-

长链二元酸是碳数≥10的直链二羧酸,是一类广泛应用于化工、医药、农药等领域的重要精细化工中间体。生物发酵制备长链二元酸由于其生产工艺简单、成本低且收率高,是目前二元酸生产的最主要工艺。伴随着生物发酵过程,每生产1 t长链二元酸会排放约50~60 t废水,这些废水具有有机物浓度高、盐度大、高SO42−等特点[1-2]。二元酸废水多采用“混凝沉淀(除盐和硫酸根)+好氧曝气(除有机物)”预处理后排入化工园区综合污水厂的方式与其他废水进行混合处理。由于废水的有机物浓度高,而好氧生物处理的有机负荷率低,使好氧曝气预处理单元的占地面积大、处理能耗高,而且产生大量剩余活性污泥。相比好氧处理,以上流式厌氧污泥床(up-flow anaerobic sludge bed,UASB)反应器为代表的厌氧生物处理具有能耗低、污泥产量少、可产生二次能源、耐冲击负荷等优势[3],常用于高浓度有机废水如石油化工[4]、生物制药[5]、食品发酵[6]等工业废水的处理。但在厌氧条件下,硫酸盐还原菌(sulfate reducing bacteria,SRB)会将SO42−还原为硫化物并生成有毒气体H2S,抑制微生物活性,降低有机物去除效率,威胁现场工作人员的健康。因此,厌氧处理二元酸废水过程必须控制体系中的硫化物浓度,降低沼气中H2S的含量。

有研究表明,添加金属或金属盐可与S2−形成硫化物沉淀,可减轻其对产甲烷菌的抑制作用[7-8];利用微曝气将S2−氧化为单质硫,也可以有效减少沼气中H2S的含量,同时抑制SRB的活性和避免硫酸盐厌氧还原产生S2-[9-11]。然而,2种方法应用于二元酸废水的厌氧生物处理过程并未见相关报道。本研究通过分析上述2种不同控制策略对废水中有机物的去除、硫化物的控制效果和微生物群落结构的影响,探究了零价铁和微曝气在二元酸废水厌氧生物处理过程中的作用机制,以期为厌氧生物处理二元酸废水的高效稳定运行提供参考。

-

实验所用的零价铁购自中冶鑫盾合金研究所,球形度98%以上,纯度为99.995%,粒径为300目。反应器接种污泥取自辽河石化水解酸化池,污泥浓度为22.76 g·L−1,VSS/TSS为0.64。本研究中的长链二元酸废水取自江苏省淮安市清江石化厂二元酸车间物化处理单元。废水的水质指标如下:COD为3 000~3 500 mg·L−1,SO42−为1 500~4 500 mg·L−1,NH4+-N为8.6~11.3 mg·L−1,总磷为3.7~12.5 mg·L−1。

-

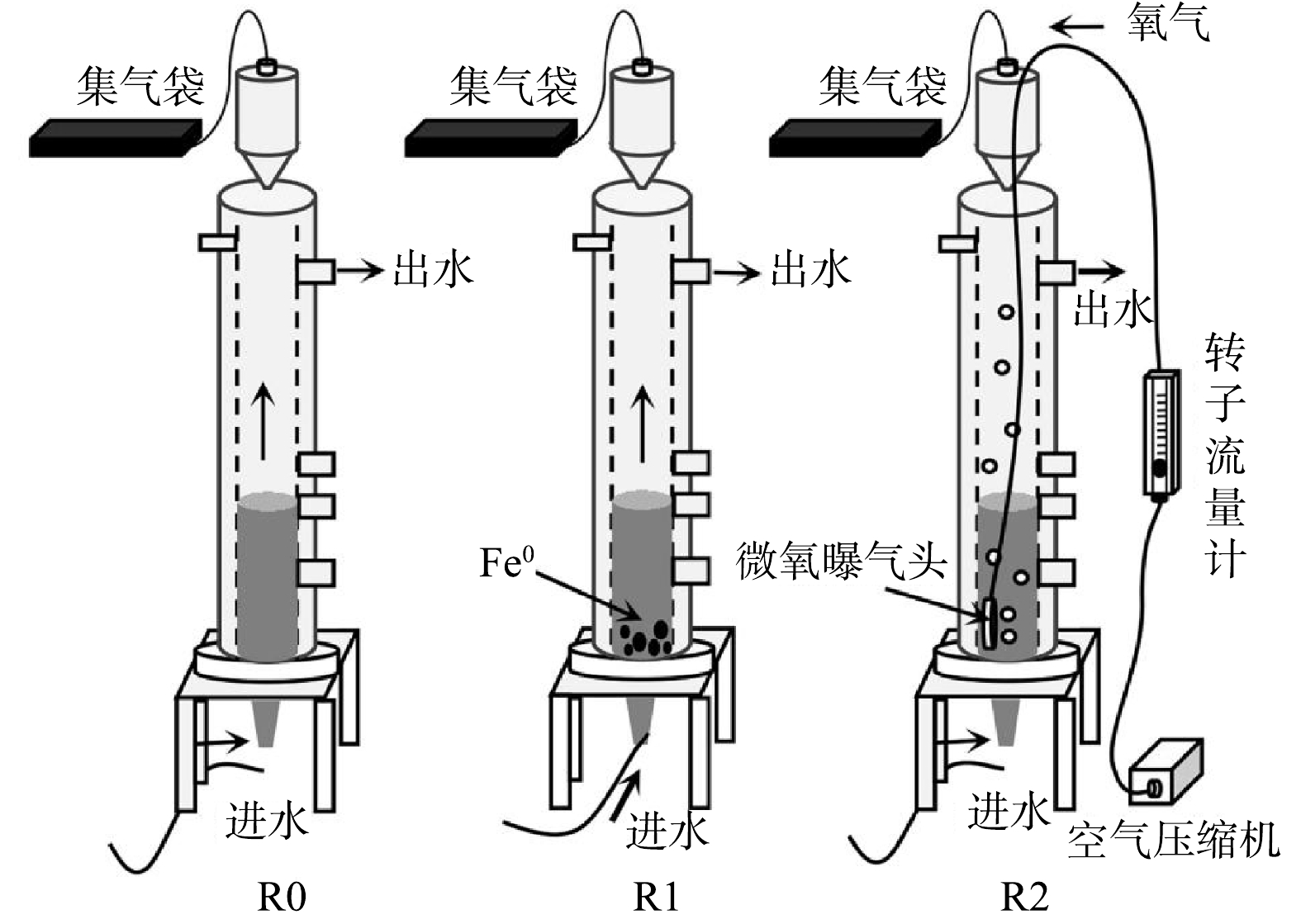

3组UASB反应器分别为对照组R0、投加Fe0反应器R1和微曝气反应器R2。UASB反应器由有机玻璃制成,高100 cm,内径8 cm,有效容积4.5 L。实验装置如图1所示。

-

根据前期预实验结果,Fe0与SO42−的摩尔比为0.6时H2S的抑制效果最好。按照每30 d 投加1次Fe0和进水中硫酸根的浓度计算第30、60和90天的投加量(式(1))。R2反应器底部设置微曝气系统,DO控制在0.1~0.3 mg·L−1。实验过程中,反应器运行温度为(37±1) °C,HRT(hydraulic retention time)为30 h。

式中:c(SO42−)是进水SO42−的质量浓度,mg·L−1;m(Fe)为Fe0的单次投加量,g;V为R1有效容积,L;t为水力停留时间,d。

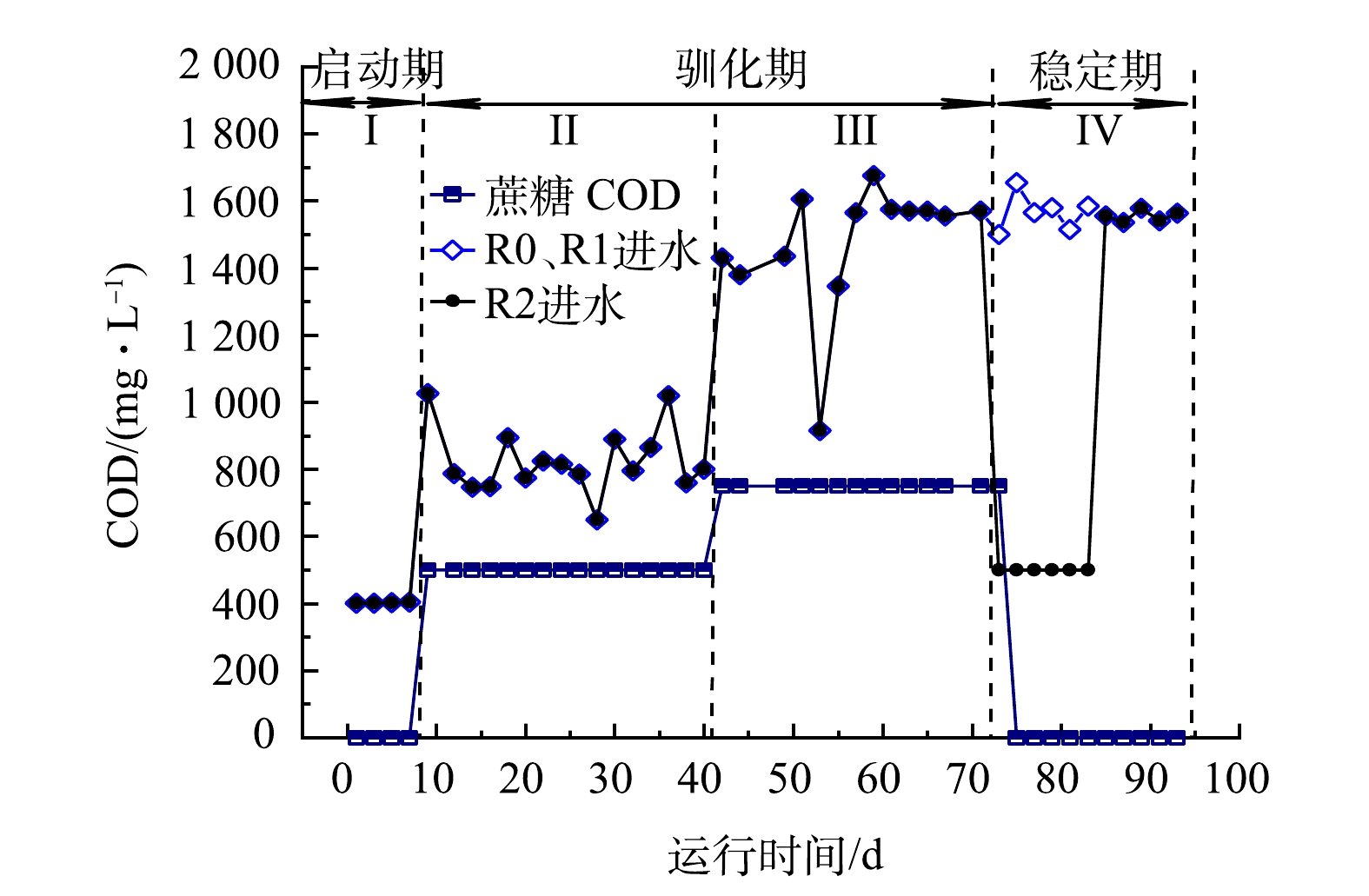

各反应器进水情况如图2所示。系统共运行93 d,包括启动期(阶段Ⅰ: 0~9 d)、驯化期(阶段Ⅱ: 10~40 d;阶段Ⅲ:41~72 d)和稳定期(阶段Ⅳ:73~93 d)。启动期的二元酸废水经自来水稀释后(COD约400 mg·L−1)进入反应器;驯化期逐步降低稀释比例提高进水COD(800~1 600 mg·L−1),同时添加蔗糖作为辅助碳源促进微生物的快速生长(蔗糖COD为500~800 mg·L−1);稳定期停止添加蔗糖,进水全部为稀释物化出水(COD为1 600 mg·L−1),但在R2中反应进行至75~85 d时进水稀释至COD 500 mg·L−1,第86天后恢复进水浓度。

-

COD、SO42−和硫化物使用DR1010分光光度计(HACH,美国)测定。pH使用便携式pH计(希玛818,中国)测量。沼气由集气袋收集,沼气体积采用100 mL注射器测量。沼气中甲烷、CO2和H2含量使用气相色谱仪(温岭GC7808,中国)测量,采用TCD检测器,进样口、柱温和检测器温度分别为80 ℃、100 ℃和150 ℃。硫化氢采用K-600型便携式可燃气气体检测仪(保时安,中国)测量。

进出水有机物组成使用GC7890B/MSD5977B GC-MS(Agilent,美国)测量,色谱柱使用DB-35毛细管色谱柱(30 m×0.25 mm×0.25 μm),进样口和检测器温度分别为50 ℃和300 ℃。色谱柱升温程序为50 ℃恒温2 min;10 ℃·min−1升至100 ℃,恒温2 min;10 ℃·min−1升至200 ℃,恒温2 min;10 ℃·min−1升至280 ℃。利用9.4 T Apex-Ultra FT-ICR MS(Bruker,德国)对水中极性有机物进行分析,极化电压为-4500 V,进样速度为480 μL·h−1,采样频率为1 s,分子质量为115~1 000 Da,谱图叠加64次。样品预处理均依据YE等[12]的方法。

采用高通量基因测序方法分析微生物群落组成,DNA提取、PCR扩增、高通量测序委托上海美吉生物医药科技有限公司进行。PCR扩增引物采用古菌细菌通用引物,515FmodF和806RmodR,其序列分别为GTGYCAGCMGCCGCGGTAA和GGACTACNVGGGTWTCTAAT。测序结果通过美吉公司生物云平台进行数据分析(http://www.majorbio.com/)。

-

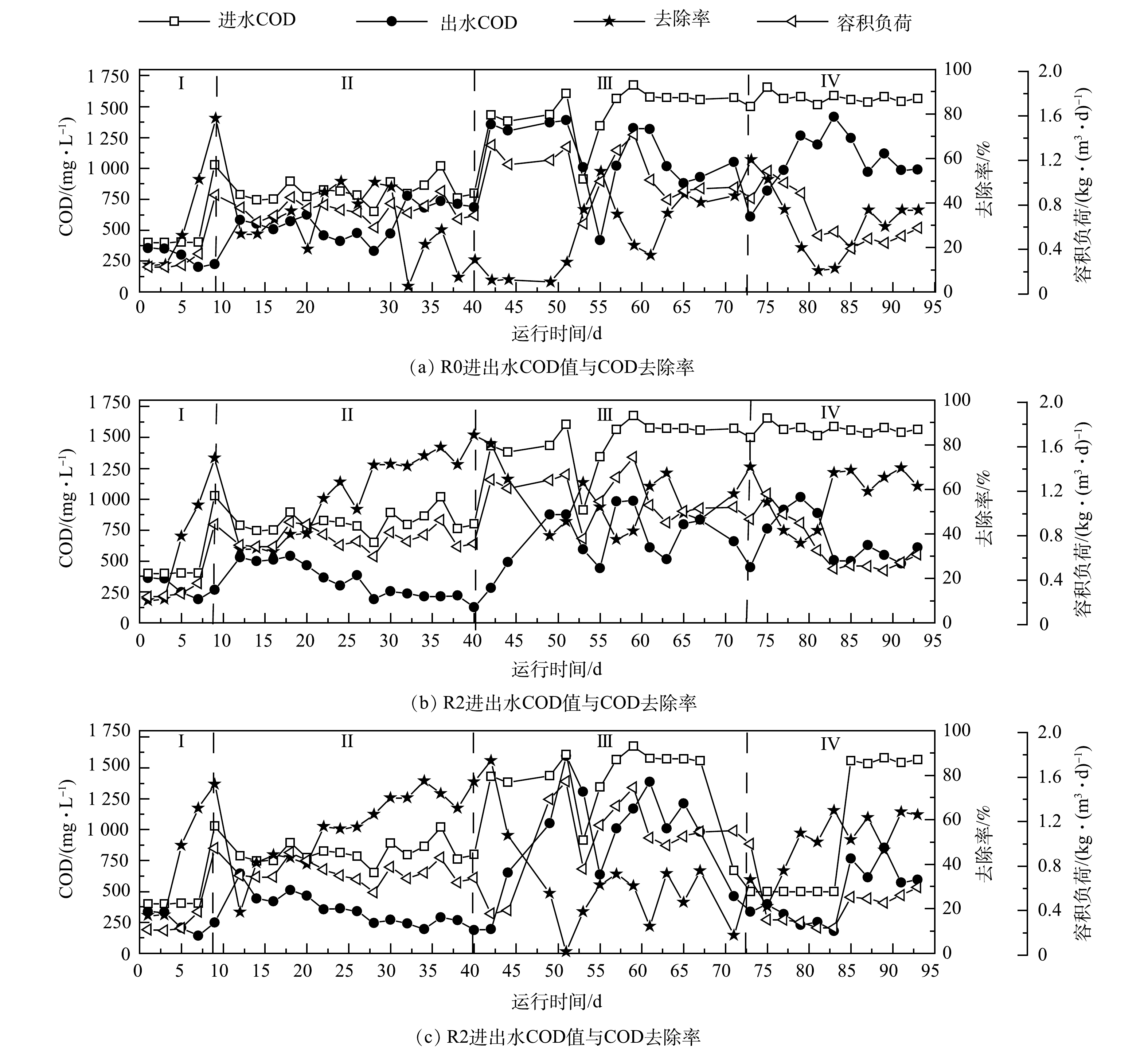

图3为3个反应器中的COD去除效果。在启动期0~9 d,R0、R1和R2的COD去除率稳步提升,运行至第9天分别达到77.8%、73.9%和75.8%。进入驯化期后,由于进水稀释比例降低,3个反应器的COD去除率均有下降,但随着驯化时间的延长,R1和R2的COD去除率逐渐提高,到第40天分别达到84%和78%,而R0仅为14.4%。随后进水负荷继续提升,各反应器都受到了不同程度的冲击,COD去除率明显下降,但R1经过10 d后运行效果有明显恢复,第72天的去除率达到70%,而R2的COD去除率仍小于40%。此时R2的出水pH小于7,低COD去除率的原因可能是有机酸的积累导致。为了缓解酸积累现象,降低R2进水的COD至500 mg·L−1以恢复系统功能,第82天提升R2进水COD至与R0和R1一致(COD为1 600 mg·L−1),稳定运行后R0、R1和R2的平均COD去除率分别为32.0%、65.2%和56.7%,仍然为R1最佳。

在高SO42−含量下,传统的厌氧生物处理工艺难以有效去除水中的有机物。而R1、R2所使用H2S控制方法均可以在一定程度上缓解SO42−还原产物的毒性效应,从而促进对耗氧有机物(以COD计)的降解。但微曝气条件不利于产甲烷菌的生长繁殖,高进水负荷时易发生有机酸积累,其微生态系统相对较脆弱,在遭受冲击后,所需恢复时间较长,反应器的运行稳定性差。另外,3个反应器在阶段Ⅱ的COD去除率优于阶段Ⅲ和阶段Ⅳ,表明在较低的进水负荷和硫酸盐浓度条件下,有助于有机污染物的去除;而随着进水负荷的增加和硫酸盐浓度的提高,有机物的厌氧降解性能受到影响。

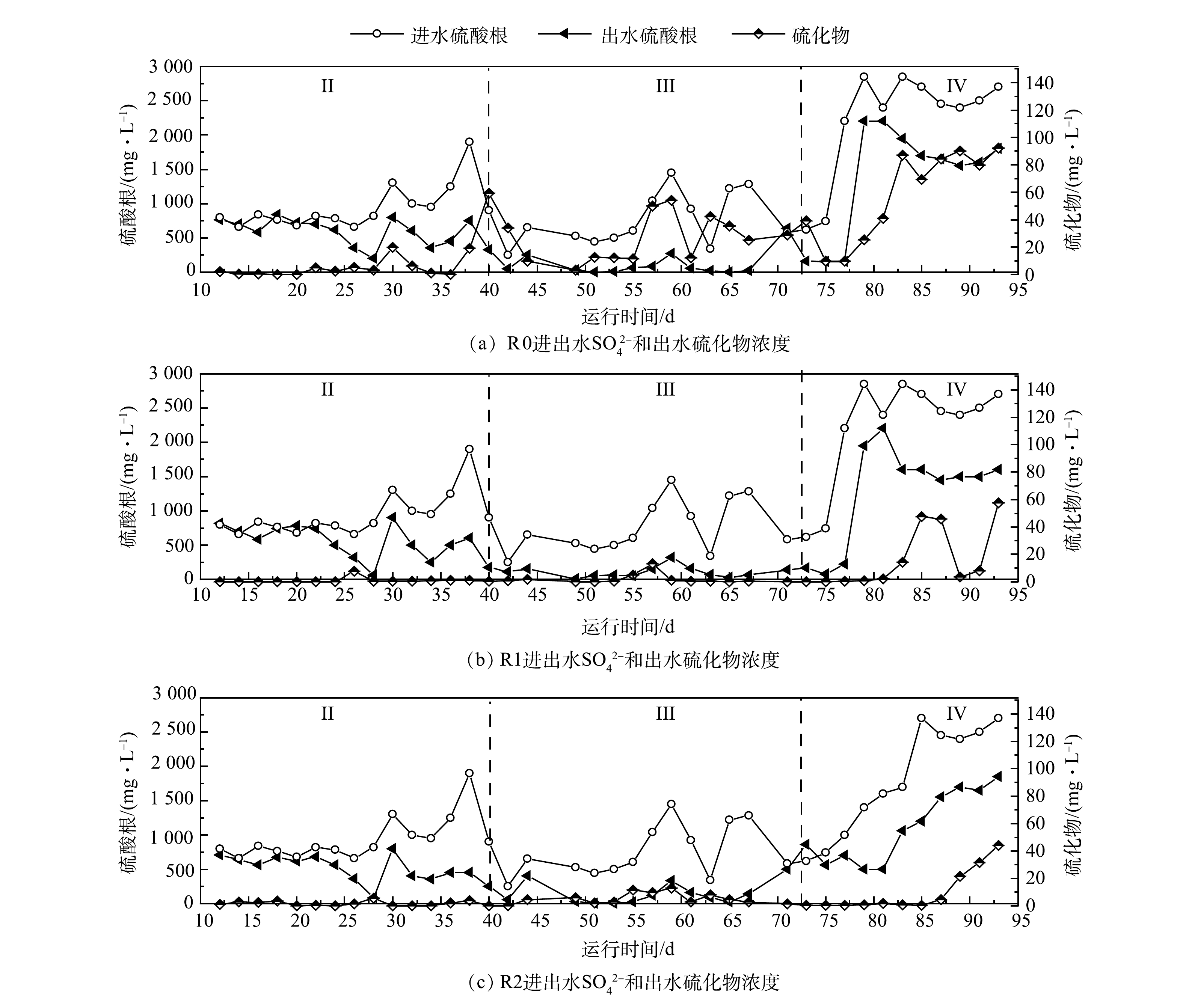

图4反映了3个反应器的进出水SO42−浓度和出水硫化物含量的变化。阶段Ⅱ进水SO42−质量浓度在620~1 900 mg·L−1内波动,3个反应器出水SO42−均低于进水,说明进水中SO42−刺激了反应器中SRB的生长,发生了SO42−还原。3个反应器出水中均检测到还原产物硫化物,但R1和R2中的出水硫化物质量浓度平均仅为0.83 mg·L−1和1.64 mg·L−1,远低于R0的8.27 mg·L−1。进入阶段Ⅲ后,随着进水有机物浓度的增高,COD/SO42−增大至2.5,说明碳源充足更有利于硫酸盐的还原,导致出水硫酸根浓度进一步降低,3个反应器的硫酸根去除率均超过了80%。此阶段R0出水中的平均硫化物含量高达27.8 mg·L−1,但R1和R2仅为1.6 mg·L−1和4.9 mg·L−1。稳定期进水SO42−浓度进一步升高至2 200~2 850 mg·L−1,COD/SO42−降低至约0.6,硫酸盐还原虽然一定程度上受到限制,但较高的进水浓度使R0反应器出水硫化物含量增加至92.2 mg·L−1,R1在第85天出水硫化物也增加至47.5 mg·L−1,补充Fe0后虽有所降低但随后发生波动。这可能是由于Fe0释放铁离子速率低于硫酸盐还原速率,硫酸盐还原产生的硫离子未发生化学沉淀即随出水流出反应体系。R2反应器在第85天后的出水硫化物也逐渐升高,但平均质量浓度为20.3 mg·L−1,低于R0和R1。综上所述,当进水SO42−质量浓度小于1 900 mg·L−1时,投加Fe0和微氧曝气都可显著降低出水硫化物的含量,有助于控制体系的H2S溢出,但在高浓度SO42−的进水条件下,2种控制策略均对硫化物的去除作用有限。

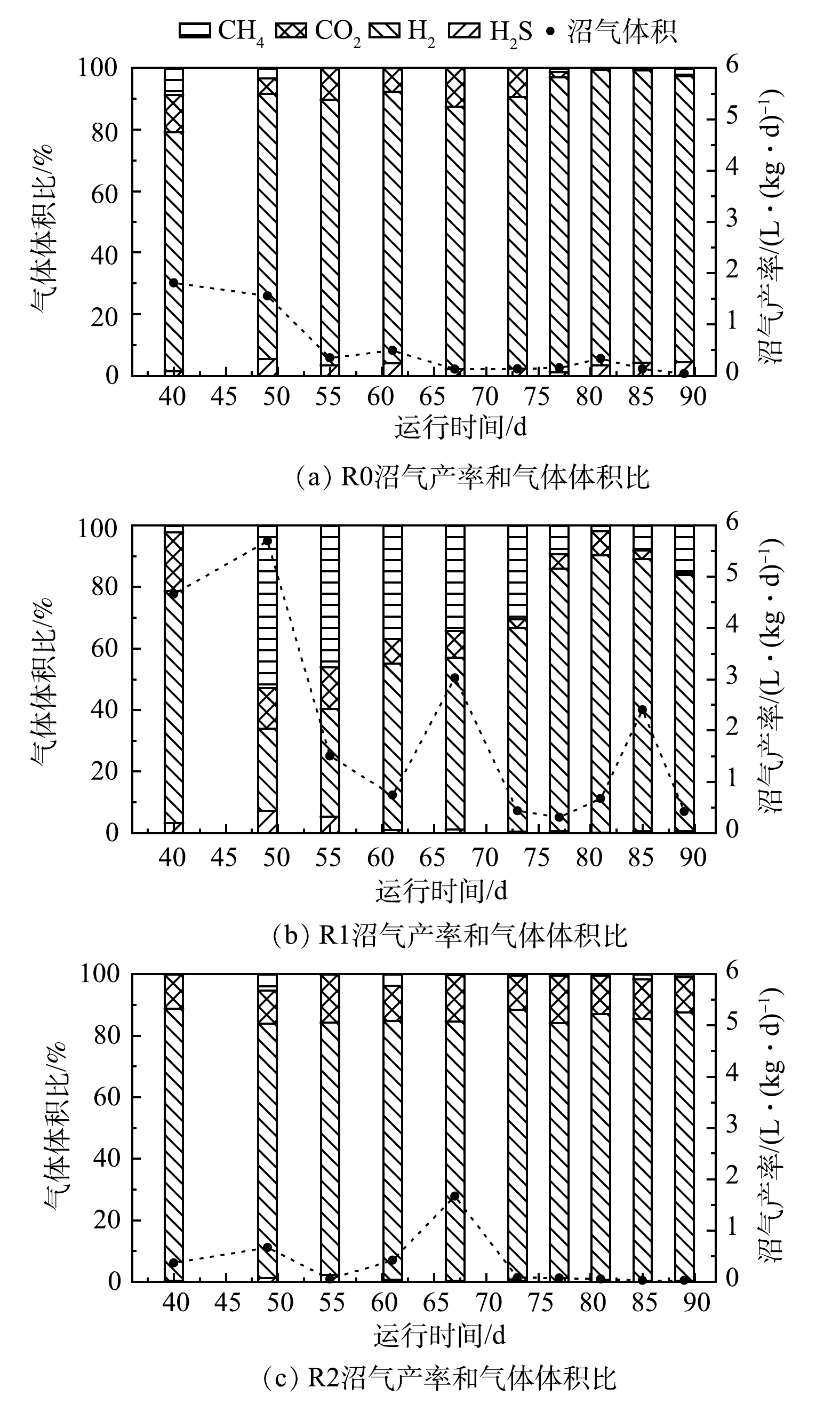

3个反应器运行至第40天时开始收集沼气,沼气产率及H2S、CO2、H2、CH4的气体体积比见图5。受到硫酸盐还原菌的竞争和硫化物毒性作用的影响,3个反应器的产气性能均较差,H2是主要的气体产物。这说明厌氧过程主要发生在产氢产酸阶段,较低的pH促进了H2S气体的溢出,R0、R1和R2的平均H2S体积比分别为3.19%、2.12%和0.59%。尽管3个反应器的产甲烷性能均不足,但相比R0和R2,R1的沼气产率和甲烷含量最高,分别为2.0 L·(kg·d)−1(以COD计)和23.8%,其甲烷产量是其余反应器的60倍以上。其原因可能是:投加的Fe0与反应器内的酸反应生成了Fe2+和H2,使体系的pH有所升高,同时Fe2+与S2−结合生成FeS削弱了硫化物的毒性;而且Fe0会降低反应体系内的氧化还原电位,为产甲烷菌的生长提供了更优的环境条件。

-

本研究分别利用GC-MS和FT-ICR MS对第93天反应器进出水的有机组成进行了分析。二元酸废水中有机酸类化合物含量最高,其余依次为杂原子类、醇酯醛酮类和芳香类化合物。经过UASB处理后,各个反应器的出水有机物组成均发生显著变化,详见表1。出水的有机酸和醇酯醛酮类化合物相对含量降低,这是因为醇类、有机酸类物质相对易发生厌氧生物降解,使出水中生物难降解物质如芳香类化合物[13]和杂原子类化合物[14]含量升高。

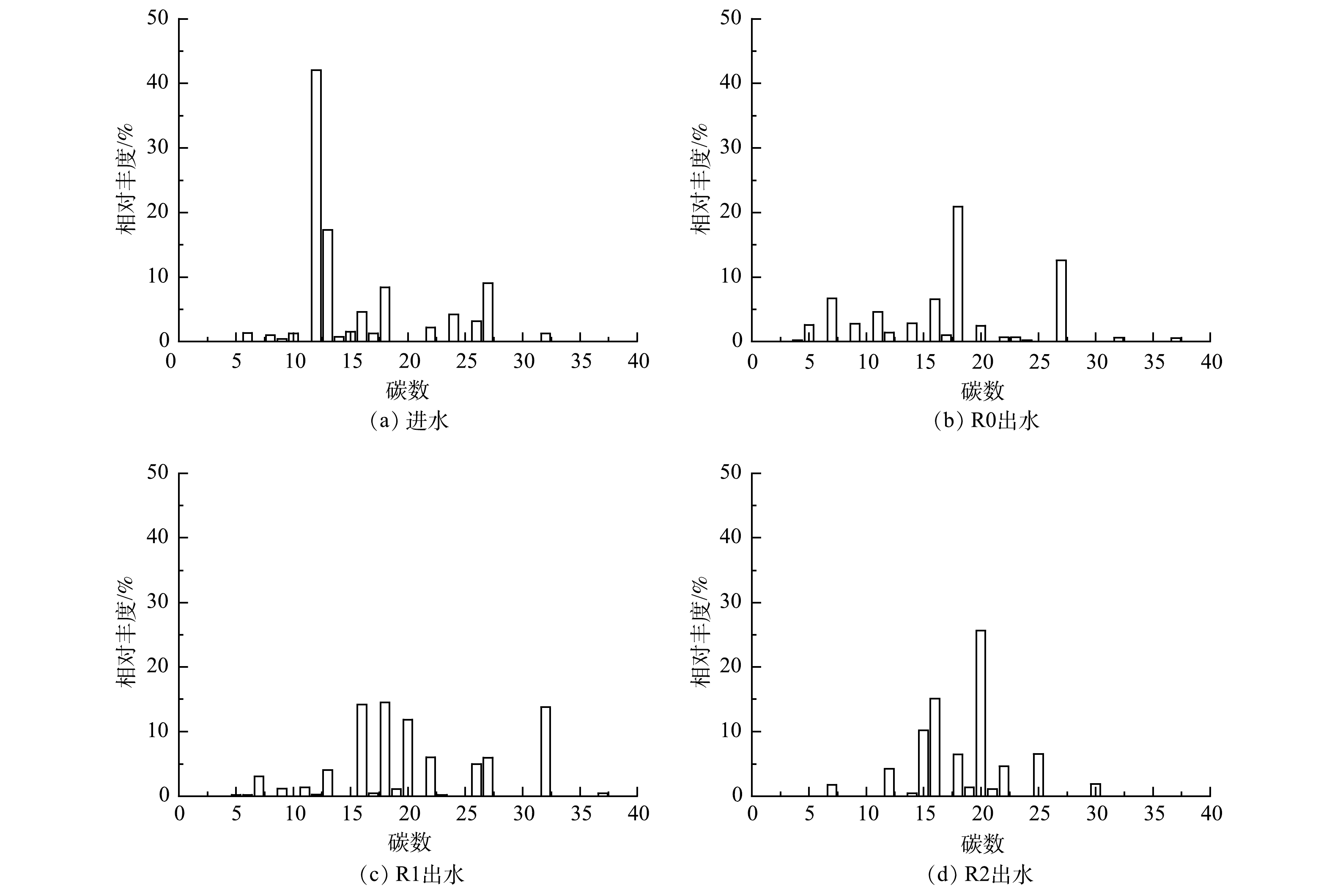

由图6中的碳数分布结果可见,进水中有机物以C12和C13为主,相对含量分别为42.02%和17.26%,其主要为生产的十二碳二元酸和十三碳二元酸产品残余物。R0出水有机物碳数分布较为均匀,检测到较多C15以下的小分子物质。这可能与R0反应器对废水中有机物的厌氧降解不彻底有关。一般情况下,当有机物碳数大于10时,随着碳原子数的增加其可生物降解性能相应下降[15]。而R1和R2出水中的有机物主要为碳原子数大于15的物质,其占比分别高达73.5%和72.8%,表明经R1和R2处理后,水中残留的物质主要为大分子难降解类有机物。

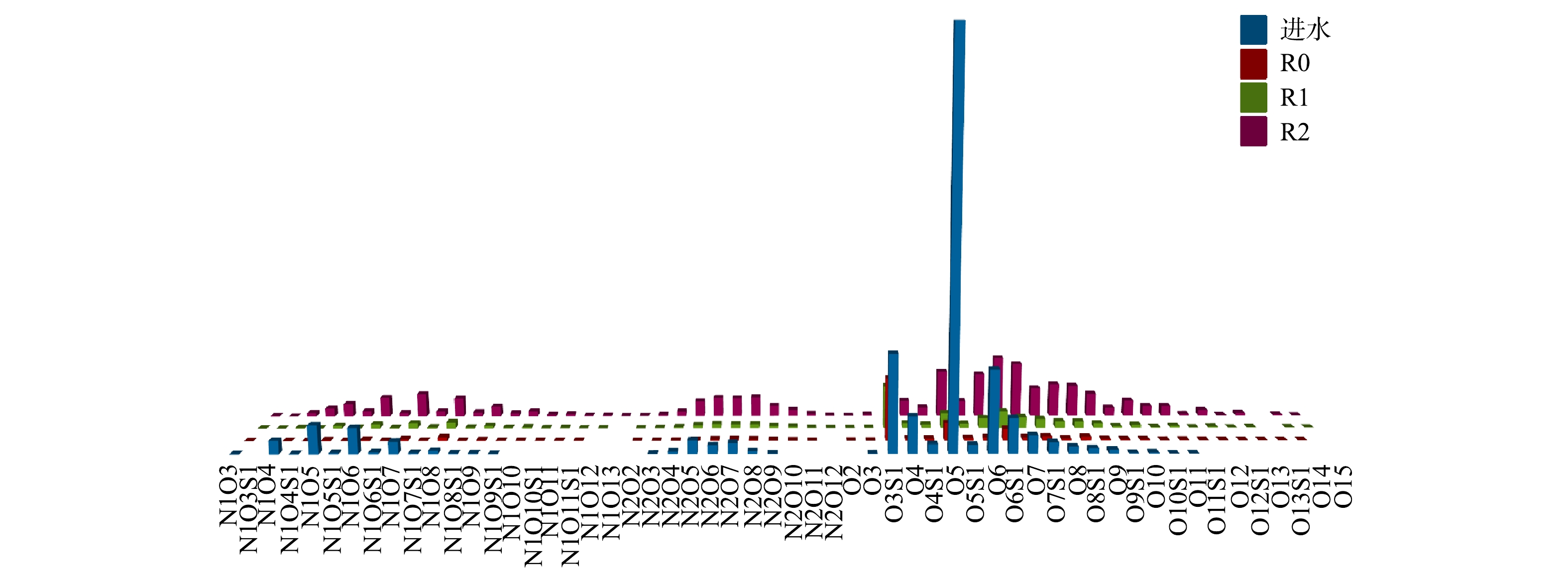

高分辨质谱的分析结果(图7)表明,进水中的有机物含有大量含氧类物质,说明含有较多亲水性官能团如羧基、羟基等的有机物,这些物质在UASB处理后的相对含量明显降低。进出水中的O3-9S1、N1O4-9和N1O4-9S1类物质的含量均较高,说明这些物质在厌氧生物处理过程中难以被降解转化。例如,O3S1化合物可能是烷基苯磺酸,是直链烷基苯磺酸盐的表面活性剂衍生物[12],其可生化性较差且易残留在出水中。N1O4-9类含有2个或多个烷基的氮衍生物,往往具有较高的毒性[16],是出水中残留的主要组分。对比3个反应器出水中的有机物组成发现,R1中O3S1等难降解物质的相对含量低于R0和R2,说明加入零价铁可提高厌氧微生物对难降解物质的生物转化能力。此外,R2中含氧有机物的含量均高于R0和R1。这一结果与微曝气有关:在微氧条件下有机物发生了部分好氧降解,在加氧酶的作用下使有机物分子上发生了加氧反应。

结合GC-MS和FT-ICR MS的结果可见,有机酸类是二元酸废水中的主要有机物,但这类物质在UASB反应器中的厌氧降解效果较好,主要的难降解类有机物为含硫、氮杂原子类物质,加入零价铁可促进这类物质的厌氧生物降解。

-

采用高通量测序对接种污泥和第93 天从R0、R1、R2采集的污泥样本进行了微生物群落结构分析。表2为Alpha多样性分析结果。所有样本的覆盖率指数均达到99.7%以上,表明每个样本都具有足够的测序深度。Ace和Chao指数的大小依次为R2>种泥>R0>R1,说明R2的群落丰富度最高,这可能与微氧环境同时促进了兼性好氧和兼性厌氧菌的生长有关。Shannon指数为种泥>R1、R2>R0,说明种泥的生物多样性最高。这是因为接种污泥取自炼化废水处理厂水解酸化池,炼化废水相比二元酸废水具有更为复杂的有机物组成,使种泥中的微生物群落多样性较高,而经二元酸废水驯化后多样性下降。R1和R2的Shannon指数明显高于R0,说明R0的微生态系统最为脆弱,这也与R0反应器较差的运行效果一致,添加Fe0和微曝气均缓解了硫化物的毒性效应,提高了系统的微生物多样性。

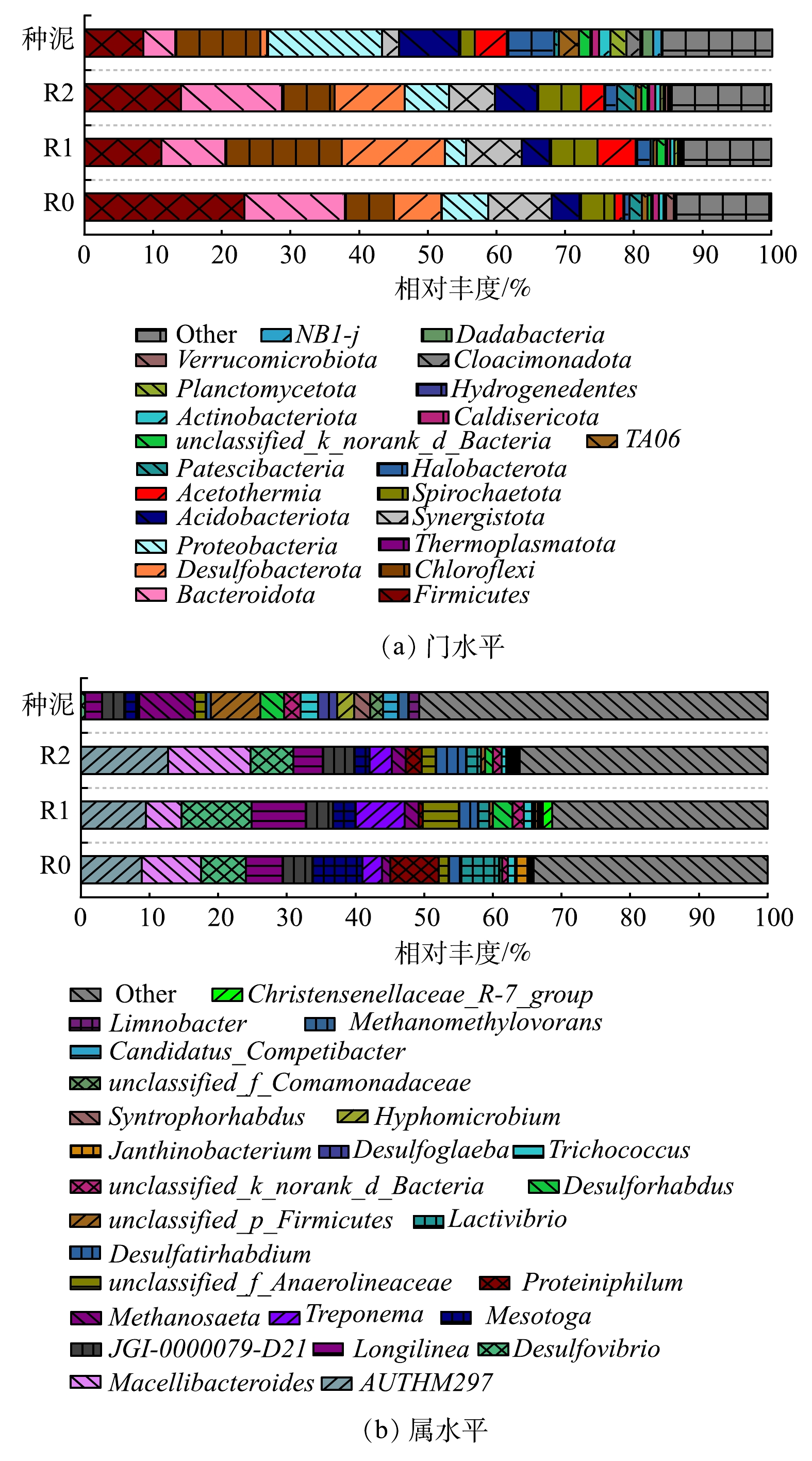

图8为4个样品门水平和属水平的群落结构结果。其中,相对丰度小于1%的物种均归为“Others”。种泥丰度最高的门为变形菌门(Proteobacteria)、绿湾菌门(Chloroflexi)、酸杆菌门(Acidobacteriota)和厚壁菌门(Firmicutes)。经过93 d的驯化,优势菌门的类型不变但相对丰度发生了改变。其中,厚壁菌门和脱硫菌门在R0、R1和R2中的相对丰度显著提高,分别达到了23.3%、11.2%和14.1%以及6.9%、15.0%和10.2%。而变形菌门和酸杆菌门的相对丰度均有降低。这是由于厚壁菌门是UASB反应器处理高硫酸盐废水的优势门[17],具有较强的有机物降解能力。较高的进水硫酸盐浓度促进了脱硫菌门中硫酸盐还原菌的生长。

在属水平上,反应器中的优势菌属与种泥有显著差异。相对丰度最高的属分别为AUTHM297(R0为8.9%;R1为9.5%;R2为12.7%)、Macellibacteroides(R0为8.6%;R1为5.1%;R2为12.0%)、Desulfovibrio(R0为6.5%;R1为10.2%;R2为6.2%)和Longilinea(R0为5.4%;R1为7.9%;R2为4.3%)。AUTHM297广泛存在于抗生素生产废水[18]、聚丙烯酰胺生产废水[19]等厌氧处理反应器中。Macellibacteroides和Desulfovibrio分别为水解酸化菌和硫酸盐还原菌,均可利用大分子有机物为碳源进行异养代谢[20]。Longiline是一种兼性厌氧菌,可促进污水中有机物的厌氧降解,有效降低水中的COD[21]。这些优势菌属的富集可能在UASB处理二元酸废水中发挥重要作用。对比3个反应器,R1中的硫酸盐还原菌如Desulfatirhabdium、Desulfoglaeb和Desulforhabdus的含量更高。这些菌属可以利用硫酸盐作为电子受体、乙酸等[22]有机物作为电子供体生长繁殖,R1较高的COD去除率可能与这些菌属的富集有关。此外,R1中产甲烷菌Methanosaeta和Methanomethylovorans的总丰度最高为2.3%,而R2中的丰度最低为1.3%,这表明微氧环境同时抑制了硫酸盐还原菌和产甲烷菌的生长。

以上结果表明,添加Fe0及微曝气均可通过控制体系中硫化物浓度提升UASB的运行性能,但其作用机制完全不同。添加Fe0可同时促进硫酸盐还原菌和产甲烷菌的生长,硫酸盐还原和产甲烷过程可协同提高有机物的降解效率。而微曝气通过刺激部分兼性好氧微生物的代谢提高有机物降解,但对硫酸盐还原菌和产甲烷菌的生长均有抑制作用,虽然有效降低了体系中硫化物的浓度,但也同时对产甲烷过程产生不利影响,反应体系的微生态系统较为脆弱。因此,添加Fe0是更优的硫化物控制方法,在提高UASB对高硫酸盐二元酸废水的处理性能、运行稳定性和甲烷产量方面均更具优势。

-

1)添加Fe0抑制剂和微曝气均能够在一定程度上降低出水硫化物浓度,提高UASB对长链二元酸废水的处理效果。其中,添加Fe0对COD去除率、反应器抗冲击能力和产甲烷性能的提升效果更优。

2)有机酸是二元酸生产废水中的主要有机污染物,其厌氧可生物降解性较好,含硫、氮杂原子类物质是主要的难降解组分,添加Fe0有助于难降解有机物的去除。

3)微氧环境提高了微生物的丰富度,但抑制了产甲烷菌的生长;Fe0更有助于提高群落多样性,并促进硫酸盐还原菌和产甲烷菌的富集,硫酸盐还原和产甲烷过程共同发挥了去除废水中有机污染物的作用。添加Fe0是UASB处理二元酸废水更有效的控制硫化物浓度和提升反应器性能的技术策略。

UASB处理高硫酸盐二元酸废水的效果及硫化物控制技术

Treating effect of dicarboxylic acids wastewater with high sulfate content by UASB and the sulfite control technology

-

摘要: 长链二元酸生产废水具有高有机物和硫酸盐含量的特点。本研究探索了在控制出水硫化物的条件下厌氧生物处理工艺对二元酸废水的处理效能。实验在空白对照(R0)、添加Fe0抑制剂(R1)和微曝气(R2)3组UASB反应器中进行。经过93 d的连续运行后发现:添加Fe0和微曝气均可提高UASB的运行性能;在稳定期,R1和R2的COD去除率相比R0分别提升了104%和77%,并减少了48%和78%的出水硫化物含量。添加Fe0有助于产生甲烷,但微曝气降低了沼气产率和甲烷含量。微生物群落分析表明,AUTHM297、Desulfovibrio、Macellibacteroides、Longilinea是厌氧生物处理二元酸废水中的优势菌属。硫酸盐还原和产甲烷过程可共同作用于二元酸废水中有机物的去除。

-

关键词:

- 二元酸废水 /

- 硫酸盐 /

- 上流式厌氧污泥床(UASB) /

- 微曝气 /

- 零价铁

Abstract: Long chain dicarboxylic acid wastewater has the characteristics of high organic matter and sulfate content. In this study, the anaerobic treatment performance of long chain dicarboxylic acid wastewater under the condition of controlling effluent sulfite concentration was investigated. Three reactors were set up which were R1 added with Fe0 and R2 with micro-aeration, R0 as control. After 93 days of continuous operation, Fe0 addition and micro-aeration improved the operational performance of UASB. In the stable period, the COD removal efficiencies of R1 and R2 increased by 104% and 77%, respectively, compared with R0, and effluent sulfide content was reduced by 48% and 78%. Fe0 improved the methanogenesis, but micro-aeration reduced biogas yield and methane content. The dominant genus in the anaerobic treatment systems were AUTHM297, Desulfovibrio, Macellibacteroides and Longilinea. Both of sulfate reduction and methanogenic processes contributed to organic compounds removal from long chain dicarboxylic acid wastewater. -

-

表 1 各反应器进出水有机物组成

Table 1. Organic composition of influent and effluent in each reactor %

取样单元 有机酸类 醇酯醛酮类 芳香类 杂原子类 烷烃类 其他 进水 51.3 18.4 7.6 21.9 0 0.7 R0出水 20 6.2 13.2 59.2 0 1.4 R1出水 14.7 13.8 11.5 59.7 0 0.3 R2出水 16 11 15.5 55.6 0 1.9 表 2 Alpha多样性指标计算结果

Table 2. Alpha diversity index results

样品来源 Ace Chao Shannon 覆盖率/% 种泥 998.03 986.13 5.04 99.88 R0 956.94 923.31 4.31 99.74 R1 939.49 920.79 4.65 99.74 R2 1 074.58 1 064.39 4.60 99.70 -

[1] 杨文焕, 隋秀斌, 于玲红, 等. AMBBR-SMBBR工艺处理二元酸废水中试研究[J]. 水处理技术, 2017, 43(8): 109-113. [2] 沈润, 孙波, 张德光, 等. 发酵法生产长链二元酸工艺的废水深度处理方法[J]. 药物生物技术, 2009, 16(2): 1. [3] 王庆宏, 余静诗, 梁家豪, 等. UASB处理高硫酸盐废水及人工神经网络模型的构建[J]. 工业水处理, 2021, 41(7): 77-81. [4] STERGAR V, ZAGORC-KONČAN J, AZGAJNAR-GOTVAN A, Laboratory scale and pilot plant study on treatment of toxic wastewater from the petrochemical industry by UASB reactors[J]. Water Science & Technology, 2003, 48(8): 97-102. [5] 林锡伦, 大型UASB装置处理发酵药物混合废水工程[J]. 中国沼气, 1990(3): 29-31. [6] 王炜, 何好启. UASB+接触氧化法处理食品废水的工程应用[J]. 广州化工, 2012, 40(19): 106-107. [7] 苗英霞, 王静, 张雨山. 含盐污泥厌氧消化过程中金属离子对硫化氢产气率的抑制作用[J]. 工业水处理, 2010, 30(3): 16-19. [8] 徐中慧, 李东伟, 王克浩, 等. 两相厌氧反应器相分离实验研究[J]. 环境工程学报, 2010, 4(12): 2786-2788. [9] WU C Y, ZHOU Y X, WANG P C, et al. Improving hydrolysis acidification by limited aeration in the pretreatment of petrochemical wastewater[J]. Bioresource Technology, 2015, 194: 256-262. doi: 10.1016/j.biortech.2015.06.072 [10] DÍAZ I, LOPES A C, PÉREZ S I, et al. Performance evaluation of oxygen, air and nitrate for the microaerobic removal of hydrogen sulphide in biogas from sludge digestion[J]. Bioresource Technology, 2010, 101(20): 7724-7730. doi: 10.1016/j.biortech.2010.04.062 [11] XU X J, CHEN C, WANG A J, et al. Enhanced elementary sulfur recovery in integrated sulfate-reducing, sulfur-producing rector under micro-aerobic condition[J]. Bioresource Technology, 2012, 116: 517-521. doi: 10.1016/j.biortech.2012.03.095 [12] YE H F, LIU B D, WANG Q H, et al. Comprehensive chemical analysis and characterization of heavy oil electric desalting wastewaters in petroleum refineries[J]. Science of the Total Environment, 2020, 724: 138117. doi: 10.1016/j.scitotenv.2020.138117 [13] 何苗, 张晓健, 瞿福平, 等. 焦化废水中芳香族有机物及杂环化合物在活性污泥法处理中的去除特性[J]. 中国给水排水, 1997, 1: 14-17. [14] LI Y M, GU G W, ZHAO J F, et al. Anoxic degradation of nitrogenous heterocyclic compounds by acclimated activated sludge[J]. Process Biochemistry, 2001, 37(1): 81-86. [15] 张自杰, 马若冰, 刘玉川. 某些化学物质的分子结构对生物降解的影响[J]. 中国给水排水, 1999, 5: 23-25. [16] LI Y Y, FANG Z, HE C, et al. Molecular characterization and transformation of dissolved organic matter in refinery wastewater from water treatment processes: characterization by fourier transform ion cyclotron resonance mass spectrometry[J]. Energy & Fuels, 2015, 29(11): 6956-6963. [17] 苗雨. 高浓度硫酸盐有机废水厌氧生物处理及其微生物学特性研究[M]. 南京: 南京大学, 2015. [18] LU M Q, NIU X J, CHEN W Y, et al. Phosphine production in anaerobic wastewater treatment under tetracycline antibiotic pressure[J]. Journal of Environmental Sciences, 2018, 69: 239-250. doi: 10.1016/j.jes.2017.10.018 [19] ZHANG K, CHEN S B, CHANG M D, et al. Treatment of polyacrylamide production wastewater by multistage contact reactor with activated and anammox sludge[J]. Biochemical Engineering Journal, 2019, 150: 107287. doi: 10.1016/j.bej.2019.107287 [20] HE Y P, TIAN Z, YI Q Z, et al. Impact of oxytetracycline on anaerobic wastewater treatment and mitigation using enhanced hydrolysis pretreatment[J]. Water Research, 2020, 187: 116408. doi: 10.1016/j.watres.2020.116408 [21] SONG G Q, XI H B, ZHOU Y X, et al. Influence of organic load rate (OLR) on the hydrolytic acidification of 2-butenal manufacture wastewater and analysis of bacterial community structure[J]. Bioresource Technology, 2017, 243: 502-511. doi: 10.1016/j.biortech.2017.06.162 [22] OUDE ELFERINK S J, MAAS R N, HARMSEN H J, et al. Desulforhabdus amnigenus gen. nov. sp. nov., a sulfate reducer isolated from anaerobic granular sludge[J]. Archives of Microbiology, 1995, 164(2): 119-124. doi: 10.1007/BF02525317 -

下载:

下载: