-

煤矸石是我国在煤炭开采和选洗加工过程中排放量最大的工业固体废弃物之一[1]。煤矸石的含碳量较低且硬度高于煤,因其热值较低、利用困难,大量的煤矸石堆放于地表,会占用土地,造成水土流失、滑坡、泥石流等地质灾害,给周边生态安全造成极大影响。若煤矸石长期遭受雨水侵蚀,在渗滤和淋溶的作用下,会产生诸多有毒有害物质,这些有毒有害物质会对矿区周边的土壤和地下水造成危害,进而带来一系列严重的生态污染问题[2]。

根据国家统计局数据,2021年受国内下游需求增加和国际能源供求关系影响,我国原煤产量增长至4.13×109 t,同比增长5.9%。根据《中国大宗工业固体废物综合利用产业发展报告》(2021—2022年度)测算的数据,2021年煤矸石产生量约为7.43×108 t,增长5.84%,增幅明显[3]。近年来随着我国煤矸石利用技术不断涌现,煤矸石的利用途径逐年增加,煤矸石的综合利用率逐年提高。2021年全国煤矸石利用量5.43×108 t,综合利用率73.1%,同比增长0.9%[4]。图1(a)显示我国2012—2021年煤炭生产及消费数据,随着煤炭生产量和用量的升高,煤矸石的产生量也在逐年增加。图1(b)显示2011—2021年煤矸石产生量及同比上一年的增长率,煤矸石的综合利用率相对平稳,但增长率呈现上涨趋势。图1(c)显示煤矸石综合利用数据及其增长率。

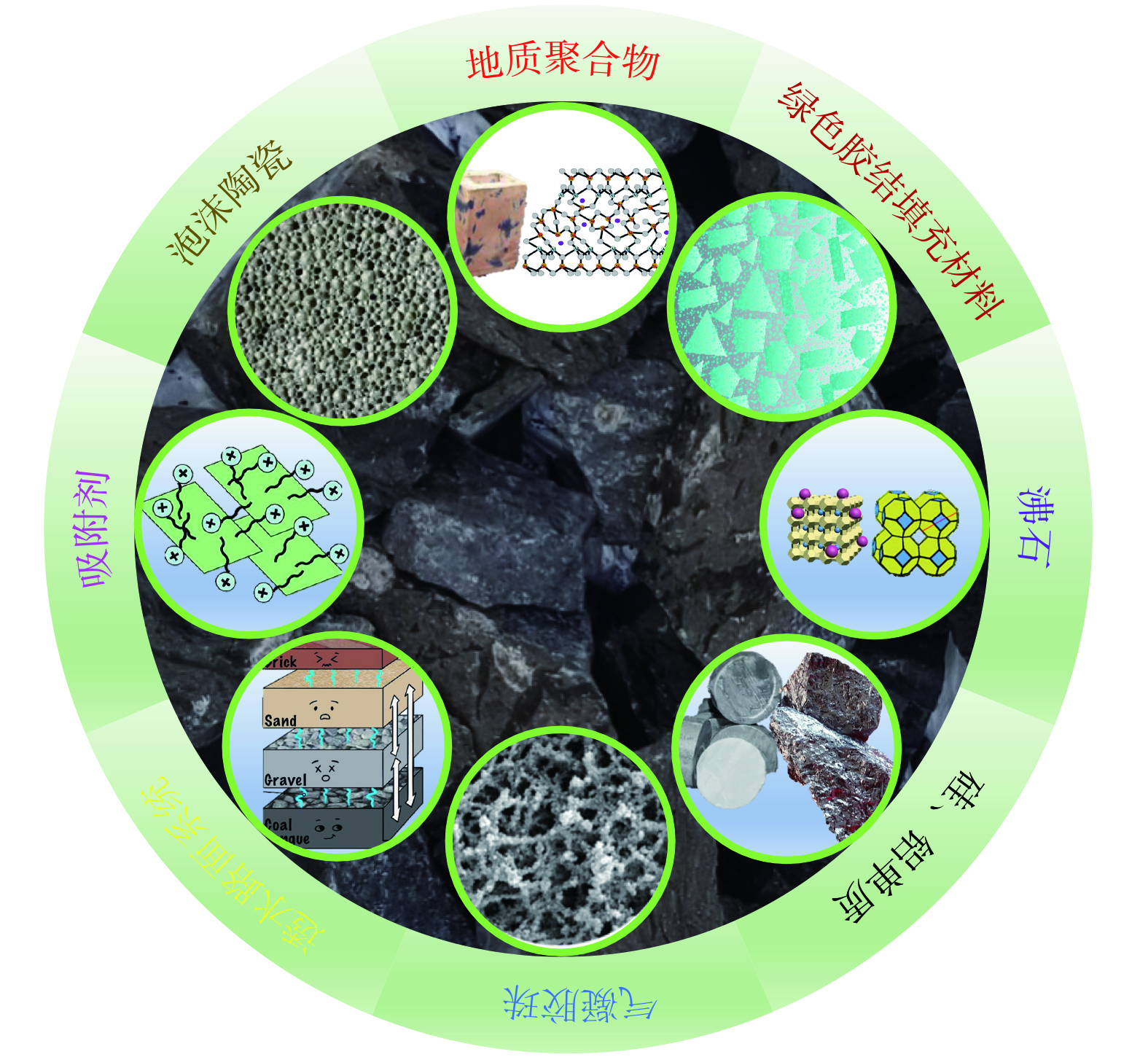

为保护生态环境,进一步促进煤矸石综合利用产业集聚,提高煤矸石综合利用水平,推动煤矸石综合利用产业高质量发展,加强煤矸石综合利用管理,我国针对煤矸石的处置与利用问题出台了《煤矸石综合利用管理办法 (2014年修订版) 》[5]、《关于推进大宗固体废弃物综合利用产业集聚发展的通知》[6]、《关于加快推进大宗固体废弃物综合利用示范建设的通知》[7]等一系列政策与法规来全面推进煤矸石高值化利用[8]。同时随着各地在生态保护、能源利用、资源节约和污染防治等政策的推动以及相关激励机制的支持下,煤矸石的综合利用途径愈来愈多 (图2) ,主要包括:1) 供电供热、脱碳生产蒸汽[9];2) 制备路基材料、制备土壤改良剂、生态土壤等、塌陷区回填、土地复垦[10-20];3) 制备特种水泥、地基材料,烧结墙体砌块、陶瓷、岩板等建筑材料[21-40];4) 制备铝系硅系化工产品,制备分子筛[41-52];5) 回收煤、黄铁矿、高岭土,回收稀土元素等有价部分[3,53-58]。

本文立足于煤矸石资源综合利用的现状与形势,对煤矸石利用中存在的各类问题进行了归纳总结,吸取国内外对煤矸石高值化利用领域的最新研究进展,重点介绍了煤矸石在建筑材料、地质聚合物、化工产品、新型材料、土地复垦等方面的前沿成果,阐述了煤矸石在高新技术领域的应用潜力,最后分析了推进煤矸石资源利用效率的局限性,展望了煤矸石未来的应用发展前景。本文目的是让科研人员及企业聚焦于煤矸石大规模工业高值化应用,进而提高大宗固体废弃物的综合利用水平,助力经济社会的高质量健康发展。

-

煤矸石是一种与煤层伴生的黑灰色沉积岩,由炭质页岩、泥岩、砂岩及煤炭等组成。它的特点是含碳量低、硬度高于煤、干基灰分大于50%,颗粒密度范围为2 100~2 900 kg·m−3。煤矸石的原矿粒度较大,矿物共生紧密,呈细粒浸染状。煤矸石在自然堆放情况下缓慢氧化并释放大量的热,当超过临界温度后即发生自燃,由于燃烧过程中碳和有机物产生气体,以及岩体结构破坏导致孔隙度增加致使煤矸石的堆积密度降低[2,8]。

煤矸石一般在煤层中、底或顶呈薄层状分布,可分为黏土岩类、砂石岩类、碳酸盐类、铝质岩类。根据来源和最终状态的不同,煤矸石可分为掘进矸石、选煤矸石和自然矸石3类。

煤矸石中含有残留煤、碳质泥岩和废木材等可燃物,其中的碳和硫是引发自燃的直接原因。煤矸石野外露天堆放,日积月累,矸石山内部的热量逐渐积蓄,当温度达到可燃物的燃点时,矸石山中的残煤便可自燃,分解并放出大量的CO、CO2、SO2、H2S、氮氧化合物及苯并芘等有害气体[4]。煤矸石元素组成主要为Si和Al,其中SiO2的占比最高,其次是Al2O3,并含有一定量的Fe、Ca、Mg、S、Mn、Cu、Zn、Cl等其他化学元素[59],以及微量的Ti、V等稀有金属。不同地区的化学组成和矿物成分有所不同[2],我国煤矸石的化学组成范围如表1所示[60]。

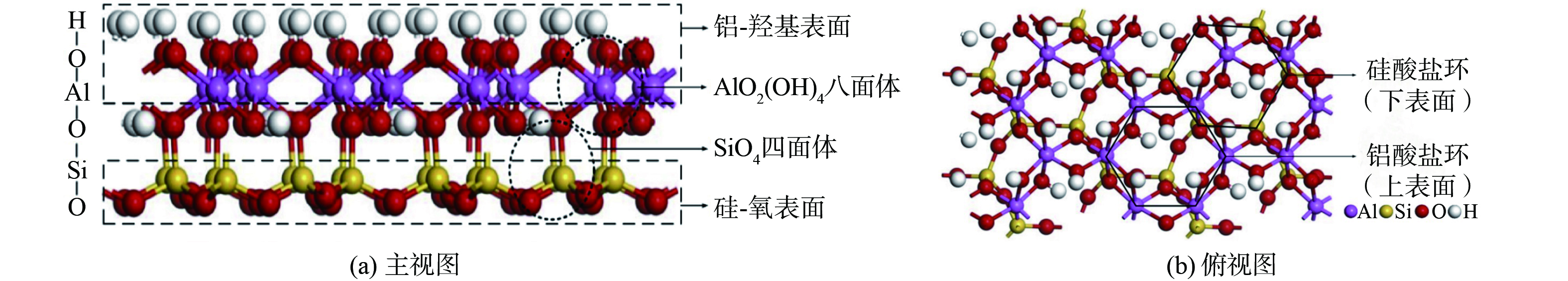

煤矸石含有的主要矿物有石英、高岭石、伊利石、长石、白云石、蒙脱石、绿泥石、菱铁矿、黄铁矿以及其他矿物等[59-60]。典型高铝煤矸石黏土矿物含量很高,主要矿物为高岭石[49],其晶体结构如图3所示,铝氧八面体通过定点氧与硅氧四面体连接,在a轴和b轴方向延伸,也在c轴方向上堆叠。铝氧八面体的铝原子周围有6个氧原子,包括4个表面羟基氧和两个连接氧。表面羟基氧与其他铝原子共享,连接氧与其他硅原子共享[61]。因此,高铝煤矸石中有价值的氧化铝和二氧化硅组分主要来源于高岭石。

-

2022年我国煤矸石整体利用率在70%左右,但部分地区煤矸石利用率仍旧较低,煤矸石综合利用产业亟需扩大。六盘水市人民政府在《推进煤矸石消纳为煤炭产业可持续发展解困的建议》[62]中指出,近4年来全市煤矸石综合利用率徘徊在40%左右,其中,回填占61.35%,建材占9.15%,发电占4.32%。主要以回填、筑路等低水平直接利用为主,少部分用于发电、建材等领域,大规模经济适用的利用技术没有得到突破,煤矸石消纳量远远赶不上煤矸石产出量,煤炭产业发展受限。黑龙江鸡西市仍旧有大量未处理的煤矸石堆等待所有人、使用人对矸石堆进行认领确权。

为迎合市场需求,已有多家以黏土为主要原料的制砖公司进行了技术改造,生产以煤矸石为主要原料的煤矸石烧结砖,年综合利用煤矸石接近百万吨。但这相比于每年未被综合利用的煤矸石来说无异于杯水车薪。煤矸石可以替代一部分石灰石作为水泥的原料,但是我国水泥工业生产中煤矸石的综合利用率大约仅为20%左右。

-

煤矸石成分复杂且分布广泛,各个地区煤矸石的组成成分、利用领域和方法也不尽相同[63]。我国江苏、安徽等地区煤矸石种类多为铝质岩类和黏土岩类;山西、内蒙古多为铝质岩类;河北多为黏土岩类;新疆为黏土岩类、砂岩类和钙质岩类;辽宁则多为砂岩类和自然煤矸石。其中山西省、内蒙古自治区的煤矸石中高岭土含量高,部分矿区SiO2和Al2O3含量合计接近甚至超过90%[64-65],而其他地区的煤矸石并无此特征。但山西、内蒙古等地煤矸石排放量高且综合利用程度低。相比之下,煤炭资源相对短缺的东部、东南部如江苏、浙江等地拥有一批大型煤矸石处理骨干企业,将煤矸石用于水泥生产、建筑用砖。然而,由于运输成本过高,将煤矸石及其综合利用产品运输到这些地区并不现实。同时,华东地区先进且多样化的煤矸石处理技术并不能完全覆盖全国的煤矸石种类,各地区又因为煤矸石种类不尽相同亦不能完全引进其他地区的煤矸石处理技术。另外,部分煤化工企业在前端并未分类,给后端分类以及综合利用带来麻烦[3]。

-

国家对煤矸石高值化利用领域长期实行增值税、所得税优惠政策,支持和鼓励发展煤矸石高值化利用企业[66-67]。近些年,一些地方政府出台了关于煤矸石高值化利用的政策或方案,但欠缺金融扶持、税收减免、专项资金补贴、运输优惠等鼓励措施[68]。而煤矸石高值化利用又是一个创新度较高、技术革新较快的领域,很容易使得优惠政策跟不上技术创新,导致新技术落地得不到有力的政策经济扶持[66-67]。此外,由于制定的政策没有结合当地实际情况,致使规划与本地实际脱节,规划缺乏科学性[63],致使部分煤矸石高值化利用项目难以实施[3]。一些地区对传统建材仍有强烈依赖,这导致以煤矸石制备的环保产品在市场上难以竞争,市场空间小,因此煤矸石综合利用项目的审批更加困难[3]。

美国和欧盟从20世纪70年代开始一直推行对废弃物的处置办法,并对各级政府职能的制定、管理、监督进行划分,对责任方面进行规定,对责任目标进行约束。例如美国颁布的《Resource Conservation and Recovery Act》 (简称RCRA,即《资源保护与回收法案》) ,建立了废弃物管理系统,设置了管理危废的基本框架[69]。在此基础下,美国研究出了可以使煤矸石中燃料完全燃烧且同时可以控制产生的热能和烟尘的燃烧控制法。此外还广泛将煤矸石用于发电、生产肥料等,对于不便利用的煤矸石,则填埋复垦成为牧场或果园。欧盟在2008年推出了替代早期废物框架指令、危险废物指令和废油指令的《Waste Framework Directive》 (即《废弃物框架指令》计划) ,对成员国进行了更详细的指导和约束[69]。例如法国将自燃煤矸石进行破碎并划分等级,用于空地和公共场所表面装饰,铺路或停车场。波兰研究了以煤矸石为主要原料生产砖制品和空心砌块的工艺。匈牙利马特劳力、伏特赫斯煤矿公司经过十多年的努力,在没有表土层的情况下,仅用一个生长期就能使煤矸石覆盖层变成肥沃的土壤。德国通过强制要求促使采矿单位努力研究新的利用办法,通过在矸石场地混合播种,筛选出促使矸石地表土壤化最好的植物种类进行矸石场的复垦。而英国把自燃煤矸石与铝土矿按4∶1的比例混合,制成防滑简易路面。还利用煤矸石生产建材,如制备标号较低的混凝土,预制混凝土砌块等[70]。

-

近年来,环境保护要求不断提高,煤矸石的利用方法不断涌现。但是由于企业在煤矸石综合利用方面投入不足,技术创新滞后、研发人员和专业技术人员不能完全满足煤矸石综合利用产业的发展需要,政校企三方相互合作不够紧密致使高新和成熟技术无法得到及时商用,从而导致大多数技术产业化实施困难[2,71],如从煤矸石提取铝元素等问题仍未得到解决[72]。同时,制备分子筛等需要破碎研磨的产品也存在问题,如很多企业破碎粒径不符合实验室要求。

由于煤矸石综合利用产品多为低附加值,成本高利润低,应用推广困难。在高附加值产品上方面,生产成本高且工艺复杂等致使大多数停留在实验室阶段,难有突破性进展[73],抑制了企业的探索积极性,形成恶性循环。

伴随着疫情带来的全球经济下行和日益抬头的单边贸易主义,市场对煤矸石需求量总体不高[63]。

-

1) 混凝土。传统混凝土由水泥、砂石,水等按一定比例混合配比而成,同时还需要加入外加剂和橡胶胶结料来实现某些特定的功能和性质[23]。GUAN等[40]将煤矸石煅烧陶瓷颗粒取代沙砾,发现制备的混凝土在抗压强度、劈裂抗拉强度以及抗折强度上均优于普通混凝土,有效解决了建筑工程中砂石的过度消耗问题。WANG等[21]利用煤矸石对部分水泥进行替代,借助热重/差示扫描量热分析、扫描电子显微镜 (SEM) 、X射线衍射 (XRD) 和核磁共振详细研究了煤矸石的热活化机理,开发了一种更环保的新型水泥制备方法。粒径小于5 mm的煤矸石硬度高、结构均匀,常用于生态混凝土的粗骨料。DONG等[27]对煅烧煤矸石骨料进行了离子溶蚀试验,创新性地利用煤矸石骨料的离子溶出量和比表面积作为活性定量指标进行评价,揭示了煤矸石骨料活性对砂浆力学性能的影响,促进了煤矸石骨料在混凝土砂浆中的应用。

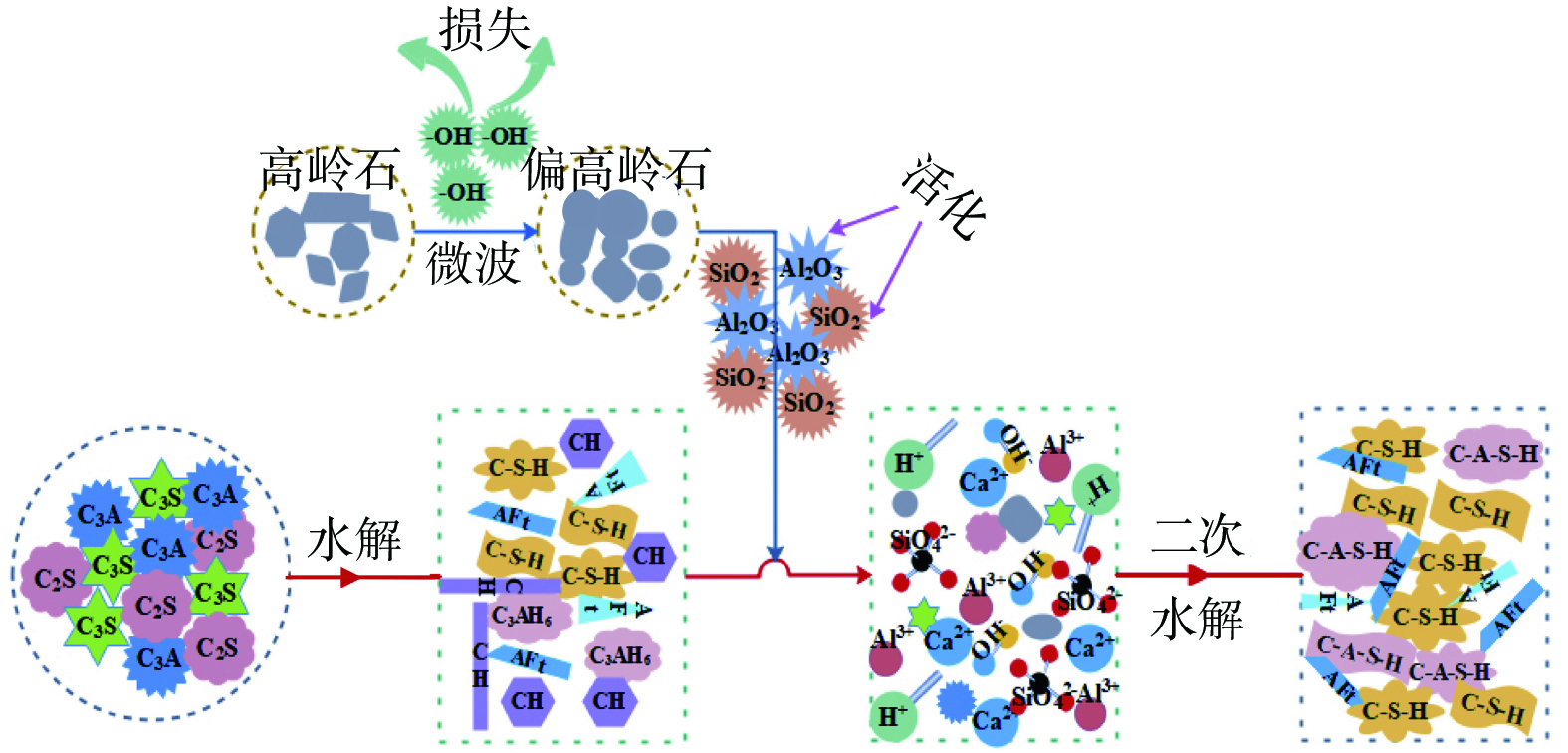

煤矸石中硅铝含量较高,经过高温煅烧活化后加入混凝土可明显提升其抗压强度。ZHANG等[74]综述了4种主要活化方法的活化效果,讨论了它们与煤矸石的相互作用机理,发现了黏土矿物的粒径和脱羟基程度决定了火山灰的活性。并进一步讨论了掺入活性煤矸石的水泥基材料的火山灰反应性、水泥水化、力学性能和耐久性。罗凯等[30]以活化煤矸石与石灰石替代熟料,制备了活化煤矸石-石灰石复合水泥,并研究了不同活化温度对煤矸石活性的影响。最终确定了最佳活化温度,并测得该复合水泥胶砂的抗压强度可达到水泥的104%。GUAN等[28]采用XRD、SEM、激光粒度分析和汞侵入孔隙度测定法等手段研究了微波活化法制备的活性煤矸石粉 (ACGP) 作为辅助胶结材料使水泥-煤矸石动力砂浆强度提高的原因。图4为ACGP的水化过程示意图,液相中的Ca(OH)2的快速浓缩促进了水泥的进一步水化,进而大大提高其机械强度。

依据煤矸石具备的性质,以生态利用为导向,归纳总结了煤矸石作为陶瓷颗粒、粗骨料等制备绿色环保的混凝土的方法,能够有效解决煤矸石大量占用土地问题,缓解环境污染压力,为建筑及公路等行业的发展提供新思路、新机遇。

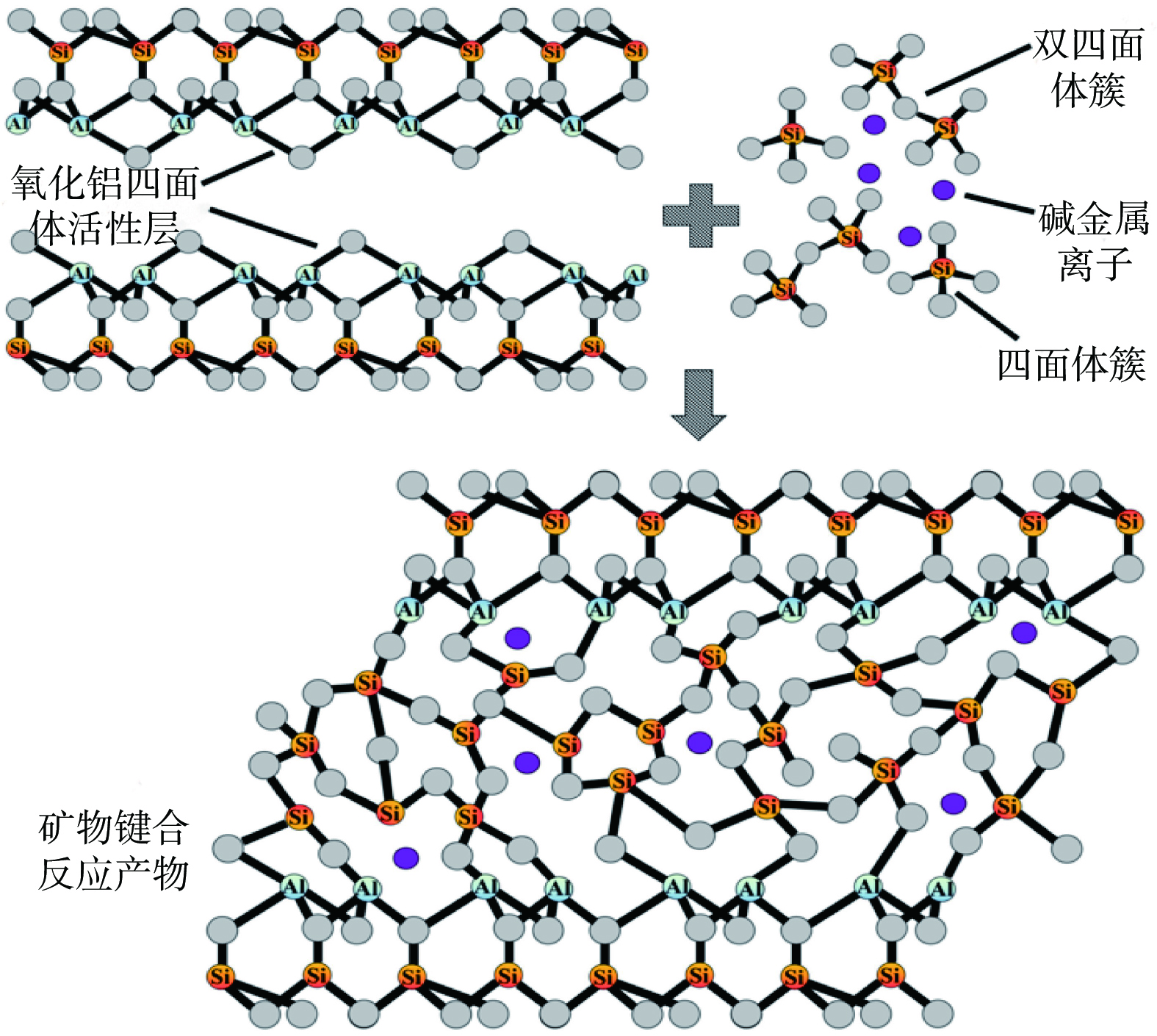

2) 地质聚合物。煤矸石基地质聚合物 (CGGP) 因其良好的综合力学性能,是煤矸石资源循环利用的热点之一。但煤矸石结构稳定,反应性差,因此煤矸石在利用前需要活化来提高其反应性。活化后的煤矸石能与碱溶液形成Si(OH)4和Al(OH)4单体。然后,通过聚合将单体转化为低聚物,通过低聚物缩聚形成地质聚合物[37] (图5) 。

ZHANG等[33]研究了煤矸石在不同机械活化方法和热活化方法下的微观结构变化,以及CGGP试样的力学性能和微观结构变化,结果表明煤矸石在900 ℃条件下活化更有利于地质聚合物的形成。YANG等[38-39]利用不同活性剂对超细煤矸石和细磨的高炉炉渣进行活化来制备高强度新型地质聚合物,探讨了活性剂种类和用量对地质聚合物强度影响及机理,为后续绿色经济的地质聚合物提供了理论依据。GENG等[36]提出了一种无需煅烧的共磨预活化新方法,即利用赤泥和煤矸石进行混合共磨合成相应地质聚合物。结果表明,在共磨作用下,赤泥和煤矸石混合物中的主要氧化铝硅酸盐转变为低聚合相后溶解在碱性溶液中并重新聚合,为其他固废合成地质聚合物的预活化以及节能减排提供了参考和方案。HUANG等[35]将煅烧后的煤矸石与高炉矿渣和熟石灰混合,在增加钙含量的基础上制成地聚合物,以提高其强度。结果表明,煤矸石中活性钙含量低是导致地聚合物强度低的主要原因。随着活性钙含量的增加,地聚合物的强度逐渐提高,这为以后替代传统硅酸盐水泥提供了理论和实验依据。

目前煤矸石基地质聚合物的研究多侧重于添加剂和活化剂种类对于其强度等综合力学性能的影响,通过微观角度解释其高强度原因,但对于碱激发剂激发活化理论仍然没有一个明确的解析,这也是将来地质聚合物研究的方向之一。

-

煤矸石含有丰富的硅和铝等元素,可利用煤矸石作为廉价的工业原料制备硅系、铝系等高附加值化工产品。YANG等[53]利用水化学工艺从富氧化铝煤矸石中提取氧化铝,使得氧化铝取率达到94.68%,表明了该工艺有良好的应用前景。范剑明[54]研究了热活化条件下高铝煤矸石酸浸溶出Al2O3反应过程的最优工艺条件以及酸浸渣在氢氧化钠溶液中溶出SiO2反应过程的最优工艺条件。在此工艺条件下,Al2O3浸取率可达82.95%,SiO2溶出率为69.74%。KONG等[55]和KONG等[75]为获得适宜的工艺条件和从高铁低铝煤矸石中浸出铝、铁离子的酸浸动力学模型,研究了煅烧温度、煅烧时间、酸类型对铝、铁离子浸出结果的影响。并利用上述高铁低铝煤矸石制备高效凝结剂聚合氯化铝 (PAFC) ,PAFC的浊度去除率达到了99.6%,优于其他凝结剂。ZHANG等[58]研究了富高岭石煤矸石在橡胶基体中的分散性、煤矸石/丁苯橡胶复合材料的力学性能和热稳定性,该研究结果有助于缓解煤矸石堆积,促进富高岭石煤矸石在功能填料领域的利用。LV等[76]以碳酸钙和煅烧后的玉米秸秆灰为添加剂,通过高温活化将煤矸石转化为煤矸石基硅肥。通过采用XRD和傅立叶变换红外光谱测量技术研究了煤矸石基硅肥的形成机理及影响因素,通过试验验证了其可靠性,为煤矸石基硅肥在农业中的应用提供了理论和实验依据。

目前提取铝制备氧化铝或氯化铝、提取硅制备二氧化硅以及做添加剂制备高分子化合物国内外研究报道很多,硅铝的提取率大多都在90%以上,但进行元素协同资源化利用,避免过程产生新的固体废弃物是主要问题之一。

-

1) 微晶玻璃。煤矸石中有含量可观的硅铝,甚至有些地区煤矸石的铝含量可比肩一些低品位铝矿,因此制造微晶玻璃所需的二氧化硅、氧化铝可以考虑从煤矸石中获得,可见煤矸石在环境保护和经济方面存在优势。DANG等[41]利用煤矸石和黏土,通过优化加工参数制备出了一种高性能微晶玻璃,并开发出了一种更出色的烧结微晶玻璃的方法,是一种利用工业固废制备微晶玻璃的新途径。WANG等[42]采用熔融法制备了具有优异力学性能的CaO-MgO-Al2O3-SiO2微晶玻璃。结果显示煤矸石和铁矿尾矿试验中最佳热处理为成核温度780 ℃,结晶温度980 ℃,抗弯强度可达283.3 MPa。

湛玲丽等[43]以煤矸石为主要原料,辅助添加硅砂、方解石、纯碱等,以CaF2为晶核剂制备煤矸石微晶玻璃。揭示了煤矸石固废微晶玻璃中析出的主晶相为钙长石相 (CaAl2Si2O8) ,用该方法制备的微晶玻璃,具有对煤矸石包容性好、消纳性强的特点。初步实现了煤矸石的大掺量高值化利用,为解决煤矸石固废堆积、环境污染等问题提供了理论基础和实验依据。罗冰等[44]以CaO为助熔剂,采用直接烧结法制备微晶玻璃,研究了热处理对微晶玻璃物相组成、吸水率、体积密度、线收缩率等物化性能的影响,为煤矸石的资源化利用提供了一种途径。利用煤矸石制备微晶玻璃,能够实现煤矸石的高值化利用,同时减少生态破坏和环境污染,产生显著的经济和社会效益。

2) 分子筛、沸石。沸石是一种含水的碱或碱土金属铝硅酸盐矿物,其由硅氧四面体和铝氧四面体组成。沸石具有离子交换性、吸附分离性、催化性、化学反应性、可逆的脱水性、电导性等,因而广泛应用于工农业。LI等[45]和LI等[46]通过CO2活化和水热合成方法,以煤矸石为原料,分别添加煤和竹子作为额外的碳源成功合成了沸石-活性炭 (ZAC-C) 和竹基沸石活性炭 (ZAC-B)复合材料,ZAC-C的比表面积 (669.4 m2·g−1) 远大于纯NaA沸石的比表面积 (249.3 m2·g−1) ,且对Cu2+和大分子有机染料 (Rh-B) 均有较高的吸附率。ZAC-B有着相比于ZAC-C更大的比表面积,对无机重金属离子和有机大分子污染物的吸附能力比ZAC-C更高,且二者经过多次吸附降解循环后仍保持较高的吸附能力。此外系统性的研究了纯沸石和ZAC-C吸附Cu2+和Rh-B的热力学和动力学过程。图6表明此种复合材料的吸附机理以及Cu2+和Rh-B在ZAC-C和ZAC-B上的吸收曲线,说明了以煤矸石为原料制备的高附加值产品是处理工业废水的良好替代品。

ZHANG和WANG[47]以内蒙古煤矸石为原料,采用碱熔-水热合成法制备了一系列以铜改性的X型沸石分子筛催化剂,该催化剂用于亚甲基蓝染料的降解和脱色,具有优异的活性和稳定性,可在90 min内完全降解染料,总有机碳去除率高达97.8%。KONG等[48]采用高铁、高石英含量的煤矸石为主要原料,通过酸浸-碱熔活化-水热合成成功制备了NaA分子筛 (图7) ,得到了相变规律以及最佳工艺条件。此研究的制备条件更温和,产品纯度更高且无杂质结晶。

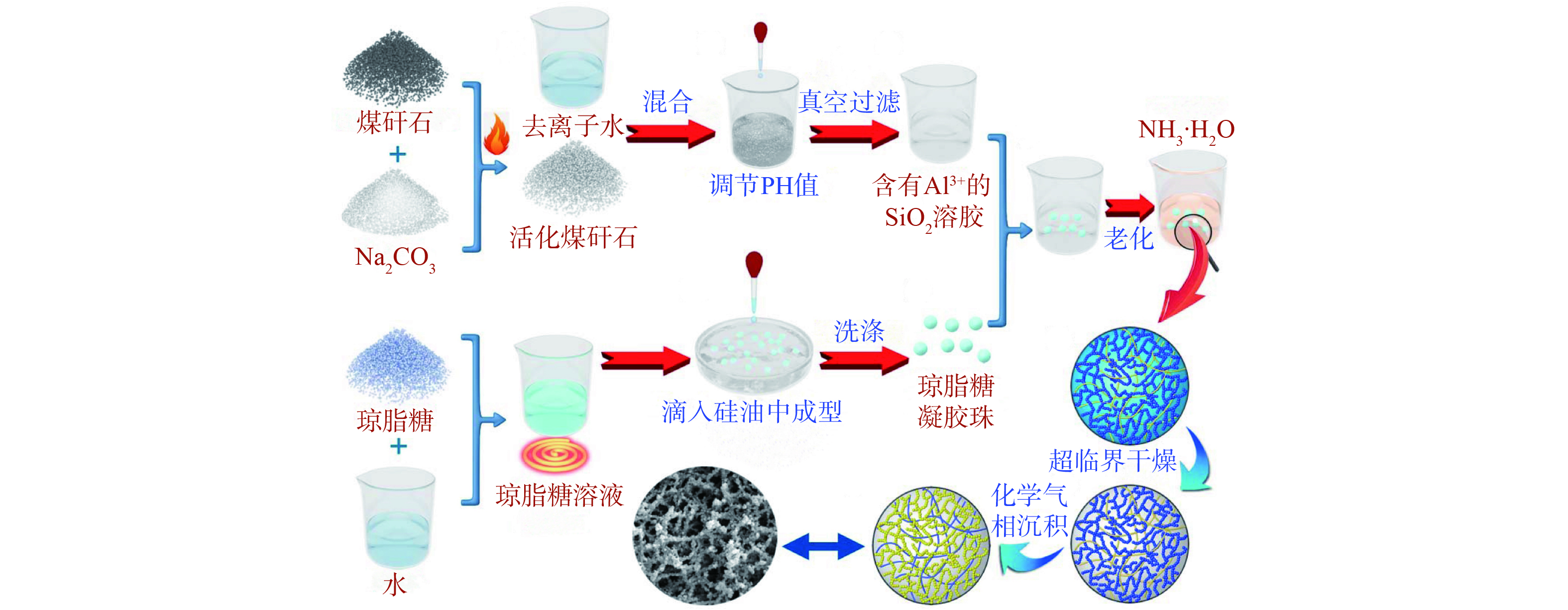

3) 气凝胶。气凝胶是21世纪的优质材料,具有超低密度、高孔隙率、低导热系数、高比表面积、低介电常数和高声阻抗等优点。GU等[50]以煤矸石为原料,在多孔琼脂糖气凝胶珠中构建SiO2-Al2O3气凝胶,然后通过三甲基氯硅烷的简单化学气相沉积制备SiO2-Al2O3/琼脂糖复合气凝胶珠 (SCABs) (图8) 。所制得的SCABs具有独特的纳米级互穿网络结构,疏水 (约128°) ,重量轻以及比表面积高 (538.3 m2·g−1) ,热稳定性和保温性能优异。此外,与天然SiO2-Al2O3气凝胶珠相比,SCABs的抗压强度显著提高了约10倍。为设计一种不需要昂贵原料的新型保温气凝胶材料铺平了道路,并为煤矸石的综合利用提供了有效途径。

WEI等[51]以廉价的工业废煤矸石为原料制备的硅酸钠作为二氧化硅气凝胶的前驱体,通过一锅法制备了二氧化硅湿凝胶,并在常压条件下干燥这种从煤矸石衍生的湿凝胶。合成了具有3D开孔微结构和高表面积的 (约748 m2·g−1) 纳米气凝胶,显著降低了二氧化硅气凝胶的工业生产成本,实现了煤矸石的高附加值利用。

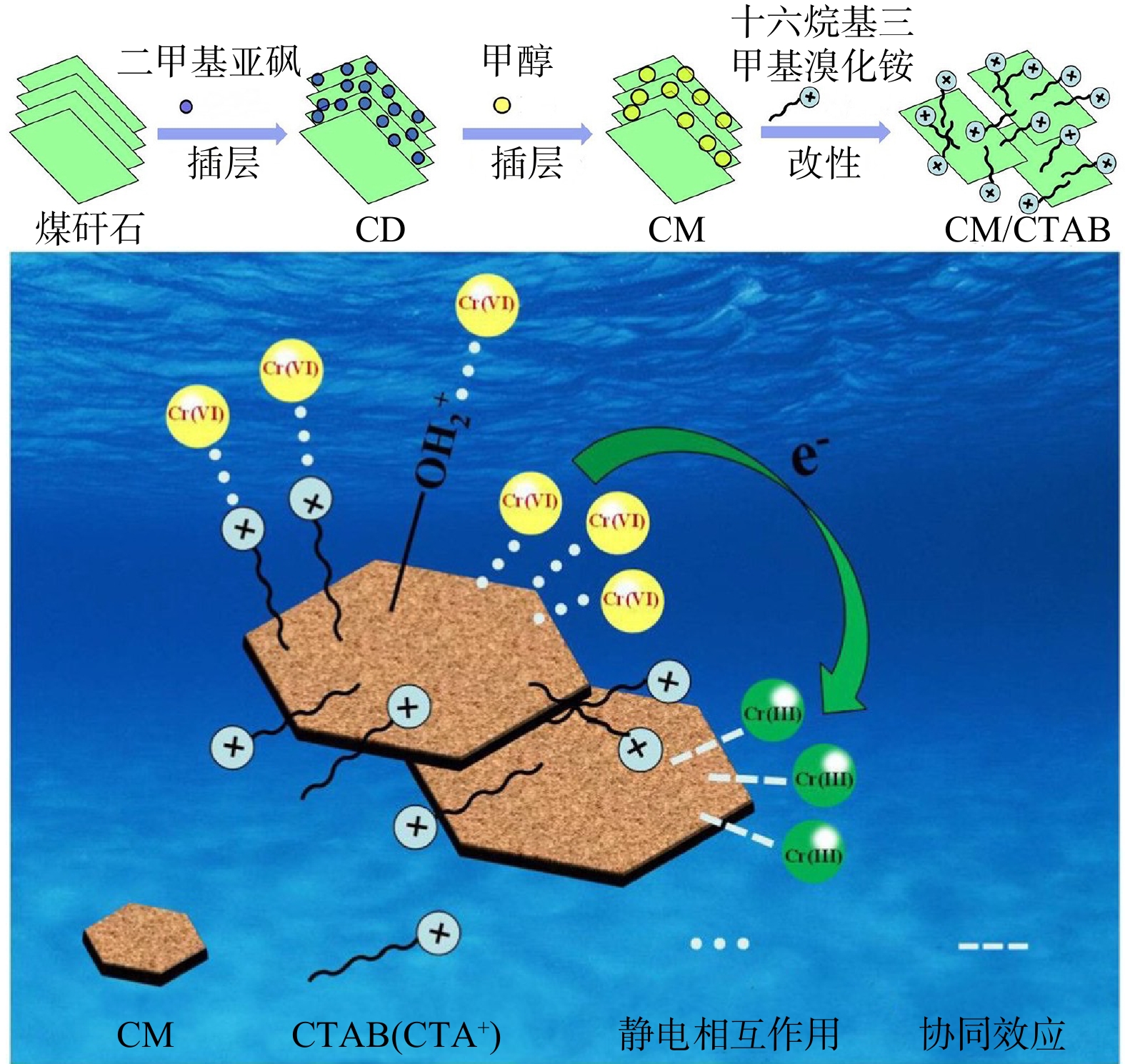

4) 其他。ZHANG等[77]以富含高岭石的煤矸石为载体,通过简单的沉淀法合成了一系列磷钨酸铵/煤矸石吸附剂,其对环丙沙星的吸附率高达82%,这项研究为富高岭石煤矸石的综合利用提供了一种新的策略,并为构建基于煤矸石的复合材料去除水中带正电荷的污染物提供了新思路。利用煤矸石衍生的硅酸钠通过低温水热法可以制备出有序的SBA-15[78],或是通过碱熔、酸浸等过程也可制备出煤矸石基活性炭-介孔硅复合材料[79]。ZHANG等[80]通过研究煤矸石去除Cr (VI) 的机理[81],首次以煤矸石和十六烷基三甲基溴化铵 (CTAB) 为基料,通过插层改性的方法成功合成了新型吸附剂CM/CTAB。图9为CM/CTAB合成过程示意图。CM/CTAB对Cr (VI) 的最大吸附量为55.09 mg·g−1,15 min内去除率可达85%,优于大多数报道的矿物基吸附剂。该吸附剂展现出极好的清除能力和对Cr (VI) 的高专一性,这项研究为去除Cr (VI) 提供了一种有效的吸附剂,同样的并为煤矸石的综合利用提供了思路。

以废玻璃和煤矸石为原料,钠长石为助熔剂,SiC为发泡剂[82],以及以煤矸石、钾长石为主要原料,四硼酸钠和氢氧化钠为助熔剂,Na2CO3和SiC为混合发泡剂[83],均可制备出综合性能极佳的发泡陶瓷。

-

HU等[10]提出了通过主成分分析法在玉米种植试验中建造的7个不同剖面的复垦土地中获得的土壤质量指数的最小数据集来评估土壤质量。实验表明灌浆前选择较厚的表层覆盖层以及控制煤矸石的pH值可以有效提高土质增强玉米的生长。为土地填埋复垦的管理和改进提供了探索性的手段和科学依据。HAN等[11]为提高矿区土壤储水能力,以4个粒径范围 (0~0.5、0.5~1、1~2、2~4 cm) 和4种厚度 (4、8、12、16 cm) 的煤矸石对高30 cm、内径15 cm的土柱表面进行覆盖,研究不同条件下的水渗透和蒸发情况。研究结果表明,厚度为8~16 cm、粒径范围为0.5~2 cm的煤矸石覆盖最有效。此研究为煤矸石覆盖技术的实施提供了科学参考,但需要进一步研究将该技术应用于植被生产。秦琪焜等[12]研究使用5种不同体积占比 (50%、60%、70%、80%、90%) 和3种不同粒径大小 (≤8.0、≤4.75、≤2.36 mm) 的煤矸石颗粒与城市污泥混合制成15种植生基质施用于沙土并种植高羊茅,研究表明煤矸石粒径大小≤8目、煤矸石与城市污泥的体积配比为1∶1时土壤改良效果最佳,验证了煤矸石与城市污泥混合制成的植生基质可用于改良土壤。但现存的关键问题是成土性和能否满足土壤环境质量要求。

-

开展煤矸石资源综合利用是我国深入实施可持续发展战略的重要内容。煤矸石量大面广,生态环境影响突出,是大宗固体废弃物利用的核心领域。然而煤矸石高值化利用发展在地区上不平衡;煤矸石无害化处置与资源化利用总体技术水平较低,制备的高值化煤矸石产品性能不足,市场竞争力小,且对设备要求高、投入成本大;煤矸石高值化利用产业链不完善,产业发展层次较低,煤矸石企业规模小,盈利能力低;区域经济低迷和需求不振,企业投资热情不高。

尽管目前对煤矸石高值化利用已开展研究,但为了更好地推进煤矸石资源利用效率,改善环境,促进社会高质量发展,对煤矸石高值化利用应考虑以下几个方面。

1) 着重于建立煤矸石的物化性质、资源属性和空间地理分布数据库,提供基础数据以实现煤矸石的多层次、多途径、快速高效综合利用。

2) 立足于煤矸石自身微结构性质,从纳米尺度发掘煤矸石高值化利用途径,制备具有特殊电学、光学、电化学等性质的煤矸石基产品。

3) 多学科交叉,提倡煤矸石以多种形式协同参与其它材料的制备,如添加剂、微生物菌剂等。

4) 构建闭合循环产业链模式,建立适应我国煤矸石资源的规模化处置与高值化利用产业化体系。

煤矸石资源高值化利用研究进展

Research progress of high-value utilization of coal gangue resources

-

摘要: 当前我国煤矸石存量和排放量大、产量高度集中、高附加值利用占比小,环境影响突出,是大宗固体废弃物综合利用的核心领域,资源化利用前景广阔。现有对煤矸石的处置能力和规模明显不能满足国家对生态环境保护及“双碳”目标下煤炭综合利用的相关要求。通过介绍煤矸石的物理、化学性质,指出了煤矸石在高值化利用中存在的涉及政策、供求、产业化和环境的问题。着重阐述了煤矸石在建筑材料、地质聚合物、化工产品、新型材料、土地复垦等方面的高值化利用现状,并对其未来的应用前景进行了讨论,提出了煤矸石高值化利用的重点研究方向。以期能够实现煤矸石的高质、高值、高效、绿色发展,不断增加煤矸石综合利用产品的附加值,增强煤矸石高值化利用产业核心竞争力。进一步推进煤矸石资源高值化利用效率,对环境质量的改善、经济社会发展的全面绿色转型具有重要意义。Abstract: The coal gangue in China is the core field of bulk solid waste comprehensive utilization due to its massive stock and emission, high concentration of output, small proportion of high-value-added utilization, and outstanding environmental impact. Hence, the prospect of resource utilization of coal gangue is broad. The existing disposal capacity and scale of coal gangue obviously dissatisfy the national ecological environmental protection and "Double Carbon" target under the comprehensive utilization of coal related requirements. By introducing the physical and chemical properties of coal gangue, this study pointed out the problems involving policy, supply and demand, and industrialization and environment in the high value utilization of coal gangue. This paper highlighted the current situation of high-value utilization of coal gangue in construction materials, geopolymers, chemical products, new materials, and land reclamation, and further discussed the future application prospects of coal gangue, proposed the key research direction of high-value utilization of coal gangue. The above review aimed at achieving the high quality, high value, high efficiency and green development of coal gangue, continuously increasing the value added of coal gangue comprehensive utilization products, and enhancing the core competitiveness of coal gangue high value utilization industry. Further promoting the high-value utilization efficiency of coal gangue resources is essential for the improvement of environmental quality, the overall green transformation of economic and social development.

-

-

图 3 高岭石晶体结构示意图[61]

Figure 3. Schematic diagram of the crystal structure of kaolinite

图 4 ACGP的水化过程示意图[28]

Figure 4. Schematic of the hydration process of ACGP

图 5 地质聚合物形成机理[37]

Figure 5. Formation mechanism of geopolymerization

图 7 NaA沸石的形成过程[48]

Figure 7. The formation process of NaA zeolite

图 8 SCABs 的制备过程示意图[50]

Figure 8. Schematic of the SCABs preparation process

图 9 CM/CTAB合成过程示意图[80]

Figure 9. Schematic diagram of the synthetic process for CM/CTAB

表 1 我国煤矸石化学组成范围[60]

Table 1. Chemical composition range of coal gangue in China

% SiO2 Al2O3 Fe2O3 CaO MgO TiO2 P2O3 K2O+Na2O V2O3 51~65 16~36 2.28

~14.630.42

~2.320.44

~2.410.9~4.0- 0.078

~0.2401.45

~3.900.008

~0.010 -

[1] 贾敏. 煤矸石综合利用研究进展[J]. 矿产保护与利用, 2019, 39(4): 46-52. [2] LI J, WANG J. Comprehensive utilization and environmental risks of coal gangue: A review[J]. Journal of Cleaner Production, 2019, 239: 117946. doi: 10.1016/j.jclepro.2019.117946 [3] 常纪文, 杜根杰, 杜建磊, 等. 我国煤矸石综合利用的现状、问题与建议[J]. 中国环保产业, 2022(8): 13-17. doi: 10.3969/j.issn.1006-5377.2022.08.024 [4] 王栋民, 左彦峰, 李俏, 等. 煤矸石的矿物学特征及建材资源化利用[J]. 砖瓦, 2006(6): 17-23. doi: 10.16001/j.cnki.1001-6945.2006.06.005 [5] 中华人民共和国国务院办公厅. 煤矸石综合利用管理办法 (2014年修订版) [EB/OL] [2023-09-10].https: //www.gov.cn/zhengce/2014-12/22/content_5713236.htm. [6] 中华人民共和国国家发展改革委办公厅 工业和信息化部办公厅. 关于推进大宗固体废弃物综合利用产业集聚发展的通知[EB/OL ]. [2023-09-10].https: //www.ndrc.gov.cn/fzggw/jgsj/hzs/sjdt/201901/t20190116_1130638.html. [7] 中华人民共和国国家发展改革委办公厅. 关于加快推进大宗固体废弃物综合利用示范建设的通知[EB/OL ]. [2023-09-10].https: //www.ndrc.gov.cn/xxgk/zcfb/tz/202201/t20220104_1311402_ext.html. [8] 王玉涛. 煤矸石固废无害化处置与资源化综合利用现状与展望[J]. 煤田地质与勘探, 2022, 50(10): 54-66. doi: 10.12363/issn.1001-1986.21.11.0614 [9] HONG P, LI Y, JIA X L. Experimental study on thermoelectric generation device based on accumulated temperature waste heat of coal gangue[J]. Energy Reports, 2022, 8(7): 210-219. [10] HU Z Q, LIU S G, GONG Y L. Evaluation of soil quality and maize growth in different profiles of reclaimed land with coal gangue filling[J]. Land, 2021, 10(12): 1307. doi: 10.3390/land10121307 [11] HAN X N, DONG Y, GENG Y Q, et al. Influence of coal gangue mulching with various thicknesses and particle sizes on soil water characteristics[J]. Scientific Reports, 2021, 11(1): 15368. doi: 10.1038/s41598-021-94806-0 [12] 秦琪焜, 方健梅, 王根柱, 等. 煤矸石与城市污泥混合制备植生基质的试验研究[J]. 煤炭科学技术, 2022, 50(7): 304-314. doi: 10.13199/j.cnki.cst.2021-0619 [13] WANG Y M, HUANG Y C, HAO Y X. Experimental study and application of rheological properties of coal gangue-fly ash backfill slurry[J]. Processes, 2020, 8(3): 284. doi: 10.3390/pr8030284 [14] 邱继生, 程坤, 张如意, 等. 煤矸石粉对矸石基绿色胶结充填体性能的影响[J]. 矿业研究与开发, 2022, 42(3): 60-65. [15] YANG X Y, ZHANG Y, LI Z H. Embankment displacement PLAXIS simulation and microstructural behavior of treated-coal gangue[J]. Minerals, 2020, 10(3): 218. doi: 10.3390/min10030218 [16] ZHANG Y, YANG X Y, TIGHE S. Evaluation of mechanical properties and microscopic structure of coal gangue after aqueous solution treatment[J]. Materials (Basel) , 2019, 12(19): 3207. doi: 10.3390/ma12193207 [17] GUAN J F, LU M, YAO X H, et al. An Experimental study of the road performance of cement stabilized coal gangue[J]. Crystals, 2021, 11(8): 993. doi: 10.3390/cryst11080993 [18] ZHANG X R, TIAN Y R, LIU J F, et al. Evaluation of modified permeable pavement systems with coal gangue to remove typical runoff pollutants under simulated rainfall[J]. Water Science and Technology, 2021, 83(2): 381-395. doi: 10.2166/wst.2020.574 [19] YE T T, MIN X Y, JIANG X Z, et al. Adsorption and desorption of coal gangue toward available phosphorus through calcium-modification with different Ph[J]. Minerals, 2022, 12(7): 801. doi: 10.3390/min12070801 [20] LI L H, LONG G C, BAI C N, et al. Utilization of coal gangue aggregate for railway roadbed construction in practice[J]. Sustainability, 2020, 12(11): 4583. doi: 10.3390/su12114583 [21] WANG A G, LIU P, MO L W, et al. Mechanism of thermal activation on granular coal gangue and its impact on the performance of cement mortars[J]. Journal of Building Engineering, 2022, 45: 103616. doi: 10.1016/j.jobe.2021.103616 [22] SHEN L L, ZHANG J X, LAI W A, et al. Microstructure and mechanical behaviors of coal gangue - Coal slime water backfill cementitious materials[J]. Journal of Materials Research and Technology, 2022, 20: 3772-3783. doi: 10.1016/j.jmrt.2022.08.089 [23] HAO Y, GUO X N, YAO X H, et al. Using Chinese coal gangue as an ecological aggregate and its modification: A Review[J]. Materials (Basel) , 2022, 15(13): 4995. [24] ZHU X X, GUO Z H, YANG W, et al. Durability of concrete with coal gasification lag and coal gangue powder[J]. Frontiers in Materials, 2022, 8: 791178. doi: 10.3389/fmats.2021.791178 [25] GAO S, ZHANG S M, GUO L H. Application of coal gangue as a coarse aggregate in green concrete production: A Review[J]. Materials (Basel) , 2021, 14(22): 6803. doi: 10.3390/ma14226803 [26] WANG Y S, QIU J P, DENG W, et al. Factors affecting brittleness behavior of coal-gangue ceramsite lightweight aggregate concrete[J]. Frontiers in Materials, 2020, 7: 554718. doi: 10.3389/fmats.2020.554718 [27] DONG Z C, XIA J W, FAN C, et al. Activity of calcined coal gangue fine aggregate and its effect on the mechanical behavior of cement mortar[J]. Construction and Building Materials, 2015, 100: 63-69. doi: 10.1016/j.conbuildmat.2015.09.050 [28] GUAN X, CHEN J X, ZHU M Y, et al. Performance of microwave-activated coal gangue powder as auxiliary cementitious material[J]. Journal of Materials Research and Technology, 2021, 14: 2799-2811. doi: 10.1016/j.jmrt.2021.08.106 [29] ZHANG D M, SUN F J, LIU T T, et al. Study on preparation of coal gangue-based geopolymer concrete and mechanical properties[J]. Advances in Civil Engineering, 2021, 2021: 1-13. [30] 罗凯, 李军, 曾计生, 等. 活化煤矸石-石灰石复合水泥的性能研究[J]. 武汉理工大学学报, 2022, 44(7): 10-15. doi: 10.3963/j.issn.1671-4431.2022.07.002 [31] 杨秋宁, 景严谊, 张东生. 纤维及矿物掺合料对煤矸石混凝土力学性能的改性研究[J]. 功能材料, 2022, 53(7): 7150-7156. [32] YANG J K, LU H J, ZHANG X, et al. An experimental study on solidifying municipal sewage sludge through skeleton building using cement and coal gangue[J]. Advances in Materials Science and Engineering, 2017, 2017: 1-13. [33] ZHANG W Q, DONG C W, HUANG P, et al. Experimental study on the characteristics of activated coal gangue and coal gangue-based geopolymer[J]. Energies, 2020, 13(10): 2504. doi: 10.3390/en13102504 [34] CHENG Y, MA H Q, CHENG H Y, et al. Preparation and characterization of coal gangue geopolymers[J]. Construction and Building Materials, 2018, 187: 318-26. doi: 10.1016/j.conbuildmat.2018.07.220 [35] HUANG G D, JI Y S, LI J, et al. Improving strength of calcinated coal gangue geopolymer mortars via increasing calcium content[J]. Construction and Building Materials, 2018, 166: 760-768. doi: 10.1016/j.conbuildmat.2018.02.005 [36] GENG J J, ZHOU M, ZHANG T, et al. Preparation of blended geopolymer from red mud and coal gangue with mechanical co-grinding preactivation[J]. Materials and Structures, 2016, 50(2): 109. [37] HAN R C, GUO X N, GUAN J F, et al. Activation mechanism of coal gangue and its impact on the properties of geopolymers: A Review[J]. Polymers (Basel) , 2022, 14(18): 3861. doi: 10.3390/polym14183861 [38] YANG X Y, ZHANG Y, LIN C. Compressive and flexural properties of ultra-fine coal gangue-based geopolymer gels and microscopic mechanism analysis[J]. Gels, 2022, 8(3): 145. doi: 10.3390/gels8030145 [39] YANG X Y, ZHANG Y, LIN C. Microstructure analysis and effects of single and mixed activators on setting time and strength of coal gangue-based geopolymers[J]. Gels, 2022, 8(3): 195. doi: 10.3390/gels8030195 [40] GUAN H B, YU J T, UMUHUZA KIBUGENZA A S, et al. Preparation of coal gangue ceramsite high-strength concrete and investigation of its physico-mechanical properties[J]. Scientific Reports, 2022, 12(1): 16369. doi: 10.1038/s41598-022-20940-y [41] DANG W, HE H Y. Glass-ceramics fabricated by efficiently utilizing coal gangue[J]. Journal of Asian Ceramic Societies, 2020, 8(2): 365-372. doi: 10.1080/21870764.2020.1743417 [42] WANG C L, REN Z Z, ZHENG Y C, et al. Effects of heat treatment system on mechanical strength and crystallinity of CaO-MgO- Al2O3-SiO2 glass-ceramics containing coal gangue and iron ore tailings[J]. Journal of New Materials for Electrochemical Systems, 2020, 22(2): 70-78. doi: 10.14447/jnmes.v22i2.a02 [43] 湛玲丽, 韩利雄, 李璟玮, 等. 高掺量煤矸石固废微晶玻璃结构与性能研究[J]. 硅酸盐通报, 2022, 41(4): 1124-1132. doi: 10.3969/j.issn.1001-1625.2022.4.gsytb202204002 [44] 罗冰, 张淑君, 石丽, 等. 煤矸石直接烧结法制备微晶玻璃[J]. 矿产保护与利用, 2022, 42(4): 113-120. [45] LI H, ZHENG F, WANG J, et al. Facile preparation of zeolite-activated carbon composite from coal gangue with enhanced adsorption performance[J]. Chemical Engineering Journal, 2020, 390: 124513. doi: 10.1016/j.cej.2020.124513 [46] LI H, LI M J, ZHENG F, et al. Efficient removal of water pollutants by hierarchical porous zeolite-activated carbon prepared from coal gangue and bamboo[J]. Journal of Cleaner Production, 2021, 325: 129322. doi: 10.1016/j.jclepro.2021.129322 [47] ZHANG M S, WANG X L. Preparation of a gangue-based X-type zeolite molecular sieve as a multiphase Fenton Catalyst and its catalytic performance[J]. ACS Omega, 2021, 6(28): 18414-18425. doi: 10.1021/acsomega.1c02469 [48] KONG D S, JIANG R L. Preparation of NaA zeolite from high iron and quartz contents coal gangue by acid leaching—alkali melting activation and hydrothermal synthesis[J]. Crystals, 2021, 11(10): 1198. doi: 10.3390/cryst11101198 [49] 王万军, 赵彦巧. 青峰煤矸石矿物学特征及分子筛制备研究[J]. 矿产保护与利用, 2006(6): 18-23. doi: 10.3969/j.issn.1001-0076.2006.06.005 [50] GU J, JI C, FU R, et al. Robust SiO2-Al2O3/Agarose composite aerogel beads with outstanding thermal insulation based on coal gangue[J]. Gels, 2022, 8(3): 165. doi: 10.3390/gels8030165 [51] WEI J, ZHU P H, SUN H. Ambient-dried silica aerogel powders derived from coal gangue by using one-pot method[J]. Materials (Basel) , 2022, 15(4): 1454. doi: 10.3390/ma15041454 [52] 郝名远, 陈欢乐, 李淑敏, 等. 煤矸石制备气凝胶研究进展[J]. 矿产保护与利用, 2022, 42(1): 172-178. [53] YANG Q C, ZHANG F, DENG X J, et al. Extraction of alumina from alumina rich coal gangue by a hydro-chemical process[J]. Royal Society Open Science, 2020, 7(4): 192132. doi: 10.1098/rsos.192132 [54] 范剑明. 高铝煤矸石铝硅分级提取实验研究[J]. 无机盐工业, 2019, 51(11): 65-68. doi: 10.11962/1006-4990.2019-0017 [55] KONG D S, ZHOU Z H, JIANG R, et al. Extraction of aluminum and iron ions from coal gangue by acid leaching and kinetic analyses[J]. Minerals, 2022, 12(2): 215. doi: 10.3390/min12020215 [56] 耿学文, 马鸿文, 苏双青, 等. 高铝煤矸石脱硅滤饼碱石灰烧结法制备氢氧化铝的实验研究[J]. 矿物岩石地球化学通报, 2012, 31(6): 635-639. [57] 滕英跃, 张永锋, 白杰, 等. 高铝煤矸石制备超细氧化铝和硅酸钠联产工艺[J]. 化工进展, 2011, 30(2): 456-462. [58] ZHANG K N, ZHANG H, LIU L S, et al. Dispersibility of kaolinite-rich coal gangue in rubber matrix and the mechanical properties and thermal stability of the composites[J]. Minerals, 2021, 11(12): 1388. doi: 10.3390/min11121388 [59] HUANG Y L, LI J M, SONG T Q, et al. Microstructure of coal gangue and precipitation of heavy metal elements[J]. Journal of Spectroscopy, 2017, 2017: 1-9. [60] 贾鲁涛, 吴倩云. 煤矸石特性及其资源化综合利用现状[J]. 煤炭技术, 2019, 38(11): 37-40. doi: 10.13301/j.cnki.ct.2019.11.014 [61] XIE M Z, LIU F Q, ZHAO H L, et al. Mineral phase transformation in coal gangue by high temperature calcination and high-efficiency separation of alumina and silica minerals[J]. Journal of Materials Research and Technology, 2021, 14: 2281-2288. doi: 10.1016/j.jmrt.2021.07.129 [62] 中华人民共和国六盘水市人民政府办公室. 推进煤矸石消纳为煤炭产业可持续发展解困的建议[EB/OL ]. [2023-09-10]. http://www.gzlps.gov.cn/hdjl/jytabl/zxta/zxwyta/202309/t20230906_82326319.html. [63] 惠鹏岳. 煤矸石的特性分析及综合利用研究[J]. 内蒙古煤炭经济, 2023, 366(1): 70-72. [64] 宋欢, 刘利波, 徐宏祥. 准格尔露天矿高品质煅烧高岭土分选工艺研究[J]. 煤炭加工与综合利用, 2021(11): 81-5+91. [65] 范剑明. 准格尔煤田高铝煤矸石矿物特征及热活性研究[J]. 煤炭加工与综合利用, 2017(11): 74-7+84+8. doi: 10.16200/j.cnki.11-2627/td.2017.11.021 [66] 谭雪莲, 沈怡青, 赵韩娣. 我国粉煤灰、煤矸石综合利用政策分析[J]. 粉煤灰综合利用, 2014(1): 49-53. doi: 10.3969/j.issn.1005-8249.2014.01.015 [67] 吴滨, 杨敏英. 我国粉煤灰、煤矸石综合利用技术经济政策分析[J]. 中国能源, 2012, 34(11): 8-11+45. doi: 10.3969/j.issn.1003-2355.2012.11.002 [68] 民建韶关市委员会. 推进煤矸石资源综合利用 推动韶关绿色发展[N]. 韶关日报, 2022-07-20 (A04) . [69] 李鹏, 夏元鹏, 张立魁, 等. 煤矸石综合利用产业政策和发展方向[J]. 陕西地质, 2021, 39(2): 96-101. doi: 10.3969/j.issn.1001-6996.2021.02.013 [70] 青方. 国外煤矸石处理及其经济效益[J]. 河北煤炭, 1990(4): 53-55. [71] 鲍丽萍. 鄂尔多斯市煤矸石综合利用路径研究[J]. 北方经济, 2023, 425(4): 60-63. doi: 10.3969/j.issn.1007-3590.2023.04.016 [72] 张伟辉. 煤矸石综合利用存在的问题及对策分析[J]. 能源与节能, 2021(2): 101-102. doi: 10.16643/j.cnki.14-1360/td.2021.02.045 [73] 李贞, 王俊章, 申丽明, 等. 煤矸石物化成分对其资源化利用的影响[J]. 洁净煤技术, 2020, 26(6): 34-44. doi: 10.13226/j.issn.1006-6772.20021801 [74] ZHANG Y L, LING T-C. Reactivity activation of waste coal gangue and its impact on the properties of cement-based materials – A review[J]. Construction and Building Materials, 2020, 234: 117424. doi: 10.1016/j.conbuildmat.2019.117424 [75] KONG D S, ZHOU Z H, SONG S J, et al. Preparation of Poly Aluminum-Ferric Chloride (PAFC) coagulant by extracting aluminum and iron ions from high iron content coal gangue[J]. Materials (Basel) , 2022, 15(6): 2253. doi: 10.3390/ma15062253 [76] LV B, ZHAO Z Y, DENG X W, et al. Sustainable and clean utilization of coal gangue: activation and preparation of silicon fertilizer[J]. Journal of Material Cycles and Waste Management, 2022, 24(4): 1579-1590. doi: 10.1007/s10163-022-01426-5 [77] ZHANG H, ZHAO R B, LIU Z L, et al. Enhanced adsorption properties of polyoxometalates/coal gangue composite: The key role of kaolinite-rich coal gangue[J]. Applied Clay Science, 2023, 231: 106730. doi: 10.1016/j.clay.2022.106730 [78] WANG J, FANG L, CHENG F Q, et al. Hydrothermal synthesis of SBA-15 using sodium silicate derived from coal gangue[J]. Journal of Nanomaterials, 2013, 2013: 1-6. [79] 李宏伟, 燕可洲, 文朝璐, 等. 煤矸石制备活性炭-介孔硅复合材料及其过程物相转变[J/OL]. 煤炭科学技术: 1-11. [80] ZHANG X, LI M, SU Y G, et al. A novel and green strategy for efficient removing Cr (VI) by modified kaolinite-rich coal gangue[J]. Applied Clay Science, 2021, 211: 106208. doi: 10.1016/j.clay.2021.106208 [81] ZHAO R B, ZHANG X, SU Y G, et al. Unprecedented catalytic activity of coal gangue toward environmental remediation: Key role of hydroxyl groups[J]. Chemical Engineering Journal, 2020, 380: 122432. doi: 10.1016/j.cej.2019.122432 [82] 解传娣, 张雷. 利用煤矸石和废玻璃制备发泡陶瓷材料及其性能的研究[J]. 中国陶瓷, 2022, 58(5): 51-56+64. [83] 赵绘婷, 董龙浩, 谢梅竹, 等. 以煤矸石制备发泡陶瓷的研究[J]. 中国陶瓷工业, 2022, 29(3): 26-30. doi: 10.13958/j.cnki.ztcg.2022.03.006 -

下载:

下载: