-

SO2、NOx会污染环境、造成酸雨、破坏臭氧[1-2]。2016年,我国发布《“十三五”生态环境保护规划》,提出了对SO2、NOx减排15%的要求。除了工业节能减排,开发及改进现有脱硫脱硝技术同样重要。目前,工业领域主流SO2、NOx净化技术为湿法脱硫和选择性催化还原法(selective catalytic reduction,SCR)[3-4]。这2种技术成本较高且易产生二次污染[5],而生物处理法因其成本低、操作简单、二次污染小等优势逐渐受到关注。

生物转鼓是一种处理废气污染物的新型生物反应器,可有效规避生物过滤和生物滴滤等传统废气生物处理工艺中填料易堵塞、污染物分布不均匀、气液传质差等问题。生物转鼓可在厌氧条件下去除SO2和NO,但需额外添加络合剂FeII(EDTA)以促进NO的传质效果[6-7]。有研究表明,在生物滴滤塔同步净化SO2和NOx时,充以O2可提高NOx的去除率[8-9]。但该方法还未应用于生物转鼓中。

为优化生物转鼓脱硫脱硝工艺性能,本研究在自制模拟装置中,探究好氧条件下生物转鼓的挂膜启动过程、生物相群落组成,考察不同进气质量浓度下生物转鼓对NOx、SO2的净化效果和去除负荷,并探讨了生物转鼓好氧同步脱硫脱硝过程中N和S的转化途径,以期为生物转鼓的好氧工艺优化提供参考。

-

生物转鼓实验装置如图1所示。装置主体部分由有机玻璃材料制得,为全密闭设计,外部采用不锈钢材料支撑,并配以温度控制和气压监测等功能。生物转鼓反应器长382 mm、宽284 mm、高470 mm,总容积为50.99 L;填料采用改性聚氨酯海绵(孔径为1 mm),填料外径为224 mm、内径为101 mm、宽160 mm,体积为5.02 L。废气从生物转鼓顶部进入,经填料上的微生物净化后,从转鼓中间的空心转轴向外排出。运行过程中,转轴缓慢转动可使填料间歇接触转鼓反应器底部的营养液,为填料上的微生物提供营养物质和水分。

活性污泥取自宁波市污水处理厂二沉池。营养液中营养物质的质量浓度分别为:C6H12O6 3 500 mg·L−1、NaCl 500 mg·L−1、K2HPO4 2 000 mg·L−1、MgSO4·7H2O 600 mg·L−1、NaHCO3 500 mg·L−1、CaCl2 55.4 mg·L−1、CaSO4·5H2O 15.7 mg·L−1、CoCl2·6H2O 16.1 mg·L−1、MnCl2·4H2O 50.6 mg·L−1、ZnSO4·7H2O 220 mg·L−1、FeSO4·7H2O 49.9 mg·L−1。

-

在活性污泥静置沉降2 h后,取10 L沉降污泥与10 L营养液混合均匀,加入生物转鼓;以NaNO3和Na2SO4作为氮源和硫源,对污泥中的反硝化细菌(denitrifying bacteria,DNB)和硫酸盐还原菌(sulfate reducting bacteria,SRB)进行富集培养,驯化挂膜。其中,NaNO3的质量浓度从100 mg·L−1逐步递增至1 200 mg·L−1,Na2SO4的质量浓度从200 mg·L−1逐步递增至1 600 mg·L−1。每隔24 h检测营养液中NO3−和SO42−的质量浓度。当营养液中NO3−和SO42−去除负荷相对稳定时,视为启动完成。整个驯化挂膜期为35 d。运行期间,温度控制在28~30 ℃、转速为3 r·min−1、液相体积为20 L;每天更换营养液2 L;用1 mol·L−1的HCl或NaOH溶液调节液相pH为6.5~7.5。

-

1)不同进气SO2、NOx浓度下生物转鼓的脱硫脱硝效果。生物转鼓正常启动后,开始通入含NOx和SO2的废气;NOx质量浓度从100 mg·m−3逐步递增至1 200 mg·m−3,SO2质量浓度从200 mg·m−3逐步递增至2 400 mg·m−3。运行过程共35 d。期间每天监测进气和出气中NOx和SO2的质量浓度,同样维持液相pH为6.5~7.5。

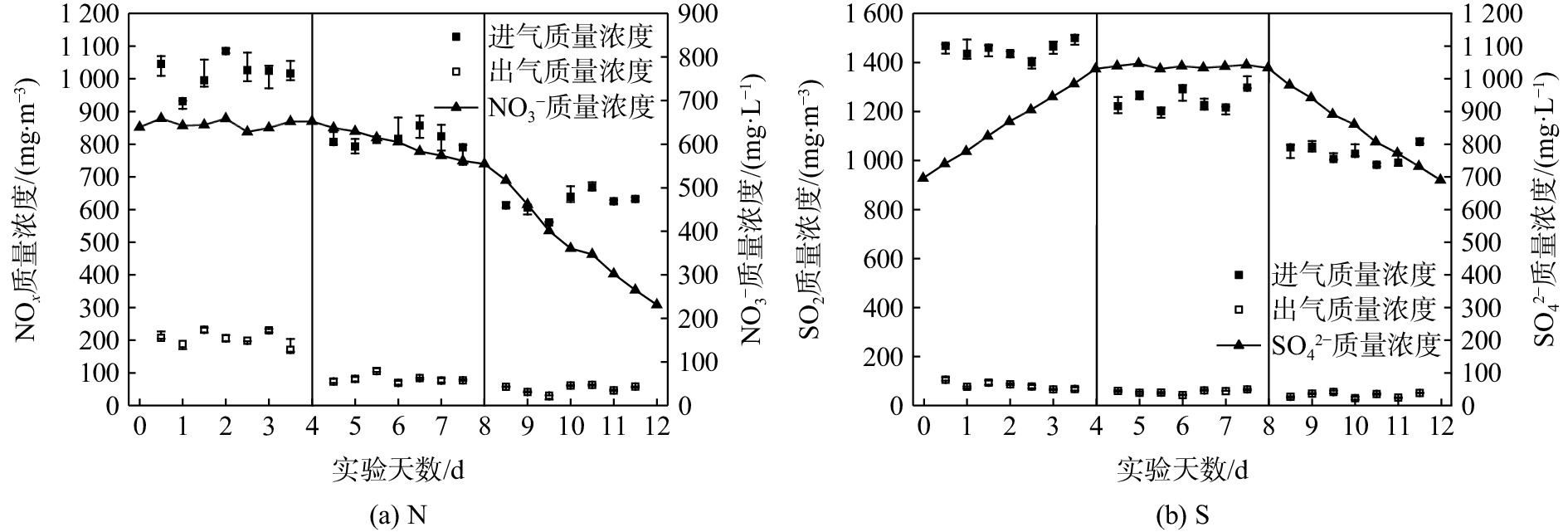

2)生物转鼓中N和S含量的变化。运行过程共12 d。在实验开始前更换10 L营养液,过程中不再更换。考察不同进气质量浓度下生物转鼓中N和S含量的变化,期间每隔12 h监测1次N(NOx、NO3−)和S(SO2、SO42−)的质量浓度。

-

上述实验均保持24 h连续进气,气体流速为0.24 m3·h−1,其余条件与启动阶段保持一致。SO2的制备方法:将1 mol·L−1的H2SO4溶液滴入1 mol·L−1的Na2SO3溶液进行反应而制得(式(1))。NOx的制备方法:将1 mol·L−1的H2SO4溶液滴入1 mol·L−1的NaNO2溶液进行反应而制得(式(2))。

通过调整Na2SO3和NaNO2溶液的滴定速度来控制SO2和NOx的质量浓度,并用空气泵将其从反应瓶中吹出,即制得实验所需SO2和NOx。

采用盐酸萘乙二胺分光光度法[10]测定NOx的质量浓度;采用甲醛吸收-副玫瑰苯胺分光光度法[11]测定SO2质量浓度;采用UV-1800型紫外可见分光光度计测定吸光度;采用ICS-600离子色谱仪测定液相中NO3−和SO42−的质量浓度。生物群落结构分析委托生工生物工程(上海)股份有限公司完成。N或S的去除负荷根据式(3)计算。

式中:RG为NOx-N或SO2-S的去除负荷,mg·(L·h)−1;M1为NOx-N或SO2-S的质量分数,%;Cin为NOx或SO2的进气质量浓度,mg·m−3;Cout为NOx或SO2的出气质量浓度,mg·m−3;Q为气体流量,m3·h−1;V为填料体积,L。

式中:RL为NO3−-N或SO42−-S去除负荷,mg·(L·h)−1;M2为NO3−-N或SO42−-S的质量分数,%;C为液相中的NO3−或SO42−的质量浓度,mg·L−1;C’为h小时后液相中NO3−或SO42−的质量浓度,mg·L−1;VL为液相体积,L;h为2次检测时间间隔,h。

-

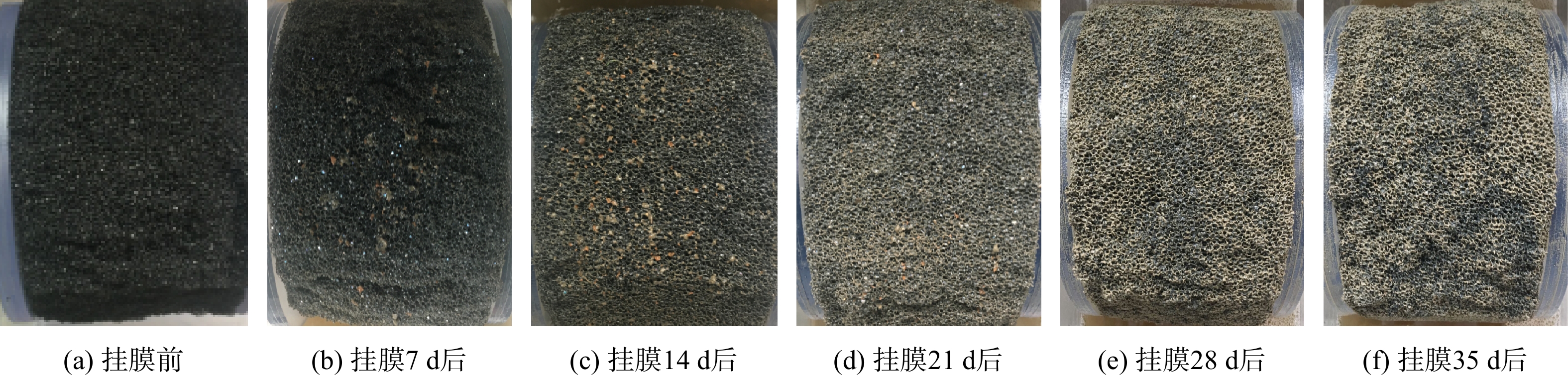

图2为启动阶段转鼓填料挂膜状态,反映了微生物的生长情况。经过35 d的驯化挂膜,液相中的微生物逐渐吸附至填料上,最终填料表面被一层棕黄色生物膜包裹。另外,在前7 d,微生物挂膜速度较慢,填料上只零星出现一些黄褐色斑点;在第7~21天,填料上的生物膜增长十分迅速;到挂膜21 d时,生物膜已将填料完全包裹,完整的生物膜基本形成;此后,生物膜基本稳定,无明显变化。

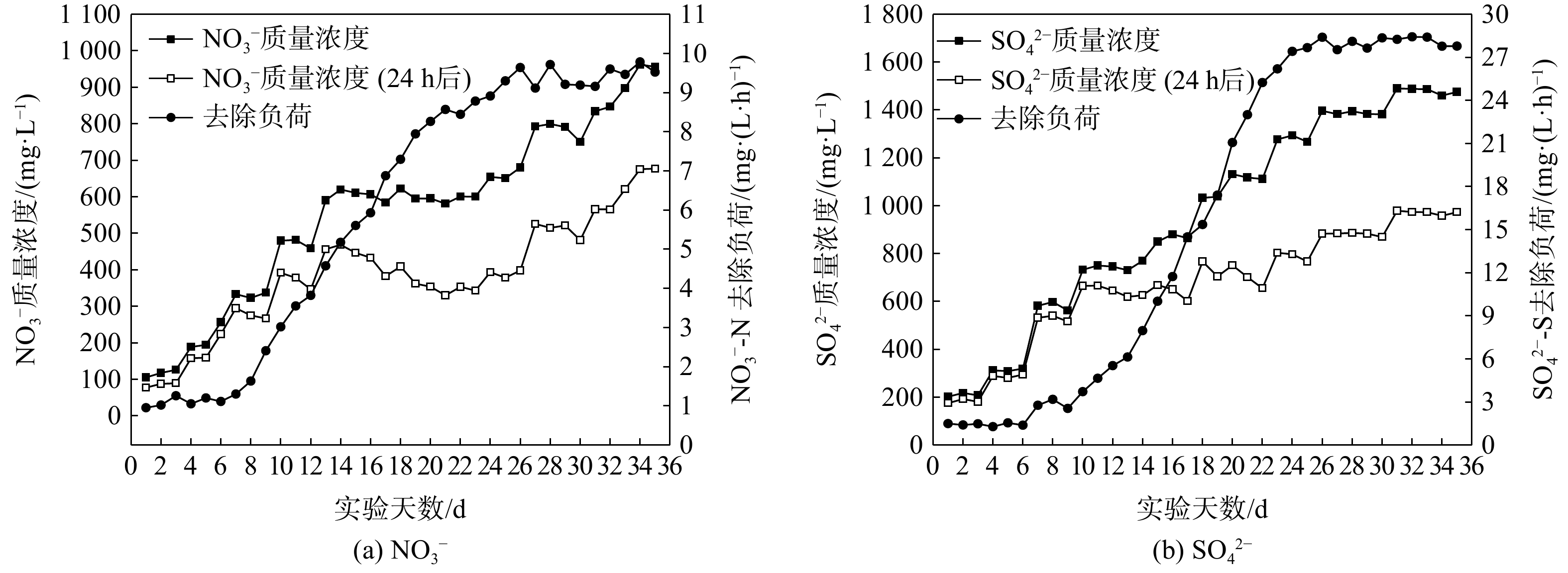

液相中NO3−-N和SO42−-S去除负荷变化亦能侧面反映系统内微生物的生长状态(见图3)。在第8~24天,生物转鼓对NO3−-N和SO42−-S的去除负荷均明显提高,并在第24天之后达到饱和。最终,生物相中NO3−-N和SO42−-S的去除负荷分别为9.45和28.12 mg·(L·h)−1。此外,图3反映的DNB和SRB生长规律,与图2中活性污泥驯化挂膜变化相吻合。由此确定,生物转鼓同步脱硫脱硝的启动即挂膜完成时间约为25 d,其中第一周为适应期,后两周进入对数期,之后微生物繁殖旺盛,挂膜迅速完成。

在挂膜完成、生物相保持稳定后,通过高通量测序技术分析生物相的群落结构,结果如图4所示。填料中生物相的优势门为变形菌门(25%)、拟杆菌门(22%)、厚壁菌门(22%)、绿弯菌门(11%)、浮霉菌门(9%)。其中,变形菌门、拟杆菌门、绿弯菌门对N和S的去除起到了关键作用[12-13]。3个门的优势属分别Hyphomicrobium、Prevotella、Anaeroline。

-

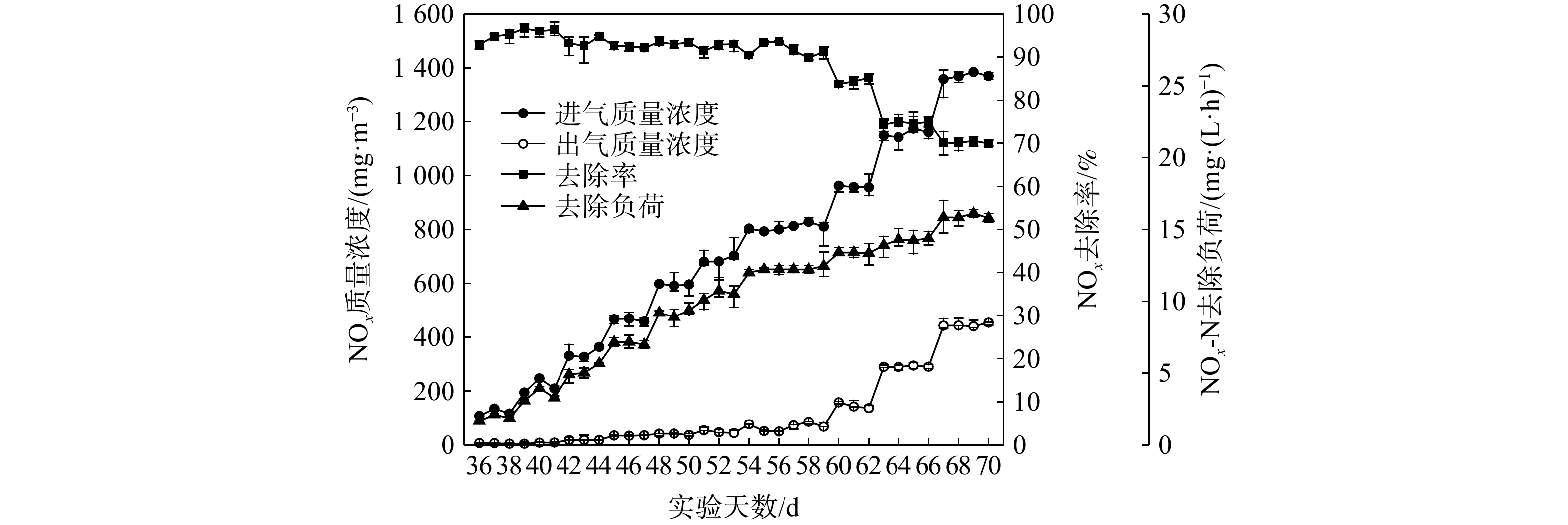

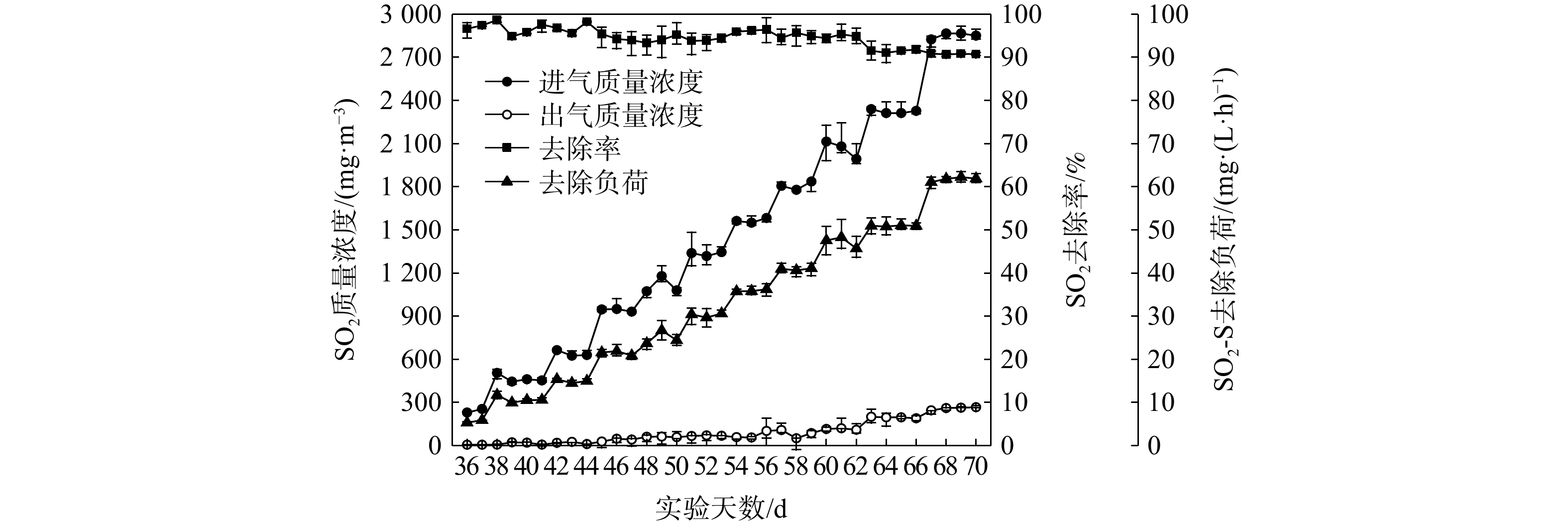

图5表明生物转鼓对NOx的去除率随进气NOx质量浓度增加而降低。当进气NOx质量浓度低于800 mg·m−3时,NOx的去除率保持在90%以上;当进气NOx质量浓度为950 mg·m−3时,NOx的去除率降至85%;当进气NOx质量浓度达到1 400 mg·m−3时,NOx的去除率已降至70%,出气NOx质量浓度达450 mg·m−3。而NOx-N去除负荷则随进气NOx质量浓度的增加,呈上升趋势,最大NOx-N去除负荷为16.1 mg·(L·h)−1。图6反映出:生物转鼓对SO2的去除率会随进气SO2质量浓度增加而降低。然而,相比于NOx,SO2的去除下降趋势较慢。在进气SO2质量浓度低于2 000 mg·m−3时,对SO2的去除率大于94%;当进气SO2质量浓度为2 800 mg·m−3时,去除率仍有90%。同样,SO2-S去除负荷也随着SO2进气质量浓度的增加而增加,最终为61.9 mg·(L·h)−1。

为更客观地比较NOx和SO2的净化效果,从物质的量角度来分析该实验结果。当去除率均为90%时,NOx质量分数800 mg·m−3换算成浓度约为17.4×10−3 mol·m−3,而SO2质量分数2 800 mg·m−3换算成浓度约为43.7×10−3 mol·m−3。因此,生物转鼓对SO2的净化效率更高。这是由于:SO2为易溶气体,而NOx为微溶气体,在物理扩散和化学吸收之后,SO2会更易被微生物直接吸附净化[14]。随着进气质量浓度的增加,NOx-N和 SO2-S的去除负荷一直增大,最高分别为16.1和61.9 mg·(L·h)−1,远大于挂膜期间N和S的去除负荷。

-

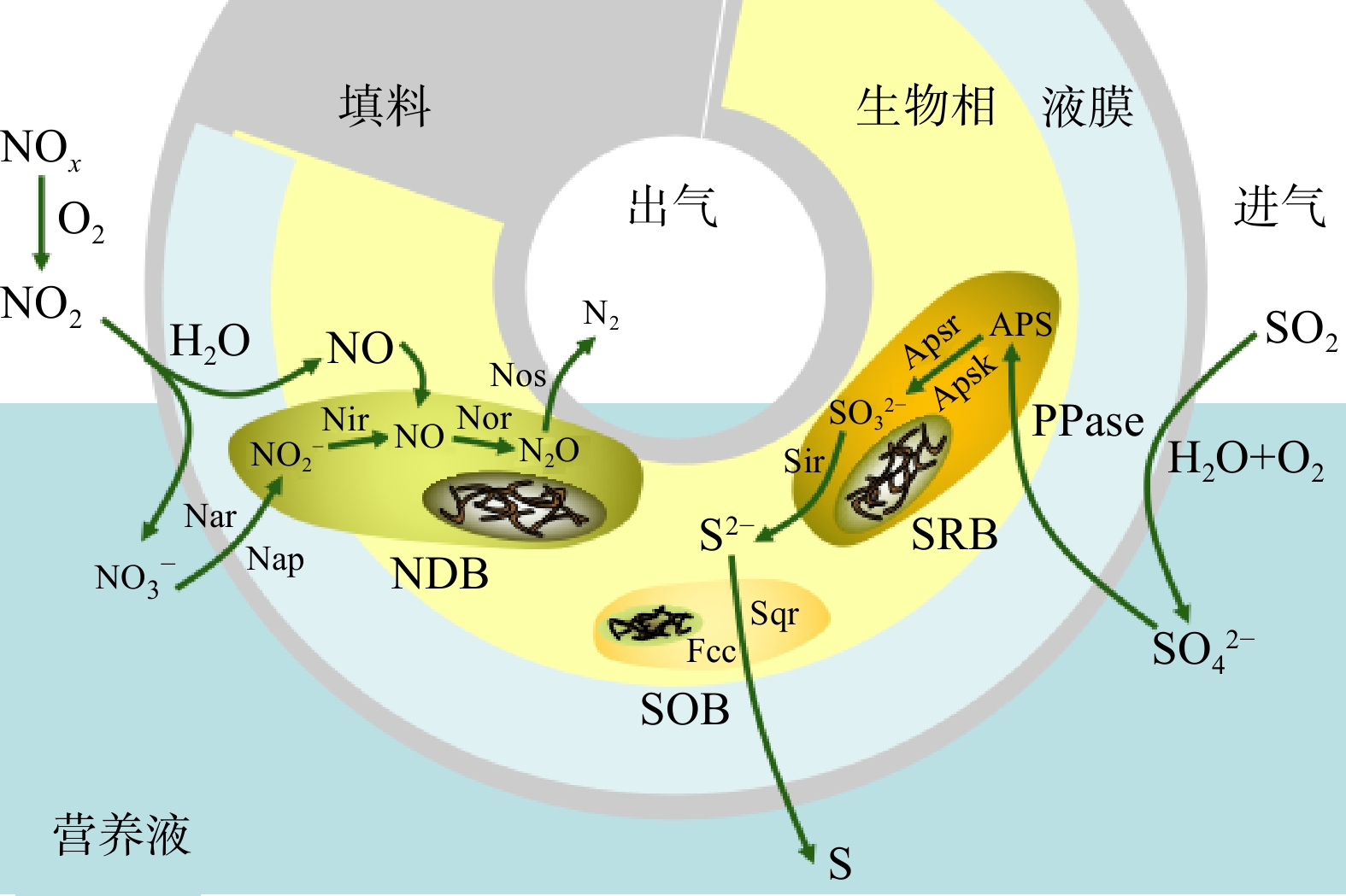

N和S元素在生物转鼓内在转化过程中涉及的主要反应如图7所示。对N而言,NOx在进气过程中会被周围空气环境完全氧化形成NO2;NO2进入转鼓后与水相反应生成NO3−和NO,NO3−和NO又会被DNR内源吸收,通过反硝化反应最终被还原为N2[15-16]。而SO2进入转鼓后,会立即与液膜和氧气反应形成SO42−,SRB可通过硫酸盐还原途径将SO42−还原为S2−,S2−最终被硫氧化细菌(sulfur-oxidizing bacteria,SOB)氧化成单质S[17]。除此之外,微生物生长和凋亡活动会造成一些其他形式的N和S吸收与释放。由于生物转鼓的运行已进入稳态,可认为这些形式的N和S处在一个动态平衡状态,故不将这些氮考虑在内[18-19]。因此,N和S元素的转化过程可简化为“气相输入-液相吸收-生物净化”。

-

气相N和S的去除负荷远大于生物去除负荷。根据生物相对NO3−-N和SO42−-S的去除负荷(分别为11.4和28.1 mg·(L·h)−1),推算出对应的NOx和SO2质量浓度分别为800和1 200 mg·m−3。进一步考察了生物转鼓在净化不同质量浓度NOx和SO2废气时,转鼓内气、液相中N和S的变化情况。

N含量变化情况如图8所示。在NOx的理论进气质量浓度约为800 mg·m−3时,转鼓内液相中NO3−应保持基本平衡,但实际却表现出缓慢下降趋势。基于上述分析中的N转化过程,NOx在被氧化成NO2后,无法完全以NO3−的形式进入反应系统,有部分可能仍以NO形式被微生物直接吸收净化,实际进入液相的NO3−少于理论值。而当进气NOx质量浓度约为1 000 mg·m−3时,转鼓内液相中的NO3−恰好保持相对稳定。此时,NOx-N的去除负荷为11.81 mg·(L·h)−1。

同样,转鼓内液相中的SO42−质量浓度会在进气SO2质量浓度较高(1 400 mg·m−3)时增大,在进气SO2质量浓度较低(1 000 mg·m−3)时减小。不同的是,SO2可被液相完全吸收,因此,当进气SO2质量浓度为1 200 mg·m−3时,转鼓内液相中SO42−基本保持平衡。此时的SO2-S去除负荷为28.41 mg·(L·h)−1。

-

运行12 d内生物转鼓中气、液相N总量变化见表1。在3种进气质量浓度下,N的质量在净化前后差距大于9%,△N约为0.44。根据N的转移途径可推测,这可能是由于NO2与水反应形成的NO会直接被微生物吸收净化所致。其次,3种浓度下△N始终保持不变,分析其原因,可能是当NOx进气质量浓度为600 mg·m−3时,生物相对NO的去除负荷已达饱和,因此不再随着进气质量浓度的增加而增加。表2反映出:不同SO2进气质量浓度下,生物转鼓中的S在净化前后基本保持平衡,质量之差小于1%。然而,实验误差会导致存在一定△S。综上所述,生物转鼓对N和S的去除负荷远大于生物相对N和S的去除负荷,且会随着进气质量浓度的增加而不断上升,其原因为N和S是以NO3−和SO42−状态富集在液相中。

-

1) 在前期的挂膜阶段,挂膜速率与微生物对NO3−、SO42−去除负荷变化趋势基本一致。整个挂膜期需耗时约25 d。最终,生物相的NO3−-N和SO42−-S去除负荷分别为9.45和28.12 mg·(L·h)−1。稳态下填料中生物相的优势门为变形菌门、拟杆菌门、厚壁菌门、绿弯菌门、浮霉菌门。起脱硫脱硝作用的包括变形菌门、拟杆菌门和绿弯菌门,共占比58%。

2) 在运行阶段,NOx进气质量浓度低于800 mg·m−3,去除率大于90%;当进气质量浓度提高到1 400 mg·m−3时,去除率为63%。SO2进气质量浓度低于2 000 mg·m−3,去除率高于94%;当进气质量浓度为2 800 mg·m−3时,去除率仍大于90%。

3) 通过分析生物转鼓内N和S的转化途径,以及N和S含量检测和平衡计算,在SO2、NOx进气质量浓度较高时,会以NO3−-N和SO42−-S的形式富集在液相中,故气相N和S的去除负荷远大于生物相中的去除负荷。

4) 在NOx的进气质量浓度为1 000 mg·m−3、SO2的进气质量浓度为1 200 mg·m−3时,生物转鼓的生物相去除负荷达到饱和。其中,最大NOx-N去除负荷为11.81 mg·(L·h)−1,最大SO2-S去除负荷为28.41 mg·(L·h)−1。

生物转鼓工艺好氧同步处理工业废气中的SO2和NOx

Simultaneous treatment of SO 2 and NO x in industrial waste gas by aerobic rotating drum biofilter

-

摘要: 为提升基于脱硫脱硝工艺的生物转鼓对工业废气中SO2、NOx的处理效果,在好氧条件下,分析了生物转鼓的启动过程、稳态下的生物相群落结构,考察了不同进气质量浓度下生物转鼓对SO2、NOx的处理效果和去除负荷,并探讨了生物转鼓同步脱硫脱硝过程中N和S的转化途径。结果表明:生物转鼓的启动挂膜需耗时约25 d;门水平的脱硫脱硝优势菌为变形菌门、拟杆菌门和绿弯菌门,这些菌总占比58%。在NOx进气质量浓度低于800 mg·m−3、SO2进气质量浓度低于2 850 mg·m−3时,生物转鼓的同步脱硫脱硝效率高于90%;而当NOx和SO2进气质量浓度较高时,N和S会以NO3−和SO42−的形式富集在液相中。当NOx进气质量浓度为1 000 mg·m−3、SO2进气质量浓度为1 200 mg·m−3时,NO3−和SO42−可维持平衡。此时,生物转鼓达到最大N、S去除负荷,即最大NOx-N去除负荷为11.81 mg·(L·h)−1、最大SO2-S去除负荷为28.41 mg·(L·h)−1。本研究可为生物转鼓好氧同步脱硫脱硝工艺的优化提供参考。Abstract: In order to improve the treatment effect of rotating drum biofilter based on desulfurization and denitrification process on SO2 and NOx in industrial waste gas, the start-up process of rotating drum biofilter and the biophase community structure in the steady state were analyzed under aerobic conditions. The treatment effect and removal load of rotating drum biofilter on SO2 and NOx under different inlet mass concentrations were also investigated. The transformation of N and S in the synchronous desulfurization and denitrification process of the rotating drum biofilter was also discussed. The results showed that it took about 25 days to start and hang the membrance of the bio-drum. The dominant bacteria of desulfurization and denitrification at the phylum level were Proteobacteria, Bacteroidetes and Chloroflexi, which accounted for 58% in total. When the mass concentration of NOx was lower than 800 mg·m−3 and the mass concentration of SO2 was lower than 2 850 mg·m−3, the simultaneous desulfurization and denitrification efficiency of the rotating drum biofilter was higher than 90%. However, when the mass concentration of SO2 and NOx was high, N and S would be enriched in the liquid phase in the form of NO3− and SO42−. When the inlet mass concentration of NOx was 1 000 mg·m−3, and the inlet mass concentration of SO2 was 1 200 mg·m−3, NO3− and SO42− in the liquid phase maintained a balance. At this point, the rotating drum biofilter realized the maximum removal loads of N and S, with the maximum NOx-N removal load of 11.81 mg·(L·h)−1, and the maximum SO2-S removal load of 28.41 mg·(L·h)−1. This study can provide reference for the optimization of bio-drum aerobic synchronous desulfurization and denitrification process.

-

-

表 1 生物转鼓内气、液相中的N含量平衡

Table 1. Balance of N content in gas and liquid phase in rotating drum biofilter

进气质量浓度/

(mg·m−3)M1(气相NOx−N)/g M2(液相NO3−−N)/g M3(生物净化)/g △N/g MI/

(M2+M3)进 出 合计 进气前 进气后 合计 1 000 6.33 1.27 5.06 2.88 2.93 0.05 4.561) 0.45 1.09 800 5.07 0.50 4.57 2.93 2.50 −0.43 4.56 0.44 1.11 600 3.86 0.32 3.54 2.50 1.04 −1.46 4.56 0.44 1.14 注:1)NO3−−N生物净化量按挂膜期间NO3−−N的去除负荷计算。 表 2 生物转鼓内气相、液相中的S含量平衡

Table 2. Balance of S content in gas and liquid phase in rotating drum biofilter

进气质量浓度/

(mg·m−3)M1(气相SO2−S)/g M2(液相SO42-−S)/g M3(生物净化)/g △S /g MI/

(M2+M3)进 出 合计 进气前 进气后 合计 1 400 16.73 0.94 15.79 4.64 6.87 2.23 13.55 0.01 1.00 1 200 14.34 0.65 13.69 6.87 6.89 0.02 13.55 0.12 1.01 1 000 11.83 0.49 11.34 6.89 4.60 −2.29 13.55 0.08 1.01 注:2)SO42-−S生物净化量按挂膜期间SO42-−S的去除负荷计算。 -

[1] BRIMBLECOMBE P, STEDMAN D H. Historical evidence for a dramatic increase in the nitrate component of acid-rain[J]. Nature, 1983, 303(5912): 88. doi: 10.1038/303088a0 [2] NIU Y, LI X, HUANG Z, et al. Chemical characteristics and possible causes of acid rain at a regional atmospheric background site in eastern China[J]. Air Quality Atmosphere & Health, 2017, 10(4): 1-10. [3] 颜金培, 杨林军, 鲍静静. 湿法脱硫烟气中细颗粒物的变化特性[J]. 东南大学学报, 2011, 41(02): 387-392. [4] 邹斯诣. 选择性催化还原(SCR)脱硝技术应用问题及对策[J]. 节能技术, 2009, 27(6): 510-512. doi: 10.3969/j.issn.1002-6339.2009.06.008 [5] 王文兴, 柴发合, 任阵海, 等. 新中国成立70年来我国大气污染防治历程、成就与经验[J]. 环境科学研究, 2019, 32(10): 1621-1635. [6] CHEN J, GU S Y, ZHENG J, et al. Simultaneous removal of SO2 and NO in a rotating drum biofilter coupled with complexing absorption by FeII(EDTA)[J]. Biochemical Engineering Journal, 2016, 114(10): 87-93. [7] 杨宣, 陈浚, 朱滨欢, 等. 多层填料生物转鼓去除NO废气的效能比较研究[J]. 环境科学学报, 2013, 33(1): 224-229. [8] WANG X C, BI X Y, SUN P S, et al. Effects of oxygen content on the simultaneous microbial removal of SO2 and NOx in biotrickling towers[J]. Biotechnology and Bioprocess Engineering, 2015, 20(5): 924-930. doi: 10.1007/s12257-015-0138-5 [9] SUN C C, YUAN J Q, XU H, et al. Simultaneous removal of nitric oxide and sulfur dioxide in a biofilter under micro-oxygen thermophilic conditions: Removal performance, competitive relationship and bacterial community structure[J]. Bioresource Technology, 2019, 290: 1-8. [10] 张丽平, 裴星媛, 赵春蓉. 盐酸萘乙二胺分光光度法测定环境空气中氮氧化物含量的不确定评定[J]. 环境科学导刊, 2020, 39(1): 91-96. [11] 孙艳平, 夏周洁, 包晓云. 甲醛吸收-副玫瑰苯胺分光光度法测定水中二氧化硫的测量不确定度评定[J]. 环境与生活, 2014(6): 57-58. [12] 李恩超. 焦化纳滤浓水的生物脱氮及其微生物菌群结构分析[J]. 环境工程学报, 2019, 13(10): 2461-2467. doi: 10.12030/j.cjee.201811113 [13] 鲜文东, 张潇橦, 李文均. 绿弯菌的研究现状及展望[J]. 微生物学报, 2020, 60(9): 1801-1820. [14] WANG A J, DU D Z, REN N Q, et al. An innovative process of simultaneous desulfurization and denitrification by Thiobacillus denitrificans.[J]. Journal of Environmentalence & Health. Part A Toxic/hazardous Substances & Environmental Engineering, 2005, 40(10): 1939-1949. doi: 10.1080/10934520500184590 [15] LI Y T, WANG Y R, FU L, et al. Aerobic-heterotrophic nitrogen removal through nitrate reduction and ammonium assimilation by marine bacterium Vibrio sp. Y1-5[J]. Bioresource Technology, 2017, 230: 103-111. doi: 10.1016/j.biortech.2017.01.049 [16] PAN Y T, NI B J, YUAN Z G. Modeling electron competition among nitrogen oxides reduction and N2O accumulation in denitrification[J]. Environmental Science & Technology, 2013, 47(19): 11083-11091. [17] YAN L, ZHAO H. Advances in enzyme properties and applications of sulfate-reducing bacteria[J]. Chinese Agricultural Science Bulletin, 2020, 36(31): 13-19. [18] MOGENSEN G L, KJELDSEN K U, INGVORSEN K. Desulfovibrio aerotolerans sp. nov., an oxygen tolerantsulphate reducing bacterium isolated from activatedsludge[J]. Anaerobe, 2005, 11(6): 339-349. doi: 10.1016/j.anaerobe.2005.04.002 [19] SALEHI S, CHENG K Y, HEITZ A, et al. Simultaneous nitrification, denitrification and phosphorus recovery (SNDPr)-An opportunity to facilitate full-scale recovery of phosphorus from municipal wastewater[J]. Journal of Environmental Management, 2019, 238: 41-48. -

下载:

下载: