-

市政污泥是城市生活污水处理过程中的副产物,近年来,污泥产量急剧增加。2020年我国市政污泥年产量已经超过6×107 t (以80%含水率计) [1],预计2025年将超过9×107 t (以80%含水率计) [2]。污泥含有丰富的碳元素,有机碳的质量分数为222.74~406.03 g·kg−1[3-5],资源化利用潜力巨大。解决迫在眉睫的污泥问题,实现污泥碳素资源化,对于推动碳达峰和碳中和目标的实现具有现实意义。

市政污泥热解作为一种十分高效的污泥处理和资源回收方式受到了广泛研究[6]。污泥在热解过程中不仅能实现减量化,并且会产生含碳增值产品 (如生物炭) 。研究发现,市政污泥热解过程中碳素产物的形成与污泥中含碳官能团演变有关[7]。DE等[8]发现相比于温度低于400 ℃时,污泥热解生物炭在400~700 ℃的温度区间中脂肪族基团更少而石墨碳结构更多,一定程度上证明了生物炭的结构随温度的上升更加稳定。WANG等[9]通过红外光谱 (FTIR) 发现在700 ℃时污泥热解产物中的羰基已经消失,热稳定性得到了提高。此外,在高温下,生物炭中C-O键及-OH键等含碳氧官能团数量减少,吸附吸能减弱[10]。目前对于污泥热解过程中含碳官能团的半定量分析研究较少,对污泥热解过程中从低温到高温阶段含碳官能团的演化规律分析研究比较匮乏。同时,污泥热解不同阶段速率存在差异,通过动力学方法可以表征污泥热解不同阶段趋势。REN等[11]研究污泥热解活化能发现热解温度越高,反应越慢。徐新宇等[12]分析污泥热解活化能发现随着温度的升高,热解反应受阻,但加入芬顿试剂混合热解后,热解反应加快。因此通过动力学方法可以有效分析污泥热解过程,探究热解规律,研究污泥热解碳素转化机制。

本研究拟通过热重分析和热解动力学分析市政污泥热解特性,并基于傅里叶红外光谱分析仪 (FTIR) 和X射线光电子能谱 (XPS) 对市政污泥热解过程中含碳官能团进行定性半定量分析,旨在探明市政污泥热解过程热解特性及主要含碳官能团演化机制,为市政污泥热解机理及碳形态转化研究提供理论基础。

-

市政污泥取自河北省某污水处理厂。样品经自然风干2 d后,放置于105 ℃的烘箱中烘干至恒重,研磨后过60目筛网,放入干燥器待用。工业分析参照《煤的工业分析标准方法 (GB/T 212-2008) 》进行[13],分别得到物料的水分、灰分、挥发分和固定碳质量分数。元素分析采用有机元素分析仪 (UNICUBE,德国Elemantar公司) 。本实验污泥的工业分析和元素分析结果如表1所示。

-

污泥热重实验在热重分析仪中进行 (TG/DTA720,日本日立公司) ,在其中装入约6 mg样品,温度设定为从室温升至800 ℃,升温速率分别为5、10、20 ℃·min−1。在开始实验前,通入99.999%高纯度氩气排空空气,气体流量为40 mL·min−1。最后把实验所得失重数据换算成%计算,并求导得出DTG曲线。

污泥热解实验在管式炉中进行,称取约6 g经过前处理后的样品置于炉中。以氩气作为惰性载气,通气流速为40 mL·min−1,在10 ℃·min−1的升温速率下进行升温,热解最终温度分别为200、300、400、500、600、700 ℃,保温时间为40 min。最后在氩气气氛下冷却至室温,得到不同热解温度下的残留固体。

-

通过表观动力学对热解反应中样品反应的程度进行分析,探究污泥样品中的热解规律,动力学推演的速率方程如下。

在样品受热分解过程中,α为热解转化率,如式(1)所示。

式中:m0为样品的初始质量,mg;mt为在反应t时刻时样品的质量,mg;m1为反应结束时样品的剩余质量,mg。

根据Arrhenius公式,反应速率方程如式(2)所示。

式中:f(α)为反应模型,k(T)为反应常数。

式中:A为指前因子,s−1;Eα为活化能,kJ·mol−1;R为通用气体常数,R=8.314 J·(mol·K)−1;T为温度, ℃。

结合式(2)和式(3),得到式(4)。

代入升温速率β,K·min−1;得到式(5)。

对式(5)进行积分换算,得到式(6)。

式中:x=Eα·(RT)−1,式(6)可求出近似解。本研究采用Kissinger-Akahira-Sunose (KAS) 法、Flynn-Wall-Ozawa (FWO) 法和Friedman法3种等转化率法计算市政污泥热解的活化能。

-

本研究采用傅里叶红外光谱分析仪 (Tensor Ⅱ,德国布鲁克公司) 对污泥及其热解残留固体的特征含碳官能团分布特征进行分析。将污泥样品和热解残留固体进一步研磨碎,与干燥后的KBr粉末进行混合压片后,放入光谱仪中进行扫描。样品和KBr粉末的质量比为1∶150,每个压片的制作方法相同。

X射线光电子能谱 (XPS) 的光电子强度 (光电子峰面积) 反映了原子的相对质量分数,通过对样品进行XPS分析能够进行半定量分析。污泥及其热解残渣通过XPS (K-Alpha,美国Thermo Scientific公司) 扫描得到污泥及其热解残渣中碳元素的窄谱,测得碳元素特征结合能,同时通过Avantage软件对碳元素出峰位置进行分峰,确定含碳官能团的相对质量分数。XPS谱图中纵轴代表电子数,横轴代表电子结合能。

-

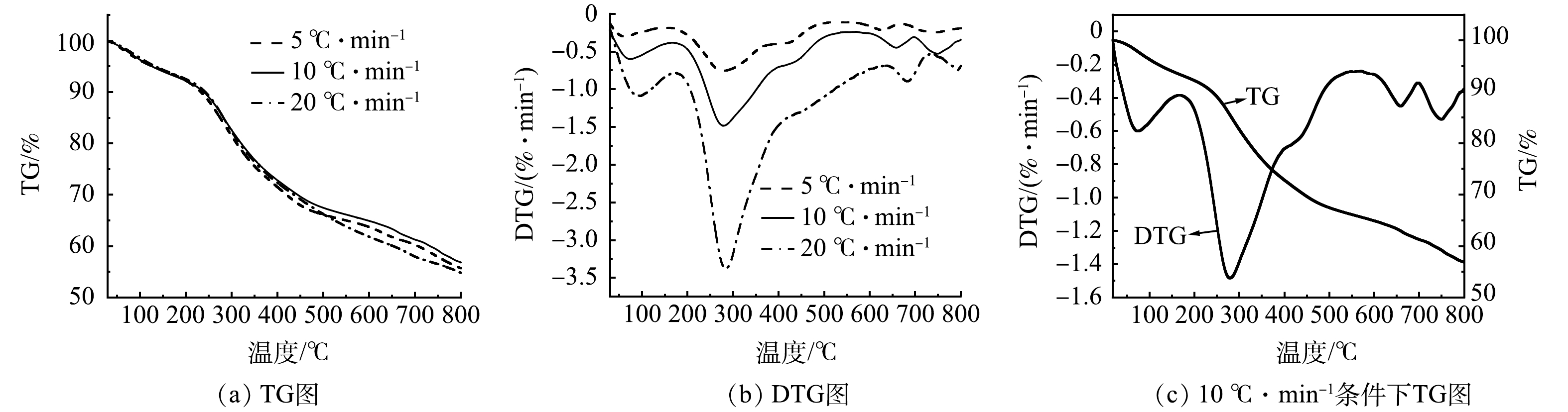

1) 市政污泥热失重分析。通过对污泥热解特性的研究,可以探寻市政污泥热解规律并分析污泥热解碳素资源化机制。图1(a)和图1(b)表示市政污泥在加热速率分别为5、10、20 ℃·min−1的情况下的热重 (TG) 和微商热重 (DTG) 曲线。由图1(a)可见,在800 ℃时,5、10、20 ℃·min−1的残炭率分别为9.93%、11.76%、9.72% (灰分不计入内) ,平均残炭率为10.47%。3个升温条件下的TG曲线变化趋势和残炭率随升温速率提高的变化并不明显,说明升温速率对热失重影响较小,改变升温速率并不会改变热解过程。这与KIM等[14]的结论相一致。由图1(b)可知,5、10、20 ℃·min−1 3个升温速率下的第1个最大失重温度分别为62、74、96 ℃,而当温度继续上升,在第4个峰和第5个峰的最大失重温度分别为626、658、683 ℃和732、749、793 ℃。随着升温速率的提高,污泥热解反应过程中出现热滞后效应,DTG曲线中出峰温度延后,且当温度越高时,热滞后现象越明显。这可能是因为污泥样品导热系数较低,热传导性能差,在加热过程中表面和内部表现出局部的非热平衡状态,当热解炉中的升温速率提高时,样品本身受加热的时间缩短,进而导致热解时间的缩短,使非热平衡状态更加明显,其挥发分不能及时分解析出,出现热滞后现象[15]。

因为升温速率对热失重影响较少,结合残炭率、升温耗时、物料传热等多方面因素,本实验选择在升温速率为10 ℃·min−1的情况下进一步开展污泥热重情况分析,深入讨论污泥热解转化过程。从图1(c)中可以看出,市政污泥热解过程中主要存在5个明显的失重峰,第2个峰是最大的失重峰。污泥热解主要可分为3个阶段,分别为脱水阶段 (30~170 ℃) 、有机物失重阶段 (170~696 ℃) 和无机盐分解阶段 (696~800.0 ℃) 。在30~170 ℃,出现第1个失重峰,其中的最大失重温度出现在72 ℃,此阶段市政污泥失重率约为7.14%。这可能主要是污泥中的结合水和吸附水以及少量低沸点挥发分的析出[16]。当温度继续上升,在170~398 ℃出现1个巨大失重峰,其中最大失重温度为281 ℃,在这个温度段,污泥失重率为20.30%,最大失重速率为1.48 ℃·min−1。在此温度段,污泥中占大部分的半纤维素、纤维素以及一些小分子蛋白质等有机物开始分解,半纤维素的主要热解失重温度段在250~320 ℃,纤维素的主要热解失重段在300~400 ℃,此外,在300 ℃以下,污泥中部分蛋白质 (不稳定蛋白) 也发生了热裂解析出。这可能是由于较多有机物热分解温度相近,导致热解温度区间重叠,由此形成较大的失重峰[17-19]。紧接着在398~540 ℃,热解过程中出现1个较小的肩峰,污泥失重率为7.20%。此温度段主要是大分子蛋白、脂类以及部分木质素的分解[19-21]。随温度继续升高,热解过程中出现第4个失重峰,温度范围在597~696 ℃,其最大失重温度和失重速率为658 ℃和0.45 %·min−1,此温度段市政污泥失重率为4.67%。这一阶段可能主要是源于污泥中未裂解完的有机物的继续热分解和炭渣的二次裂解导致[12]。随后第5个峰出现,其最大失重温度为749 ℃,最大失重速率为0.53 %·min−1,在这个阶段,污泥失重率为4.49%。这一阶段可能主要是由于污泥中无机盐的分解导致出现的峰[22-23]。可以发现,不同热解阶段污泥热解反应和效率存在差异,因此含碳官能团的演替也存在差异,可能是因为热解不同阶段活化能存在差异。

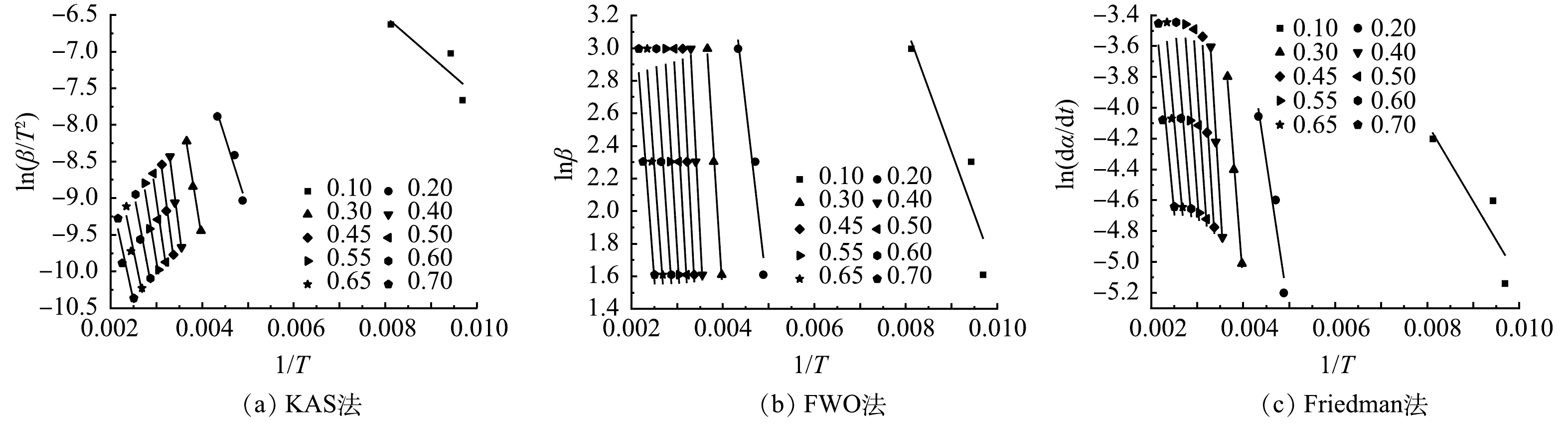

2) 市政污泥热解动力学分析。为进一步分析不同热解温度下污泥热解特性以及含碳官能团差异,通过动力学分析市政污泥热解过程中动力学进行分析,为探究其含碳官能团转化规律提供基础。KAS法、FWO法和Friedman法是3种主要研究热解动力学参数的等转化率法。其方程分别为式(7)、式(8)和式(9)。

图2是通过KAS法、FWO法和Friedman法拟合出的曲线,活化能和相关度R2如表2所示。由表2可知,KAS、FWO和Friedman这3种方法的R2值在转化率α=0.20~0.70内拟合效果较好,R2基本在0.90以上,而在小于0.20和大于0.70之间,R2均小于0.90,无法较为准确地分析预测热解特性。在等转化率法的假设中,样品的活化能连续,故转化率在0.20~0.70内的数据对计算活化能同样准确[24]。从表中可以发现,使用FWO法在转化率为0.20~0.70内计算出的活化能结果要略高于KAS法和Friedman法,但采用3种方法计算出的活化能结果趋势一致,表明拟合结果的可靠性。不同热解阶段KAS法、FWO法和Friedman法计算出的活化能存在差异,在转化率为0.20~0.40时,其活化能变化范围分别为163.84~405.98、190.18~432.04、164.22~405.14 kJ·mol−1,而当转化率为0.40~0.70时,其活化能变化范围分别为405.98~238.02、432.04~293.78、405.14~262.88 kJ·mol−1,活化能表现为先上升后下降。这可能是因为热解过程中挥发分的扩散造成固相反应物的孔状结构形成,有利于挥发分的分解反应,故在热解反应中表现出活化能略微下降的趋势[12]。

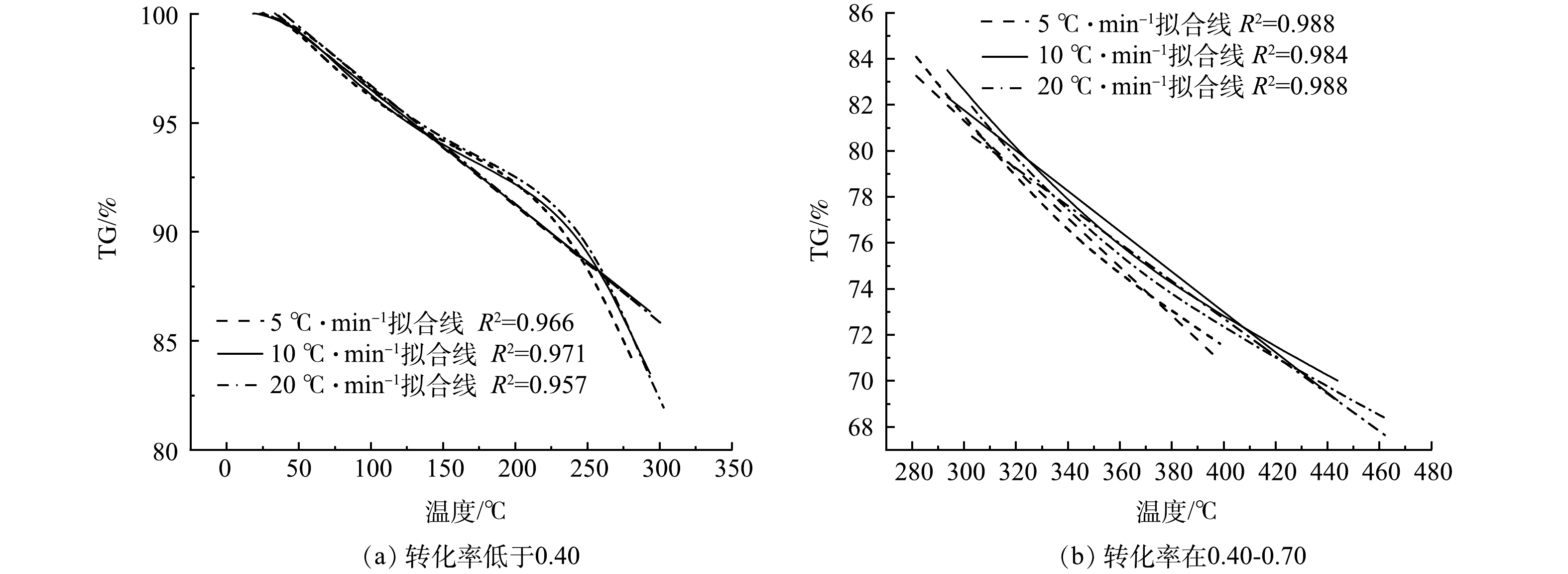

进一步通过对市政污泥不同转化率区间的TG曲线进行线性拟合,如图3所示,当转化率α低于0.40时,3个升温速率下的拟合线斜率平均为−0.053,平均R2>0.95,而当转化率α在0.40~0.70时,3个升温速率下的拟合线斜率平均为−0.092,平均R2>0.98。相比于转化率低于0.40的阶段,转化率在0.40~0.70时污泥的TG曲线斜率更小,倾斜度更接近Y轴。这说明随着热解反应的进行,污泥在转化率为0.40~0.70内热解转化效率更高,热解速率加快,污泥中含碳官能团加速发生热解转化,这与活化能变化趋势结果相一致。

-

从2.1节中热失重分析结果发现,当升温速率为10 ℃·min−1时污泥热解残炭率最高,故选择此升温速率条件下得到的不同热解阶段固体残炭进行表面含碳官能团分析[25-26],探究市政污泥热解过程中含碳官能团的变化趋势。图4(a)中市政污泥在3 600~3 000 cm−1波段出现了1个宽且强的吸收峰,这表明污泥中存在一定醇、酚、羧酸等游离态羟基基团伸缩频率下的分子间氢键 (-H) ,从而使得伸缩振动范围较宽。在30~300 ℃内,峰强逐渐减弱,当温度继续升高,在400~700 ℃内,峰强变化则明显减小。这说明在热解过程中,污泥中有酚羟基、醇羟基或者羧基发生了脱羟基反应。1 353 cm−1处的峰代表酚羟基中的弯曲振动,从图4(a)中可以发现,其峰强随温度的上升逐渐增强,但当把1 420~1 300 cm−1波段内的峰谱进行二阶导数转换后发现 (如图4(b)所示) ,酚羟基的红外吸收强度在30~400 ℃内逐渐增强,在400 ℃时最大,随后随温度的上升,其峰强逐渐减弱,并与C-N键红外吸收峰逐渐重叠。同时,对1 760~1 610 cm−1波段内的峰谱进行二阶导数转换后发现 (如图4(c)所示) ,羧基中的C=O键在30~300 ℃内的红外吸收强度略微减弱,但在400 ℃时峰强有明显的增强,此后在500~700 ℃内峰强继续减弱。这表明在30~400 ℃内,热解反应中的脱羧基反应主要是由醇羟基导致,结合热失重分析,说明这主要是源于污泥中纤维素以及半纤维素等多糖类物质的分解。在400 ℃左右,污泥残炭中羧基及酚羟基质量分数最高,随着温度的上升,羧基及酚羟基进一步分解。

在图4(a)中,2 925、2 850、2 780 cm−1处存在窄而小的吸收峰,对应污泥及热解炭中的脂肪族C-H (-CH3、-CH2等) ,随着温度的上升,其峰强逐渐减弱,说明污泥在热解过程中脂肪族烃类C-H键发生断裂,使得小分子烃的析出,如CH4、C2H4等[12]。1 650 cm−1处对应的峰是污泥及其热解产物中C=C键的吸收峰,且随着热解开始温度逐渐升高,峰强逐渐减弱,在600 ℃后消失。这说明热解过程中C=C双键物质发生缩合反应以及裂解反应,使污泥中的不饱和键断裂,并进一步促进了炭状结构和苯环的形成[27]。

1 033 cm−1处的位置对应C-O键的伸缩振动,其中在500 ℃时,C-O键峰强最大。这与XU等[28]的研究结果相一致。随热解温度的上升,其振动范围缩减,在污泥热解过程中,C-O键发生断键,碳素向CO以及一些短链小分子结构物质进行迁移转化[23, 29]。在红外二阶转换后的结果中,1 692 cm−1处对应羰基中C=O键的伸缩振动,在热解升温的过程中,C=O键红外吸收峰强度先增加后减弱,在400 ℃左右达到最强。这可能是由于污泥中蛋白质以及多糖等物质不稳定化学键在热解过程中断裂,形成了C=O结构,随着温度继续上升,C=O键则进一步开裂,转化成CO2等气体[30]。在1 372~1 367 cm−1处为C-N键的吸收峰,在30~700 ℃内,C-N键的峰强逐渐减弱,在400 ℃以上时,其吸收峰强度随温度上升明显减弱。综合热重分析,推测其主要归因于污泥中蛋白质的分解,在温度高于400 ℃时,蛋白质进入快速热解阶段。

1 618 cm−1处存在1个强的吸收峰,这对应着污泥及其残留固体中的苯类化合物,773 cm−1处的峰表示取代苯上的C-H键。可以发现,随着温度的升高,苯环上C-H峰强度逐渐增强,说明在热解过程中残渣中芳构化反应加剧,随着温度的上升,具有芳香碳结构的物质形成。这可能主要是由于污泥在升温过程中纤维素和半纤维素等物质发生脱羧反应后,羧基和碳键在高温下的芳构重整反应所导致[23, 31]。

-

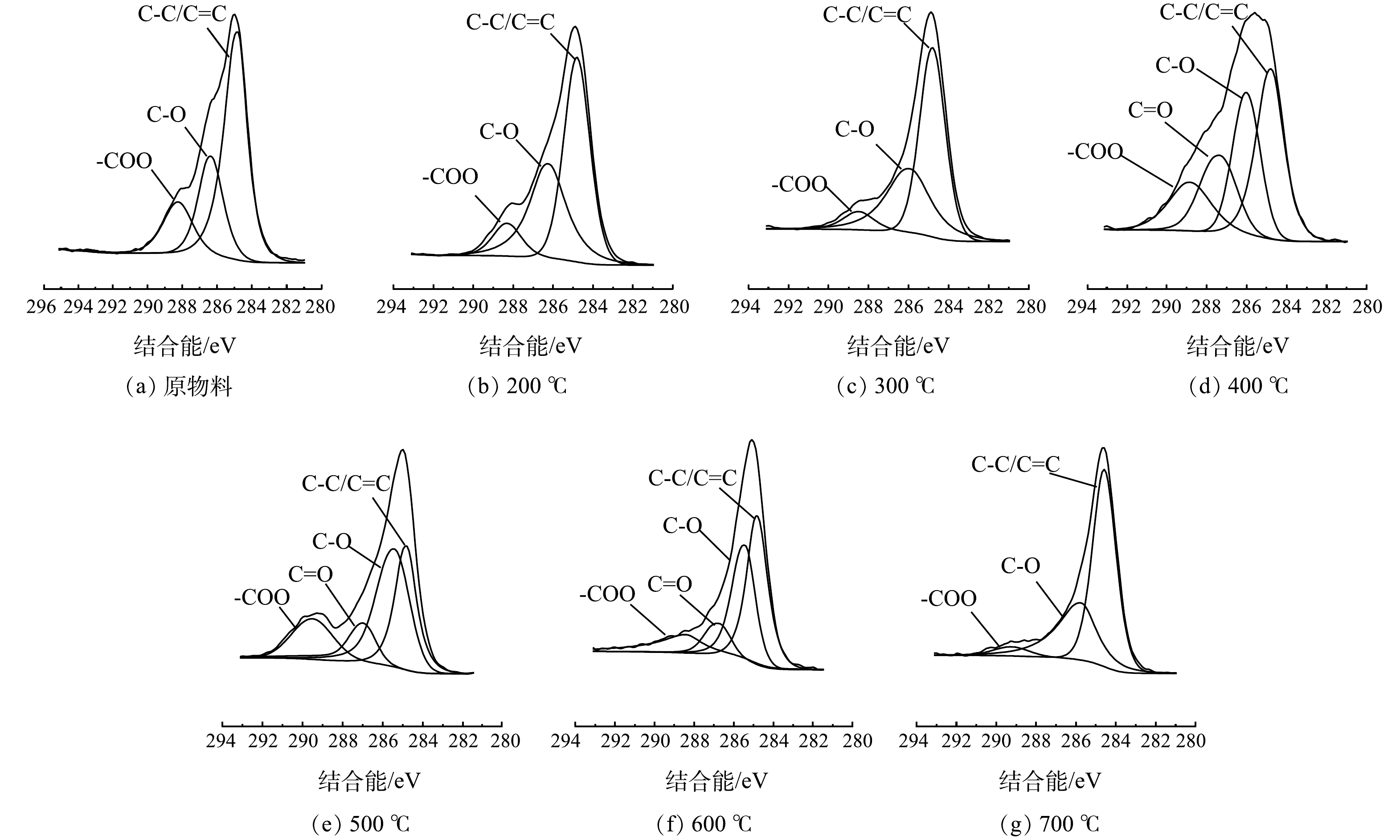

图5和表3分别为污泥及其不同温度下热解残炭的C1s谱图及分峰拟合后表面含碳官能团的相对质量分数。由表可知,随着温度的上升,在污泥及其热解过程中,C-C/C=C是污泥表面碳元素的主要形态,在30~500 ℃内,C-C/C=C键相对质量分数从58.09%下降至30.82%,随后当温度升高至700 ℃时,其相对质量分数又上升至62.30%。结合红外分析结果,这是由于在热解过程中C=C结构发生了缩合以及裂解反应,导致了C=C键质量分数减少,而温度继续升高后,热裂解和重组反应加剧,C-C结构相对质量分数则进一步上升。

C-O键的相对质量分数总体上下振动,在500 ℃时相对质量分数最高,为40.90%,这证明了红外结果的可靠性。在30~300 ℃内,C=O键相对质量分数并未检出,但在400 ℃时,C=O键相对质量分数为20.33%,随后随着温度的升高,其相对质量分数持续下降,到600 ℃时,其相对质量分数下降了10.19%。此结果印证了红外分析结果的可靠性。

污泥中-COO键的相对质量分数为13.42%,在30~300 ℃内,其相对质量分数持续下降,但在400 ℃和500 ℃时,其相对质量分数分别上升至15.47%和16.57%,此后随温度继续上升,其相对质量分数继续下降。在热解反应中,污泥中纤维素和半纤维素等物质发生脱羧以及羧基的脱羰反应[32],导致-COO键质量分数下降。而随反应的进行,杂环的开裂 (如糖类物质中半缩醛结构的裂解) 可能会导致-COO结构的生成[33],这解释了为什么400和500 ℃时-COO键相对质量分数反而上升。

在400~600 ℃内,热解过程生成了较多的含碳氧官能团 (C-O、C=O、-COO) ,这3种基团的相对质量分数分别为63.98% (400 ℃) 、69.17% (500 ℃) 、58.04% (600 ℃) ,说明市政污泥残炭具有较高的吸附性和稳定性。这可能主要归因于基团之间形成的共价键、氢键和表面络合等作用[34-36]。

-

1) 在市政污泥热解过程中,改变升温速率对热失重影响较小,在800 ℃时,3个升温速率下的平均残炭率为10.47%。市政污泥热解过程中含碳官能团的生成在不同的阶段存在差异,在α=0.40~0.70内热解转化效率更高,热解速率加快,污泥中含碳官能团加速发生热解转化。

2) 在400 ℃以下时,醇羟基快速分解。在400 ℃时,酚羟基和C=O键相对质量分数最多,而在500 ℃时,羧基和C-O键相对质量分数最高。C=C结构和C-N结构随温度升高持续减少,而C-C结构先减少后增加,在500 ℃时相对质量分数最低。高温下芳构化反应更加剧烈,芳香结构随温度的上升而上升。污泥热解残炭在400~600 ℃内的含碳氧官能团较多,吸附性和稳定性较高。

市政污泥热解特性及含碳官能团演化过程分析

Pyrolysis characteristics of municipal sludge and transformation of carbon-containing functional groups during pyrolysis process

-

摘要: 我国市政污泥年产量大,研究其热解机理和碳形态转化可为实现污泥无害化和资源化提供理论基础。采用热重、动力学拟合、红外光谱 (FTIR) 、X射线光电子能谱 (XPS) 等检测和分析方法,对市政污泥热解特性、活化能变化和含碳官能团进行分析。结果表明:市政污泥热解过程中含碳官能团的生成在不同的阶段存在差异,进一步采用Kissinger-Akahira-Sunose (KAS) 法、Flynn-Wall-Ozawa (FWO) 法和Friedman法进行动力学分析,其活化能结果显示在转化率为0.40~0.70时,市政污泥热解速率加快,污泥中含碳官能团加速发生热解转化。FTIR和XPS结果表明,在400 ℃以下时,醇羟基的分解是导致污泥结构中羟基减少的主要原因。在400 ℃时,酚羟基和C=O键相对质量分数最多,而在500 ℃时,羧基和C-O键相对质量分数最高。C=C键和C-N键随温度升高持续减少,C-C结构则先减少后增加,在500 ℃时相对质量分数最低,而芳香结构随温度的上升持续增加。在400~600 ℃内,污泥残炭的含碳氧官能团较多,吸附性和稳定性较高。本研究结果可为市政污泥热解机理及碳形态转化提供参考。Abstract: The annual production of municipal sludge in China is massive. The study of its pyrolysis mechanism and the transformation of carbon-containing functional groups can provide a theoretical basis for the reduction of the sludge harmlessness and the resource utilization. Thermal gravity, kinetic fitting, fourier transform infrared spectroscopy (FTIR), X-ray photoelectron spectroscopy (XPS) and other detection and analysis methods were used to analyze the pyrolysis characteristics, activation energy changes and carbon-containing functional groups of municipal sludge. The results showed that there were differences in the generation of carbon-containing functional groups in different stages during the pyrolysis of municipal sludge. Kissinger-Akahira-Sunose (KAS), Flynn-Wall-Ozawa (FWO) and Friedman methods were used for further kinetic analysis. The results of activation energy showed that when the conversion rate was between 0.40 and 0.70, the pyrolysis rate of municipal sludge was accelerated, and the carbon-containing functional groups in the sludge were accelerated to undergo pyrolysis conversion. The results of FTIR and XPS showed that in the range of 30-400 ℃, the decomposition of alcoholic hydroxyl groups was the main reason for the reduction of hydroxyl groups in the sludge structure. At 400 ℃, the relative mass fraction of phenolic hydroxyl groups and C=O bonds was the highest, while at 500°C, the relative mass fraction of carboxyl groups and C-O bonds was the highest. The C=C bond and C-N bond decreased continuously with the increase of temperature, while the C-C structure first decreased and then increased, and the relative mass fraction was the lowest at 500 ℃. Meanwhile, the aromatic structure increased with the increase of temperature. In the range of 400-600 ℃, the carbon and oxygen functional groups of the sludge residue carbon were more, and the adsorption and stability were higher. This study analyzed the pyrolysis characteristics of municipal sludge and the evolution process of carbon-containing functional groups, providing a theoretical basis for the study of municipal sludge pyrolysis mechanism and carbon form transformation.

-

Key words:

- municipal sludge /

- pyrolysis /

- dynamics /

- carbon-containing functional group /

- carbon conversion

-

-

表 1 市政污泥工业分析和元素分析

Table 1. Industrial analysis and elemental analysis of municipal sludge

% 工业分析 元素分析 水分 挥发分 灰分 固定碳 C H O* N S 4.48 47.56 45.15 2.81 20.14 3.51 27.33 3.32 0.55 注:*表示氧元素质量分数由差减法计算得来。 表 2 表观活化能结果

Table 2. Results of apparent activation energy

转化率 KAS FWO Friedman 活化能/(kJ·mol−1) R2 活化能/(kJ·mol−1) R2 活化能/(kJ·mol−1) R2 0.20 163.84 0.938 3 190.18 0.958 7 164.22 0.945 8 0.30 321.85 0.992 9 347.32 0.994 3 319.66 0.994 7 0.40 405.98 0.990 7 432.04 0.992 4 405.14 0.992 5 0.45 394.11 0.977 4 423.26 0.981 9 396.96 0.980 9 0.50 357.80 0.965 3 391.49 0.973 1 365.41 0.970 6 0.55 320.19 0.953 2 358.84 0.965 2 332.37 0.960 7 0.60 277.49 0.937 0 321.99 0.955 8 294.44 0.948 2 0.65 253.37 0.913 8 303.51 0.942 6 274.49 0.930 6 0.70 238.02 0.891 5 293.78 0.930 9 262.88 0.914 3 表 3 不同温度下市政污泥热解后产物的相对质量分数

Table 3. Relative mass fraction of municipal sludge pyrolysis products at different temperatures

热解温度/ ℃ C-C/C=C C-O -COO C=O 相对质量分数/% 结合能/eV 相对质量分数/% 结合能/eV 相对质量分数/% 结合能/eV 相对质量分数/% 结合能/eV 30 58.09 284.80 28.49 286.38 13.42 288.28 — — 200 57.55 284.80 32.93 286.28 9.52 288.28 — — 300 56.27 284.80 36.40 286.08 7.33 288.48 — — 400 36.02 284.80 28.18 285.58 15.47 288.80 20.33 287.34 500 30.82 284.80 40.90 285.45 16.57 289.50 11.70 287.00 600 41.97 284.80 34.65 285.45 13.25 288.42 10.14 286.72 700 62.30 284.80 33.17 285.96 4.53 289.46 — — 注:表中“—”表示未检出。 -

[1] 路瑞娟, 付杰, 王晨晨, 等. 城市污泥处理过程中重金属迁移转化特性研究进展[J]. 环境工程技术学报, 2023, 13(1): 318-324. doi: 10.12153/j.issn.1674-991X.20210762 [2] 张彦平, 裴佳华, 高珊珊, 等. 生物质材料用于污泥深度脱水的研究进展[J]. 工业水处理, 2022, 42(7): 24-32. doi: 10.19965/j.cnki.iwt.2021-0571 [3] ZHU F F, WU X M, ZHAO L Y, et al. Lipid profiling in sewage sludge[J]. Water Research, 2017, 116: 149-158. doi: 10.1016/j.watres.2017.03.032 [4] MOLDED A, CENDON Y, BARRAL M T. Evaluation of municipal solid waste compost as a plant growing media component, by applying mixture design[J]. Bioresource Technology, 2007, 98(16): 3069-3075. doi: 10.1016/j.biortech.2006.10.021 [5] 吕丰锦, 韩云平, 刘俊新, 等. 污泥有机成分与污泥厌氧消化潜能的研究进展[J]. 环境工程, 2016, 34(S1): 780-785+467. [6] ZHANG Z Y, RUI J, ZHOU H T, et al. Migration characteristics of heavy metals during sludge pyrolysis[J]. Waste Management, 2021, 120: 25-32. doi: 10.1016/j.wasman.2020.11.018 [7] TSAI W T, LEE M K, CHANG J H, et al. Characterization of bio-oil from induction-heating pyrolysis of food processing sewage sludges using chromatographic analysis[J]. Bioresource Technology, 2009, 100(9): 2650-2654. doi: 10.1016/j.biortech.2008.11.023 [8] DE S S C, BOMFIM M R, CONCEICAO D A M, et al. Induced changes of pyrolysis temperature on the physicochemical traits of sewage sludge and on the potential ecological risks[J]. Scientific Reports, 2021, 11(1): 974-974. doi: 10.1038/s41598-020-79658-4 [9] WANG S Z, WANG J L. Nitrogen doping sludge-derived biochar to activate peroxymonosulfate for degradation of sulfamethoxazole: modulation of degradation mechanism by calcination temperature[J]. Journal of Hazardous Materials, 2021, 418: 126309. doi: 10.1016/j.jhazmat.2021.126309 [10] CHEN W F, MENG J, HAN X R, et al. Past, present, and future of biochar[J]. Biochar, 2019, 1(1): 75-87. doi: 10.1007/s42773-019-00008-3 [11] REN M G, FONG C W W, MOHD N S A, et al. Pyrolysis of waste activated sludge from food manufacturing industry: thermal degradation, kinetics and thermodynamics analysis[J]. Energy, 2021, 235: 121264. doi: 10.1016/j.energy.2021.121264 [12] 徐新宇, 杨家宽, 宋健, 等. 调理脱水污泥的热解特性及动力学分析[J]. 环境化学, 2016, 35(5): 972-981. doi: 10.7524/j.issn.0254-6108.2016.05.2015122103 [13] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 煤的工业分析标准方法: GB/T 212-2008[S]. 北京: 中国标准出版社, 2009. [14] KIM S S, LY H V, KIM J, et al. Thermogravimetric characteristics and pyrolysis kinetics of alga sagarssum sp. biomass[J]. Bioresource Technology, 2013, 139: 242-248. doi: 10.1016/j.biortech.2013.03.192 [15] 杨凯, 丁志江, 肖立春, 等. 城市污泥耦合锯末共热解特性及动力学分析[J]. 热能动力工程, 2018, 33(3): 112-118. doi: 10.16146/j.cnki.rndlgc.2018.03.017 [16] SAID N, BISHARA T, GARCIA-MARAVER A, et al. Effect of water washing on the thermal behavior of rice straw[J]. Waste Management, 2013, 33(11): 2250-2256. doi: 10.1016/j.wasman.2013.07.019 [17] THIPKHUNTHOD P, MEEYOO V, RANGSUNVIGIT P, et al. Describing sewage sludge pyrolysis kinetics by a combination of biomass fractions decomposition[J]. Journal of Analytical and Applied Pyrolysis, 2007, 79(1): 78-85. [18] BIAGINI E, BARONTINI F, TOGNOTTI L. Devolatilization of biomass fuels and biomass components studied by TG/FTIR technique[J]. Industrial and Engineering Chemistry Research, 2006, 45(13): 4486-4493. doi: 10.1021/ie0514049 [19] ZHOU P, XIONG S J, ZHANG Y X, et al. Study on the nitrogen transformation during the primary pyrolysis of sewage sludge by Py-GC/MS and Py-FTIR[J]. International Journal of Hydrogen Energy, 2017, 42(29): 18181-18188. doi: 10.1016/j.ijhydene.2017.04.144 [20] CAO J P, XIAO X B, ZHANG S Y, et al. Preparation and characterization of bio-oils from internally circulating fluidized-bed pyrolysis of municipal, livestock, and wood waste[J]. Bioresource Technology, 2011, 102(2): 2009-2015. doi: 10.1016/j.biortech.2010.09.057 [21] FRANCIOSO O, RODRIGUEZ-ESTRADA M T, MONTECCHIO D, et al. Chemical characterization of municipal wastewater sludges produced by two-phase anaerobic digestion for biogas production[J]. Journal of Hazardous Materials, 2010, 175(1): 740-746. [22] 张曌. 污泥催化热解工艺过程效能与机理研究[D]. 哈尔滨: 哈尔滨工业大学, 2020. [23] 卢艳军. 污泥含碳和含氧化学基团热解演变机制研究[D]. 杭州: 浙江工业大学, 2019. [24] DAMARTZIS T, VAMVUKA D, SFAKIOTAKIS S, et al. Thermal degradation studies and kinetic modeling of cardoon (Cynara cardunculus) pyrolysis using thermogravimetric analysis (TGA)[J]. Bioresource Technology, 2011, 102(10): 6230-6238. doi: 10.1016/j.biortech.2011.02.060 [25] WANG B, XU X, CAO X, et al. Pyrolysis of predried dyeing sludge: weight loss characteristics, surface morphology, functional groups and kinetic analysis[J]. The Canadian Journal of Chemical Engineering, 2021, 99(12): 2619-2634. doi: 10.1002/cjce.24048 [26] YANG X X, ZHAO Y Y, LI R, et al. A modified kinetic analysis method of cellulose pyrolysis based on TG-FTIR technique[J]. Thermochimica Acta, 2018, 665: 20-27. doi: 10.1016/j.tca.2018.05.008 [27] KRUEGER B C, FOWLER G D, TEMPLETON M R, et al. Faecal sludge pyrolysis: understanding the relationships between organic composition and thermal decomposition[J]. Journal of Environmental Management, 2021, 298: 113456. doi: 10.1016/j.jenvman.2021.113456 [28] XU Q Y, TANG S Q, WANG J C, et al. Pyrolysis kinetics of sewage sludge and its biochar characteristics[J]. Process Safety and Environmental Protection, 2018, 115: 49-56. doi: 10.1016/j.psep.2017.10.014 [29] ZONG P J, JIANG Y, TIAN Y Y, et al. Pyrolysis behavior and product distributions of biomass six group components: starch, cellulose, hemicellulose, lignin, protein and oil[J]. Energy Conversion and Management, 2020, 216: 112777. doi: 10.1016/j.enconman.2020.112777 [30] WANG C X, BI H B, LIN Q Z, et al. Co-pyrolysis of sewage sludge and rice husk by TG-FTIR-MS: pyrolysis behavior, kinetics, and condensable/non-condensable gases characteristics[J]. Renewable Energy, 2020, 160: 1048-1066. doi: 10.1016/j.renene.2020.07.046 [31] LIU T T, GUO Y C, PENG N N, et al. Nitrogen transformation among char, tar and gas during pyrolysis of sewage sludge and corresponding hydrochar[J]. Journal of Analytical and Applied Pyrolysis, 2017, 126: 298-306. doi: 10.1016/j.jaap.2017.05.017 [32] MANIK M M, ALAM N, AHOMMED M S, et al. Emerging applications of sludge biochar-based catalysts for environmental remediation and energy storage: a review[J]. Journal of Cleaner Production, 2022, 360: 132131. doi: 10.1016/j.jclepro.2022.132131 [33] 胡艳军, 吴亚男, 高涛, 等. 污泥热解中残焦表面官能团结构演化特征[J]. 燃烧科学与技术, 2018, 24(2): 126-131. [34] 袁志航, 楼紫阳. 市政污泥衍生功能化炭材料合成及热解过程污染控制研究进展[J]. 硅酸盐通报, 2021, 40(5): 1520-1528. doi: 10.16552/j.cnki.issn1001-1625.2021.05.010 [35] JIAO Y X, LI D Y, WANG M, et al. A scientometric review of biochar preparation research from 2006 to 2019[J]. Biochar, 2021, 3: 283-298. doi: 10.1007/s42773-021-00091-5 [36] 辛旺, 宋永会, 张亚迪, 等. 污泥基碳吸附材料的制备及其吸附性能研究进展[J]. 环境工程技术学报, 2017, 7(3): 306-317. doi: 10.3969/j.issn.1674-991X.2017.03.044 -

下载:

下载: