-

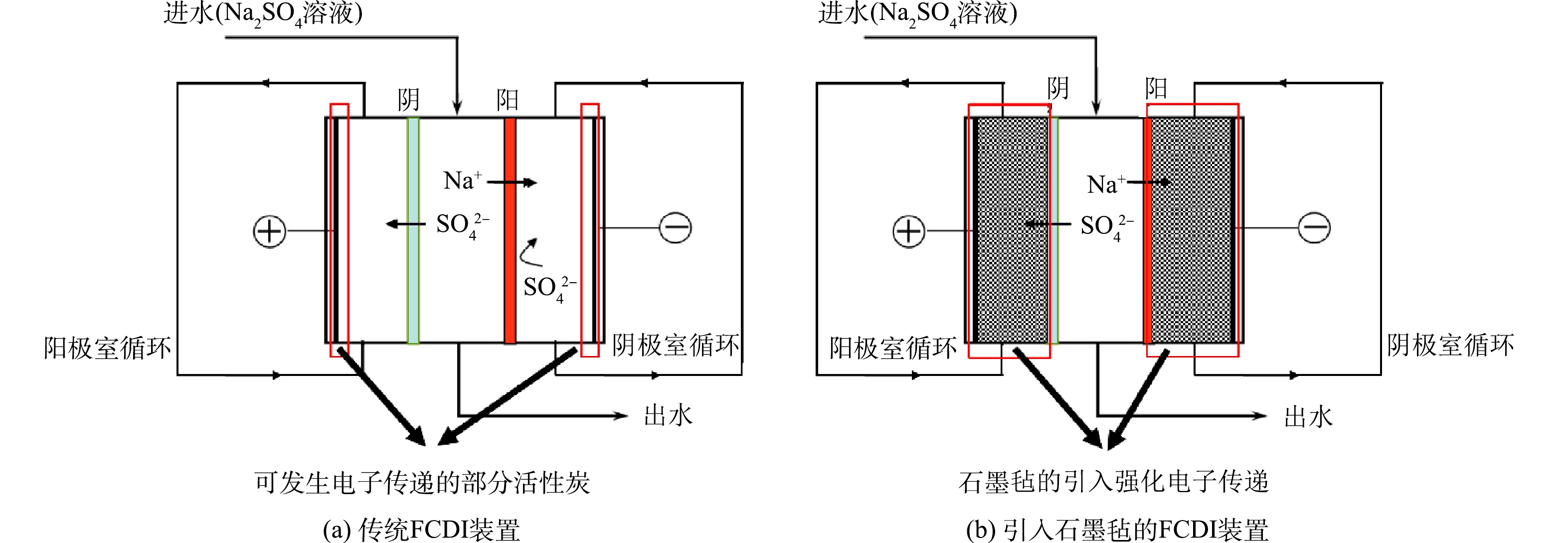

电容去离子(capacitive deionization,CDI)技术作为一种低能耗,绿色的脱盐技术受到了很多研究者的关注[1-9]。CDI技术主要依赖于在电极表面形成的双电层来捕获进水中的阴阳离子[7-13]。而CDI技术的工作原理如图1所示。

然而,受限于固定电极的低吸附容量,CDI技术在现阶段只适用于处理中低盐度的苦咸水[7-9]。并且CDI的电极材料在吸附饱和之后需要再生,这将导致无法实现连续流的操作[6-9,14]。因此,JEON的研究团队于2013年提出了流动电极电容去离子技术(flow electrode capacitive deionization,FCDI),其使用流动的粉末活性炭浆液替代传统的固定碳电极[15]。这里使用的流动电极含有更多的活性物质(活性炭),因此,可提高系统整体的吸附容量,这将使得处理高盐度进水(例如海水等)成为可能[16-21]。同时,吸附饱和的流动电极可以通过在系统外混合阴极和阳极材料来实现再生,实现FCDI系统连续运行[22-25]。

然而,在流动电极中粉末活性炭的导电能力很弱,导致了粉末活性炭之间的电子传递非常低效。只有靠近集流体的部分粉末活性炭可以形成双电层结构从而捕获离子,导致流动电极中大部分处于电中性的粉末活性炭无法有效的实现离子去除[26-27]。研究者通过增加流动电极中的活性碳含量,提高了活性炭颗粒之间的碰撞概率,强化了颗粒之间的电子传递[28-29]。然而,活性炭含量的提高将会导致流动电极的黏度增加,这有可能导致流道的堵塞。因此,活性炭含量的提高是存在上限的,通常大约在15%[30-31]。同时,一些研究者通过在流动电极中添加高导电性的物质来建立高效的导电网络,从而提升活性炭的利用率以增加FCDI系统的脱盐效率[32-36]。增加活性炭的含量或者是添加高导电性物质的目的是促进活性炭与集流体之间的电子转移。因此,是否有可能通过优化集流体的材料来强化系统的电子转移?

在传统的FCDI装置中,现阶段使用最多的集流体材料是石墨板[30,37],这主要是因为其良好的导电性和耐腐蚀性。然而,石墨板本身易碎,凹槽的加工耗时昂贵,而且石墨板的密度很大,不利于FCDI系统的工程应用。因此,需要更为合适的材料来取代石墨板。而石墨毡是由石墨碳纤维组成的,同时拥有良好的导电性、耐腐蚀性、高孔隙度和良好的液体渗透性[38]。与二维石墨板相比,石墨毡作为三维多孔电极可以提供更多的接触位点,促进流动电极与集流体之间的电子转移。并且,石墨毡的密度很小(约为石墨板密度的1/20),易于加工处理,也有利于FCDI设备的扩大化和工业化应用。

因此,本研究预期使用石墨毡而不是石墨板,作为FCDI系统的集流体,利用石墨毡的三维多孔结构来增加流动电极与集流体之间的电子转移,强化脱盐性能。本文侧重于探究石墨毡在强化FCDI系统脱盐性能上的可行性以及石墨毡在强化脱盐过程中的机理,以对FCDI技术的应用发展提供帮助。

-

Na2SO4(分析纯,中国医药集团有限公司)、粉末活性炭(YP-50F,可乐丽株式会社)、石墨毡(北海炭素有限公司、密度0.13~0.16 g·cm-3、厚度5 mm)。

-

每个FCDI装置包括1个镂空的硅胶垫、1对阴阳离子交换膜(150 mm×150 mm,日本ASTOM株式会社)、2个石墨毡(5 mm×40 mm×40 mm)、2个空心塑料板和2个有机玻璃板。在质量浓度为2 g·L-1的硫酸钠溶液中,通过分散5%的粉末活性炭以制备流动电极,并且所有的FCDI实验均在隔离闭合循环(isolated close cycle, ICC)模式下进行。文章中所使用的FCDI装置如图2所示,石墨毡强化脱盐性能的相关机理也在图2中有所体现,主要是通过自身的三维多孔结构为流动电极提供充足接触位点,提高活性炭利用率,以强化电子转移过程,实现系统脱盐能力提升的。而本文中所示的GF+AC组为以石墨毡为集流体,活性炭为流动电极的实验组;AC组为以石墨板为集流体,活性炭为流动电极的实验组;GF组为以石墨毡为集流体,硫酸钠溶液为电极液的实验组,通过各实验组之间运行效能的对比来体现石墨毡强化脱盐的能力。

-

FCDI系统中的脱盐率根据式(1)进行计算。盐平均去除率(average salt removal rate, ASRR)和去除单位盐量所需能耗(energy consumption required for removed of unit salt, ECRS)分别根据式(2)和式(3)进行计算。

式中:Q为脱盐率,%;R为盐平均去除率(ASRR),µmol·(cm2·min)-1,E为去除单位盐量所需能耗(ECRS),J·μmol-1,C0为盐初始浓度,mg·L-1,Ct为运行后的盐浓度,mg·L-1,t为运行时间,s,V为进水体积,L,Aion为离子交换膜的有效工作面积,m2,I为装置电流,A,U为装置电压,V,n为盐离子的电荷量,F为法拉第常数,C·mol-1,M为盐的摩尔质量,g·mol-1。

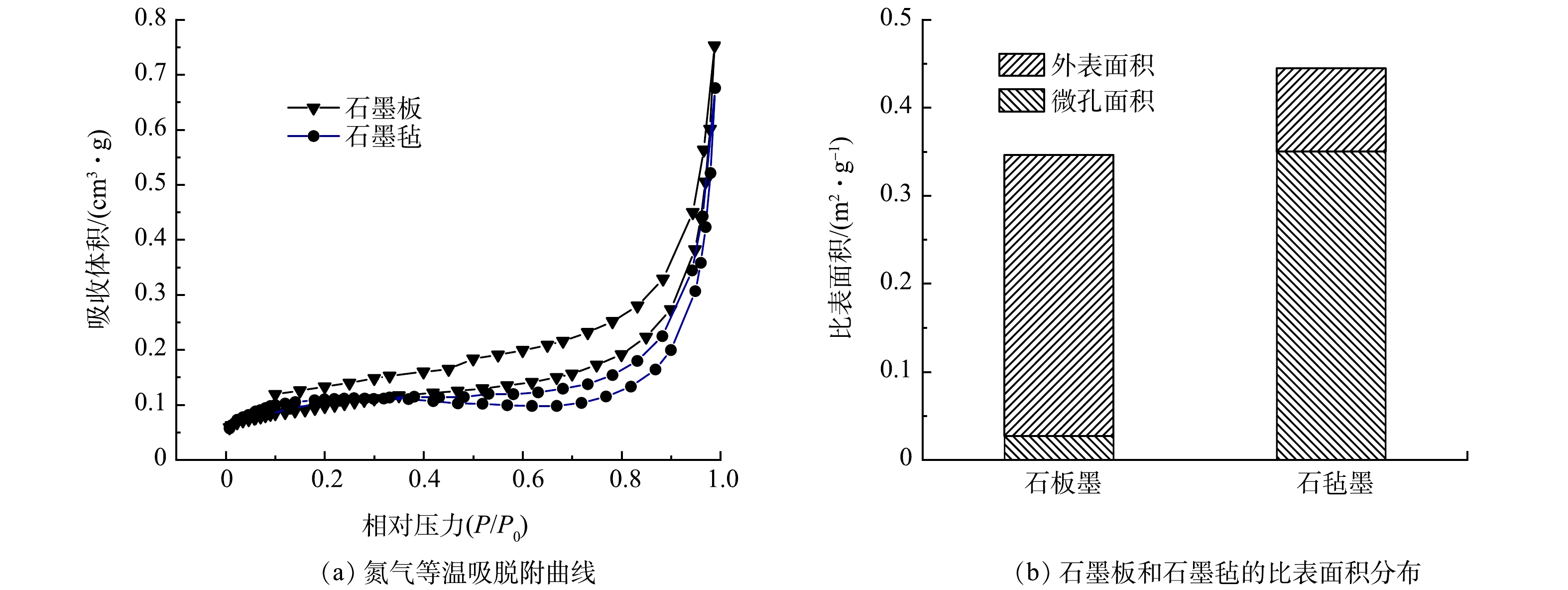

石墨毡和石墨板的孔径分布情况是用氮气吸附-解吸仪(ASAP 2460, Micromeritics)测定的,其中比表面积采用Brunauer-Emmett-Teller法计算,孔径分布参数采用Barrett-Joyner-Halenda法计算,外表面积采用t-plot法计算,并最终由氮气等温吸脱附曲线确定。

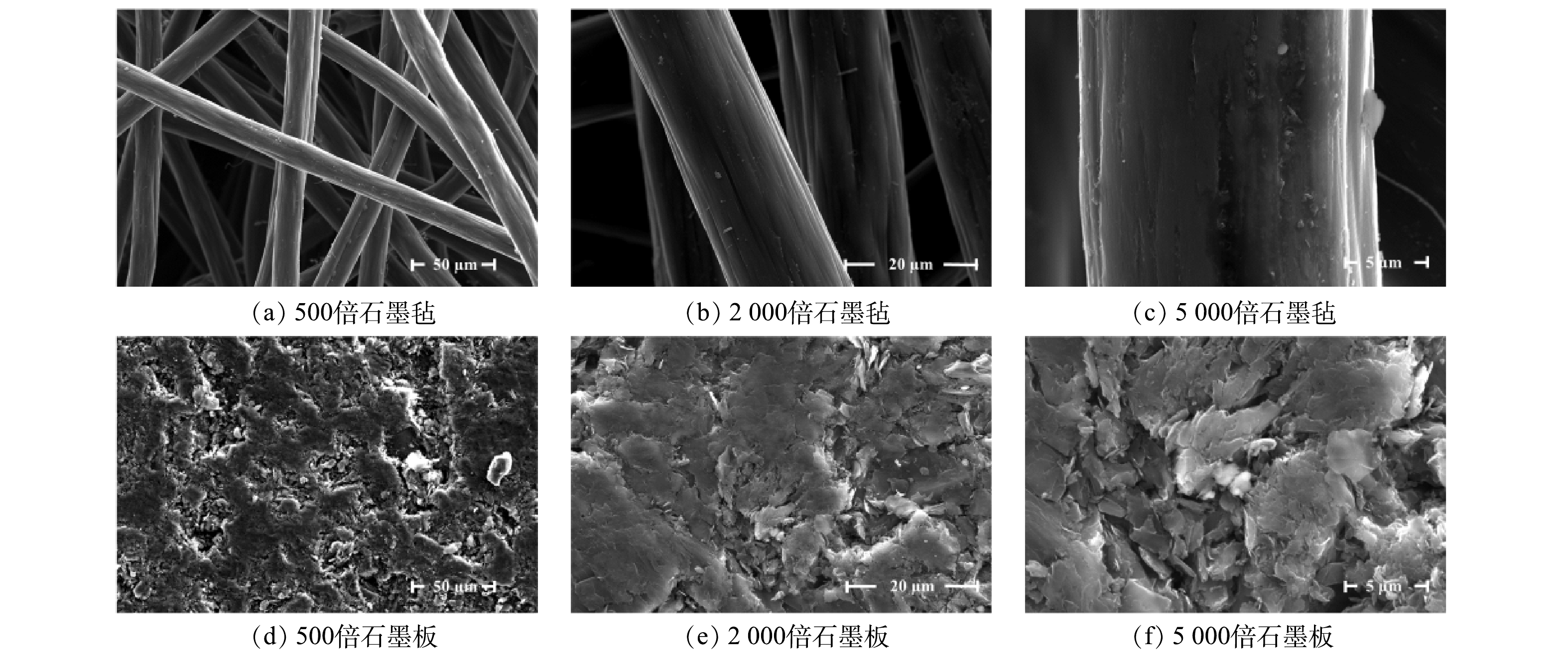

对于石墨毡与石墨板的SEM表征采用如下方法进行:首先将石墨毡与石墨板样品粘贴固定在金属样品台上,并完成喷金操作,后使用扫描电镜(Quattro, FEI, America)在特定倍数(500、2 000和5 000倍)下进行拍照分析。同时该扫描电镜配备了数字慢扫图像记录系统(SemAfore),用于查看和图像捕获。

-

为了验证石墨毡是否可以提高FCDI系统的脱盐性能,比较了石墨毡存在和不存在条件下FCDI系统的脱盐性能,二者均使用YP-50粉末活性炭制备流动电极,结果如图3所示。在引入石墨毡后,FCDI系统的脱盐率得到了极大的提高。在1.0 V的电压下,FCDI系统的脱盐速率增加了2倍,从0.026 µmol·(cm2·min)-1增加到了0.072 µmol·(cm2·min)-1。随着电压的提高,脱盐效果逐步提升。结果表明,石墨毡的引入的确可以提升FCDI系统的脱盐性能。

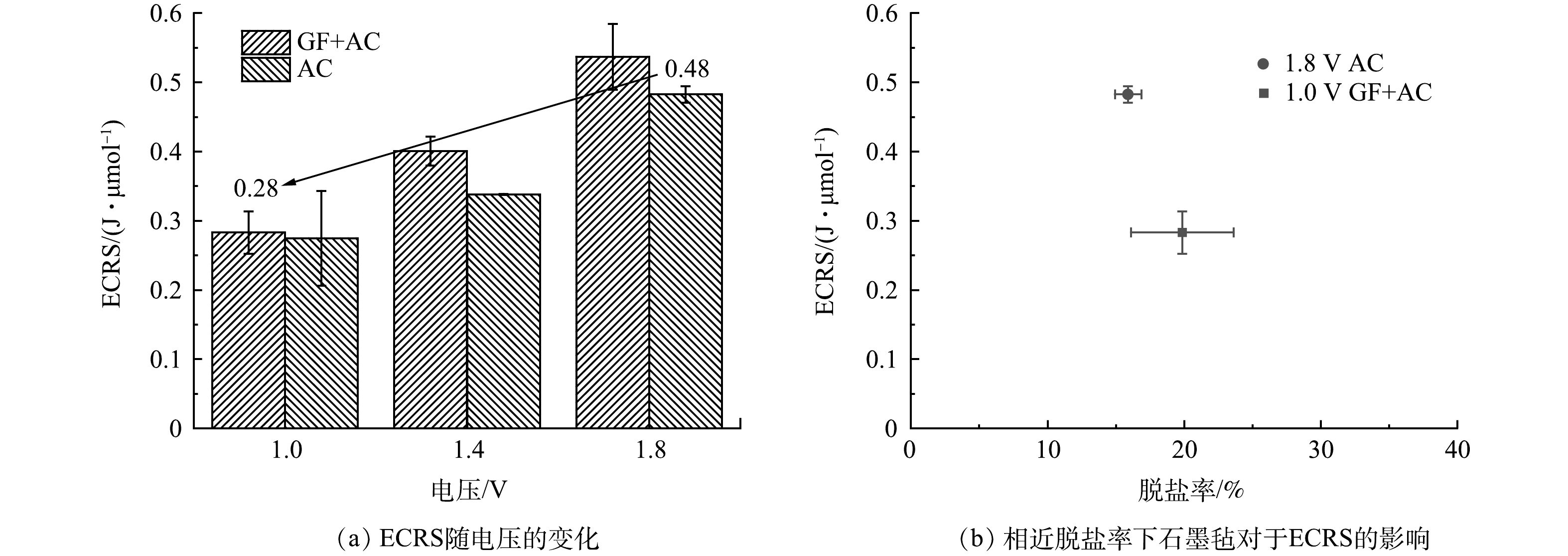

同时,在去除等量盐离子的情况下,含有石墨毡的FCDI系统的能耗相对较低,如图4(b)所示。当脱盐率约为20%时,石墨毡的引入可以将单位能耗从0.48 J·μmol−1降至0.28 J·μmol−1,能耗降低了40%。因此,根据图3和图4所得结论,表明石墨毡的引入不仅可以提高FCDI系统的脱盐性能,还可以降低系统的能耗,以提升FCDI系统的整体能效。

-

1)石墨毡和活性炭在脱盐过程中的贡献。为了探究石墨毡提升FCDI系统脱盐性能的机理,我们比较了FCDI系统在活性炭与石墨毡单独存在和共存条件下的脱盐性能。从图5可以看出,当施加的电压从1.0 V增加到1.8 V时,石墨毡单独存在的FCDI系统的脱盐率从0增加到9.9%。在低压条件(1.0 V)下,仅含有石墨毡的FCDI系统没有脱盐效果。而在高压条件(1.8 V)下,仅有石墨毡存在的FCDI系统的脱盐率仅占石墨毡和活性炭共存系统的15%,这主要是由于石墨毡本身的电吸附效应[6-9]。因此,可以认为石墨毡的电吸附效应在FCDI系统的脱盐过程中发挥了一定的作用,但这个效应的贡献占比相对较小。石墨毡的电吸附效应并非是石墨毡与活性炭共存条件下大幅提升FCDI脱盐性能的主要原因。

2)石墨毡比表面积对于脱盐过程的影响。盐离子的电吸附效应主要依赖于电极材料的高比表面积。从氮气等温吸脱附曲线(图6(a))得知,石墨毡的比表面积非常小(接近于石墨板的比表面积),表明其自身的电吸附能力很弱。这也就解释了石墨毡单独存在的FCDI系统在低压条件下没有脱盐效果的现象。与此同时,在活性炭单独存在的条件下,当施加的电压从1.0 V增加到1.8 V时,FCDI系统的脱盐率由7.2%上升到15.8%,这一数值高于石墨毡单独存在的实验组。然而,这一数值仅占石墨毡与活性炭共存条件下整体脱盐率的约25%。因此,石墨毡与活性炭共存条件下FCDI系统更高的脱盐性能主要归功于石墨毡与活性炭之间的相互作用。

石墨板是由石墨片的不断累积形成的,表面的石墨片见图7。石墨板中的石墨片紧密相连并且拥有着良好的导电性能,这也是其可以被用作二维电极的原因。而石墨毡是由直径约为20 µm的石墨化碳纤维制成,碳纤维之间的间隙非常大,从而保证石墨毡的高孔隙度。与二维石墨板相比,拥有三维多孔结构的石墨毡具有更大的接触面积。因此,当使用石墨毡作为FCDI系统的集流体时,流动电极与集流体之间的接触概率增加,从而提高了流动电极中活性炭的利用率。同时,石墨毡的使用也突破了只有靠近集流体表面的活性炭才能够被利用的限制。因此,与石墨板相比,石墨毡通过增加活性炭与集流体之间的电子转移,增强了FCDI系统脱盐过程的驱动力,从而提高了整体系统的脱盐性能。

为了证实石墨毡的三维多孔结构的确可以促进FCDI系统中的电子转移,我们对压实前后的FCDI系统的脱盐性能进行了比较。验证实验中所使用的FCDI装置是由相同的石墨毡和活性炭组成的,唯一的区别是其使用的石墨毡是提前压实的。这使得石墨毡从最初的5 mm厚度压实到目前的3 mm,从而极大的降低活性炭和石墨毡集流体之间的接触面积。如图8所示,当石墨毡被压实后,FCDI装置的脱盐性能迅速下降。当施加的电压为1.0、1.4和1.8 V时,脱盐率仅为3.2%、7.5%和10.6%。其脱盐率仅为压实前的16%~26%,其脱盐率甚至低于仅存在活性炭时的实验组。石墨毡的压实降低活性炭与石墨毡集流体之间的接触面积,减少了活性炭与集流体之间的电子转移,从而限制FCDI系统脱盐。因此,石墨毡主要是通过三维多孔结构为活性炭提供充足的接触位点,以提高流动电极中活性炭的利用率,强化系统中的电子转移,从而提升FCDI装置的脱盐性能。

-

为了进一步确认是石墨毡的引入促进了活性炭与集流体之间的电子转移过程,利用电化学工作站直接对阴极和阳极的电子转移能力进行了评估。将质量浓度为2 g·L-1的硫酸钠溶液放置在H型电解池两侧充当电解质,并使用离子交换膜分隔阳极室和阴极室。然后分别将活性炭和石墨毡添加到阴极室和阳极室中,并在三电极体系(石墨棒作为工作电极和对电极,Ag/AgCl电极作为参比电极)下测定活性炭和石墨毡的电子转移能力。由图9中可以看出,石墨毡和活性炭共存条件下的电流远大于仅有活性炭存在下的电流。当施加的电位为−0.1 V时,石墨毡和活性炭共存条件下的电流比活性炭单独存在下的电流高5.5倍,而当施加的电位为+0.1 V时,石墨毡和活性炭共存条件下的电流比活性炭单独存在下的电流高7.8倍。而石墨毡单独存在下的电流却低于活性炭单独存在下的电流。以上结果表明,石墨毡的引入的确可以有效促进活性炭和电极之间的电子传递过程。

与石墨棒相比,石墨毡的接触面积更大,从而为活性炭提供了更多的接触位点,因此,流动电极中的活性炭可以得到更为充分的利用。同时,强化活性炭和电极之间的接触可以增强电极与活性炭之间的电子传递。在FCDI系统中,脱盐过程的驱动力主要来自于活性炭与电极之间的电子转移。电子转移越快,脱盐效果就越好。因此,石墨毡是通过增强流动电极中活性炭与电极之间的电子传递提高FCDI系统的脱盐性能。

-

1)石墨毡被引入到FCDI系统中以提升流动电极中活性炭的利用率,从而提高FCDI系统的脱盐率。与传统的FCDI系统相比,石墨毡的引入增强了系统中的电子转移过程,使得系统的脱盐率提高了175%。同时,在达到相同的脱盐率时,FCDI系统的能耗可以减少40%。因此,石墨毡的引入能够有效的提升FCDI系统的脱盐性能。

2)石墨毡对于FCDI系统脱盐性能的提升机制在于其与活性炭之间的相互作用。石墨毡主要是通过自身的三维多孔结构为活性炭提供充足的接触位点,提高流动电极中活性炭的利用率,以强化电子转移,实现更高效率的脱盐。

3)石墨毡本身的密度仅为石墨板的1/20,更易于加工处理。使用石墨毡而非石墨板得以有效减轻FCDI装置的整体重量,更容易实现FCDI系统的扩展和集成应用。下一阶段我们将在FCDI系统的规模化和长期运行方面进行更为深入的研究。

石墨毡集流体提升流动电极电容去离子脱盐性能

Enhanced desalination performance of flow electrode capacitive deionization by introduction of graphite felt as current collector

-

摘要: 针对流动电极电容去离子技术(FCDI)中活性炭利用率低的问题,采用三维多孔石墨毡充当集流体,强化系统的电子转移,提升脱盐性能。结果表明,石墨毡的引入使FCDI系统的脱盐效果提升了175%,并且将脱盐能耗降低了40%。通过分别比较石墨毡和活性炭对于系统脱盐效果的贡献,发现石墨毡主要是通过强化活性炭与集流体之间的电子传递,实现FCDI系统脱盐效率的提升。同时,阴阳极侧电子传递实验也证实了石墨毡的引入的确提升了集流体与活性炭之间的电子传递。这项研究解决了FCDI系统中活性炭的低利用率问题,为FCDI技术的应用与推广提供了理论上的指导。Abstract: As a new desalination technology, flow electrode capacitive deionization (FCDI) has received great attention. However, the poor electrical conductivity of activated carbon used in FCDI system has an adverse effect on its desalination performance. Therefore, in this study, three-dimensional porous graphite felt was introduced as current collector to increase the utilization of activated carbon in the flow electrode, so as to improve the electron transfer and the desalination performance of the FCDI system. The results showed that the introduction of graphite felt increased the desalination rate of FCDI by 175% and reduced the power consumption per unit desalination by 40%. By comparing the contribution rate to FCDI desalination between graphite felt and activated carbon, it was shown that graphite felt improved the desalination performance of FCDI mainly by strengthening the electron transfer between activated carbon and current collector. The experiment of electron transfer between cathode and anode confirmed that the introduction of graphite felt promoted the electron transfer between current collector and activated carbon. This study solves the problem of low utilization of activated carbon in FCDI system and provides a theoretical guidance for the popularization and application of FCDI.

-

-

-

[1] ZHAO R, BIESHEUVEL P M, VAN DER WAL A. Energy consumption and constant current operation in membrane capacitive deionization[J]. Energy & Environmental Science, 2012, 5(11): 9520-9527. [2] SUSS M E, BAUMANN T F, BOURCIER W L, et al. Capacitive desalination with flow-through electrodes[J]. Energy & Environmental Science, 2012, 5(11): 9511-9519. [3] GARCÍA-QUISMONDO E, SANTOS C, LADO J, et al. Optimizing the energy efficiency of capacitive deionization reactors working under real-world conditions[J]. Environmental Science & Technology, 2013, 47(20): 11866-11872. [4] TANG W, LIANG J, HE D, et al. Various cell architectures of capacitive deionization: Recent advances and future trends[J]. Water Research, 2019, 150: 225-251. doi: 10.1016/j.watres.2018.11.064 [5] RAMACHANDRAN A, OYARZUN D I, HAWKS S A, et al. High water recovery and improved thermodynamic efficiency for capacitive deionization using variable flowrate operation[J]. Water Research, 2019, 155: 76-85. doi: 10.1016/j.watres.2019.02.007 [6] XUE Y, CAO M, GAO J Z, et al. Electroadsorption of uranium on amidoxime modified graphite felt[J]. Separation and Purification Technology, 2021, 255: 117753. [7] 蒋绍阶, 张若汉, 熊关全. 电容去离子过程电吸附行为与法拉第反应关系及去除水体硬度[J]. 水处理技术, 2017, 43(9): 24-32. [8] 董旭明, 张胜寒, 狄杰, 等. 电吸附电极材料的研究进展[J]. 工业水处理, 2022, 42(1): 48-55. [9] 徐斌, 吴文倩, 张毅敏, 等. 石墨烯基电吸附电极材料的研究进展[J]. 水处理技术, 2020, 46(2): 13-24. [10] PORADA S, ZHAO R, VAN DER WAL A, et al. Review on the science and technology of water desalination by capacitive deionization[J]. Progress in Materials Science, 2013, 58(8): 1388-1442. doi: 10.1016/j.pmatsci.2013.03.005 [11] SUSS M E, PORADA S, SUN X, et al. Water desalination via capacitive deionization: What is it and what can we expect from it?[J]. Energy & Environmental Science, 2015, 8(8): 2296-2319. [12] LI H, ZOU L, PAN L, et al. Novel graphene-like electrodes for capacitive deionization[J]. Environmental Science & Technology, 2010, 44(22): 8692-8697. [13] ALMARZOOQI F A, AL GHAFERI A A, SAADAT I, et al. Application of capacitive deionisation in water desalination: A review[J]. Desalination, 2014, 342: 3-15. doi: 10.1016/j.desal.2014.02.031 [14] CHO Y, LEE K S, YANG S, et al. A novel three-dimensional desalination system utilizing honeycomb-shaped lattice structures for flow-electrode capacitive deionization[J]. Energy & Environmental Science, 2017, 10(8): 1746-1750. [15] JEON S I, PARK H R, YEO J G, et al. Desalination via a new membrane capacitive deionization process utilizing flow-electrodes[J]. Energy & Environmental Science, 2013, 6(5): 1471-1475. [16] 雍天智, 李阳, 陆建刚, 等. 流动电极电容去离子技术研究进展[J]. 工业水处理, 2023, 43(1): 17-25. [17] 莫恒亮, 唐阳, 陈咏梅, 等. 流动电极电吸附(FCDI)与电渗析(ED))耦合实现连续脱盐技术研究[J]. 现代化工, 2019, 39(5): 91-95. [18] 杨宏艳, 张卫珂, 葛坤, 等. 流动性电极电容去离子技术的脱盐性能研究[J]. 环境污染与防治, 2017, 39(8): 911-919. [19] XU L, MAO Y, ZONG Y, et al. Membrane-current collector-based flow-electrode capacitive deionization system: A novel stack configuration for scale-up desalination[J]. Environmental Science & Technology, 2021, 55(19): 13286-13296. [20] YANG S, CHOI J, YEO J G, et al. Flow-electrode capacitive deionization using an aqueous electrolyte with a high salt concentration[J]. Environmental Science & Technology, 2016, 50(11): 5892-5899. [21] TANG K, ZHOU K. Water desalination by flow-electrode capacitive deionization in overlimiting current regimes[J]. Environmental Science & Technology, 2020, 54(9): 5853-5863. [22] ZHANG C, WU L, MA J, et al. Integrated flow-electrode capacitive deionization and microfiltration system for continuous and energy-efficient brackish water desalination[J]. Environmental Science & Technology, 2019, 53(22): 13364-13373. [23] MA J, ZHANG C, YANG F, et al. Carbon black flow electrode enhanced electrochemical desalination using single-cycle operation[J]. Environmental Science & Technology, 2020, 54(2): 1177-1185. [24] MA J, MA J, ZHANG C, et al. Water recovery rate in short-circuited closed-cycle operation of flow-electrode capacitive deionization (FCDI)[J]. Environmental Science & Technology, 2019, 53(23): 13859-13867. [25] HE C, MA J, ZHANG C, et al. Short-circuited closed-cycle operation of flow-electrode CDI for brackish water softening[J]. Environmental Science & Technology, 2018, 52(16): 9350-9360. [26] ZHANG C, MA J, WU L, et al. Flow electrode capacitive deionization (FCDI): Recent developments, environmental applications, and future perspectives[J]. Environmental Science & Technology, 2021, 55(8): 4243-4267. [27] DENNISON C R, GOGOTSI Y, KUMBUR E C. In situ distributed diagnostics of flowable electrode systems: resolving spatial and temporal limitations[J]. Physical Chemistry Chemical Physics, 2014, 16(34): 18241-18252. doi: 10.1039/C4CP02820A [28] HATZELL K B, HATZELL M C, COOK K M, et al. Effect of oxidation of carbon material on suspension electrodes for flow electrode capacitive deionization[J]. Environmental Science & Technology, 2015, 49(5): 3040-3047. [29] PARK H, CHOI J, YANG S, et al. Surface-modified spherical activated carbon for high carbon loading and its desalting performance in flow-electrode capacitive deionization[J]. RSC Advances, 2016, 6(74): 69720-69727. doi: 10.1039/C6RA02480G [30] MA J, MA J, ZHANG C, et al. Flow-electrode capacitive deionization (FCDI) scale-up using a membrane stack configuration[J]. Water Research, 2020, 168: 115186. doi: 10.1016/j.watres.2019.115186 [31] MA J, HE C, HE D, et al. Analysis of capacitive and electrodialytic contributions to water desalination by flow-electrode CDI[J]. Water Research, 2018, 144: 296-303. doi: 10.1016/j.watres.2018.07.049 [32] CHO Y, YOO C-Y, LEE S W, et al. Flow-electrode capacitive deionization with highly enhanced salt removal performance utilizing high-aspect ratio functionalized carbon nanotubes[J]. Water Research, 2019, 151: 252-259. doi: 10.1016/j.watres.2018.11.080 [33] LIANG P, SUN X, BIAN Y, et al. Optimized desalination performance of high voltage flow-electrode capacitive deionization by adding carbon black in flow-electrode[J]. Desalination, 2017, 420: 63-69. doi: 10.1016/j.desal.2017.05.023 [34] TANG K, YIACOUMI S, LI Y, et al. Enhanced water desalination by increasing the electroconductivity of carbon powders for high-performance flow-electrode capacitive deionization[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(1): 1085-1094. [35] LUO L, HE Q, YI D, et al. Indirect charing of carbon by aqueous redox mediators contributes to the enhanced desalination performance in flow-electrode CDI[J]. Water Research, 2022, 220: 118688. doi: 10.1016/j.watres.2022.118688 [36] MA J, HE D, TANG W, et al. Development of redox-active flow electrodes for high-performance capacitive deionization[J]. Environmental Science & Technology, 2016, 50(24): 13495-13501. [37] TANG K, ZHENG H, DU P, et al. Simultaneous fractionation, desalination, and dye removal of dye/salt mixtures by carbon cloth-modified flow-electrode capacitive deionization[J]. Environmental Science & Technology, 2022, 56(12): 8885-8896. [38] CASTAÑEDA L F, WALSH F C, NAVA J L, et al. Graphite felt as a versatile electrode material: Properties, reaction environment, performance and applications[J]. Electrochimica Acta, 2017, 258: 1115-1139. doi: 10.1016/j.electacta.2017.11.165 -

下载:

下载: