-

印染废水具有水质复杂、pH变化大、色度高、COD高、可生化性差等特点,属于较难处理的工业废水之一[1-3]。处理印染废水的方法主要包括吸附法[4-7]、絮凝法[8-10]、生物法[11-12]、高级氧化[13-14]等,在实际应用中常将其中两种或多种方法联用来提高脱色效率,而在众多的染料中以水溶性阴离子染料最为常见且极难去除[15-16]。

常规的无机絮凝剂(铝盐、铁盐等)处理方法对水溶性染料不易形成胶体颗粒,在实际应用中往往通过加大投药量来解决脱色性差的问题,导致运行成本偏高,产泥量偏大[17-18]。而在众多有机絮凝剂中,阳离子型的双氰胺甲醛(DDF)高分子絮凝剂因其附带正电荷而对废水中的阴离子染料有良好的去除效果。但因其分子质量较低,导致其在絮凝脱色过程中形成的絮体数量少且体积小,沉降性差,废水出水浊度较高[19]。前人多使用3聚氰胺、聚合氯化铝、尿素、氯化铵、硫酸铵等对DDF进行改性,所制备的改性DDF对废水均有较高的脱色率,但对于较高的出水浊度并不能有效改善[19-24]。

聚丙烯腈(PAN)纤维被广泛应用于诸多行业。此外,丙烯腈易与多种单体发生共聚反应,其分子链中的氰基也为PAN纤维进一步功能化提供了可能[25-28]。为改善DDF在脱色过程中的絮凝效果,降低出水浊度,本实验以PAN为基体接枝DDF,增大其分子质量,制得阳离子型有机高分子絮凝剂PAN-DDF。选择了直接染料、酸性染料、活性染料3类阴离子染料的代表染料,刚果红、酸性兰9、活性嫩黄K-6G,并对其单一染料组分和混合染料组分的模拟废水进行脱色实验,采用单因素法考察了PAN-DDF投加量、沉淀时间、pH、温度对絮凝脱色效果的影响,通过粘度法测定了PAN-DDF的分子质量,并使用扫描电镜对其进行微观形态分析,使用傅里叶变换红外光谱对其进行结构分析。

全文HTML

-

实验主要仪器包括ZR4-6六联混凝实验搅拌机,LH-NYU3M浊度测定仪,UV-1800S紫外/可见光光度仪,KDM-2000调温电热加热套,FlexSEM1000扫描电子显微镜,FTIR-850傅里叶变换红外光谱仪。

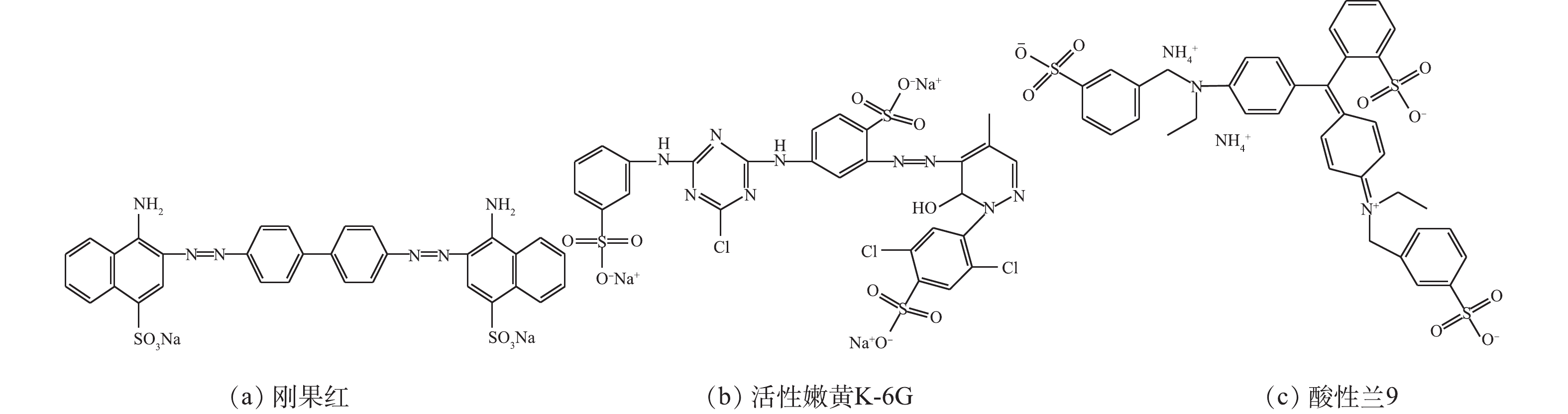

实验所用PAN购买于诸城市瑞祥纺织有限公司;主要试剂包括N-N二甲基甲酰胺,国药集团化学试剂有限公司;丙酮,国药集团化学试剂有限公司;氯苯,阿拉丁化学试剂公司;以上试剂均为分析纯。实验所用染料及其性质如表1所示,实验所用染料分子结构如图1所示。

-

近年来对于DDF的研究颇多。有研究[29-32]表明,合成DDF时甲醛、双氰胺和氯化铵的物料摩尔比在(1.8~2.2)∶1∶(0.7~0.9),而市场上的DDF在实际应用中均表现出了不同的脱色效果。为保证产物具有优异的脱色除浊性,经前期实验对比,确定DDF聚合物的合成条件为:甲醛、双氰胺、氯化铵的物质的量比为2∶1∶0.7,反应温度为70 ℃,反应时间为2 h。

-

首先将PAN纤维用沸水冲洗若干次,再经丙酮浸洗3遍,用氯苯溶胀24 h后经50 ℃恒温干燥后研磨成粉。称取10 g经过预处理的PAN加入盛有N-N二甲基甲酰胺的3口烧瓶,在常温下搅拌至PAN完全溶解于N-N二甲基甲酰胺中后,加入3倍于PAN质量的已合成的DDF聚合物,加热至90 ℃恒温,在pH>9下持续搅拌,反应4 h后,直至白色浑浊液体变为黄色浑浊液体,待冷却至常温后将产物溶液放入烧杯中,加入丙酮溶液进行沉析,最后经离心分离得到纯化后产物,经干燥后得到PAN-DDF黄色粉末,产率为65.85%,接枝率为163.4%。PAN与DDF之间的反应如式(1)所示。

(1)

(1)

-

1)单一染料组分模拟废水脱色实验。分别配置染料浓度为20 mg·L−1的刚果红、活性嫩黄K-6G和酸性兰9模拟废水200 mL,依次加入PAN-DDF絮凝剂。调节pH后,以200 r·min−1搅拌2 min、再以50 r·min−1搅拌15 min,静置沉淀后,取上清液测试其浊度和吸光度,从而计算脱色率。

2)混合染料组分模拟废水脱色实验。将上述3种染料溶液等比例混合配置为染料浓度20 mg·L−1的混合染料组分模拟废水,此时刚果红、活性嫩黄K-6G、酸性兰9的吸光度分别为0.591、0.131、0.310,浓度分别为14.82、15.91、15.15 mg·L−1。取200 mL混合模拟废水于烧杯中,依次加入PAN-DDF絮凝剂。调节pH后,以200 r·min−1搅拌2 min,50 r·min−1搅拌15 min,静置沉淀后,取上清液测试其浊度和吸光度值,从而计算脱色率。

-

采用SX-620笔式pH计进行测定。将经过校准后的pH计浸润进待测的模拟废水中,待显示的pH稳定后读取读数。取待测样品上清液20 mL置于φ为25 mm比色管中,放入已校准过后的浊度测定仪中,待显示的浊度数值稳定后读取读数。浊度单位为NTU。采用傅里叶变换红外光谱仪分析PAN-DDF絮凝剂中带有的活性基团;采用扫描电子显微镜FlexSEM1000观察PAN-DDF絮凝剂表面微观结构。我国常用的废水色度分析方法有稀释倍数法、铂钴比色法、铬钴比色法,其均属于目视比色,会带来极大的操作误差[33],故可使用紫外/可见光光度仪在各类染料模拟废水的最大吸收波长下测量其絮凝后上清液的吸光度,根据吸光度-浓度标准曲线,倒推对应的染料浓度,计算脱色率[34-35](式(2))。

式中:T为脱色率;C1为模拟废水中的染料浓度,mg·L−1;C2为上清液中的染料浓度,mg·L−1。

采用黏度法测定PAN-DDF的分子质量[36]。PAN-DDF聚合单元分子质量为250 Da,则PAN-DDF聚合度根据式(3)进行计算。

式中:D为PAN-DDF的聚合度;

$ {M_{{\rm{PAN}} - {\rm{DDF}}}} $ 为PAN-DDF的分子质量,Da。

1.1. 实验仪器与药品

1.2. 实验所用DDF

1.3. PAN-DDF絮凝剂的制备

1.4. 脱色实验

1.5. 测定方法

-

黏度法测得PAN-DDF的分子质量为1 086 718 Da,根据式(3)计算可得,PAN-DDF的聚合度为4 347,而DDF的分子质量仅为1 000~10 000 Da[37],这说明PAN-DDF具有优异的脱色除浊性能。

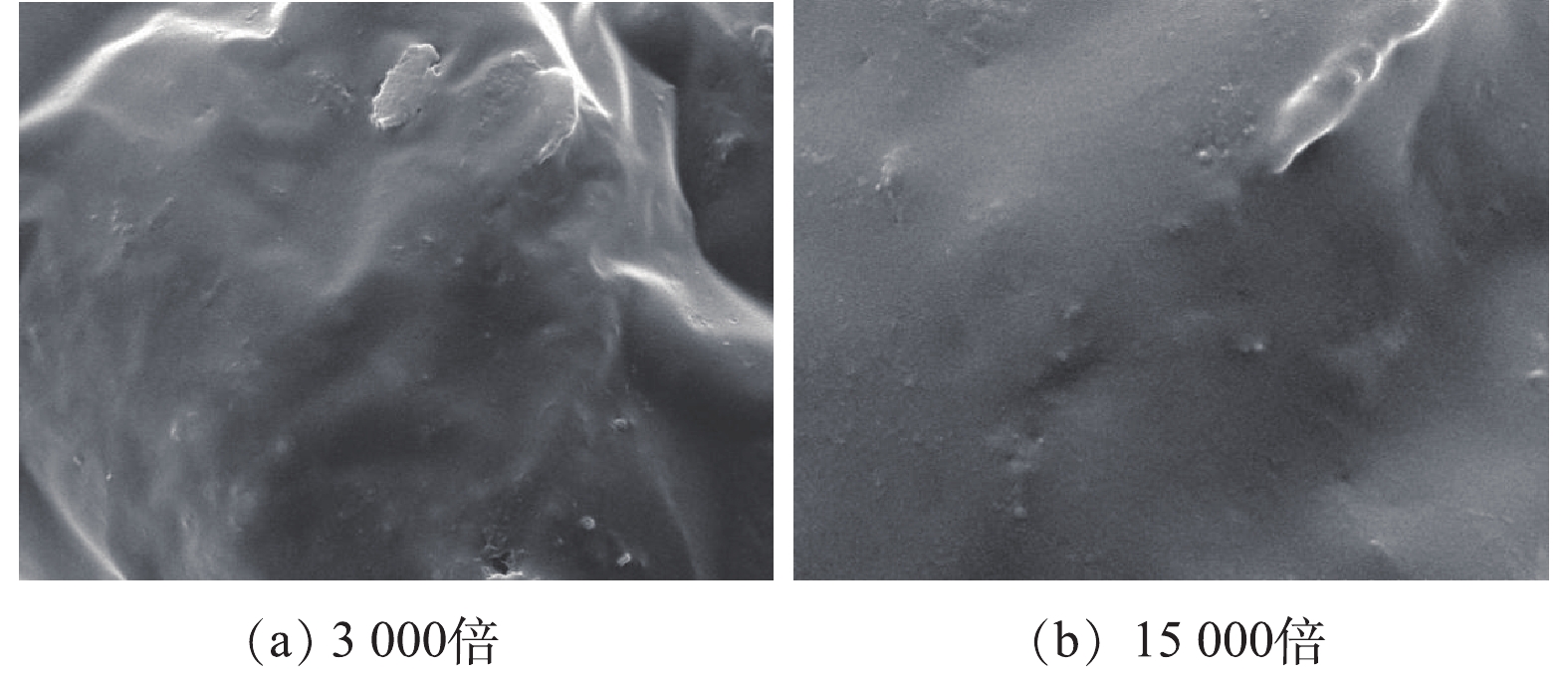

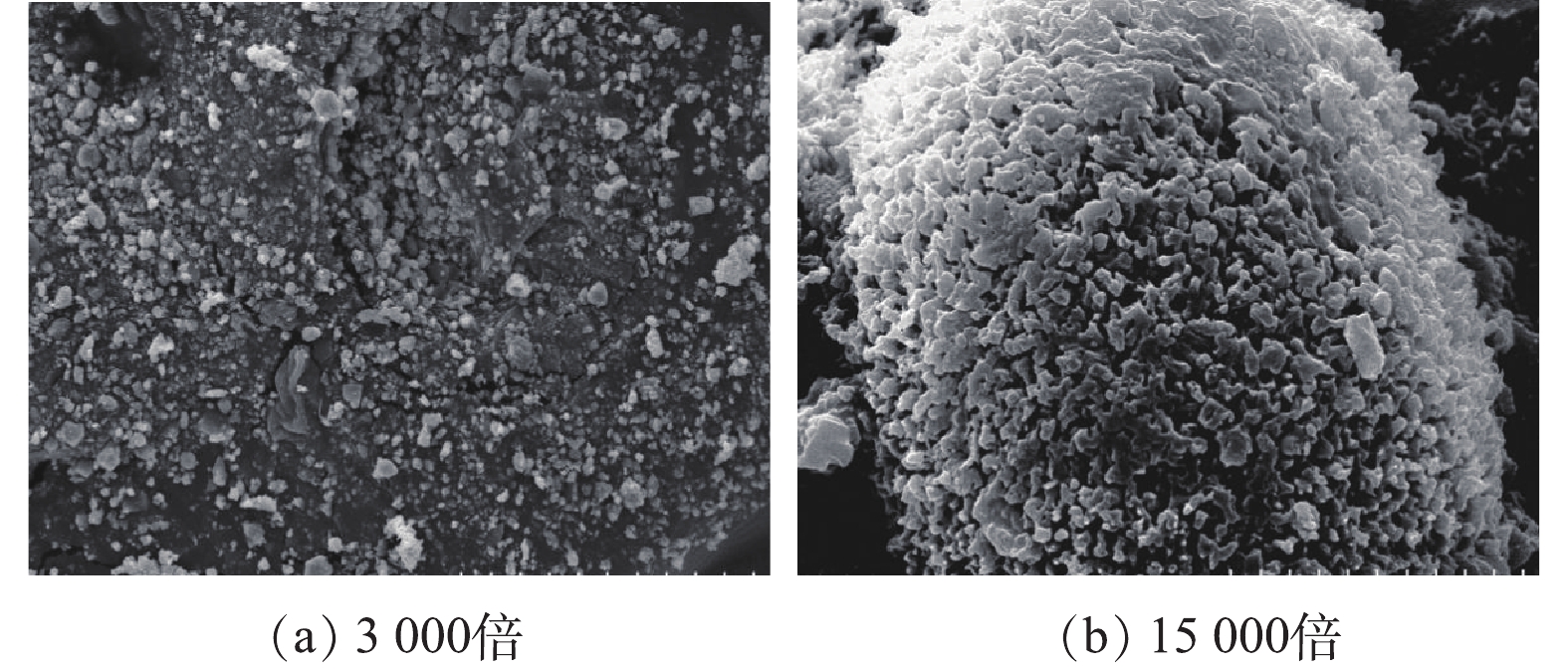

如图2和图3所示,原PAN粉末表面光滑,经接枝DDF后可明显看出,样品表面结构发生了改变,附着大量不规则颗粒,其呈粉末状聚集。与原来光滑表面相比,PAN接枝DDF后表面较为粗糙,这表明PAN已成功接枝DDF。

-

通常4 000~2 500 cm−1区被认为是X—H(X可为C、O、N、S等)伸缩振动区。如图4所示,PAN-DDF絮凝剂在此区域有一强吸收峰,由于絮凝剂为胺类化合物,此处应为N—H类伸缩振动,由此可判断,絮凝剂中含有伯胺基或仲胺基。其中,絮凝剂在3 385 cm−1处为—NH2对称伸缩振动峰,且峰面积较大;在1 080 cm−1处为羟甲基—CH2OH伸缩振动峰;通常1 400~1 700 cm−1处被认为是伯胺盐和仲胺盐的N—H剪式振动引起的吸收峰。由此可见,PAN-DDF絮凝剂分子可能以伯胺盐或仲胺盐形式存在,正是伯胺盐或仲胺盐的存在使其带有正电荷,在絮凝沉淀阶段发挥吸附电中和作用,对染料废水达到絮凝脱色目的。由以上结果可以判断,PAN-DDF絮凝剂中含有—NH2、—NH、—NH+、—

$ {\rm{NH}}_{\rm{3}}^{\rm{ + }}$ 、C=N=C等基团,这表明PAN已成功接枝DDF。 -

刚果红分子上含有—OH、—NH2、—

$ {\rm{SO}}_{\rm{3}}^{\rm{ - }}$ 等基团,—$ {\rm{SO}}_{\rm{3}}^{\rm{ - }}$ 可与PAN-DDF上的—NH2、—NH—等基团发生反应,—OH、—NH2基团可与PAN-DDF上的—OH、—NH2形成氢键,其线性形态更有利于刚果红与PAN-DDF之间的相互作用。酸性兰9分子上的—$ {\rm{SO}}_{\rm{3}}^{\rm{ - }}$ 在H+的作用下可在水溶液中游离出来,可与PAN-DDF上的—NH2化合成盐,使其分子质量增大。活性嫩黄K-6G分子中含有活性基团Cl−,可与PAN-DDF分子上的—OH、—NH2发生反应形成共价键[38]。染料分子上的—$ {\rm{SO}}_{\rm{3}}^{\rm{ - }}$ 数目越多,则废水的脱色率越高;当染料的—$ {\rm{SO}}_{\rm{3}}^{\rm{ - }}$ 数目相同时,其脱色效果受芳环结构的影响较大;染料分子中芳环的体积越大,染料的脱色率越高[39]。刚果红分子上分别含有2个—$ {\rm{SO}}_{\rm{3}}^{\rm{ - }}$ 、苯环、萘、酸性兰9分子中含有3个—$ {\rm{SO}}_{\rm{3}}^{\rm{ - }}$ 、4个苯环,活性嫩黄K-6G分子中含有3个—$ {\rm{SO}}_{\rm{3}}^{\rm{ - }}$ 和2个苯环。此外,这3种染料均携带负电荷基团,其可与PAN-DDF在絮凝沉淀阶段发挥吸附电中和的作用。综上所述,在絮凝脱色过程中,3种染料分子与PAN-DDF之间的相互作用受到了化学作用、疏水作用、吸附电中和等因素的共同制约,从而使PAN-DDF对3种染料表现出不同的脱色效果。

-

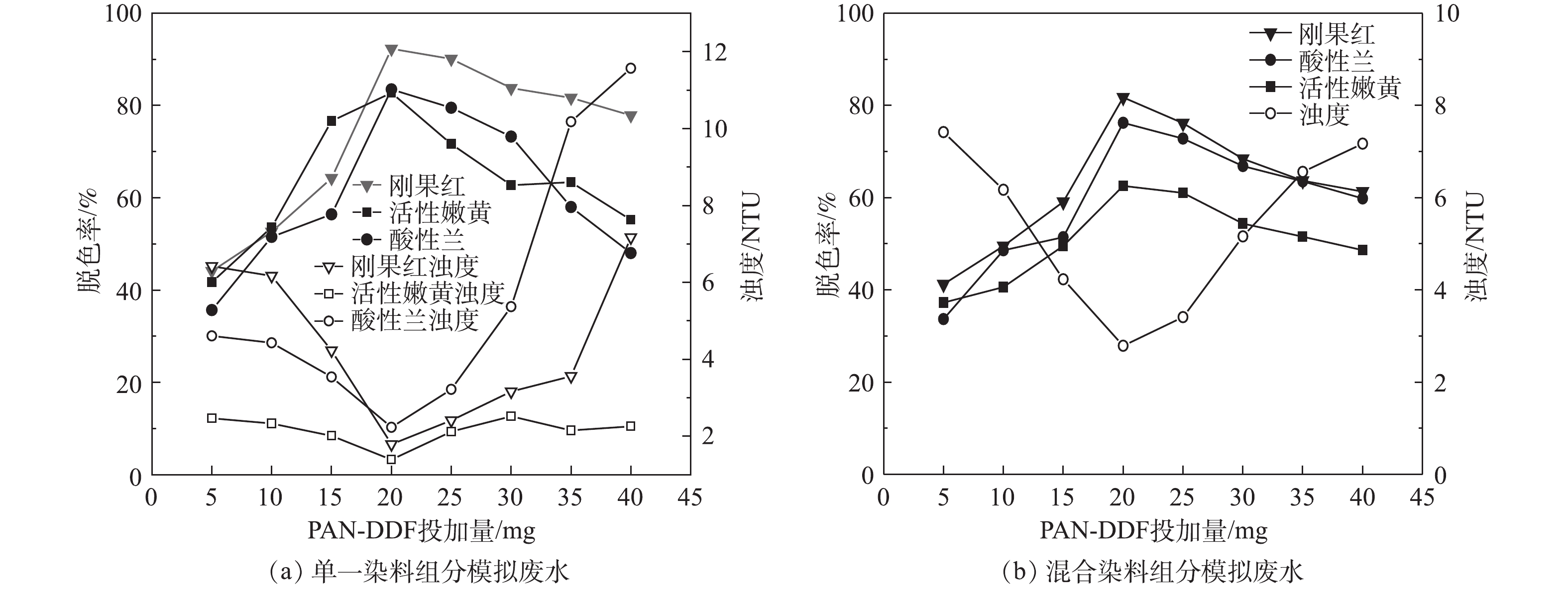

1) PAN-DDF投加量对染料脱色效果的影响如图5所示。随着PAN-DDF投加量的增加,3种染料的脱色率先上升后降低,且同时伴随着浊度的先降低后升高。在PAN-DDF的投加量为20 mg时,模拟废水上清液的浊度最低、脱色率最高。此时,刚果红、酸性兰9、活性嫩黄K-6G 3种染料模拟废水上清液浊度分别为1.79、2.23、1.39 NTU,3种染料的脱色率分别为92.31%、83.53%、82.78%;混合染料组分模拟废水上清液浊度为2.79 NTU,3种染料的脱色率分别为81.74%、76.24%、62.57%。可以明显看出,PAN-DDF在同等实验条件下在混合染料组分模拟废水中的脱色效果较差于单一染料组分模拟废水,这可能与染料分子之间相互作用有关。

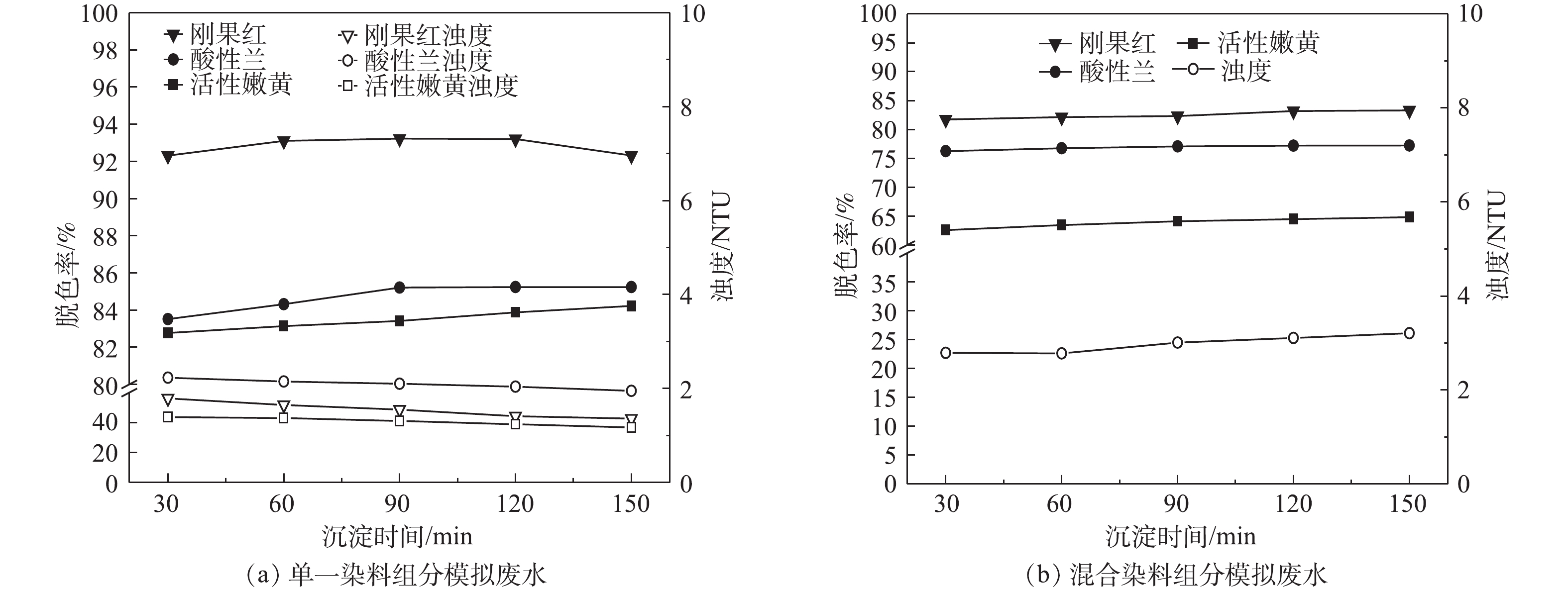

2)沉淀时间对脱色效果的影响结果如图6所示。从30 min开始,随着絮凝沉淀时间的增加,PAN-DDF对于3种染料的脱色效果影响逐渐变弱,脱色率与浊度均变化不大。但相比于单一染料模拟废水,混合染料模拟废水的脱色率有所降低,而浊度有所提升。考虑到在工程应用中延长沉淀时间会增加废水的处理成本,所以本文中PAN-DDF对模拟废水的最佳沉降时间为30 min。

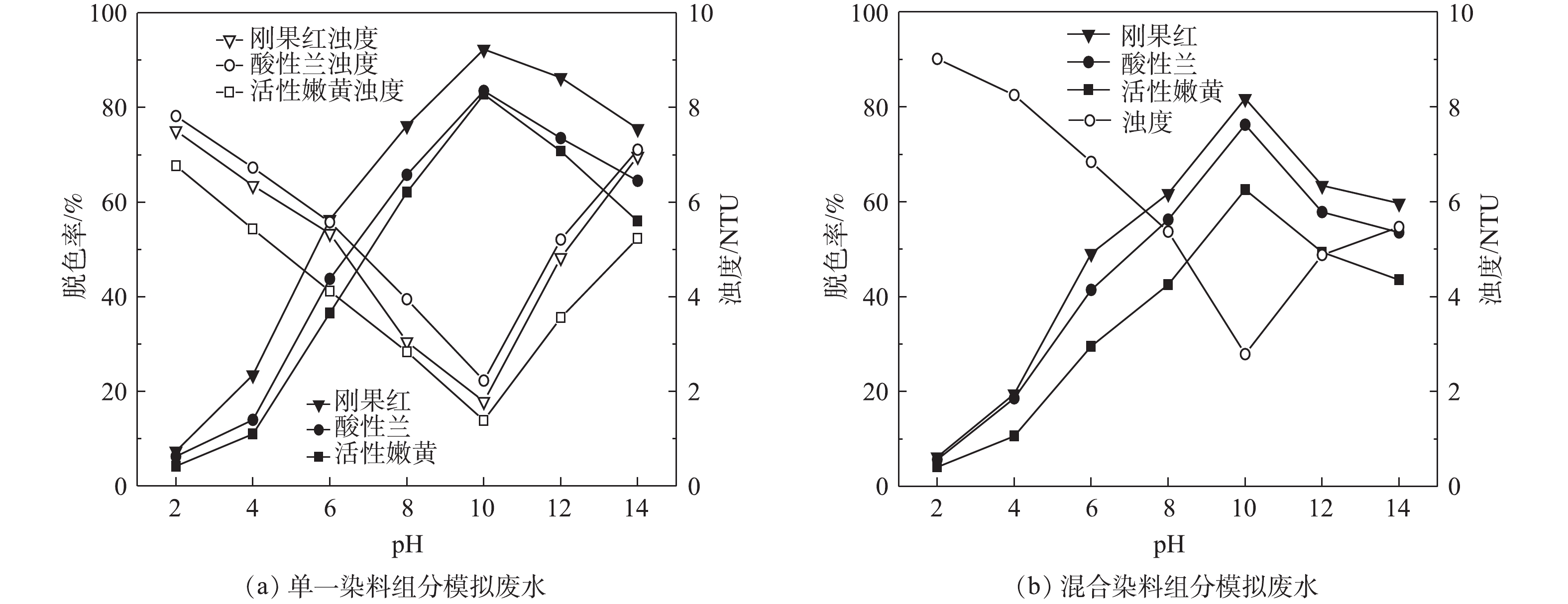

3) pH对脱色效果的影响如图7所示。随着模拟废水pH的升高,3种染料的脱色率先上升后降低,且同时伴随着浊度的先降低后升高。在pH为10时,脱色效果最好,此时,单一染料组分模拟废水中,刚果红、酸性兰9、活性嫩黄K-6G的脱色率分别为92.31%、83.53%、82.78%,浊度分别为1.79、2.23、1.39 NTU;而混合染料组分模拟废水的脱色效果有所下降。其原因为:PAN-DDF水溶液呈弱碱性,调节pH时所用的盐酸标准溶液与原模拟废水先发生酸碱中和反应,在强酸性条件下,染料分子上的—NH2、—SO3等基团得到H+而被质子化,导致刚果红染料表面带正电,不利于吸附与架桥作用;在碱性条件下,OH−与属性阴离子的刚果红分子会产生竞争吸附,不利于染料分子的去除[40]。同时,PAN-DDF是一种季铵盐的阳离子型絮凝剂,在废水pH过高的条件下,其所带的—C—

$ {\rm{NH}}_{\rm{3}}^{\rm{ + }}$ 和C=N+=C基团会在OH−的影响下转变为—C—NH2和C=N=C,导致絮凝剂所带的正电荷基团逐渐被转为中性基团,絮凝能力下降[41]。4)温度对脱色效果的影响。由表2可知,模拟废水在10 ℃和40 ℃时脱色效果较差;在30 ℃时脱色效果最好。由表3可知,在相同实验条件下,混合组分模拟废水的脱色效果较差于单一组分模拟废水。其原因为:在温度较低时,絮凝剂分子和染料胶体颗粒运动缓慢,有效碰撞概率降低,电中和作用和吸附作用均减弱,形成的絮体少且小,架桥卷扫作用也随之减弱,故脱色率较低;当温度较高时,分子运动速率加快,有效碰撞概率增大,电中和作用显著,絮体随之增大,架桥卷扫作用明显,脱色率较高;但温度过高会导致染料颗粒脱离絮凝剂长链的吸附,降低吸附架桥作用,从而影响其脱色效果。

2.1. PAN-DDF分子质量的测定及扫描电镜分析

2.2. PAN-DDF红外光谱分析

2.3. 絮凝脱色机理分析

2.4. PAN-DDF对模拟染料废水脱色条件的优化

-

1)PAN-DDF对刚果红、活性嫩黄K-6G和酸性兰9模拟废水的脱色率明显高于单独DDF,并且有效降低了废水出水浊度;PAN-DDF对模拟废水的脱色与除浊效果一致,在相同实验条件下,脱色率的变化总伴随者浊度的相应变化。

2)在30 ℃下,在200 mL染料浓度为20 mg·L−1、pH=10的模拟废水中投加20 mg PAN-DDF,沉淀30 min后,对其脱色和除浊效果可达到最佳。

3)相比于含有单一染料组分模拟废水,混合染料组分模拟废水的脱色效果有所降低,这与混合染料组分模拟废水中染料分子的相互作用有关。在絮凝脱色过程中,3种染料分子与PAN-DDF之间的相互作用受到了化学作用、疏水作用、吸附电中和等因素的共同制约,故使得PAN-DDF对3种染料表现出不同的脱色效果。

下载:

下载: