-

生物质能是仅次于石油、煤炭和天然气的世界第四大能源,具有可再生和环境友好的双重属性[1-3]。生物质燃料是生物质能最直接的利用方式。随着我国“双碳”目标的提出,生物质燃料将迎来更广阔的发展空间。尽管生物质燃料具有可再生和环境友好的优势,但其在锅炉燃烧利用过程中仍会产生一定浓度的烟尘、NOx和SO2等大气污染物[4]。其中,因其生成机理复杂、脱硝成本高等因素,NOx的治理已成为生物质锅炉烟气治理的重点和难点。针对生物质锅炉烟气大气污染物,尤其NOx排放进行严格管控具有重要的现实和环境意义。

与实验室研究相比,数值模拟具有低成本、简单、快捷等优势,成熟的模拟软件可较准确地描述整个流场参数[5]。国内外已有学者将数值模拟应用于生物质锅炉研究中。ZHANG等[6]利用FLIC和FLUENT模拟生物质锅炉内的燃烧过程,发现生物质燃料产生的CO2和NOx更少,可通过减少空气量来减少污染物的产生。JAKOV等[7]在以生物质、垃圾为燃料的焚烧炉内进行SNCR脱硝模拟,验证了以尿素为还原剂的脱硝效率较好,计算结果贴合实际情况。SEYED等[8]利用数值模拟研究了生物质锅炉烟气SNCR脱硝中还原剂氨的喷射高度与流量对其脱硝效果的影响,其脱硝效率最高可达63%。我国生物质锅炉方面的研究起步较晚,且主要借鉴燃煤锅炉。尽管燃煤锅炉烟气脱硝主要采用SNCR和SCR技术,但由于SCR脱硝技术存在投资和运行成本高等不足之处,因此,国内生物质锅炉烟气脱硝普遍采用SNCR脱硝技术。胡小翠等[9]对生物质直燃锅炉燃烧过程进行了模拟计算,通过计算得出的温度场与NO分布情况,可为锅炉优化提供参考。李穹等[10]在进行SNCR脱硝模拟时,以尿素作为还原剂,研究了温度、氨氮摩尔比、喷射参数、循环灰等因素对脱硝效果的影响。陆燕宁等[11]以生物质锅炉为研究对象,通过对锅炉 SNCR脱硝过程进行模拟计算,优化了还原剂喷嘴的布设形式,以探究最佳氨氮比。

在锅炉烟气中,大气污染物的组成,尤其NOx生成,不仅与锅炉燃烧条件有关,而且与燃料组成特性密切相关。与燃煤不同,生物质燃料来源广,燃料组成特性存在明显差异,因而对生物质燃料组成进行测定,是开展生物质锅炉燃烧、烟气排放特性及烟气脱硝数值模拟的前提。采用数值模拟手段探究生物质燃料组成对锅炉烟气排放特性影响的研究还鲜有报道。

本研究以河北省某生物质发电厂生物质锅炉为研究对象,在对其农林生物质燃料组成进行分析的基础上,借助FLUENT软件对生物质锅炉烟气排放特性及SNCR脱硝性能进行数值模拟,以期指导农林生物质锅炉企业优选生物质燃料,从而减少生物质锅炉烟气中大气污染物排放浓度。在此基础上,优化SNCR工艺的运行参数,可为实现NO低排放提供重要的理论基础和数据支持。

-

河北省内某典型生物质发电厂采用生物质直燃锅炉,所用的农林生物质燃料主要有小麦秸秆、果木枝、树皮等。3种生物质燃料一般按照0.3∶0.4∶0.3的质量配比混合 (称为混合燃料) 后直接进入生物质锅炉燃烧。采用本课题组前期研究的分析方法[12],对生物质燃料的组成及热值进行测定,结果如表1所示。

工业分析结果表明,3种生物质燃料的挥发分和固定碳含量高,故生物质燃料普遍具有易点燃、发热量高的特点。其中,树皮的灰分含量最低,因而其燃烧产生的烟尘量最小。从元素分析来看,3种燃料的C含量均大于40%,燃料可燃部分较多。其中,树皮中N含量偏低,因而其燃烧过程NOx的理论生成量会偏低,而果木枝中S含量偏低,经燃烧会生成较少量的SO2。对燃料热值进行分析发现,3种单一生物质燃料热值较高的是小麦秸秆,其热效率较高。与单一生物质燃料相比,混合燃料的固定碳含量略有提高、N含量有所降低。分析其原因,可能是受燃料结构与特性的影响,不同生物质燃料表现出不同的燃料特性[13]。因此,在保证一定燃料量的条件下,混合燃料有利于提升生物质锅炉的热效能,并减少污染物排放。

-

典型生物质发电厂生物质直燃锅炉的基本参数,如表2所示。

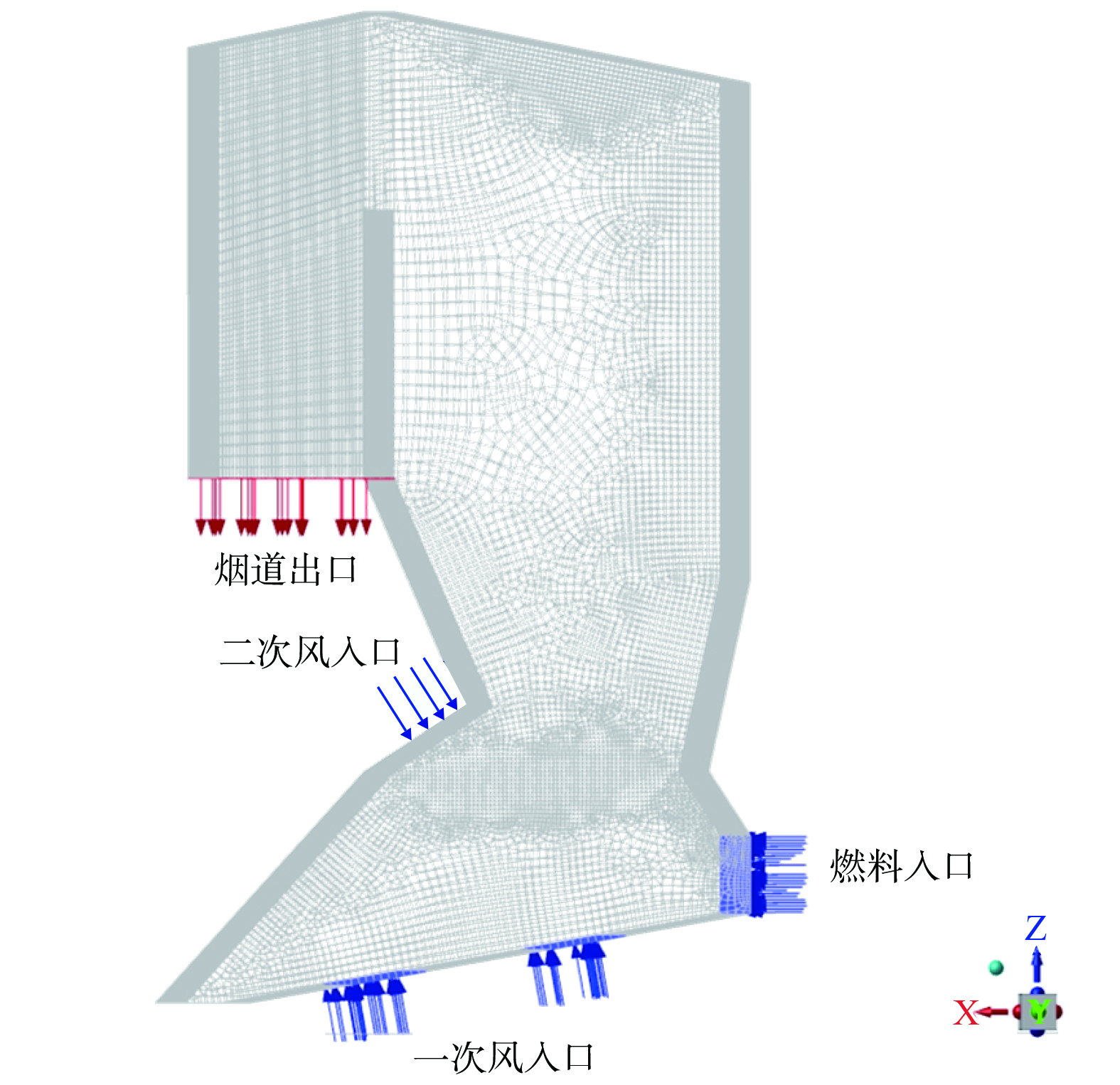

利用GAMBIT软件建立生物质锅炉结构的几何模型。锅炉网格划分数量为469 060个,网格划分结果如图1所示。将建好的几何模型进行网格划分,属于数值模拟的前处理部分。良好的网格划分是利用FLUENT软件进行数值模拟的前提和基础。本研究中进行网格划分后,结果倾斜度低于0.7,这表明网格划分精良。根据生物质电厂实际运行工况并结合相关文献报道,本研究借助FLUENT软件进行数值模拟,对该生物质锅炉内的温度场、烟气组分 (SO2、CO、CO2、NOx) 浓度场进行模拟计算。所采用的模型有:标准 k-ɛ模型、P-1模型、离散相模型、通用有限速率/涡耗散模型、NOx生成模型等。边界条件如表3所示。

生物质锅炉内燃料燃烧反应复杂,根据生物质燃料的工业分析和元素分析结果 (见表1),在燃烧反应模拟中进行相关参数设置,具体如图2所示。

-

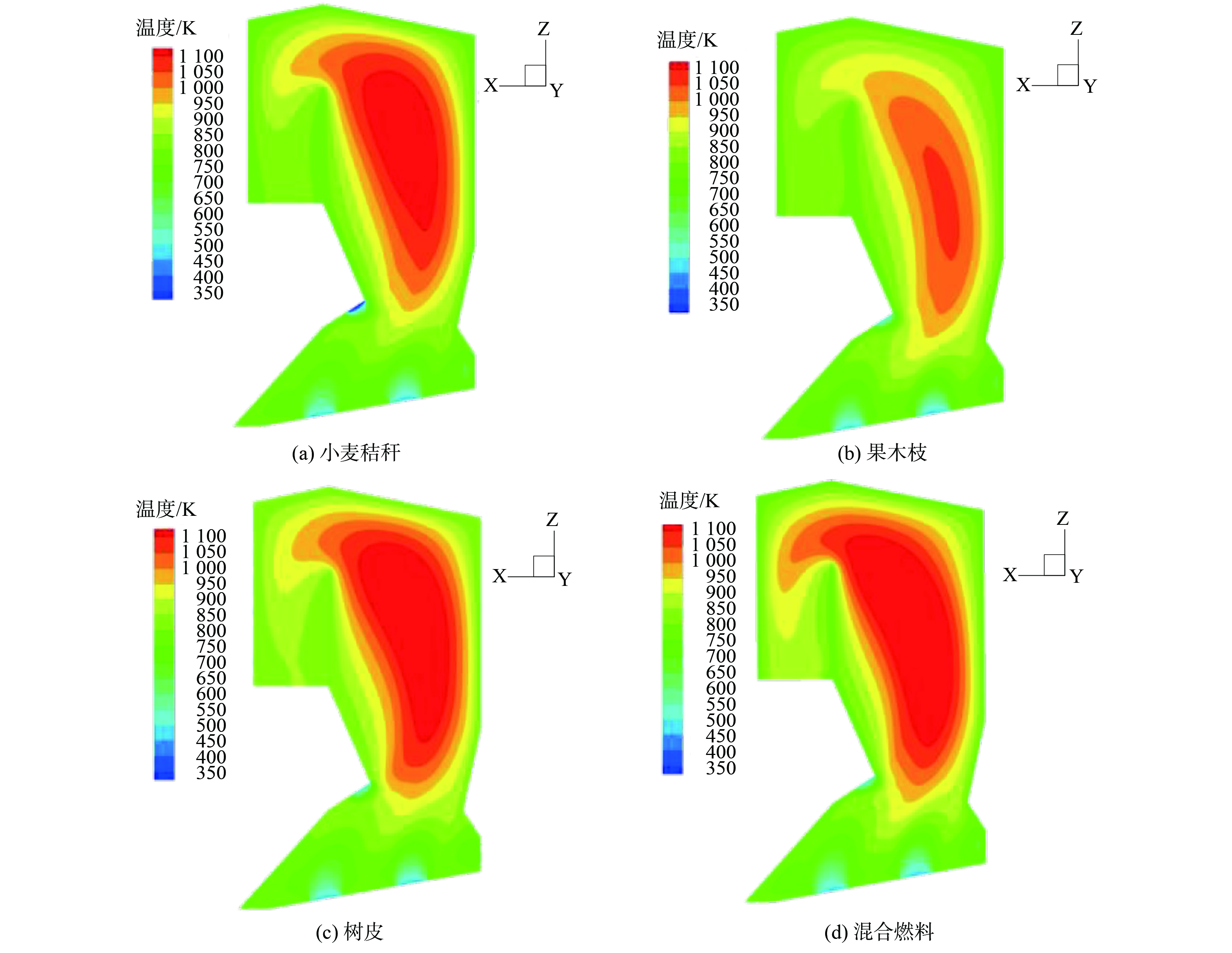

模拟小麦秸秆、果木枝、树皮及混合燃料经锅炉燃烧的过程,其中炉膛内的温度分布场如图3所示。锅炉内高温区主要集中在炉膛中心处,温度分布呈现由炉膛中心向周围递减趋势。以树皮为燃料时,炉膛内高温区分布面较高,而果木枝燃烧时高温区分布面最低。经模拟得出,燃烧最高温度分别为:1 173 K、1 097 K、1 216 K、1 140 K。该生物质发电厂实际运行中,以混合生物质为燃料时炉膛内最高温度为1 180 K。这表明数值模拟结果与实际值相对误差在4%以内,说明本研究选择的燃烧模型适用于该锅炉的实际情况。温度对生物质锅炉烟气的生成与结渣形成有一定影响。一般而言,随着温度的升高,燃料中C和N元素经充分燃烧后CO2和NOx的生成量增加;但温度过高时,CO2和NOx会发生部分还原反应,其中部分CO2还原成CO、部分NOx还原成N2。此外,生物质中微量金属元素在高温下会发生氧化反应,易形成部分结块而附着在锅炉表面上[14]。尽管以混合生物质为燃料的炉内温度并不比以树皮为燃料的高,但就炉内发生的燃烧化学反应而言,采用混合生物质燃料则会减少由于炉内过高温度而引发的烟气组分还原反应。

-

在生物质锅炉烟气中,NOx主要以NO为主,而锅炉内NO的来源主要来自于燃料型NO。经燃烧后,生物质燃料中的N元素转化成HCN与NH3。炉膛中发生了一系列反应,如式 (1)~式 (4) [15]所示。

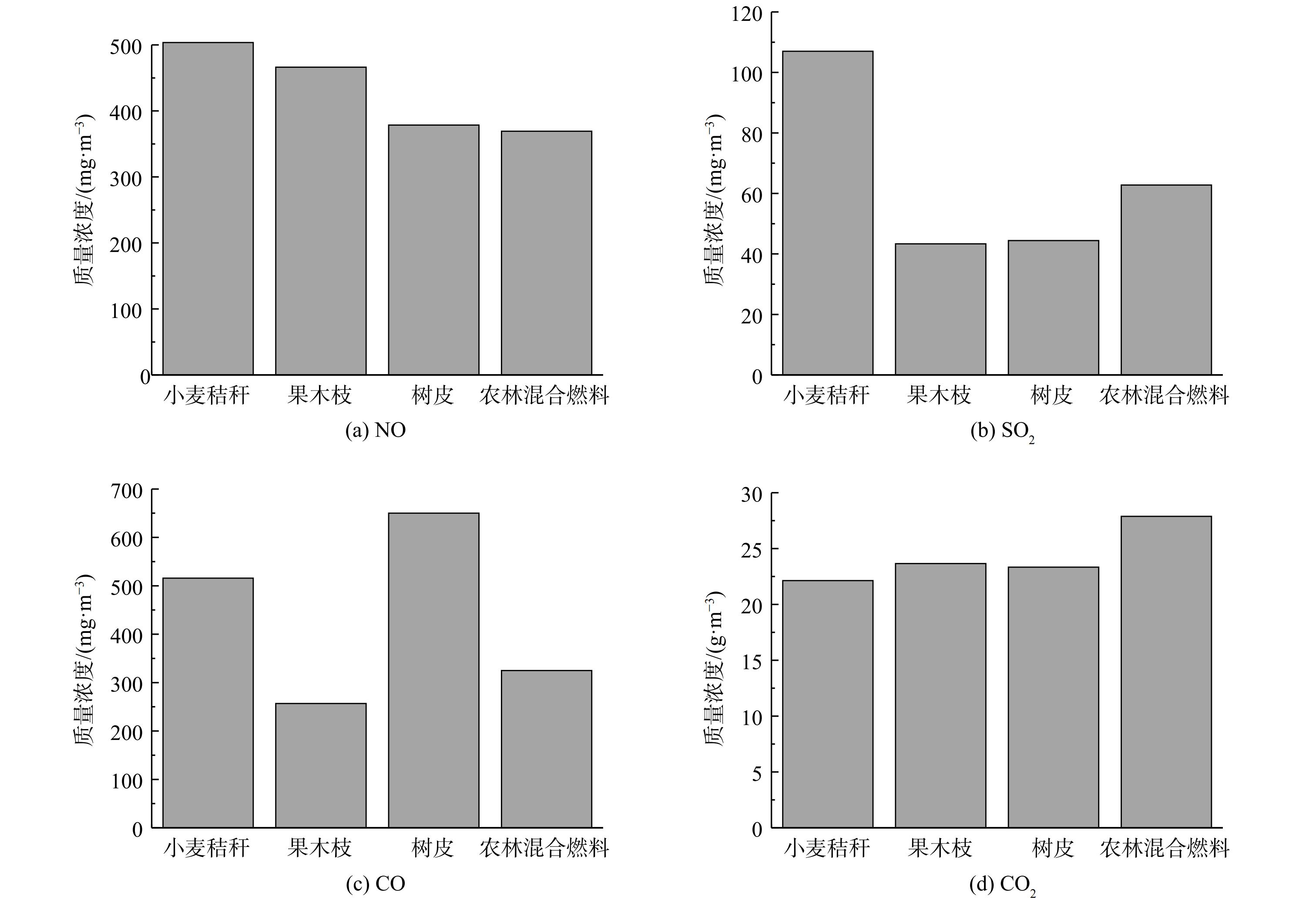

图4中各生物质燃料的NO分布状况表明,不同生物质燃料燃烧产生的NO状况大致相近,且NO主要分布在炉膛顶部与烟道出口之间。NO的平均质量浓度由高到低依次为:小麦秸秆 (503.6 mg∙m−3) >果木枝 (466.3 mg∙m−3) >树皮 (378.6 mg∙m−3) >混合燃料 (369.2 mg∙m−3)。其中,小麦秸秆的局部NO质量分数高达654.7 mg∙m−3。该电厂实际运行以混合生物质为燃料,锅炉排烟中的NO质量浓度为390~400 mg∙m−3。这表明数值模拟结果与实际值相对误差在8%以下,进而验证了模型和参数选择的合理性和准确性。结合元素分析结果 (表1) 分析发现,混合生物质燃料中N元素含量低于单一生物质燃料,其燃烧后NO的生成量最少,因此,燃料中N元素含量与NO生成量一般呈正相关关系。而对于单一生物质燃料而言,尽管果木枝N元素含量略高,但其NO生成量反而低于小麦秸秆。推测其原因可能在于,果木枝中N向挥发分N的转化不如小麦秸秆,而部分N会形成焦炭N。

-

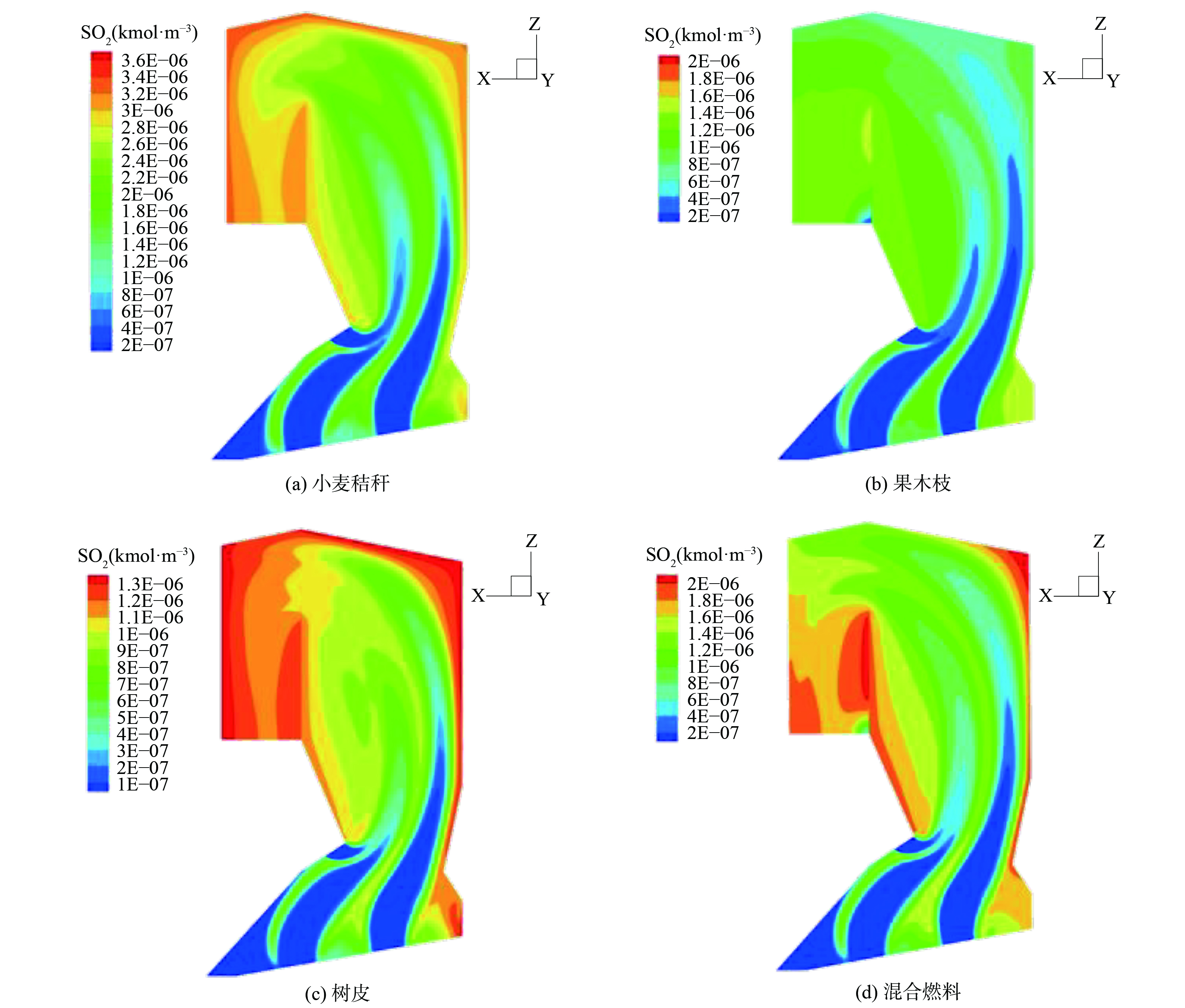

在生物质燃料中,S元素经燃烧后主要转化成SO2,少部分S元素与其他碱金属发生化学反应形成结渣附着在锅炉炉壁内。经过模拟计算后 (图5) ,烟道出口处SO2的平均质量浓度由高到低依次为:小麦秸秆 (107.0 mg∙m−3) >混合燃料 (62.8 mg∙m−3) >树皮 (43.4 mg∙m−3) >果木枝 (44.4 mg∙m−3) 。这表明由于生物质燃料中S元素含量较低 (见表1) ,生物质燃料燃烧排烟中SO2普遍偏低。相比而言,以农作物小麦秸秆为燃料排放的SO2质量浓度要远大于结构为木质的树皮、果木枝排放的SO2。不同生物质经过混合后,排放SO2质量浓度没有明显降低。这表明不同种类农林生物质燃料的混合对于S元素向SO2的转化并没有显著影响。

-

CO质量浓度表示生物质锅炉炉膛是否燃烧完全。由模拟计算可得 (如图6所示) ,不同生物质燃料燃烧排放的CO平均质量浓度由高到低依次为:树皮 (650 mg∙m−3) >小麦秸秆 (515.9 mg∙m−3) >混合燃料 (324.9 mg∙m−3) >果木枝 (256.8 mg∙m−3) 。对比可知,树皮在锅炉内燃烧不完全,在以树皮为主要燃料的生物质锅炉中,局部CO质量浓度高达6.8 g∙m−3。因此,为达到相同热能时,需消耗更多树皮。而混合燃料的CO质量浓度有所降低,与果木枝排放CO质量浓度相近。这表明不同种类生物质混合燃烧时,不同组分相互作用可促进燃烧,使得燃烧更完全。由图6可知,CO主要分布在一次风、二次风风速流动小的区域,以及炉膛高温区。CO是C元素不完全燃烧的产物,燃料在炉膛内堆积程度过高就会导致燃料不充分燃烧。在高温时,生物质燃料的燃烧剧烈,会消耗大量氧气与析出的挥发分,从而导致炉膛内CO质量浓度增加。在炉膛顶部至烟道出口处燃料的燃烧充分,因此,导致CO质量浓度降低。此外,CO在锅炉内为还原气氛,在燃烧过程中与烟气中的NO会发生还原反应。其中,发生的主要反应如式 (5) 所示[16]。

综上所述,生物质锅炉内适当含量的CO有助于降低锅炉烟气中NO含量,同时对锅炉效率的提升有一定意义。

-

在生物质燃料中,C元素占主要部分。经燃烧后,生物质燃料中的C元素主要以CO和CO2的形式存在于烟气中。在氧气充足条件下,C元素主要转化成CO2;在氧气不充足或高温条件下C元素主要转化成CO。图7表明,烟气中CO2主要分布于炉膛中心到烟道出口处,受炉膛内烟气流场运动影响,而一次风、二次风风口处及燃料入口处的CO2质量浓度较低。这主要是由于风口处流速较大、燃料入口处氧气不充分,导致燃烧反应不完全。燃料在炉膛顶部与烟道出口间的燃烧更剧烈,故生成的CO2更多。经模拟计算得到,不同燃料排放的CO2平均质量浓度由高到低依次为:混合燃料 (27.9 g∙m−3) >果木枝 (23.7 g∙m−3) >树皮 (23.3 g∙m−3) >小麦秸秆 (22.1 g∙m−3) 。在混合燃料燃烧时,C元素转化为CO2的几率较高,局部CO2的质量浓度高达59.7 g∙m−3。因此,混合生物质燃料的燃烧效果优于单一燃料。尽管现行的锅炉大气污染物排放标准未对CO2给出排放限值要求,但随着“双碳目标”的提出,提升锅炉热效能、降低碳排放必将成为生物质能利用行业亟待解决的一个重要课题。

-

模拟不同生物质燃料在锅炉内的燃烧,炉膛内不同烟气成分的质量浓度对比如图8所示。NO是生物质锅炉排放烟气的主要污染物,是生物质锅炉烟气监测与治理领域关注的重点。对比结果表明,不同生物质按比例混合燃烧后可有效减少NO的排放;混合燃料排放的CO质量浓度较低,CO2质量浓度最高。这说明混合燃料在炉膛内燃烧较完全,燃烧效果较好,有利于提升锅炉热效率。此外,混合燃料对SO2的排放影响较低,其质量浓度介于小麦秸秆与果木枝、树皮之间。在生物质锅炉企业中,通过一系列脱硫工艺可有效降低SO2的排放。在实际应用中,混合燃料能在提升锅炉热能时减少NO的排放,因此,在大多数生物质锅炉企业中混合燃料被广泛应用,还需进一步开展不同种类燃料配比的探究。

-

结合企业实际生产,该企业生物质锅炉SNCR烟气脱硝采用尿素为还原剂,涉及的主要化学反应式如式 (6)~式 (10) 所示[17]。以尿素为还原剂的SNCR反应十分复杂,尿素分解生成的NH3和HNCO,各自还会发生还原反应。在实际过程中,以NH3作为还原剂来主导SNCR脱硝反应,以HNCO作为还原剂辅助促进脱硝效率的提升[18]。在此基础上,选取NOx模型中的SNCR模型进行模拟计算,以此来探究SNCR中还原剂喷嘴布设、反应温度、氨氮比对脱硝效果的影响。

-

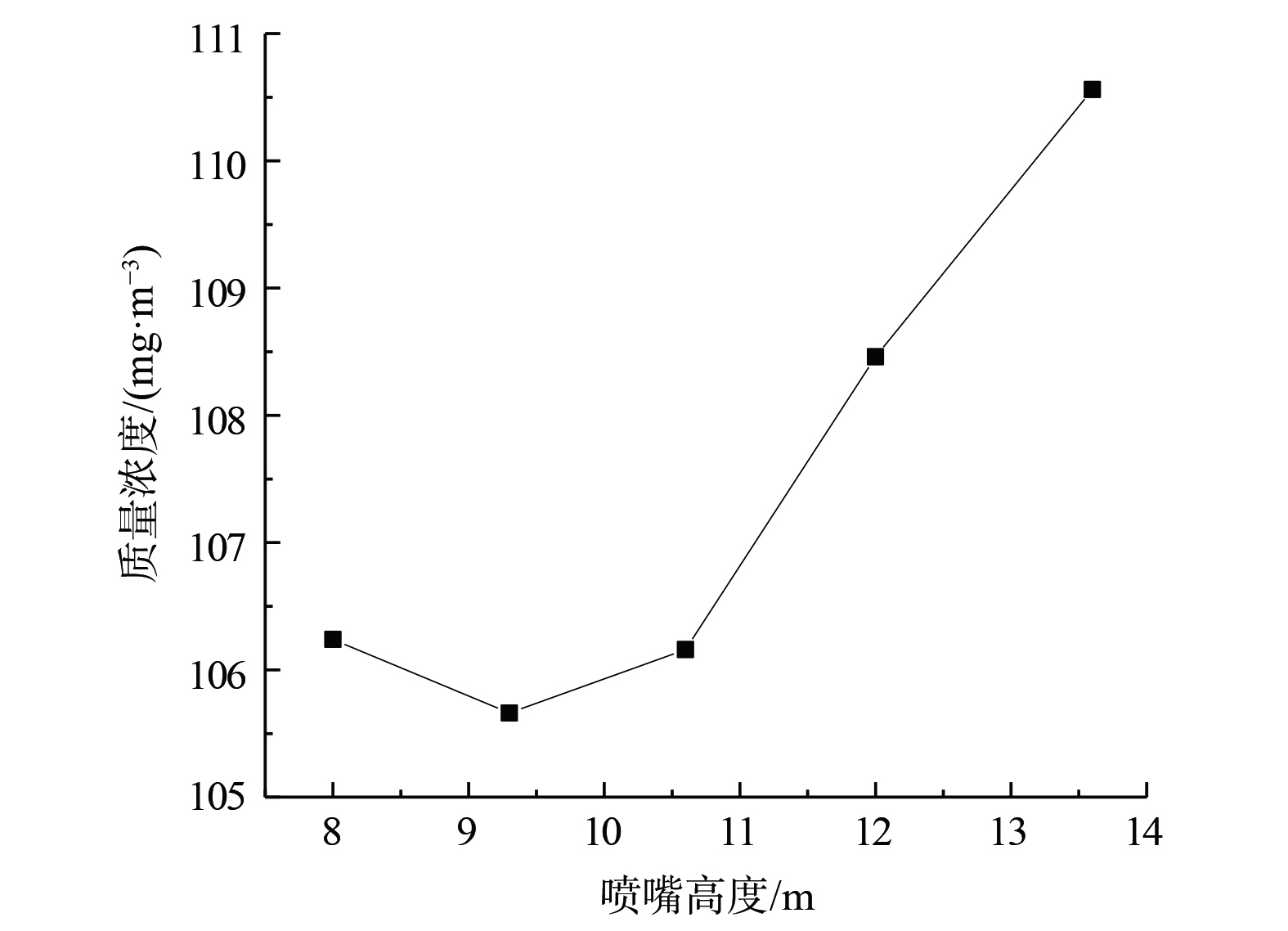

还原剂喷嘴的位置会在一定程度上影响生物质锅炉的烟气脱硝效率。本研究设置条件为:还原剂雾化粒径为1μm、雾化角度为30°;还原剂注入温度为300 K;还原剂供给速度6~7 m∙s−1;还原剂用量0.0139 kg∙s−1。生物质锅炉炉膛高度为18 m,分别在炉膛高度为z=8 m、9.3 m、10.6 m、12 m和13.6 m处布设还原剂喷嘴。由图9可知,烟道出口处NO的质量浓度会随着还原剂喷嘴布设高度的增加呈现出先降低后上升的趋势。还原剂喷嘴高度在z=9.3 m左右时,烟道出口NO质量浓度为105.7 mg∙m−3,此时脱硝效果更好。还原剂喷嘴在z=13.6 m处时,出口NO质量浓度为110.6 mg∙m−3,此时脱硝效果不佳。受炉膛内温度场与烟气组分质量浓度分布场的影响,还原剂喷嘴布设位置应接近炉膛中NO生成位置会更有利于脱硝反应,并提升锅炉脱硝效率。在炉膛z=13.6 m处接近炉膛顶部的位置,这时受炉膛内烟气流场的影响,喷嘴在炉膛顶部在注入还原剂时受烟气流动方向与速度未能充分反应、混合程度较差,易造成还原剂逃逸现象。而从炉膛z=9.3 m处附近注入还原剂,还原剂会随着炉膛内烟气的流动遍及炉膛内,延长了还原剂在炉膛内的停留时间,使得还原反应更充分,混合程度也优于炉膛顶部。同时,还原剂喷嘴在炉膛高度8~11 m处的脱硝效果相近,因此,还原剂喷嘴布设高度区间以8~11 m为宜。

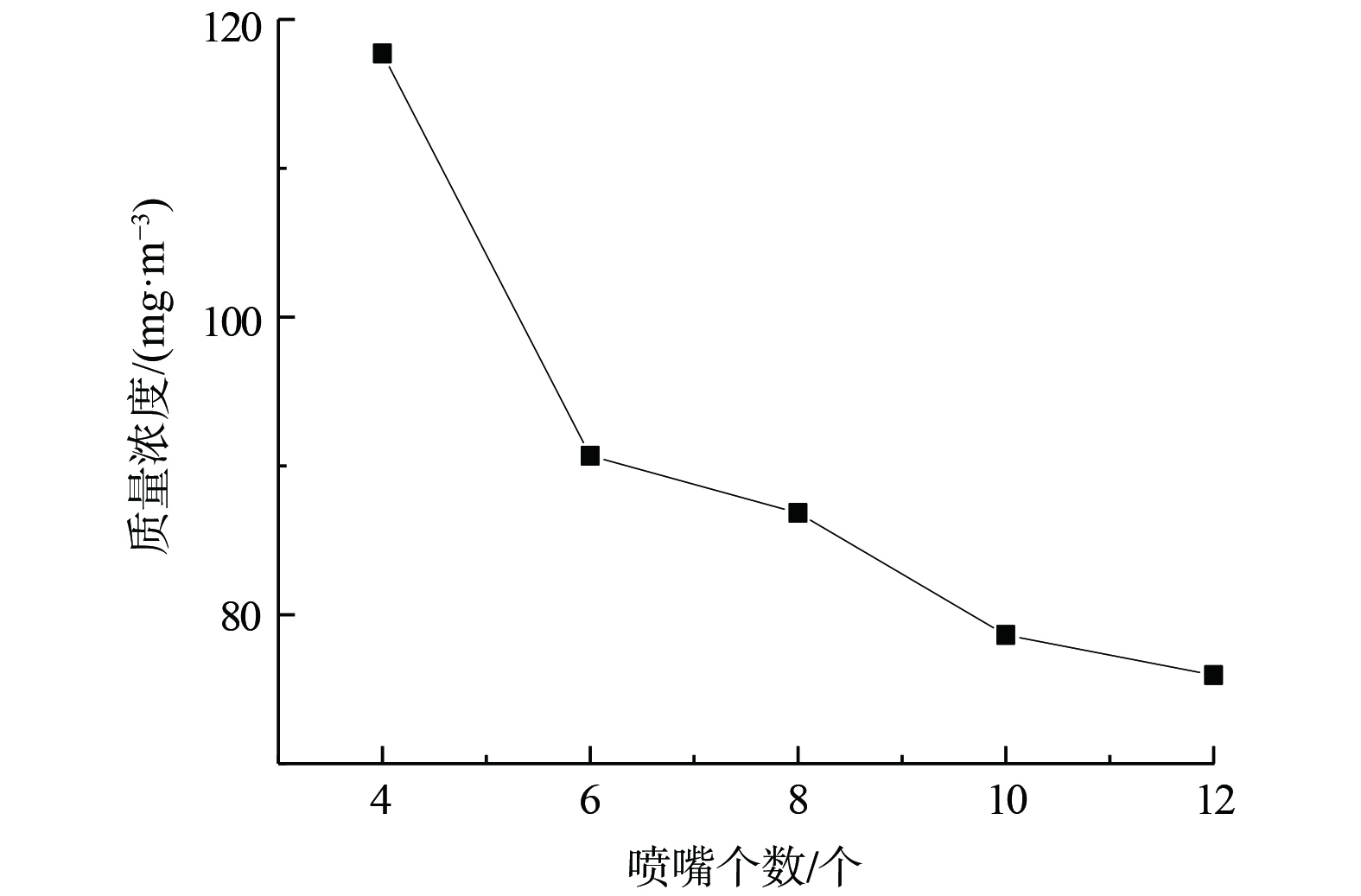

喷嘴数量与还原剂的用量呈正相关关系。喷嘴数量越多则还原剂用量会越多,在一定程度上可影响还原剂与烟气的混合程度[19],故脱硝效率就容易提升。但喷嘴数量的增加运行费用也随之增加,因此,应设计好适量的喷嘴数量,以求得脱硝效率与运行费用达到最佳平衡。模拟条件设置为:还原剂雾化粒径为1 μm,雾化角度为30°,还原剂注入温度为300 K,还原剂供给速度6~7 m∙s−1,还原剂用量0.0139 kg∙s−1。设置喷嘴数量为4支、6支、8支、10支、12支。由图10可知,随着还原剂喷枪数量的增加,烟道出口处的NO质量浓度逐渐降低。当喷枪数量由4个增加至6个时,NO质量浓度由117.7 mg∙m−3降至90.7 mg∙m−3。NO质量浓度的降低幅度较大说明了喷枪数量的增加对NO脱除效果显著。然而,喷枪数量从10个增至12个时,烟道出口处NO质量浓度降低趋势减缓。喷嘴烟道出口处NO质量浓度从78 mg∙m−3降至75.9 mg∙m−3,锅炉内脱硝效率最高达79.4%。根据河北省《锅炉大气污染物排放标准》 (DB13/5161-2020) 中生物质锅炉NOx排放标准低于80 mg∙m−3。因此,在保证运行成本的条件下,将还原剂喷嘴数量设置为10个。

-

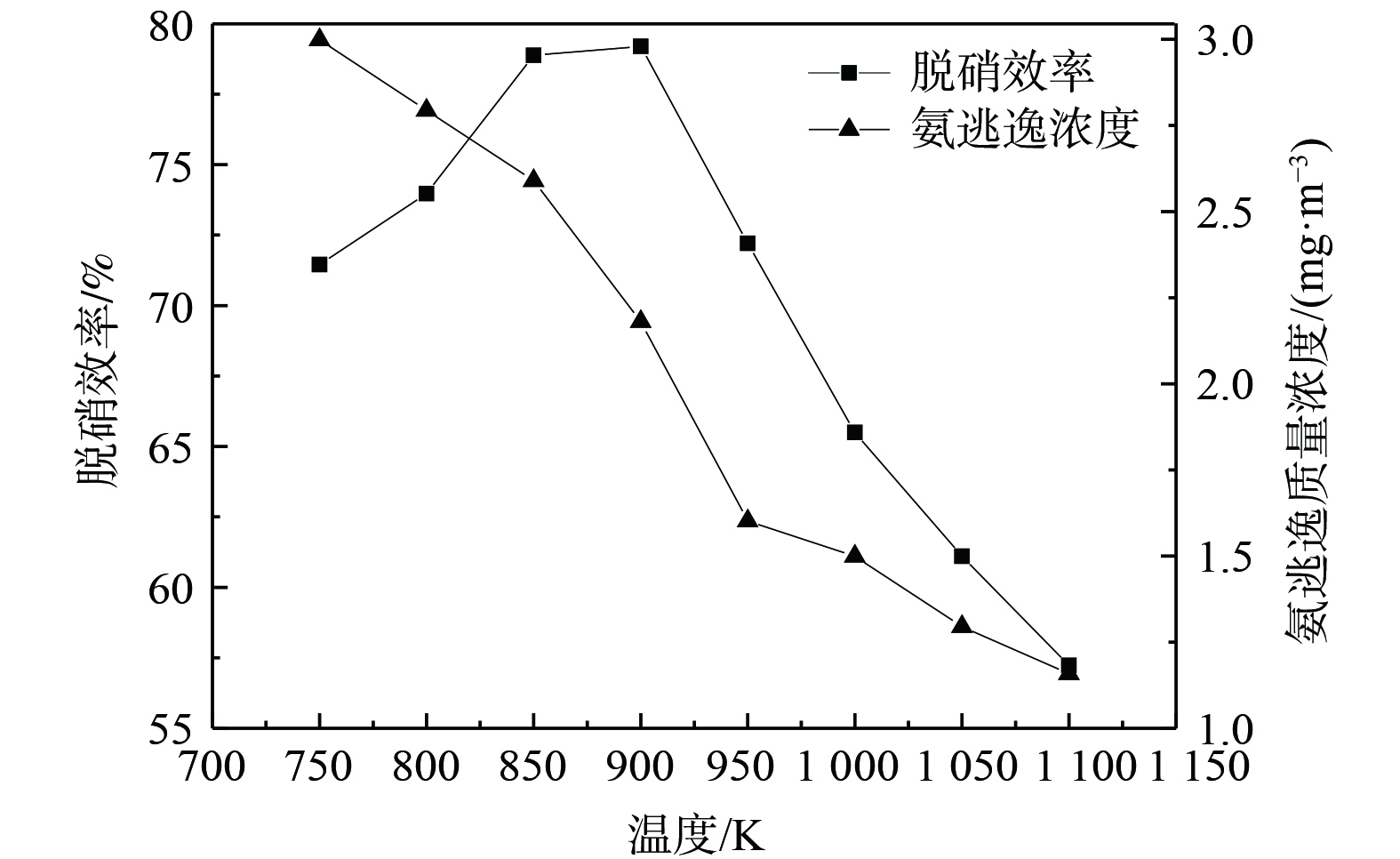

烟气中的NO还原是在特定温度下进行的。温度过高,会使部分还原剂氧化成NOx;温度过低,反应速率降低则会造成大量还原剂逃逸[20]。由于生物质锅炉炉膛温度偏低,一般达不到SNCR工艺所需的反应温度。因此,在实际运行中,通过提高还原剂供给速度,以提升还原剂与NO的反应速度,使得还原剂在低于1 000 K的温度内仍可达到较高的脱硝效率。此外,将还原剂的雾化粒径设置在40 μm以下,增强还原剂与NO的充分反应性,进而提升脱硝效率。设置模拟条件为:还原剂雾化粒径为1 μm,雾化角度为30°,还原剂注入温度为300 K,还原剂供给速度6~7 m∙s−1,还原剂用量0.0139 kg∙s−1。探究反应温度窗口为750~1 100 K时,烟道出口NO的质量浓度变化。由图11可知,随温度的增加炉膛内脱硝效率呈先上升后下降的趋势,氨逃逸量随着温度的增加呈下降趋势。当脱硝效率在70%以上时,生物质锅炉SNCR脱硝工艺的温度窗口为750~950 K。当生物质锅炉的反应温度分别处于850 K、900 K时,烟道出口NO的质量浓度分别为78 mg∙m−3、76.8 mg∙m−3,脱硝效率可达78%以上。而此时该生物质锅炉的氨逃逸量较小,还原剂逃逸量低于3 mg∙m−3。当温度为850~950 K时,氨逃逸量下降幅度明显;当温度为950~1100 K时,氨逃逸量趋于稳定。因此,当反应温度约为900 K时,锅炉脱硝效果最佳。当炉膛温度过高时,相比于NO的还原反应,炉膛内NH3发生的氧化反应占主导地位,从而导致脱硝效率降低至70%以下。

-

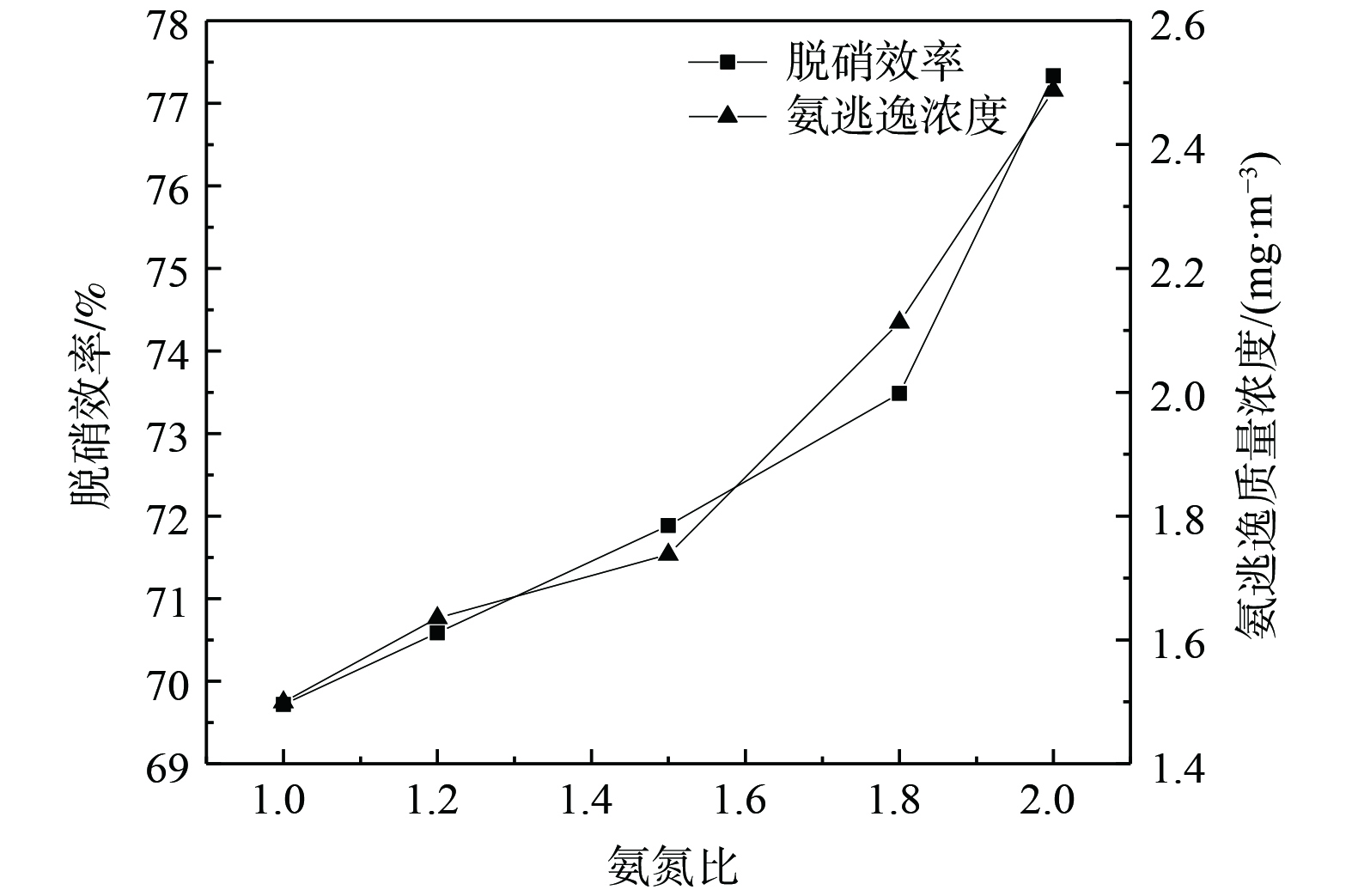

氨氮比指脱硝过程中喷入还原剂与待脱除NOx的当量比值,是影响SNCR反应脱硝效率的一个重要因素。控制还原剂雾化粒径为1 μm、雾化角度为30°,还原剂注入温度为300 K,还原剂供给速度6~7 m∙s−1,还原剂用量为0.0139 kg∙s−1。分别设置氨氮比为1、1.2、1.5、1.8、2,以研究不同氨氮比对脱硝效率的影响。由图12可知,随着氨氮比的增加,脱硝效率呈上升趋势。在氨氮比为1.0~1.8时,脱硝效率的上升幅度相对较平缓。而在氨氮比为1.8~2.0时,锅炉的脱硝效率上升幅度较陡。当氨氮比为1.2时,脱硝效率就已达到70%以上;当氨氮比为2时,脱硝效率高达77.3%。从氨逃逸来看,氨逃逸量呈上升趋势,当氨氮比为1.5时,氨逃逸量上升幅度增加。整体来看,随着氨氮比的增加,脱硝效率虽有所增加,但烟气脱硝效率仅有70%~80%,因此,结合氨逃逸量来看,并非氨氮比越高越好。当氨氮比为1.5左右时,能控制氨逃逸量为1.7 mg∙m−3,脱硝效率为71.9%,从而确保生物质锅炉烟气的脱硝效果呈最佳状态。

-

1) 与单一生物质相比,混合燃料具有较高的固定碳含量和较低N含量。混合燃料有利于提升生物质锅炉的热效能,并减少污染物排放。

2) 不同生物质燃料燃烧过程的数值模拟结果表明,混合燃料燃烧效果好,炉膛内温度高达1 140 K,烟气中NO排放的质量浓度最低,平均值为369.2 mg∙m−3;混合燃料的SO2排放浓度介于小麦秸秆与果木枝、树皮间,SO2生成量与燃料种类没有明显相关性;混合燃料的CO生成量较低、CO2的生成量最高。在烟气中,CO2排放量较高,降低生物质锅炉碳排放仍是值得关注的问题之一。

3) 以农林混合生物质燃料为研究对象,通过数值模拟探究了生物质锅炉SNCR影响因素。最佳条件为:将还原剂喷枪位置设置在8~11 m;还原剂喷嘴数量设置为10个;当反应温度约900 K、氨氮比为1.5,SNCR脱硝率高达78.7%,NO排放质量浓度最低为78.7 mg∙m−3。

Flue gas emission characteristics and SNCR denitrification numerical simulation of agro-forestry biomass boiler

- Received Date: 12/04/2022

- Available Online: 31/10/2022

-

Key words:

- biomass fuel /

- fuel composition /

- flue gas composition /

- numerical simulation /

- SNCR

Abstract: Biomass boiler of typical biomass power plant in Hebei Province is taken as the research object. On the basis of analyzing the composition of agricultural and forestry biomass fuel, FLUENT software is used to conduct numerical simulation of flue gas emission characteristics and SNCR denitration performance of biomass boiler. The results showed that, compared with single biomass, the mixture of wheat straw, fruit wood branch and bark with a ratio of 0.3:0.4:0.3 have lower nitrogen content (0.39%). The average emission concentration of NO in flue gas of different biomass fuels after boiler combustion is in the order of wheat straw (503.6 mg∙m−3) > fruit wood branch > bark > mixed fuel (369.2 mg∙m−3); SO2: wheat straw> mixed fuel > bark > fruit wood branch; CO: bark > wheat straw >mixed fuel > fruit wood branch. CO2: mixed fuel> fruit wood branch > bark > wheat straw. Numerical simulation of SNCR denitrification shows that when the height of reducing agent (urea) nozzles is set between 8 m and 11 m, the number of nozzles is 10, the reaction temperature is about 900 K, and the ammonia nitrogen ratio is 1.5, the SNCR denitrification rate is up to 78.7%, and the NO emission concentration is the lowest (78.7 mg∙m−3). The results show that the mixed agroforestry biomass fuel has better combustion performance, and the NO concentration generated by combustion is the lowest. Under the condition of meeting the optimal SNCR process operating parameters, NO is easier to achieve the requirements of low emissions.

DownLoad:

DownLoad: