-

截至2020年,我国已建成城镇污水处理厂9 000余座,日处理能力达2.3×108 m3。污水处理过程会伴随大量恶臭气体产生[1],这不仅会危害厂区工作人员和周边居民身体健康[2],还会污染周围环境。因此,污水处理厂恶臭气体治理已受到高度关注。

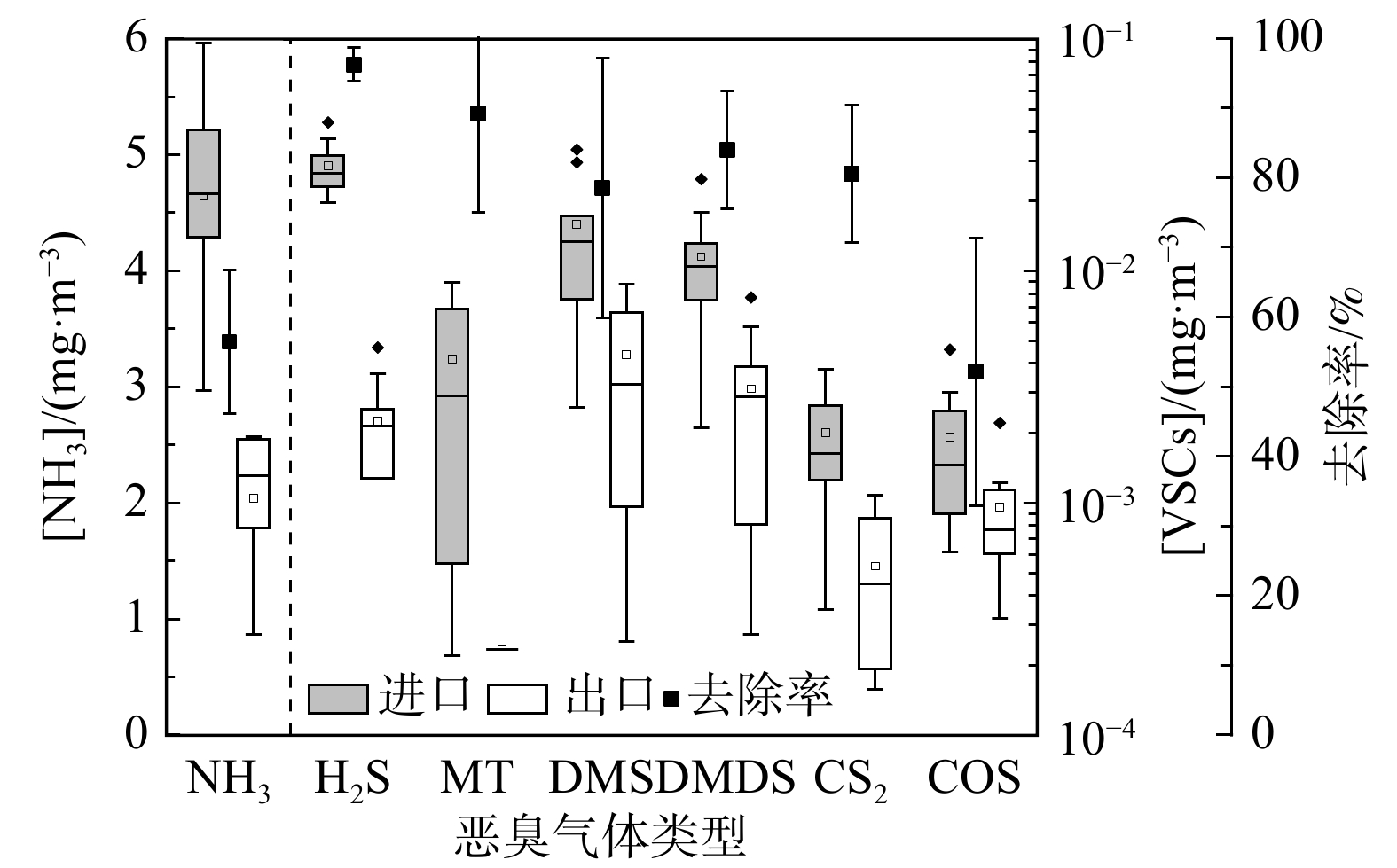

污水处理厂排放的恶臭气体主要有氨(NH3)和6种挥发性硫化物(volatile sulfur compounds,VSCs,包括硫化氢(H2S)、甲硫醇(MT)、甲硫醚(DMS)、二甲二硫醚(DMDS)、二硫化碳(CS2)和羰基硫(COS))[3-5]。污水处理厂应先收集再处理以上恶臭气体。目前,常见的恶臭处理技术有:物理法、化学法和生物法[6]。物理法包括掩蔽法、稀释扩散法和活性炭吸附法;化学法包括燃烧法、化学氧化法和化学洗涤法;生物法包括生物滤池法、生物滴滤法和生物洗涤法。在污水处理厂除臭工艺中,通常采用多种技术联合除臭[7]。天津咸阳路污水处理厂采用“生物滴滤+活性炭吸附”工艺处理污水泵站排放的NH3和H2S,其去除率高达98%[8]。上海天山污水处理厂采用“化学洗涤+生物滤池”处理污泥脱水机房排放的高浓度恶臭气体,处理后可达到《城镇污水处理厂污染物排放标准》二级标准[9]。广州猎德污水处理厂采用“洗涤+生物滤床”处理污泥处理段产生的NH3和H2S,其去除率均在90%以上[10]。杭州七格污水处理厂采用“生物滴滤+活性炭吸附+生物滴滤”多级处理工艺处理预处理和污泥处理段产生的恶臭气体,处理后可达到《城镇污水处理厂污染物排放标准》二级标准[11]。

目前,污水处理厂的除臭工艺尚存在以下问题:1)当前除臭目标多集中在NH3和H2S,而《恶臭污染物排放标准》(GB 14554-93)规定的8种恶臭物质中有5种VSCs,且嗅阈值远低于NH3和H2S[12],故对标准中规定的其他VSCs关注度不够;2)各构筑物排放的恶臭气体组成和浓度不同,而除臭设施大多为集中收集处理,并未针对不同构筑物而选择不同的处理工艺,忽略了恶臭物质种类和浓度的差异性。

本研究对北京市某污水处理厂(A2/O工艺)恶臭气体处理工艺除臭效果进行监测,通过分析比较4种除臭工艺对NH3和VSCs的去除效果,评估不同处理工艺处理不同构筑物排放的恶臭气体的适用性,以期为污水处理厂恶臭气体的有效处理提供参考。

-

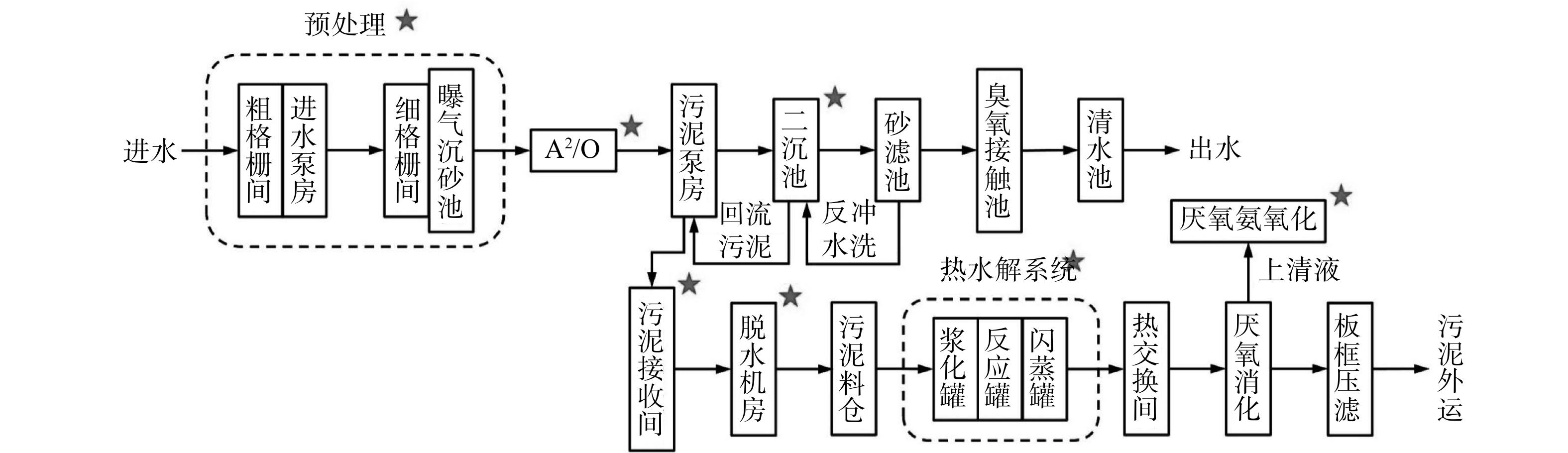

选取北京市某污水处理厂(日处理能力2×105 m3)为研究对象。该污水处理厂的污水和污泥处理工艺流程如图1所示。该厂的出水水质满足《北京市城镇污水处理厂污染物排放标准》(DB11/890-2012)B标准。污泥日处理量为1 836 t(含水率以80%计),将其脱水至60%后再外运资源化利用。该污水处理厂采取了全流程设施密闭和恶臭气体收集措施,对污水、污泥处理相关的7处构筑物(预处理段、A2/O生物池、二沉池、污泥接收间、污泥脱水机房、污泥热水解系统和污泥上清液厌氧氨氧化池(anammox生物池))产生的恶臭气体进行收集和输送。恶臭气体处理以生物法为主要工艺,并耦合水洗和化学洗涤法,具体除臭工艺见表1。在各除臭设施进、出气口设置采样监测点,分析恶臭气体的组成和浓度。处理后的气体经15 m排气筒排放,且排放速率满足《恶臭污染物排放标准》(GB 14554征求意见稿)和《北京市大气污染物综合排放标准》(DB11-501-2017)。

-

样品采集方法为罐真空采样,采集方式为恒流采样(14.4 mL·min−1)。采样前,使用清罐仪(3100A,Entech)通氮气对苏玛罐(3 L,杭州天净检测技术有限公司)进行循环清洗并抽至真空(<50 mTorr,约6.67 Pa);在苏玛罐安装限流阀和过滤器后,打开阀门,在达到设定恒定流量所对应的采样时间后,关闭阀门,并用密封帽密封[13];记录采样时间、地点、温度、管道风速和除臭装置运行参数。采样频率为每月2次,于 2020年10月—2021年6月共计采样12次。本研究的进气口质量浓度和排气口排放速率以12次采样结果的平均值计。

-

NH3和H2S分析使用泵吸式检测器(GT-903,深圳市科尔诺电子科技有限公司),测量范围为0~10 mg·m−3,测定的标准偏差为3%。其余VSCs分析采用大气预浓缩仪-气相色谱联用的方法。大气预浓缩仪(Entech 7200,USA)用于实现气体样品的高度富集,配备FPD检测器的气相色谱(GC 7890A,Agilent Technologies,USA)用以分析 VSCs的质量浓度[14]。

1)预浓缩仪条件。一级冷阱:捕集温度-150℃,捕集流速100 mL·min−1,解析温度10℃,阀温100℃,烘烤温度150℃,烘烤时间15 min;二级冷阱:捕集温度-15℃,捕集流速10 mL·min−1,捕集时间5 min,解析温度180℃,解析时间3.5 min,烘烤温度220℃,烘烤时间15 min;三级聚焦:聚焦温度−160℃,解析时间2.5 min,烘烤温度200 ℃,烘烤时间5 min。

2)气相色谱条件。色谱柱型号为DB-1毛细管色谱柱(30 m×0.32 mm×5 μm)。色谱柱升温程序:初始温度50 ℃,保持4 min;以20 ℃·min−1速率升温至150 ℃,保持4 min;以25 ℃·min−1速率升温至220 ℃,保持4 min。载气流量1 mL·min−1,分流比20∶1。

3)保留时间和检出限。连续分析7次接近检出限浓度实验室加标样品,计算标准标准偏差S,按检出限MDL = S×t(n-1,0.99)(t6,0.99=3.143),计算检出限,VSCs的保留时间和检出限见表2。VSCs的加标回收率高于80%,相对标准偏差为4.74%~12.07%,均小于20%,满足挥发性化合物的检测要求。

-

恶臭气体排放速率的计算公式为式(1),其去除率计算公式为式(2)。

式中:Q为恶臭气体排放速率,kg·h−1;c为恶臭气体质量浓度,mg·m−3;v为管道风速,m·s−1;D为管道内径,m;η为恶臭气体去除率,%;Q1和Q2分别为除臭设备进气口和排气口恶臭气体的排放速率,kg·h−1,若进气口有检出,排气口无检出,则Q2按检出限的50%计。

-

选取《恶臭气体排放标准》(GB 14554征求意见稿)和《大气污染物综合排放标准》(DB11/501-2017)中最严限值为恶臭气体处理效果的评价标准,将实测值与该标准值进行对比,反映其除臭效果(表3)。

-

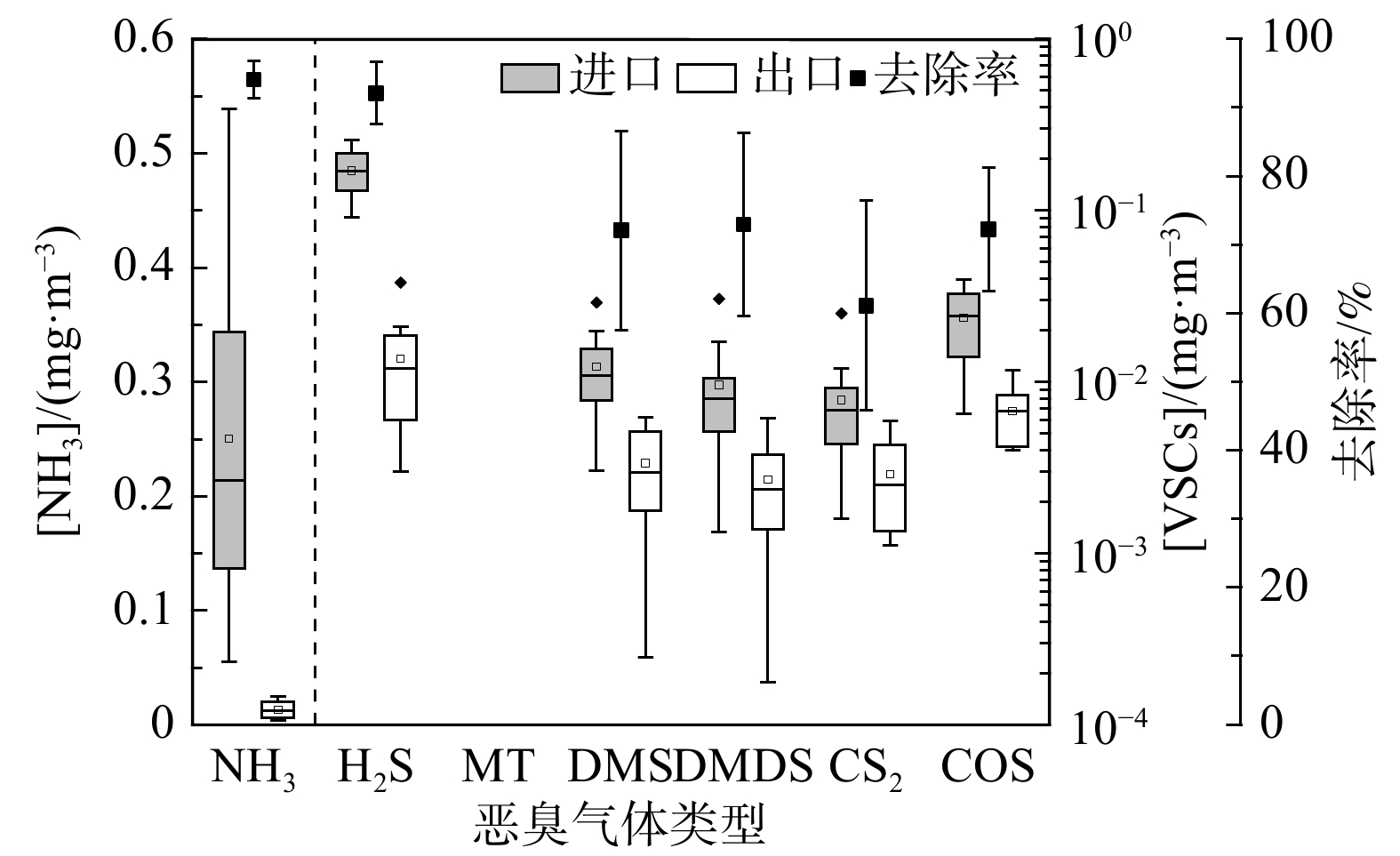

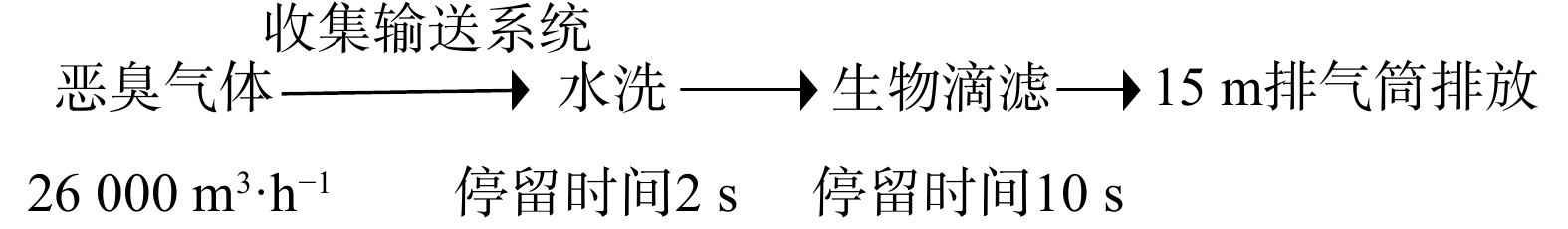

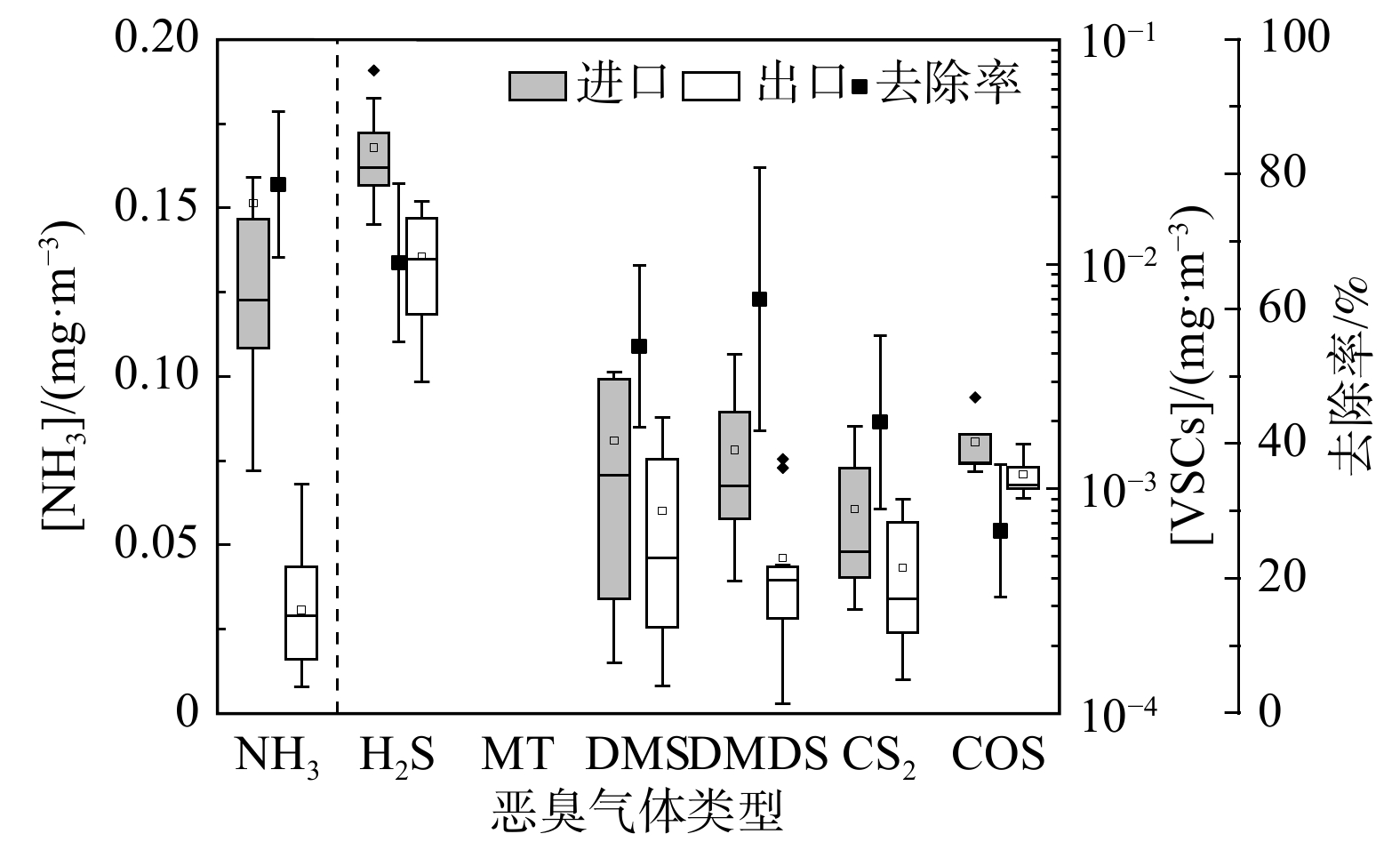

预处理段密闭收集的恶臭气体中NH3、H2S、DMS、DMDS、CS2和COS的平均质量浓度分别为0.250、0.171、0.012、0.010、0.008和0.024 mg·m−3,MT未被检出。预处理段收集的恶臭气体以NH3、H2S和COS为主。基于NH3极易溶于水(体积比1∶700)、H2S易溶于水(体积比1∶2.7)和COS微溶于水[15-16]等特性,选择水洗法为预处理方法,后经生物滴滤法二级处理,处理工艺流程见图2,处理结果见图3。

经处理后,NH3和H2S的质量浓度明显降低,去除率达到90%以上。其他VSCs不溶或微溶于水,依靠生物滴滤法处理。DMS、DMDS和COS的去除率均在70%以上,而CS2的去除率仅为61%。这表明该微生物群落中可生物降解CS2的菌种较少。在排气筒出口处,NH3和H2S的排放速率分别为1.65×10−4和1.61×10−4 kg·h−1,其余VSCs(COS未纳入标准)的排放速率均小于1×10−4 kg·h−1,满足排放要求。以上结果表明,NH3和H2S经水洗-生物滴滤二级处理后被有效去除,去除率均在90%以上,各物质经处理后均可达标排放。

-

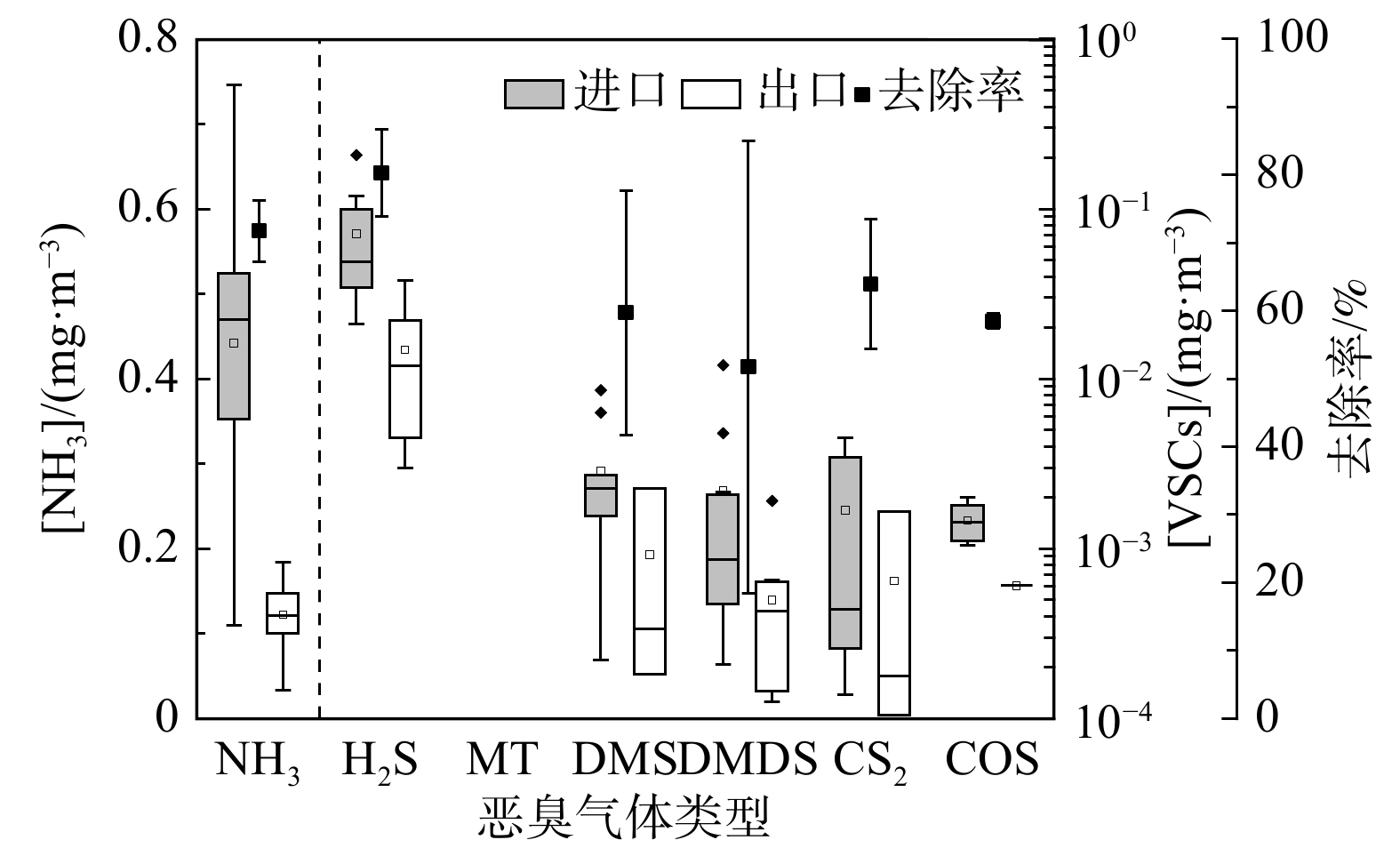

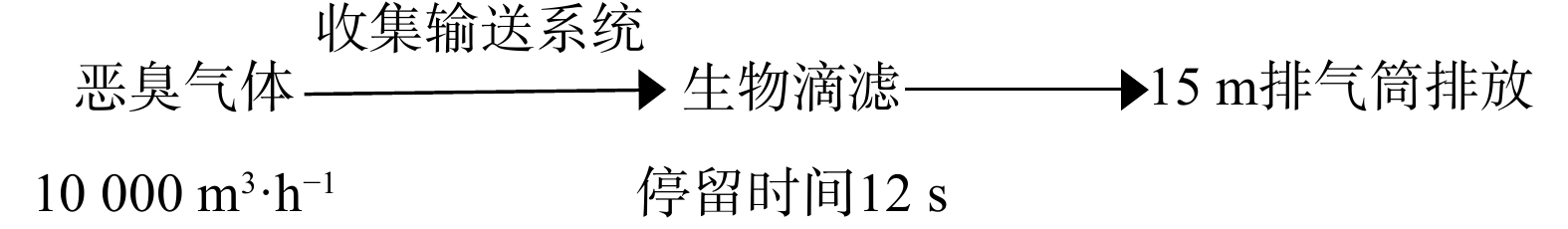

A2/O生物池密闭收集的恶臭气体中NH3、H2S、DMS、DMDS、CS2和COS的平均质量浓度分别为0.442、0.071、0.003、0.002、0.002和0.002 mg·m−3,MT未被检出。A2/O生物池收集的恶臭气体以NH3和H2S为主。基于NH3和H2S易溶于水的特点,采用水洗+生物滴滤法处理恶臭气体,处理工艺流程见图4,处理结果见图5。

A2/O生物池除臭工艺对各类恶臭物质的去除率略低于预处理段。虽然2个处理单元的除臭工艺相同,但A2/O生物池水洗段和生物段的停留时间为预处理的50%。由于恶臭气体初始质量浓度低,处理后各物质的质量浓度仍低于预处理段。排气筒出口处,NH3和H2S的排放速率分别为1.72×10−3和2.19×10−4 kg·h−1,其余VSCs的排放速率均小于1×10−4 kg·h−1。因此,A2/O生物池的除臭工艺对NH3和H2S的处理效果更好,且处理后各物质排放速率均满足标准要求。

-

二沉池密闭收集的恶臭气体中NH3、H2S、DMS、DMDS、CS2和COS的平均浓度分别为0.151、0.033、0.002、0.002、0.001和0.002 mg·m−3,MT未被检出。二沉池收集的恶臭气体以NH3和H2S为主,质量浓度均较低。综合考虑恶臭气体的特征及建设成本,仅采用生物滴滤法对其进行处理,处理工艺流程见图6,处理结果见图7。

单独采用生物法而无预处理方法(如水洗)来降低污染负荷,会使得该工艺对恶臭物质的去除率相对较低。其中,生物法对CS2和COS的处理效果较差,去除率均低于50%。虽然各类恶臭物质的去除率均较低,但由于二沉池的恶臭物质质量浓度偏低,处理后均能满足排放要求。在排气筒出口处,NH3和H2S的排放速率分别为1.59×10−4和5.63×10−5 kg·h−1,其余VSCs的排放速率均小于1×10−5 kg·h−1,远低于最高允许排放速率。

-

污泥接收间密闭收集的恶臭气体中NH3、H2S、MT、DMS、DMDS、CS2和COS的平均质量浓度分别为0.494、0.134、0.004、0.034、0.047、0.003和0.002 mg·m−3,以NH3、H2S、DMS和DMDS为主。MT检出次数极少,这是由于其易被氧化为DMDS[17-18]。由于VSCs多为酸性或还原性气体,故先采用生物滴滤处理后,再通过碱洗法进行深度处理,使难降解VSCs被NaOH与NaClO进一步中和或氧化。相关处理工艺流程见图8,处理结果见图9。

H2S、MT与NaOH发生反应,去除率均为94%。硫醚类物质可被NaClO氧化,亦有较好的去除效果,去除率在70%以上。尽管NH3为碱性气体,但在生物处理后,剩余部分可被碱性吸收液中的水分吸收,去除率可达80%。在排气筒出口处,NH3的排放速率为7.30×10−3 kg·h−1,VSCs的排放速率低于1×10−3 kg·h−1,但均低于最高允许排放速率。

-

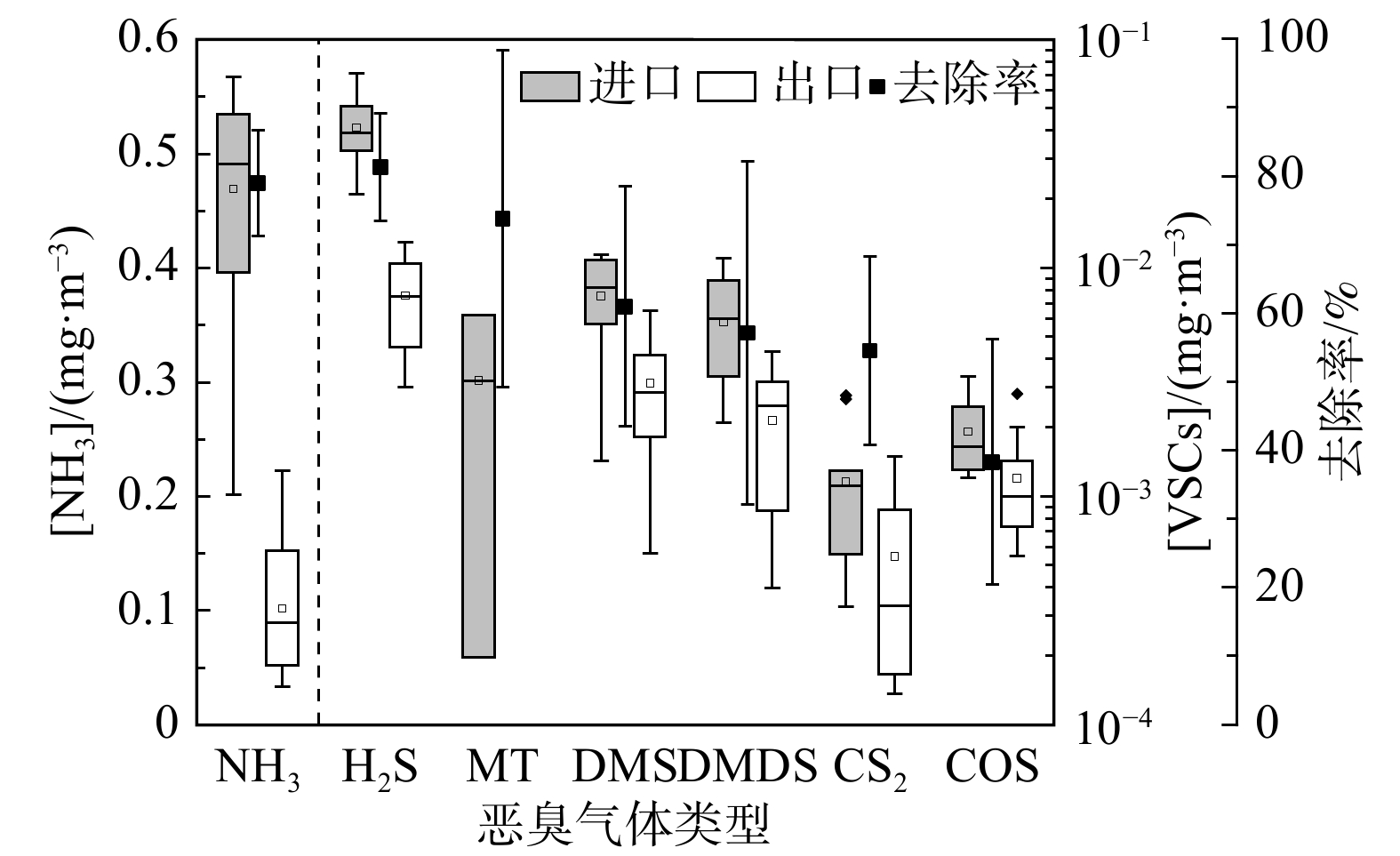

污泥脱水机房密闭收集的恶臭气体中NH3、H2S、MT、DMS、DMDS、CS2和COS的平均质量浓度分别为0.469、0.041、0.003、0.008、0.006、0.001和0.002 mg·m−3。污泥脱水机房收集的恶臭气体以NH3和H2S为主,浓度水平与污水处理单元相近。采用水洗+生物滴滤法对其进行处理,工艺流程见图10,处理结果见图11。

NH3和H2S经水洗后被转至液相中,去除率约为80%。COS微溶于水,且可生化性差,去除率仅为38%。其余VSCs再经生物滴滤法处理,MT、DMS、DMDS和CS2的去除率分别为74%、61%、57%和55%。排气筒出口处,NH3的排放速率为1.03×10−3 kg·h−1,VSCs的排放速率均小于1×10−4 kg·h−1,且满足排放标准。

-

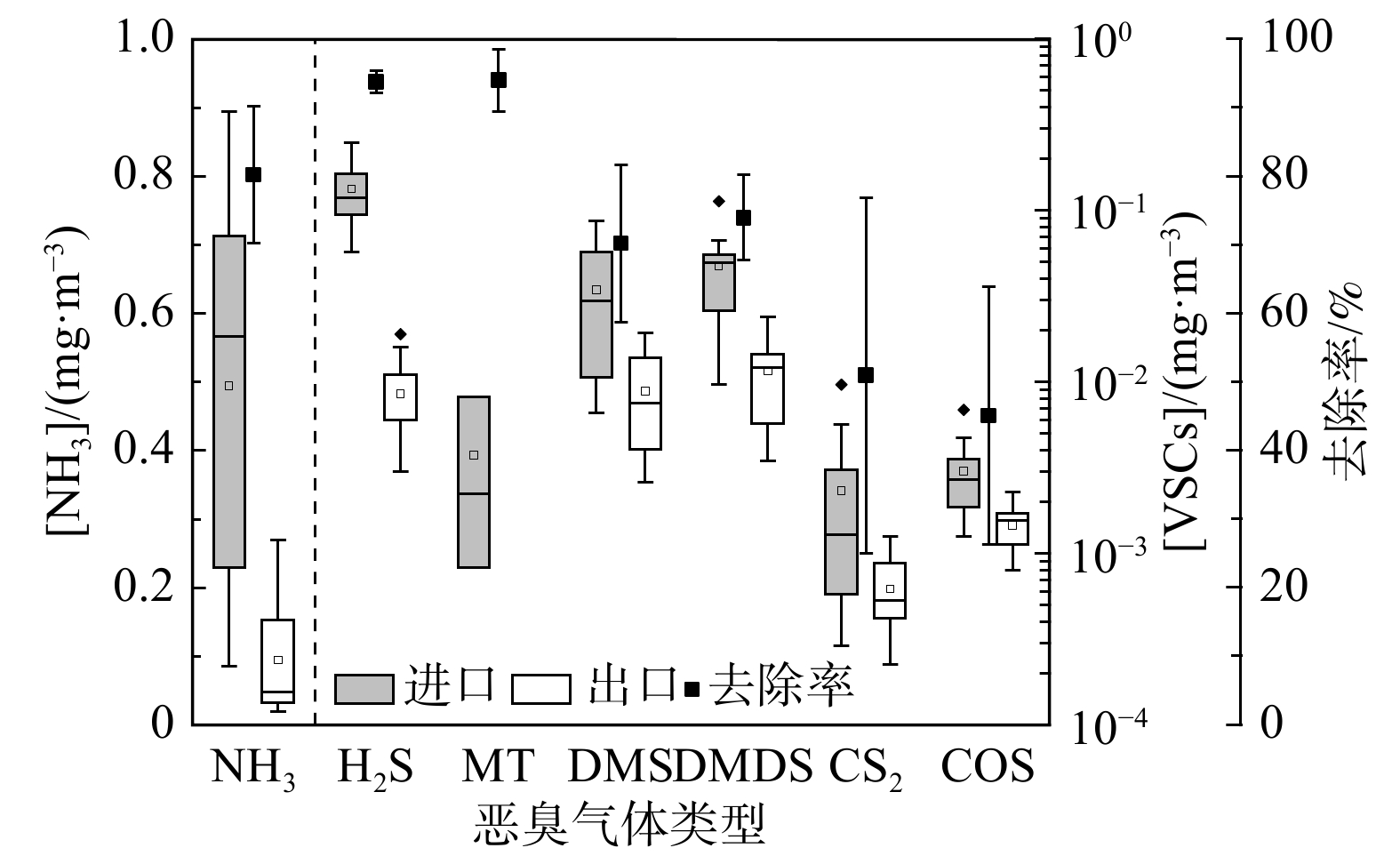

污泥热水解系统密闭收集的恶臭气体中NH3、H2S、MT、DMS、DMDS、CS2和COS的平均质量浓度分别为4.649、0.188、0.015、0.086、0.056、0.006和0.005 mg·m−3,明显高于其他6处构筑物收集的恶臭气体质量浓度。其中,该工艺段恶臭气体以NH3、H2S、DMS和DMDS为主,这是由热水解后污泥的有机物含量较高所致[19-20]。基于VSCs的酸性和还原性,采用生物+碱洗法对其进行处理,处理工艺流程见图12,处理结果见图13。

该工艺对H2S 和MT等酸性气体的去除效果好,去除率分别为96%和89%。除对COS的去除率较低(仅52%)外,对其余VSCs的去除率均大于80%。然而,由于进口NH3的质量浓度偏高,生物+碱洗法对其去除效果有限。在排气筒出口处,NH3的排放速率为8.51×10−2 kg·h−1,而VSCs的排放速率均小于1×10−3 kg·h−1。这表明上述物质均满足最高允许排放速率。

-

Anammox生物池密闭收集的恶臭气体中NH3、H2S、DMS、DMDS、CS2和COS的平均质量浓度分别为2.315、0.083、0.019、0.005、0.003和0.003 mg·m−3,MT未被检出。Anammox生物池收集的恶臭气体以NH3为主,且浓度较高。若采用水洗为预处理无法满足气液比要求,故采用酸洗法为预处理,后接生物滴滤法处理低质量浓度VSCs,处理工艺流程见图14,处理结果见图15。

NH3是碱性气体,可被酸液吸收,去除率高达95%。尽管酸洗对VSCs无作用,但该构筑物产生的VSCs质量浓度偏低,大部分NH3经酸洗处理已被去除,使得臭气负荷大大降低,从而可保证生物处理VSCs的效果。排气筒出口处NH3的排放速率为1.57×10−3 kg·h−1,H2S的排放速率为1.80×10−4 kg·h−1,其余VSCs排放速率均低于1×10−4 kg·h−1。以上结果表明,上述7种恶臭气体处理后均能达标排放。

-

实验结果表明:单独生物法的去除率较低,适用于处理低浓度的恶臭气体,对于CS2和COS的去除效果较差;水洗+生物法对NH3和H2S有良好的去除效果,适用于处理水溶性的恶臭气体,去除率最高可达90%以上;酸洗+生物法适用于处理含高浓度NH3的恶臭气体,对NH3的去除率高达95%;生物+碱洗法适用于处理含高浓度酸性及还原性气体的恶臭气体,H2S、MT、DMS和DMDS的去除率均在80%以上。综上所述,应根据恶臭气体组成及浓度来确定不同工艺组合来处理城镇污水处理厂恶臭气体,其中应以生物法为主体,并辅以水洗、酸洗和碱洗来保证其他气体(如NH3、H2S和其他酸性VSCs)的去除效果。

-

1)污水处理厂各构筑物密闭收集的恶臭气体中,主要组成和浓度各不相同。预处理段、A2/O生物池、二沉池和脱水机房的主要恶臭物质为NH3和H2S;污泥接收间和污泥热水解系统的主要恶臭物质为NH3、H2S、DMS和DMDS;anammox生物池的主要恶臭物质为NH3。

2)基于污水处理厂恶臭气体组成和浓度,可采用不同的除臭工艺对其进行处理。NH3和H2S易溶于水,采用水洗法作为预处理可有效去除。VSCs多为酸性或还原性气体,采用碱洗法可有效去除。高浓度NH3可采用酸洗法作为生物法的预处理。

3)推荐采用水洗+生物法处理预处理段、A2/O生物池和脱水机房排放的恶臭气体;推荐采用单独生物法处理二沉池恶臭;推荐采用生物+碱洗法处理污泥接收间和污泥热水解系统恶臭;推荐采用酸洗+生物法处理anammox生物池恶臭。

某A2/O工艺污水处理厂恶臭气体处理设施性能评估

Performance evaluation of odor gas treatment facilities in A2/O wastewater treatment plant

-

摘要: 污水处理厂运行中会产生大量恶臭气体,其不同构筑物中排放气体的组成和浓度不尽相同。采用不同工艺(生物法、水洗-生物法、酸洗-生物法和生物-碱洗法)对北京市某污水处理厂产生的恶臭气体进行了处理,并在1 a内开展了共计12次现场监测,以评估除臭设施对氨(NH3)和挥发性硫化物(VSCs,包括硫化氢(H2S)、甲硫醇(MT)、甲硫醚(DMS)、二甲二硫醚(DMDS)、二硫化碳(CS2)和羰基硫(COS))的处理效果。结果表明:污水预处理段、A2/O生物池、二沉池和污泥脱水机房的主要恶臭物质为NH3和H2S;NH3平均质量浓度依次为0.250、0.442、0.151和0.469 mg·m−3,H2S平均质量浓度依次为0.171、0.071、0.033和0.041 mg·m−3;污泥接收间和污泥热水解系统的主要恶臭物质为NH3、H2S、DMS和DMDS;污泥接收间各类恶臭物质的平均质量浓度依次为0.494、0.134、0.034和0.047 mg·m−3,污泥热水解系统中的各类恶臭物质的平均质量浓度依次为4.649、0.188、0.086和0.056 mg·m−3;污泥上清液厌氧氨氧化池的主要恶臭物质为NH3,平均质量浓度为2.315 mg·m−3。污水预处理段、A2/O生物池和污泥脱水机房采用水洗+生物法工艺,其对NH3和H2S的去除率最高可达94%和92%;二沉池除臭工艺为生物法,其对NH3和H2S的去除率为78%和67%;污泥接收间和污泥热水解系统采用生物+碱洗法,其对H2S、MT、DMS、DMDS和CS2的去除率最高分别为96%、89%、80%、84%和81%;污泥上清液厌氧氨氧化池除臭工艺为酸洗+生物法,其对NH3的去除率高达95%。该污水处理厂各工艺段产生的恶臭气体经处理后可同时满足《恶臭污染物排放标准》(GB 14554征求意见稿)和《北京市大气污染物综合排放标准》(DB11/501-2017)。本研究可为采用类似工艺的污水处理厂解决恶臭气体问题提供参考。Abstract: During the operation of wastewater treatment plant (WWTP), a large amount of odor gas will be produced. The odor gas produced by a WWTP in Beijing is treated by different treatment processes (biological method, water washing-biological method, acid pickling-biological method and biological-alkali washing method), and a total of 12 on-site monitoring was carried out within 1 year to evaluate the effect of deodorization facilities on ammonia (NH3) and volatile sulfide compounds (VSCs, including hydrogen sulfide (H2S), methyl mercaptan (MT), methyl sulfide (DMS), dimethyl disulfide (DMDS), carbon disulfide (CS2) and carbonyl sulfur (COS)).The results show that the main odorous substances in wastewater pretreatment section, A2/O biological tank, secondary sedimentation tank and sludge dewatering room are NH3 and H2S; The average mass concentration of NH3 is 0.250, 0.442, 0.151 and 0.469 mg·m−3; and the average mass concentration of H2S is 0.171, 0.071, 0.033 and 0.041 mg·m−3. The main odorous substances in sludge receiving room and sludge thermal hydrolysis system are NH3, H2S, DMS and DMDS; The average mass concentration of odor gas in sludge receiving room is 0.494, 0.134, 0.034 and 0.047 mg·m−3, and the average mass concentration of odor gas in sludge thermal hydrolysis system is 4.649, 0.188, 0.086 and 0.056 mg·m−3. The main odorous substance in the anammox tank is NH3, with an average mass concentration of 2.315 mg·m−3. The deodorization process of wastewater pretreatment section, A2/O biological tank and sludge dewatering room is water washing-biological method, and the maximum removal efficiencies of NH3 and H2S are 94% and 92% respectively. The deodorization process of secondary sedimentation tank is biological method, and the removal efficiencies of NH3 and H2S are 78% and 67% respectively. The deodorization process of sludge receiving room and sludge thermal hydrolysis system is biological-alkali washing method, and the maximum removal efficiencies of H2S, MT, DMS, DMDS and CS2 are 96%, 89%, 80%, 84% and 81% respectively. The deodorization process of anammox tank is acid pickling-biological method, and the removal efficiency of NH3 is as high as 95%. After treatment, the odor gas generated in each process section of the WWTP can meet both the Emission Standard for Malodorous Pollutants (GB 14554 draft) and the Comprehensive Emission Standard of Air Pollutants (DB11/501-2017). This study can provide a reference for WWTP using similar processes to solve the problem of odor gas.

-

-

表 1 污水处理厂各构筑物的除臭工艺

Table 1. Summary of deodorization process in WWTP

构筑物 除臭工艺 处理气量/(m3·h−1) 停留时间/s 化学药剂 生物段 洗涤段 预处理段 水洗+生物滴滤 53 000 20 5 无 A2/O生物池 水洗+生物滴滤 26 000 10 2 无 二沉池 生物滴滤 10 000 12 0 无 污泥接收间 生物滴滤+碱洗 56 000 15 4 NaOH + NaClO 污泥脱水机房 水洗+生物滴滤 13 000 20 3 无 污泥热水解系统 生物滴滤+碱洗 32 000 20 3 NaOH + NaClO 污泥上清液厌氧氨氧化池 酸洗+生物滴滤 28 000 20 3 H2SO4 表 2 VSCs的保留时间和检出限

Table 2. Retention time and detection limit of VSCs

检测物质 保留时间/min 检出限/(μg·m-3) COS 4.649 0.08 MT 6.791 0.20 DMS 11.712 0.17 CS2 12.604 0.10 DMDS 18.575 0.08 表 3 恶臭气体处理效果评价标准

Table 3. Evaluation standard for treatment effect of odor gas

序号 监测项目 排气筒高度 最高允许排放速率/( kg·h−1) DB11/501-2017 GB 14554(征求意见稿) 评价标准 1 NH3 15 m 0.72 0.60 0.60 2 H2S 15 m 0.036 0.06 0.036 3 MT 15 m 0.025 0.006 0.006 4 DMS 15 m 0.25 0.06 0.06 5 DMDS 15 m 0.22 0.15 0.15 6 CS2 15 m 0.14 1.5 0.14 -

[1] 杜亚峰, 李军, 赵珊, 等. 污水处理厂恶臭气体分布规律及挥发性气体定量评价[J]. 净水技术, 2018, 37(7): 69-74. [2] AATAMILA M, VERKASALO P K, KORHONEN M J, et al. Odour annoyance and physical symptoms among residents living near waste treatment centres[J]. Environmental Research, 2011, 111(1): 164-170. doi: 10.1016/j.envres.2010.11.008 [3] LI R, HAN Z, SHEN H, ET al. Volatile sulfur compound emissions and health risk assessment from an A2/O wastewater treatment plant[J]. Science of the Total Environment, 2021, 794: 148741. doi: 10.1016/j.scitotenv.2021.148741 [4] LI R, HAN Z, SHEN H, et al. Emission characteristics of odorous volatile sulfur compound from a full-scale sequencing batch reactor wastewater treatment plant[J]. Science of the Total Environment, 2021, 776: 145991. doi: 10.1016/j.scitotenv.2021.145991 [5] LIU Z. Urban sewage treatment odor gas release characteristics and regional differences[J]. Environmental Technology & Innovation, 2021, 21: 101190. doi: 10.1016/j.eti.2020.101190 [6] 郑斯宇, 杨延梅. 污水处理厂恶臭气体控制综述[J]. 给水排水, 2015, 51(S1): 109-114. [7] 邹博源, 陈广. 城镇污水处理厂臭气污染与除臭技术研究进展[J]. 净水技术, 2020, 39(5): 109-115. [8] 王令凡, 蒋国津. 生物滴滤床技术用于市政污水泵站除臭[J]. 中国给水排水, 2009, 25(20): 73-76. doi: 10.3321/j.issn:1000-4602.2009.20.020 [9] 刘晓兰, 康磊, 卢义程. 生物滤池加离子换风除臭技术在污水处理厂的应用[J]. 中国市政工程, 2013, 38(3): 45-47. doi: 10.3969/j.issn.1004-4655.2013.03.015 [10] 李亮, 赵忠富, 张明杰, 等. 猎德污水处理厂污泥系统除臭工程设计[J]. 给水排水, 2007, 44(12): 40-43. doi: 10.3969/j.issn.1002-8471.2007.12.009 [11] 张丽丽, 郭红峰, 严国奇, 等. 七格污水厂三期工程生物除臭系统的运行效果[J]. 中国给水排水, 2020, 36(1): 69-73. [12] 王亘, 翟增秀, 耿静, 等. 40种典型恶臭物质嗅阈值测定[J]. 安全与环境学报, 2015, 15(6): 348-351. [13] 崔连喜, 关玉春, 王艳丽. 苏玛罐采样-气相色谱-质谱法测定环境空气中99种挥发性有机物[J]. 广州化工, 2020, 48(3): 95-102. doi: 10.3969/j.issn.1001-9677.2020.03.035 [14] 沈秀娥, 常淼, 刘保献, 赵红帅, 王小菊. 大气预浓缩仪-GC/FPD测定环境空气中的痕量硫化物[J]. 中国环境监测, 2015, 31(6): 103-108. doi: 10.3969/j.issn.1002-6002.2015.06.022 [15] 马慧. 吸附法脱除低浓度羰基硫的研究[D]. 大连: 大连理工大学, 2011. [16] RATNASAMY C, WAGNER J P, SPIVEY S, et al. Removal of sulfur compounds from natural gas for fuel cell applications using a sequential bed system[J]. Catalysis Today, 2012, 198(1): 233-238. doi: 10.1016/j.cattod.2012.04.069 [17] HIGGINS M J, CHEN Y C, YAROSZ D P, et al. Cycling of volatile organic sulfur compounds in anaerobically digested biosolids and its implications for odors[J]. Water Environment Research, 2006, 78(3): 243-252. doi: 10.2175/106143005X90065 [18] CHENG X, PETERKIN E, BURLINGAME G A. A study on volatile organic sulfide causes of odors at Philadelphia's Northeast Water Pollution Control Plant[J]. Water Research, 2005, 39(16): 3781-3790. doi: 10.1016/j.watres.2005.07.009 [19] 陈思思, 杨殿海, 庞维海, 等. 污泥中蛋白类物质厌氧转化影响因素及其促进策略研究进展[J]. 化工进展, 2020, 39(5): 1992-1999. [20] 肖本益, 阎鸿, 魏源送. 污泥热处理及其强化污泥厌氧消化的研究进展[J]. 环境科学学报, 2009, 29(4): 673-682. doi: 10.3321/j.issn:0253-2468.2009.04.001 -

下载:

下载: