-

随着全球气候变化和人口增长的影响,水资源问题已经成为一个全球性的挑战。饮用水厂生产废水回用是将生产过程中的沉淀池排泥水和滤池反冲洗水排再次利用,用于生产过程。回用可以提高水资源的利用效率,减少废水排放对环保的影响,实现生产和环保的双赢。目前国内外对生产废水回用的研究逐渐增多。在国外,例如美国[1]、英国[2]、日本[3]等地,生产废水回用技术已经成熟并广泛应用[4]。而在国内,目前对生产废水回用的研究主要集中于对滤池反冲洗水的回用,而且多为未经处理或仅静置沉淀后直接进行回用,对沉淀池排泥水的回用研究较少。

相较于直接回用,生产废水回用技术包括混凝沉淀[5]、气浮[6]、膜滤[7]等,这些方法能够有效地去除废水中的悬浮物、微生物等污染物,从而提高回用水的质量,使其能够更加安全地再次用于生产过程[8]。滤池反冲洗水主要是由滤料中截留下来的固体颗粒物、有机污染物和一些化学药剂的残留物组成。沉淀池排泥水主要由较多的胶体颗粒、泥沙、悬浮物、混凝剂和混凝剂形成的氢氧化物构成[9]。但不同水厂的排泥水具有不同的特性,受水源及水厂的工艺影响较大[10]。对于水厂而言,2种不同水质能否直接回用以及直接回用和处理后回用对水厂的影响仍值得深入探究。

本研究基于南方某水厂实际水样,首先通过污染负荷分析对比2种生产废水直接回用对水厂工艺负荷带来的不同影响;其次,开展小试实验探究了不同混凝剂及其剂量对反冲洗水和排泥水中不同污染物的去除效果和机理;最后,通过混凝-超滤中试装置对2种生产废水进行了处理,研究了中试处理过程中的不同现象,分析了生产废水处理后回用对水厂带来的效益。本研究结果以期为其他水厂提供了宝贵的经验参考和技术指导,推动生产废水回用在饮用水厂中的应用。

-

聚合氯化铝(Al2O3≥28%,上海阿拉丁生化科技有限公司);无水三氯化铝(99%)、聚合硫酸铁(Fe≥21%)、聚合氯化铝铁(优纯级)购于上海麦克林生化科技股份有限公司。

总有机碳分析仪(TOC-V cph,日本岛津)、pH计(PHS-3C上海大浦公司)、浊度计(HACH2100N,美国哈希)、紫外分光光度计(DR-6000,美国哈希)、荧光分光光度计(F-7000,日本日立)、六联搅拌仪(TU-1901,中国普析通用仪器有限公司)、电感耦合等离子体发射光谱仪(iCAP7 200 duo,美国赛默飞)、超纯水仪(Milli-Q A10,德国默克)。超高液相色谱三重四级杆质谱 (UPLC-MS/MS)。

-

混凝小试实验设置3组平行样品,将废水水样充分振荡摇匀后,静置30 min,取中部水样250 mL于锥形瓶中,加入相应剂量的混凝剂于样品中,首先以200 r·min−1的转速保持1 min,充分搅匀反应体系,然后以70 r·min−1的转速保持15 min,最后静置20 min,待悬浮物沉降后取上清液50 mL,测定其浊度、UV254和三维荧光。

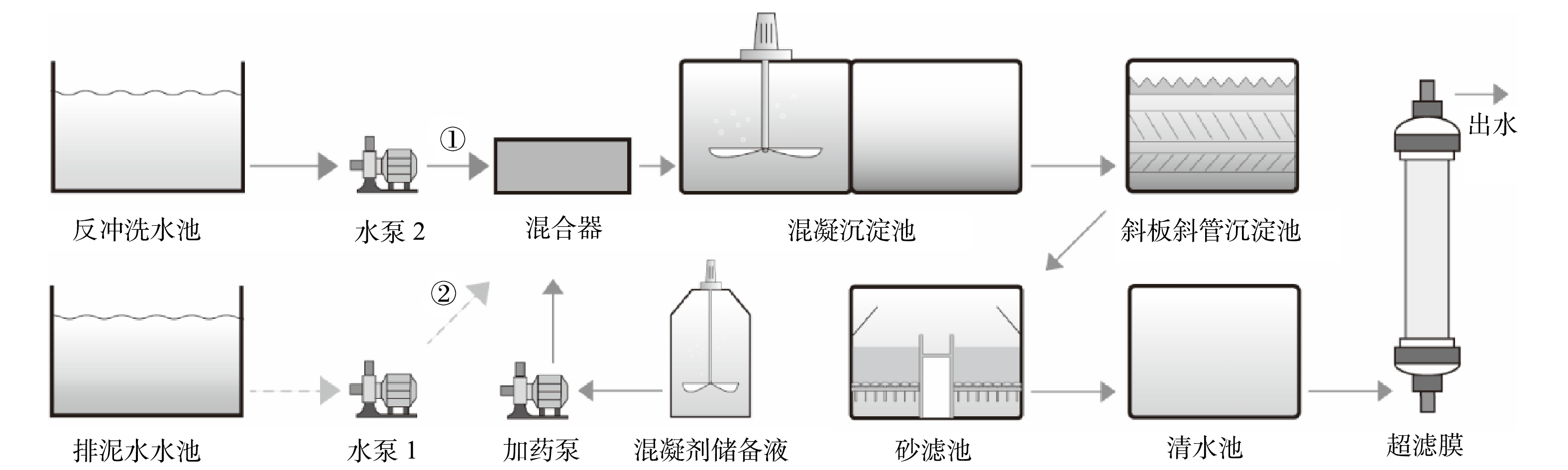

混凝-超滤中试采用混凝、沉淀、砂滤、超滤工艺分别对反冲洗水和排泥水进行处理(图1)。中试运行时,进水流量为1 800 L·h−1,混凝剂流量为14 L·h−1,PAC质量浓度为10 mg·L−1,进水和混凝剂在中试前端混合器混合后进入混凝沉淀池,池体前段为搅拌区,搅拌均匀后进入沉淀区,沉淀池上清液溢流至斜板斜管沉淀池中,进水从斜板斜管沉淀池底部向上流动,通过溢流堰进入砂滤池中,经过滤后进入到清水池中,清水池水先流经一台50 μm的精密过滤器,然后通过0.1 μm的超滤膜后出水。

-

DOC测定采用总有机碳分析仪;pH采用pH计直接测定;浊度采用浊度计测量;UV254使用紫外分光光度计在245 nm波长下测量;三维荧光采用荧光光度计测量后使用Matlab进行区域积分分析;Al3+质量浓度分析采用《水质32种元素的测定 电感耦合等离子体发射光谱法》(HJ 776-2 015) 中的方法。

PFASs的测定首先对水样进行固相萃取处理,HLB小柱分别使用甲醇、1:23盐酸溶液和超纯水进行活化。水样以5 mL·min−1富集FPASs,之后使用5%的甲醇和超纯水洗去杂质,真空干燥30 min去除残留水分。采用甲醇洗脱小柱后通过氮吹吹干洗脱液,后加入甲醇洗脱管壁,再加入超纯水,注射入液相小瓶,使用超高液相色谱三重四级杆质谱(UPLC-MS/MS)对10种PFASs进行分析。色谱柱型号为ACQUITY BEH C18,离子源为ESI源,电离模式为正离子模式,离子源温度为150 ℃,锥孔反吹气流量为50 L·h−1,脱溶剂气温度为500 ℃,脱溶剂气流量为900 L·h−1,监测模式为MRM模式[11]。

-

本节开展污染负荷测算比较2类水的差异并验证2类生产废水可否直接回用。表1中详细列举了该水厂原水,滤池反冲洗水和沉淀池排泥水的部分常规水质指标和PFASs质量浓度。可以看出,原水和2类生产废水中的pH、UV254、DOC基本处在相似的水平,但3种水中有机物的亲疏水性及分子质量大小分布可能仍存在一定差异,致使其处理难度通常大于原水[12]。此外,排泥水中的NH4+-N和其他2类水中的浊度、Al3+和PFASs均与原水存在显著差异。从这些结果来看,直接回用生产废水会对水厂污染负荷带来较大的影响。

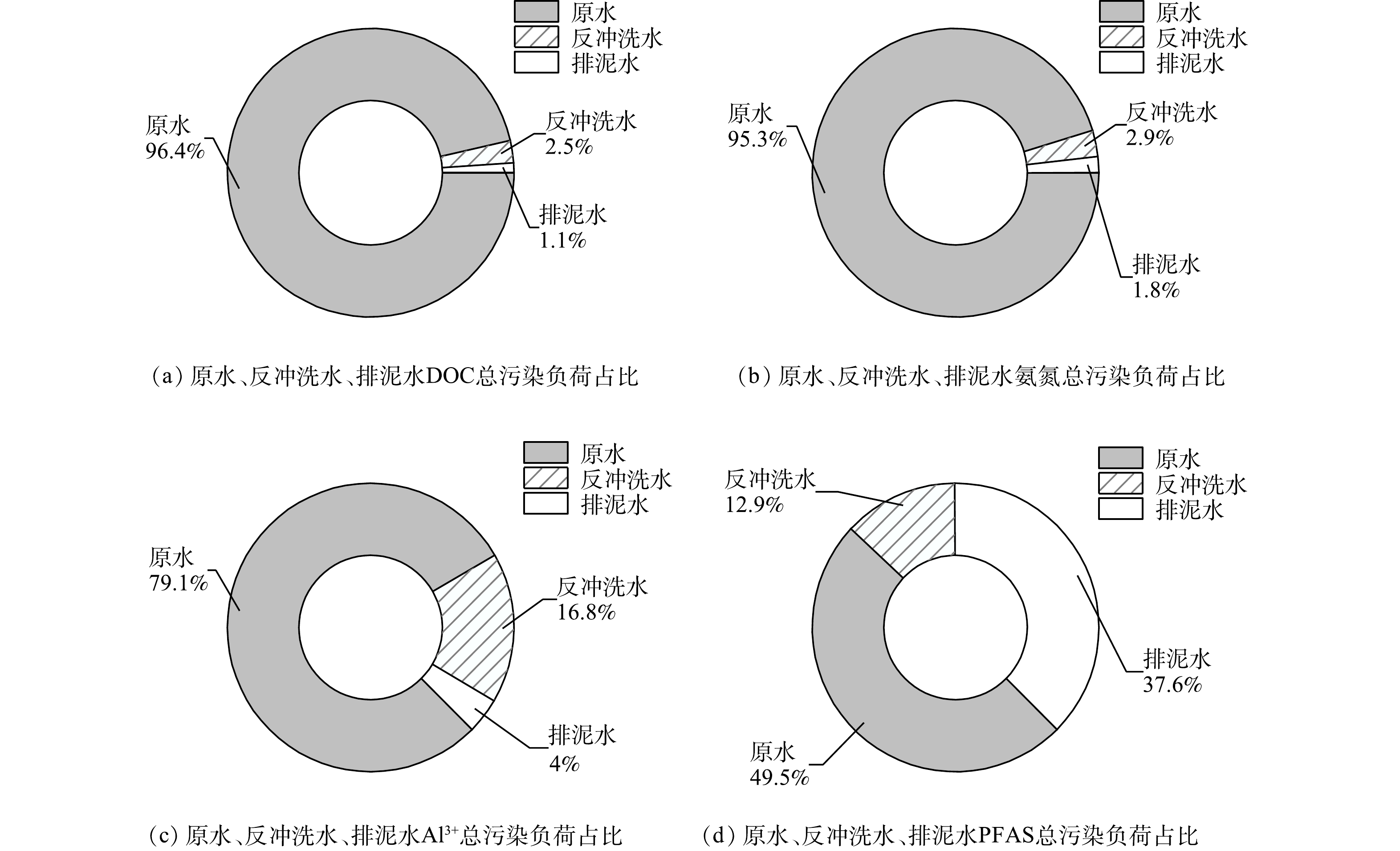

根据该水厂实际生产情况,原水、反冲洗水、排泥水流量分别以6×105、1.96×104、8×103 t·d−1计算,污染物质量浓度采取多次测量的平均值计算,可得到回用污染负荷分布,具体如图2所示。由图2(a)和图2(b)中可以看出,在NH4+-N总负荷中,原水、反冲洗水、排泥水分别提供的负荷占比分别为95.3%、2.9%和1.8%;在DOC负荷中,3类水分别提供的负荷占比分别为96.4%、2.5%和1.1%。综上所述,生产废水的直接回用可增加水厂4.7%的NH4+-N负荷及3.6%的DOC负荷,对水厂的传统工艺提出了更高的要求。

除上述指标外,生产废水中会含有一定的混凝剂残留及富集的微污染物,对于使用聚合氯化铝作为混凝剂的该水厂而言,生产废水中Al3+含量也会更高[13]。因此,本研究也对Al3+负荷及PFASs负荷进行了研究。由图2可以看出,反冲洗水带来的Al3+负荷约是排泥水的4倍左右,而排泥水回用对PFASs负荷的影响则约是反冲洗水的3倍。这可能是由于排泥水中主要成分为Al3+生成的胶体及絮体沉淀,难沉降的含Al3+细小颗粒则会被滤池截留下来,这部分含Al3+物质则会在对滤池反冲洗的过程中转移到反冲洗水中,造成反冲洗水中Al3+含量较高[14]。此外,絮凝过程中形成的絮体对水中的微污染物及细小颗粒有一定的吸附作用[15],致使含有较多絮体沉淀的排泥水中PFASs含量较高。生产废水回用为该水厂带来了20.9%的Al3+负荷和50.5%的PFASs负荷,2类水直接回用会对水厂工艺带来较大的压力。

直接回用2类反冲洗水会带来额外的污染负荷,其中反冲洗水和排泥水会分别带来较多的Al3+负荷和PFASs负荷,尤其是在雨天或藻类爆发季节等会对原水水质带来较大波动的时间段[16- 17],直接回用增加了水厂出水水质的不确定性,从而带来一定的潜在风险。

-

2种生产废水具有不同的理化性质及组成成分,为了深入了解混凝对2类废水的去除效果,提前为中试装置运行积累经验,本研究进行了小试实验,评估了市场上常见的4种商业混凝剂在处理2种生产废水方面的效果。通过多个角度的对比,探究了反冲洗水和排泥水之间的差异,以寻找最佳的混凝剂及剂量。

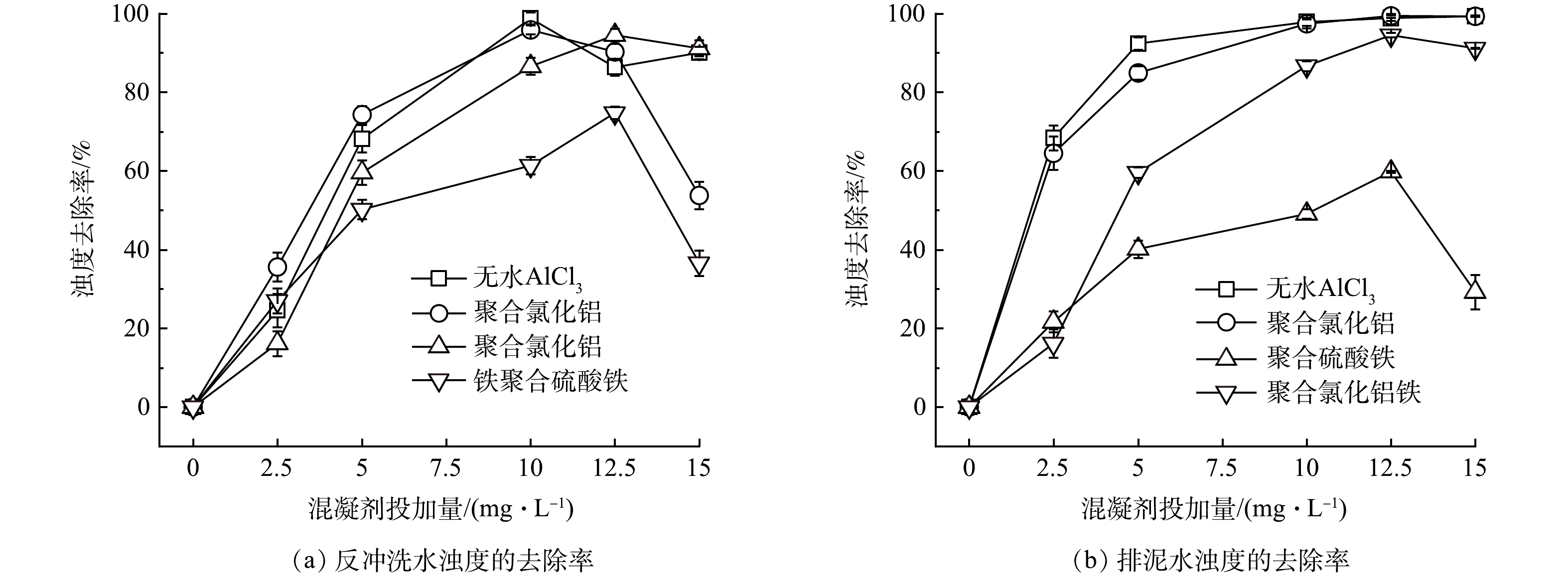

1)不同混凝剂对浊度的去除效果。由图3中可以看出,不同的混凝剂种类及剂量均可以对浊度有一定的去除效果,但不同混凝剂之间以及同一混凝剂的不同剂量之间均表现出不同程度的去除效果。同时,在处理2类废水的实验中,无水AlCl3、聚合氯化铝、聚合氯化铝铁在最佳投加量下去除率均可以达到95%以上。当混凝剂混凝效果达到峰值后,反冲洗水和排泥水均出现了随着混凝剂剂量增加去除率却降低的趋势。这可能是因为当混凝剂的剂量增加到一定程度时,其对水中悬浮颗粒和胶体物质的凝聚能力会达到饱和状态,继续增加混凝剂的用量则会出现过混凝的现象,导致颗粒间的排斥力较大,颗粒物的生长速度变慢,反而会难以沉淀[18]。

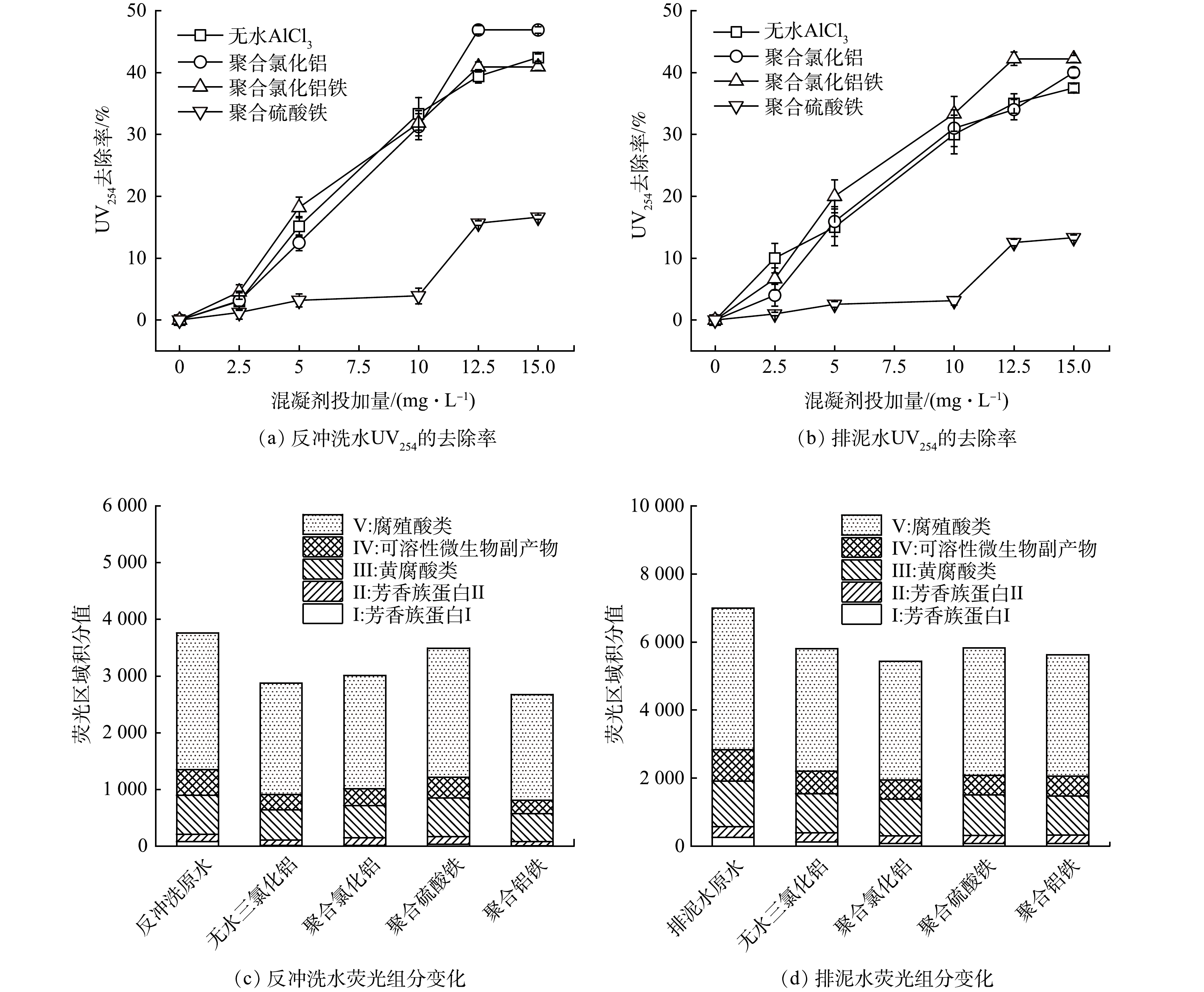

2) 不同混凝剂对有机物的去除效果。图4(a)~(b)展示了4种混凝剂对UV254的去除率随投加量的变化。UV254的去除率随着混凝剂投加量的变化趋势不同于浊度,其会随着剂量的增加而逐渐增加。其中聚合氯化铝处理反冲洗水时UV254的去除率可以达到45%以上,无水AlCl3、聚合氯化铝铁的去除率可以达到40%以上。而在处理排泥水的时候,去除效果最好的为聚合氯化铝铁,去除率可以达到40%以上。图4(c)~(d)反映了在投加量为10 mg·L−1时,4种混凝剂对反冲洗水和排泥水中5种荧光组分去除效果的影响。可以看到,排泥水中的总荧光区域积分值约是反冲洗水中的2倍,但几种组分所占比例与反冲洗水类似。在2类生产废水中,腐殖酸类占比最高,芳香族蛋白I占比最少。其中聚合铝铁对反冲洗水中荧光组分的去除效果较好,而聚合氯化铝对排泥水中荧光组分的去除效果最好。

小试实验结果表明,10 mg·L−1聚合氯化铝对浊度的去除效果较好,对UV254也有30%以上的去除,且投加量相对较低,除了有利于控制回用成本,还能降低回用时Al3+超标的风险。通过对浊度、UV254和5种荧光组分的去除效果的对比,4种混凝剂中聚合硫酸铁的去除效果最差,而聚合氯化铝和聚合铝铁效果最好且各有优势。分析认为铝盐相较于铁盐可以产生更大的絮体,能够更好的捕集悬浮物,对有机物的网捕卷扫效果更强,具有更好的去除效果[19]。在小试实验中,反冲洗水的混凝处理效果稍好于排泥水,这可能是由于排泥水中的浊度远高于反冲洗水,影响到混凝剂的作用效果。同时也可能是由于排泥水中的高浊度影响了混凝剂的作用效果[20]

-

中试项目位于某南方水厂厂区内,采用混凝-沉淀-砂滤-超滤工艺,其中混凝阶段采用10 mg·L−1的聚合氯化铝。滤池反冲洗水和排泥水经场内管网收集至不同调节池后,通过潜水泵按照设置流量进入中试系统。本节将通过分析常规水质指标、5种荧光组分变化、Al3+质量浓度及PFASs质量浓度变化探究不同工艺段的处理效果并对2类废水的不同表现进行对比。

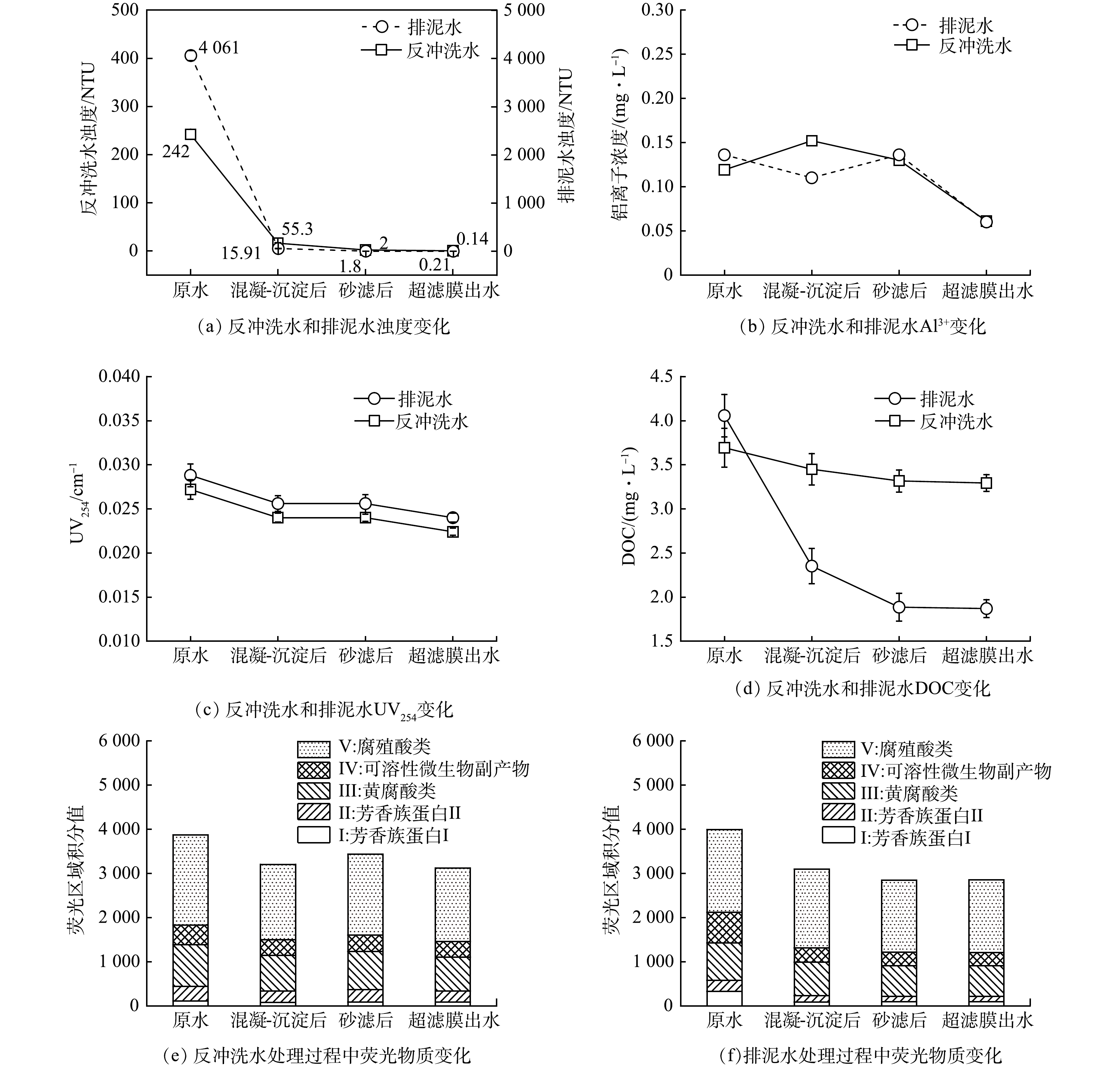

1)不同工艺段对浊度的去除效果。图5(a)反映了浊度在处理过程中的变化,其中混凝沉淀将排泥水和反冲洗水的浊度分别由4 061 NTU和242 NTU降至55.3 NTU和15.91 NTU,几乎绝大多数悬浮颗粒物得以去除,可实现约95%的浊度去除率。虽然2类生产废水的浊度有较大差异,但在中试装置的处理过程中并无明显区别,经中试装置处理后最终出水浊度均低于1 NTU。

2)不同工艺段对有机物的去除效果。由图5(c)可知,UV254在不同工艺段的处理过程中逐渐降低,2种不同废水经过膜处理后UV254可降至0.023 cm−1左右,去除率约为16%。同时,反冲洗水的膜出水UV254值略低于排泥水的膜出水UV254值。这可能与2种废水初始UV254值有关。在DOC的去除过程中,2类不同水质也存在有一定的差异。由图5(d)中可以看出,2者的原水DOC含量比较接近,但排泥水的去除效果优于反冲洗水,前者最大去除率可以达到53.9%,后者仅为10.8%,这可能是由于2类生产废水的构成不同。由董秉直等[21]的研究结果可知,混凝沉淀过程对大分子有机物去除效果较好,对小分子有机物的去除效果较差。反冲洗水是清洗滤料过程中产生的,其有机物来源主要为亲水性和低分子质量的有机物[22],这些有机物和颗粒在混凝过程中可能去除效果较差。相比之下,排泥水中的主要有机物主要集中在悬浮颗粒物及污泥之中,通过投加混凝剂可以使悬浮颗粒物脱稳并形成较大的絮体沉降下来,同时絮体也能吸附捕集部分有机物,使得排泥水中DOC去除效果优于反冲洗水[23]。图5(e)~(f)反映了处理过程中的5种荧光组分的变化。可以观察到,反冲洗水和排泥水的荧光组分在处理过程中每个组分都逐渐减少,整体上约有25%的去除率。

结合上述有机物指标来看,中试工艺可有效去除2类生产废水中的有机物,其中起主要作用的仍是混凝阶段。通过添加混凝剂使水中的悬浮物和胶体物质凝聚成絮体,混凝生成的较大絮体可以在沉淀过程中被较好地去除,难以自沉降的絮体也可以在后续的砂滤和超滤中被有效的去除。相较于排泥水,反冲洗水中更多的有机物为小分子有机物,再加之排泥水的絮体量要优于反冲洗水,这些絮体也对有机物也存在一定的吸附作用,所以排泥水的有机物的去除效果整体要稍优于反冲洗水。

3)不同工艺段对Al3+质量浓度的影响。由于该水厂混凝工艺采取的混凝剂为聚合氯化铝,在回用处理工艺中仍然采用铝盐可能会对水厂带来Al3+超标的风险,故本研究关注了中试处理过程中Al3+的变化。由图5(b)可知,反冲洗水和排泥水中Al3+的质量浓度分别为0.119 mg·L−1和0.136 mg·L−1,经过处理后为0.061 mg·L−1和0.060 mg·L−1。2种水质中Al3+的去除率在50%左右,低于《生活饮用水卫生标准》(GB 5749-2022)规定的0.2 mg·L−1。超滤膜对Al3+较高的去除率可能是因为多数Al3+以胶体或和其他物质聚合而成的小絮体的形式存在,而并非以Al3+的形式在水中,所以在通过超滤膜时对Al3+有较高的去除率[24]。2类水在中试装置的处理过程中,Al3+去除效果类似,最后出水质量浓度都可以达到较低的水平。

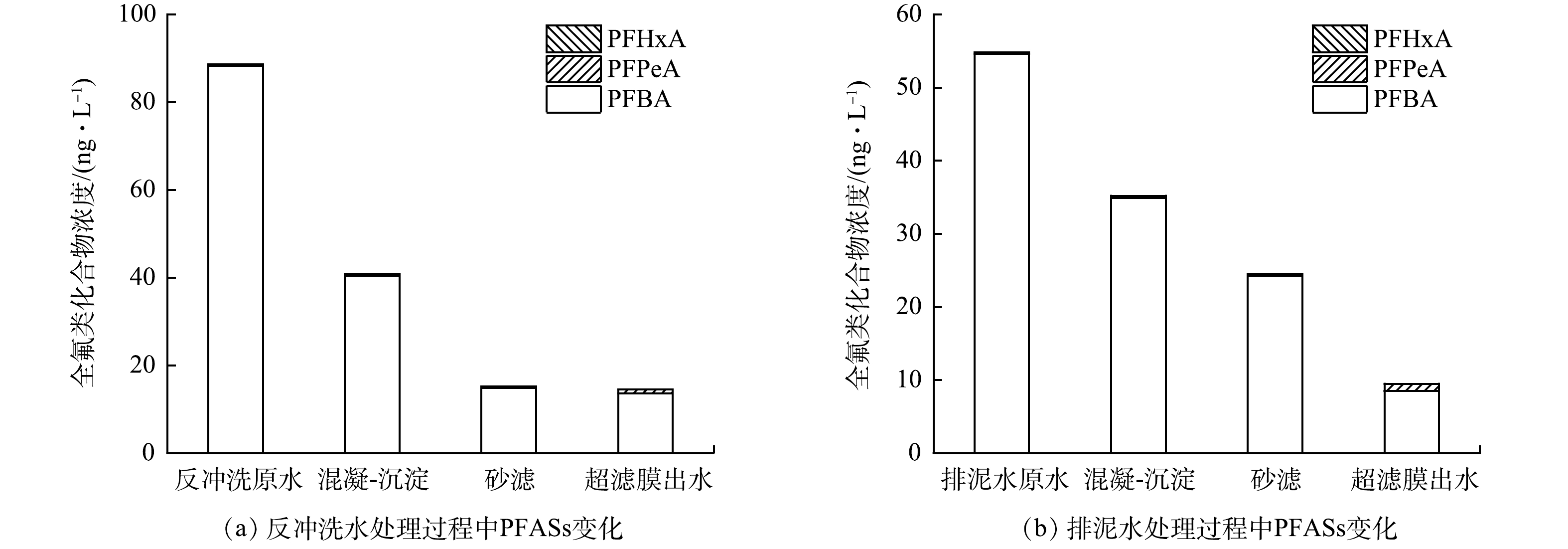

4)不同工艺段对新污染物的去除效果。本研究对中试不同工艺段出水的10种PFASs进行了检测(图6)。在2类生产废水原水中均只检测到3类物质,分别为全氟丁酸(perfluorobutanoic acid,PFBA)、全氟己酸(perfluorohexanoic acid,PFHxA)、全氟戊酸(perfluoropentanoic acid,PFPeA),其中无论是反冲洗水还是排泥水,PFBA是主要成分,占95%以上的含量。此外反冲洗水中的PFASs也要高于排泥水,前者为88.6 ng·L−1,后者为54.8 ng·L−1。经过中试装置处理后,2类废水的PFASs出水质量浓度均低于原水中的质量浓度,反冲洗水的PFASs去除率接近60%,而排泥水的去除率超过50%。因此,处理后回用的水能够有效降低PFASs的污染负荷。反冲洗水在砂滤后能达到稳定水平,这可能是因为排泥水悬浮物含量远高于反冲洗水,沉淀池停留时间不足,混凝沉淀出水中仍有少量絮体,需通过砂滤超滤后进一步去除,同时这也伴随着PFASs的减少。

中试装置可以有效去除各类污染物,从而减轻生产废水回用所带来的污染负荷及安全风险。但从浊度、DOC、UV254、PFASs和黄腐酸类、腐殖酸类等5种荧光组分变化的角度来看,混凝沉淀砂滤后的出水相比原水在回用中可大幅降低相关污染物的负荷。同时,相对于其他工艺段,超滤工艺并没有表现出更好的污染物去除率。2类生产废水在中试装置的处理过程中存在一定的区别,但最终出水水质较为相似且优于该水厂水源水。

-

1)结合南方某水厂的水源水质及生产废水污染物质量浓度开展了该水厂生产废水直接回用的污染负荷计算。研究结果显示,2类水直接回用均会对该水厂的NH4+-N及DOC负荷带来一定的影响,其中反冲洗水会对Al3+以及排泥水会对PFASs负荷的影响更为显著。

2)开展了2类生产废水的混凝小试实验,确定了混凝工艺的最佳混凝剂为聚合氯化铝,最佳剂量为10 mg·L−1,并且该条件下可有效降低2类生产废水中的浊度、UV254和5种荧光组分。2类生产废水在相同混凝条件下的不同表现与不同的组成组分相关。

3)经过中试装置处理后,2类生产废水中浊度、UV254、DOC、和5种荧光组分均有不同程度的降低,此外受生产废水回用影响较高的Al3+和PFASs负荷,在经过中试处理后也有了较为显著的去除效果。2类不同的废水经中试装置处理后的出水差异较小,较好的减轻了水厂的净水压力。

4)中试装置中的超滤工艺虽然可以带来更好的去除效果,但从水厂的回用需求及生产成本的角度考虑,其必要性仍有待商榷。

混凝-超滤工艺处理饮用水厂滤池反冲洗水和排泥水的效能

Efficacy of coagulation-ultrafiltration treatment for filter backwash water and sedimentation sludge water from drinking water treatment plants

-

摘要: 为探究饮用水厂滤池反冲洗水和排泥水的直接回用和处理后回用对水厂的影响及两类水处理过程中的差异,采用了污染负荷计算、实验室混凝小试和现场混凝-超滤中试装置对两类生产废水分别进行了研究。溶解性有机碳(dissolved organic carbon,DOC)、氨氮 (NH4+-N)、Al3+和全氟类化合物(perfluorinated compounds,PFASs)的污染负荷计算结果表明生产废水直接回用会为水厂带来一定的额外负荷,其中排泥水和反冲洗水分别对PFASs和Al3+负荷贡献较大;通过对小试中浊度,UV254以及5种荧光组分去除效果的对比,反冲洗水的混凝效果稍好于排泥水,同时10 mg·L−1的聚合氯化铝为最佳混凝剂方案;在中试过程中,两类水中的浊度、有机物、Al3+和PFASs均可被有效去除,出水差异较小,但反冲洗水中的亲水性和小分子有机物使得其去除效果低于排泥水。总体来说,经过处理之后,两类生产废水均可回用,回用可有效减少废水排放量,提高水厂水资源利用率。Abstract: To investigate the impacts of direct reuse and treated reuse of filter backwash water and sedimentation sludge water on water treatment plants, as well as the different performance in the treatment processes of these two types of water, this study employed pollution load calculations, laboratory-scale coagulation experiments, and pilot-scale coagulation-ultrafiltration trials to examine the two types of production wastewater. The pollution load calculations for dissolved organic carbon (DOC), ammonia nitrogen (NH4+-N), Al3+, and perfluorinated compounds (PFASs) indicated that the direct reuse of production wastewater would impose an additional pollution load on the drinking water treatment plants, of which sedimentation sludge water and filter backwash water contributed significantly to the load of PFASs and Al3+, respectively. Comparative analysis of turbidity, UV254, and PFASs removal in the laboratory-scale tests revealed that the coagulation performance of filter backwash water was slightly better than that of sludge discharge water. A dosage of 10 mg·L−1 of poly-aluminum chloride was found to be the optimal coagulant. In the pilot-scale experiments, turbidity, DOC, Al3+, and PFASs in both types of water were effectively removed, with small differences in effluent quality. However, the presence of hydrophilic and small-molecule organic matter in filter backwash water resulted in lower removal efficiency compared to sedimentation sludge water. Overall, after appropriate treatment, both the two wastewater types can be reused, thereby reducing wastewater discharge and improving water resource utilization in drinking water treatment plants.

-

-

表 1 水厂原水、反冲洗水和排泥水水质参数

Table 1. Water quality parameters of raw water, filter backwash water and sedimentation sludge water

样品 pH 浊度/NTU UV254/cm−1 DOC/(mg·L−1) NH4+-N/(mg·L−1) Al3+/(mg·L−1) ∑PFAS/(mg·L−1) 原水 7.5~8.3 0~50 0.021~0.053 1.92~5.11 0.14~0.27 0.003~0.056 0.2 反冲洗水 7.5~8.2 100~200 0.026~0.057 2.16~3.24 0.13~0.27 0.117~0.182 2.8 排泥水 7.7~8.1 >>200 0.024~0.049 2.40~3.58 0.10~0.64 0.066~0.130 11.4 -

[1] LI W, LIANG X, DUAN J, et al. Influence of spent filter backwash water recycling on pesticide removal in a conventional drinking water treatment process[J]. Environmental science water research & technology. 2018, 4 (7) : 157-167. [2] SCHOFIELD T. Dissolved air flotation in drinking water production[J]. Water Science and Technology. 2001, 43 (8) : 9-18. [3] OKUDA T, NISHIJIMA W, SUGIMOTO M, et al. Removal of coagulant aluminum from water treatment residuals by acid[J]. Water Research. 2014, 60: 75-81. [4] 张立. 澄西水厂生产废水处理及回用优化研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. [5] 武仁超, 王东升, 段晋明, 等. 强化混凝工艺深度处理给水厂排泥废水[J]. 环境工程学报, 2012, 6 (6) : 1915-1918. [6] 李荣光, 何文杰, 黄廷林, 等. 气浮工艺在水厂排泥水处理中的应用[J]. 供水技术, 2013, 7 (3) : 6-9. [7] 陈丽, 李佳宾, 付宛宜, 等. 陶瓷膜组合工艺对自来水厂排泥水的处理效果[J]. 环境工程, 2021, 39 (7) : 80-87. [8] 孙天晓, 唐海华, 周叶, 等. 饮用水厂中深度处理工艺生产废水研究[J]. 水处理技术, 2022, 48 (10) : 1-5. [9] 黄卓. 城市净水厂生产废水回用安全性研究[D]. 西安: 西安建筑科技大学, 2011. [10] HU C, LIU H, QU J, et al. Coagulation behavior of aluminum salts in eutrophic water: Significance of Al13 species and pH control[J]. Environmental Science & Technology. 2006, 40 (1) : 325-331. [11] WU S, YUAN T, FU W, et al. Perfluorinated compound correlation between human serum and drinking water: Is drinking water a significant contributor?[J]. Science of the Total Environment. 2023, 873: 162471. [12] QIAN Y, HU Y, CHEN Y, et al. Haloacetonitriles and haloacetamides precursors in filter backwash and sedimentation sludge water during drinking water treatment[J]. Water Research. 2020, 186: 116346. [13] LORET J F, COSSALTER L, ROBERT S, et al. Assessment and management of health risks related to the recycling of filter backwash water in drinking water production[J]. Water Practice and Technology. 2013, 8 (2) : 166-179. [14] MCCORMICK N J, PORTER M, WALSH M E. Disinfection by-products in filter backwash water: Implications to water quality in recycle designs[J]. Water Research. 2010, 44 (15) : 4581-4589. [15] MATILAINEN A, VEPSÄLÄINEN M, SILLANPÄÄ M. Natural organic matter removal by coagulation during drinking water treatment: A review[J]. Advances in Colloid and Interface Science. 2010, 159 (2) : 189-197. [16] AZIZ M T, GRANGER C O, FERRY J L, et al. Algae impacted drinking water: Does switching to chloramination produce safer drinking water?[J]. Science of the Total Environment. 2023, 877: 162815. [17] LONG D T, PEARSON A L, VOICE T C, et al. Influence of rainy season and land use on drinking water quality in a karst landscape, State of Yucatán, Mexico[J]. Applied Geochemistry. 2018, 98: 265-277. [18] ZHANG Z, JING R, HE S, et al. Coagulation of low temperature and low turbidity water: Adjusting basicity of polyaluminum chloride (PAC) and using chitosan as coagulant aid[J]. Separation and Purification Technology. 2018, 206: 131-139. [19] 陈伯俭. 南水北调 (邯郸段) 水源水预氧化-强化混凝试验研究[D]. 邯郸: 河北工程大学, 2020. [20] 熊易华. 长江上游高浊度原水及处理技术[J]. 给水排水, 2011, 47 (4) : 23-27. [21] 董秉直, 李伟英, 陈艳, 等. 用有机物分子量分布变化评价不同处理方法去除有机物的效果[J]. 水处理技术, 2003 (3) : 155-158. [22] QIAN Y, SHI Y, GUO J, et al. Molecular characterization of disinfection byproduct precursors in filter backwash water from 10 drinking water treatment plants[J]. Science of the Total Environment. 2023, 856: 159027. [23] XU Y, CHEN T, LIU Z, et al. The impact of recycling alum-humic-floc (AHF) on the removal of natural organic materials (NOM) : Behavior of coagulation and adsorption[J]. Chemical Engineering Journal. 2016, 284: 1049-1057. [24] WANG W, YUE Q, LI R, et al. Optimization of coagulation pre-treatment for alleviating ultrafiltration membrane fouling: The role of floc properties on Al species[J]. Chemosphere. 2018, 200: 86-92. -

下载:

下载: