥(D50=216.35 µm)相比,升流式矩形反应器、改进型圆形反应器的D50均减小,最后升流式矩形反应器的D50稳定在115 µm左右,改进型圆形反应器的D50稳定在125 µm左右,2个反应器的污泥粒径分布差异不大。在初期污泥粒径减小,一方面是由于曝气剪切力使物理压缩的脱水污泥分散,另一方面是由于缺少营养物质而导致的污泥解体;后期污泥粒径缓慢增大但仍小于接种污泥的中值粒径,是由于活性污泥逐步适应了反应体系从而缓慢增长,但受限于营养物质增长有限。

2反应器内活性污泥EPS变化情况如图5(b)所示。接种污泥只能检测到TB-EPS,实验结束时在活性污泥中可检测到S-EPS、LB-EPS、TB-EPS。其中LB-EPS虽然占比低,但对污泥的沉降性能和絮凝性能起决定作用,LB-EPS含量越高,形成的小粒径污泥颗粒则越多,污泥的沉降性能和絮凝性能越差[29-30]。与接种污泥相比,多糖(PS)和蛋白(PN)含量皆大幅上升,蛋白质作用于污泥颗粒的生长,多糖作用于污泥的稳定性,但同时会导致固液分离困难[31-32]。有研究[33]表明,SVI与EPS含量呈显著正相关,故体系内污泥沉降性能下降。

2个反应器中污泥的功能微生物活性见表3。将第42天的污泥活性速率(r)与接种污泥相比,改进型圆形反应器的AOB活性速率快速提升,升流式矩形反应器的AOB活性速率逐步提升;前者的NOB、DB活性速率也略有升高,后者则反之,NOB、DB活性速率均有所下降。升流式矩形反应器AOB活性与改进型圆形反应器接近,但其NOB活性一直弱于改进型圆形反应器,说明升流式矩形反应器内更容易建立短程硝化过程,2个反应器的DB活性一直相差不大。2个反应器皆未成功富集厌氧氨氧化细菌,主要是因为没有接种厌氧氨氧化污泥[34]且运行时间不够长,如果未接种厌氧氨氧化污泥,要建立短程硝化、厌氧氨氧化体系,一般需要运行230 d以上[28];沼液成分复杂,氨氮和有机物浓度过高,厌氧氨氧化菌对有机物、高氨氮和其他杂质的耐受度低[35-37],再加上连续流进水不断提供的碳源能使反硝化菌在脱氮上占优势,进而抢夺了厌氧氨氧化菌的生存空间[38-39]。

由上述结果可知,微氧反应器具有NH4+-N、TIN去除负荷较高、剩余污泥量少、曝气能耗低等优点,推广应用到工程上可实现节能减排。相较于SBR法,提高了容积利用率;相较于A/O法无需外接沉淀池和污泥、混合液回流;相较于以往常用的微氧反应器,规避了UMSR混合液回流比高、能耗大和IAUR设计结构复杂、工程上难以放大应用的缺点。

从滞泥效果看,在不同运行条件下二者出水SS低于0.10 g·L−1(表4和表5),均具有良好的滞泥效果;从污染物去除性能来看,升流式矩形反应器和改进型圆形反应器的差异不显著;但从污泥沉降性能、生物量增长和功能菌活性来看,升流式矩形反应器更容易建立短程硝化过程,其几何构型更适合放大,对建设场地地形适应性强,所以升流式矩形反应器更适合在工程中的推广应用。

-

1)升流式矩形反应器和改进型圆形反应器对沼液中污染物去除性能、污泥滞留能力的差异性不显著(P>0.05),升流式矩形反应器污泥生物量占比高、沉降性能显著优于改进型圆形反应器(P<0.05)。

2) 2个反应器的平均NH4+-N去除负荷为0.410 kg·(m3·d)−1,平均TIN去除负荷为0.105 kg·(m3·d)−1,出水SS均小于0.10 g·L−1,均拥有优良的滞泥能力和污染物去除能力。

3)综合考虑污泥性状、污染物去除性能以及工程上放大应用可能性等因素,优选出升流式矩形反应器用于工程上应用。

新型微氧反应器对沼液的处理性能

Performance of a novel micro-aerobic reactor on biogas slurry treatment

-

摘要: 针对现有微氧反应器存在回流能耗高、工程放大困难等问题,设计了2类新型曝气沉淀一体化微氧反应器。根据污泥滞留能力、污染物去除性能初步测试,优选出升流式矩形反应器和改进型圆形反应器作为沼液处理实验的微氧反应器。结果表明:2个反应器的平均NH4+-N去除负荷为0.410 kg·(m3·d)−1,平均TIN去除负荷为0.105 kg·(m3·d)−1,出水SS均小于0.10 g·L−1,都拥有优良的滞泥能力和污染物去除能力,无显著性差异(P>0.05)。在污泥浓度相近的情况下,升流式矩形反应器中污泥的VSS/SS由64.4%增至78.0%,这说明生物量明显增加,而改进型圆形反应器中污泥的VSS/SS降至62.1%;污泥指数显示升流式矩形反应器的污泥沉降性能更好。从污泥性状和工程放大可能性考虑,升流式矩形反应器更适合在工程上应用。Abstract: Aiming at the problems such as high energy consumption of reflux and difficulty in engineering scale-up, two new types of aeration-sedimentation integrated micro-aerobic reactors were designed. According to the preliminary test of sludge retention capacity and pollutant removal performance, the upflow rectangular reactor and the improved circular reactor were selected as the micro-aerobic reactors for biogas slurry treatment. The results showed that for the two reactors, their average NH4+-N removal loading was about 0.410 kg·(m3·d)−1, average TIN removal loading was about 0.105 kg·(m3·d)−1, and the effluent SS was less than 0.10 g·L−1. Both reactors had excellent sludge retention capacity and pollutant removal performance, with no significant difference (P > 0.05). At the similar sludge concentration, the VSS/SS value of sludge in the upflow rectangular reactor increased from 64.4 % to 78.0 %, indicating that the biomass increased significantly; while the VSS/SS value of sludge in the improved circular reactor decreased to 62.1 %. In addition, SVI value showed that sludge in the upflow rectangular reactor had better settling performance than that in the improved circular reactor. Considering sludge characteristics and the possibility of scaling up, the upflow rectangular reactor is more suitable for engineering application.

-

Key words:

- microaerobic reactor /

- piggery wastewater /

- micro-aerobic /

- nitrogen removal /

- sludge sedimentation

-

-

表 1 微氧反应器处理沼液实验进水水质

Table 1. Influent characteristics in the experiment of biogas slurry treatment by micro-aerobic reactor

阶段 COD/(mg·L−1) NH4+-N/(mg·L−1) NO3−-N/(mg·L−1) NO2−-N/(mg·L−1) TIN/(mg·L−1) COD/TIN Ⅰ(1~15 d) 1 556±672 845±145 0.000 0.000 845±145 1.84 Ⅱ(16~57 d) 1 416±260 722±89.0 19.3±10.1 93.0±17.6 834±84.7 1.67 表 2 微氧反应器脱氮效果比较

Table 2. Comparison of nitrogen removal by the microaerobic reactor in different studies

工艺 进水水质 NH4+-Ninf TINinf C/TIN ARR NRR 途径 来源 /(mg·L−1) /(mg·L−1) /(kg·(d·m³)−1) /(kg·(d·m³)−1) ASIMRUR 沼液 845 845 1.84 0.413 0.174 PN/DB 本研究 ASIMRIC 沼液 845 845 1.84 0.479 0.132 PN/DB 本研究 ASIMRUR 沼液+出水 722 722 1.96 0.407 0.086 PN/DB 本研究 ASIMRIC 沼液+出水 722 722 1.96 0.395 0.094 PN/DB 本研究 UMSR 干清粪猪场废水 269 273 0.68 0.712 0.664 PN/A 文献[7] UMSR 干清粪猪场废水 306 307 0.9 0.94 0.91 PN/DB 文献[9] UMBR 干清粪猪场废水 306 307 0.9 0.64 0.55 PN/DB 文献[9] SBR 干清粪猪场废水 415 417 0.63 1.158 1.047 PN/A 文献[25] SBBR 合成废水 75 75 5 0.065 0.064 PN/DB 文献[26] A/O 合成废水 50 7 0.098 PN/DB 文献[4] SFAO4 沼液+原水 729 >5 0.155 0.137 SNAD 文献[8] IAMR 无粪猪场废水 235.5 335.2 0.77 0.668 0.831 SNAD 文献[27] A2/O 无粪猪场废水 373 454 1.93 0.028 0.032 SNAD 文献[10] BNR 无粪猪场废水 783 758 2.58 0.074 0.067 SNAD 文献[24] UMSR 无粪猪场废水 393 394 0.93 0.179 0.164 PN/A 文献[28] 表 3 不同阶段的污泥活性速率

Table 3. Sludge activity at different stages

时间/d 升流式矩形反应器活性

速率/(mg·(g·h)−1)改进型圆形反应器活性

速率/(mg·(g·h)−1)rAOB rNOB rDB rAnAOB rAOB rNOB rDB rAnAOB 1 1.63 0.86 0.90 0.00 1.63 0.86 0.90 0.00 14 9.69 1.21 0.64 0.00 19.2 2.25 0.20 0.00 28 11.3 1.27 1.03 0.00 23.8 2.11 1.87 0.00 42 20.7 0.26 0.74 0.00 23.9 1.13 0.94 0.00 表 4 微氧反应器在不同HRT下的出水SS质量浓度

Table 4. Effluent SS concentration of micro-aerobic reactor at different HRTs

HRT/d 升流式矩形反应器/

(g·L−1)改进型圆形反应器/

(g·L−1)1.75 0 0 1.4 0 0 1.17 0.10 0 1.00 0 0 0.88 0 0.04 0.78 0 0 0.70 0.07 0 表 5 微氧反应器在不同曝气量下的出水SS质量浓度

Table 5. Effluent SS concentration of micro-aerobic reactor at different aeration rates

曝气量/

(L·d−1)升流式矩形反应器/

(g·L−1)改进型圆形反应器/

(g·L−1)576 0 0 720 0.01 0.01 864 0 0 1 008 0 0 1 152 0 0.01 1 296 0 0.06 1 440 0.01 0.05 -

[1] SUN J M. Pork price forecast based on breeding sow stocks and hog-grain price ratio[J]. Editorial Office of Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(13): 1-6. [2] 第二次全国污染源普查公报[J]. 环境保护, 2020, 48(18): 8-10. [3] 贺仲兵, 刘云国. 添加原水在猪场废水处理中的应用[J]. 黑龙江畜牧兽医, 2012, 24: 83-84. doi: 10.13881/j.cnki.hljxmsy.2012.24.005 [4] 陈燕, 刘国华, 范强, 等. 不同溶解氧条件下A/O系统的除碳脱氮效果和细菌群落结构变化[J]. 环境科学, 2015, 36(7): 2610-2616. doi: 10.13227/j.hjkx.2015.07.038 [5] 蔡英英, 韩志刚, 邓良伟, 等. A/O与SBR工艺处理猪场废水厌氧消化液对比研究[J]. 农业环境科学学报, 2022, 41(3): 648-657. doi: 10.11654/jaes.2021-0895 [6] 杨含. 零价铁介导下猪场废水厌氧消化液自养脱氮的影响因素与机制[D]. 北京: 中国农业科学院, 2020. [7] 范鑫帝. 养猪场废水微氧活性污泥处理系统的调控运行与脱氮机制[D]. 哈尔滨: 哈尔滨工业大学, 2019. [8] 吴杭航. 猪场废水厌氧沼液SFAO4微氧曝气处理工艺脱氮性能研究[D]. 杭州: 浙江大学, 2017. [9] 王成. 升流式微氧反应器处理低C/N比养猪废水效能[D]. 哈尔滨: 哈尔滨工业大学, 2016. [10] CHEN Y, ZHENG R, SUI Q, et al. Coupling anammox with denitrification in a full-scale combined biological nitrogen removal process for swine wastewater treatment[J]. Bioresource Technology, 2021, 329: 124906. doi: 10.1016/j.biortech.2021.124906 [11] 黄春雷, 王振旗, 孙杰, 等. 一体化低溶解氧生化处理工艺在猪场废水脱氮工程中的应用[J]. 净水技术, 2020, 39(S2): 78-83. doi: 10.15890/j.cnki.jsjs.2020.s2.015 [12] LIU G Q, WU X W, LI D Y, et al. Long-Term low dissolved oxygen operation decreases N2O emissions in the activated sludge process[J]. Environmental Science & Technology, 2021, 55(10): 6975-6983. [13] 胡纪萃. UASB反应器三相分离器的设计方法[J]. 中国沼气, 1992(3): 5-9. [14] LIU W L, YANG Q, MA B, et al. Rapid achievement of nitritation using aerobic starvation[J]. Environmental Science & Technology, 2017, 51(7): 4001-4008. [15] LEDOUX M, LAMY F. Determination of proteins and sulfobetaine with the Folin-phenol reagent[J]. Analytical Biochemistry, 1986, 157(1): 28-31. doi: 10.1016/0003-2697(86)90191-0 [16] SHARMA V, SUROLIA A. Analyses of carbohydrate recognition by legume lectins: Size of the combining site loops and their primary specificity[J]. Journal of Molecular Biology, 1997, 267(2): 433-445. doi: 10.1006/jmbi.1996.0863 [17] QIAN W T, MA B, LI X Y, et al. Long-term effect of pH on denitrification: High pH benefits achieving partial-denitrification[J]. Bioresource Technology, 2019, 278: 444-449. doi: 10.1016/j.biortech.2019.01.105 [18] 周安兴, 刘玄. 亚硝氮对COD测试的影响及掩蔽研究[J]. 工程技术研究, 2019, 4(2): 253-254. doi: 10.19537/j.cnki.2096-2789.2019.02.123 [19] PAN Y, YE L, NI B J, et al. Effect of pH on N2O reduction and accumulation during denitrification by methanol utilizing denitrifiers[J]. Water Research, 2012, 46(15): 4832-4840. doi: 10.1016/j.watres.2012.06.003 [20] 宋姬晨, 王淑莹, 杨雄, 等. 亚硝酸盐对A2O系统脱氮除磷的影响[J]. 中国环境科学, 2014, 34(9): 2231-2238. [21] YAN L, LIU Y, REN Y, et al. The effect of pH on the efficiency of an SBR processing piggery wastewater[J]. Biotechnology and Bioprocess Engineering, 2013, 18(6): 1230-1237. doi: 10.1007/s12257-013-0292-6 [22] HUNIK H J, TRAMPER J, WIJFFELS R H. A strategy to scale up nitrification processes with immobilized cells of Nitrosomonas Europaea and Nitrobacter agilis[J]. Bioprocess Engineering, 1994, 11(2): 73-82. doi: 10.1007/BF00389563 [23] 王伸, 邓良伟, 姜奕圻, 等. 加碱对猪场废水厌氧消化液好氧处理过程酸化改进作用及其对菌群结构的影响[J]. 中国沼气, 2017, 35(6): 3-9. doi: 10.3969/j.issn.1000-1166.2017.06.001 [24] WANG X, YANG R, ZHANG Z, et al. Mass balance and bacterial characteristics in an in-situ full-scale swine wastewater treatment system occurring anammox process[J]. Bioresource Technology, 2019, 292: 122005. doi: 10.1016/j.biortech.2019.122005 [25] 张布云. 好氧-微氧两级SBR处理养猪废水技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2020. [26] 吴丹. 不同曝气方式下短程硝化反硝化工艺特性研究[D]. 重庆: 重庆大学, 2012. [27] SUN Z, LI J, FAN Y, et al. Efficiency and mechanism of nitrogen removal from piggery wastewater in an improved microaerobic process[J]. Science of the Total Environment, 2021, 774: 144925. doi: 10.1016/j.scitotenv.2020.144925 [28] TIAN Y, LI J, FAN Y, et al. Performance and nitrogen removal mechanism in a novel aerobic-microaerobic combined process treating manure-free piggery wastewater[J]. Bioresource Technology, 2022, 345: 126494. doi: 10.1016/j.biortech.2021.126494 [29] 王红武, 李晓岩, 赵庆祥. 胞外聚合物对活性污泥沉降和絮凝性能的影响研究[J]. 中国安全科学学报, 2003, 13(9): 31-34. doi: 10.3969/j.issn.1003-3033.2003.09.008 [30] 王红武, 李晓岩, 赵庆祥. 活性污泥的表面特性与其沉降脱水性能的关系[J]. 清华大学学报(自然科学版), 2004, 44(6): 766-769. doi: 10.3321/j.issn:1000-0054.2004.06.013 [31] FRøLUND B, PALMGREN R, KEIDING K, et al. Extraction of extracellular polymers from activated sludge using a cation exchange resin[J]. Water Research (Oxford), 1996, 30(8): 1749-1758. doi: 10.1016/0043-1354(95)00323-1 [32] WANG S, HUANG X, LIU L, et al. Insight into the role of exopolysaccharide in determining the structural stability of aerobic granular sludge[J]. Journal of Environmental Management, 2021, 298: 113521. doi: 10.1016/j.jenvman.2021.113521 [33] 周健, 龙腾锐, 苗利利. 胞外聚合物EPS对活性污泥沉降性能的影响研究[J]. 环境科学学报, 2004, 24(4): 613-618. doi: 10.3321/j.issn:0253-2468.2004.04.009 [34] FAN Z, ZENG W, LIU H, et al. A novel partial denitrification, anammox-biological phosphorus removal, fermentation and partial nitrification (PDA-PFPN) process for real domestic wastewater and waste activated sludge treatment[J]. Water Research, 2022, 217: 118376. doi: 10.1016/j.watres.2022.118376 [35] LI J, PENG Y, ZHANG L, et al. Quantify the contribution of anammox for enhanced nitrogen removal through metagenomic analysis and mass balance in an anoxic moving bed biofilm reactor[J]. Water Research, 2019, 160: 178-187. doi: 10.1016/j.watres.2019.05.070 [36] 朱葛夫, 张净瑞, 刘超翔, 等. 厌氧氨氧化工艺的启动及有机物浓度对其影响研究[J]. 环境工程, 2016, 34(2): 27-32. doi: 10.13205/j.hjgc.201602007 [37] STROUS M, KUENEN J G, JETTEN M S M. Key physiology of anaerobic ammonium oxidation[J]. Applied and Environmental Microbiology, 1999, 65(7): 3248-3250. doi: 10.1128/AEM.65.7.3248-3250.1999 [38] LIANG W, YU C, REN H, et al. Minimization of nitrous oxide emission from CASS process treating low carbon source domestic wastewater: Effect of feeding strategy and aeration rate[J]. Bioresource Technology, 2015, 198: 172-180. doi: 10.1016/j.biortech.2015.08.075 [39] LANGONE M, FERRENTINO R, CADONNA M, et al. Stoichiometric evaluation of partial nitritation, anammox and denitrification processes in a sequencing batch reactor and interpretation of online monitoring parameters[J]. Chemosphere, 2016, 164: 488-498. doi: 10.1016/j.chemosphere.2016.08.094 -

下载:

下载: